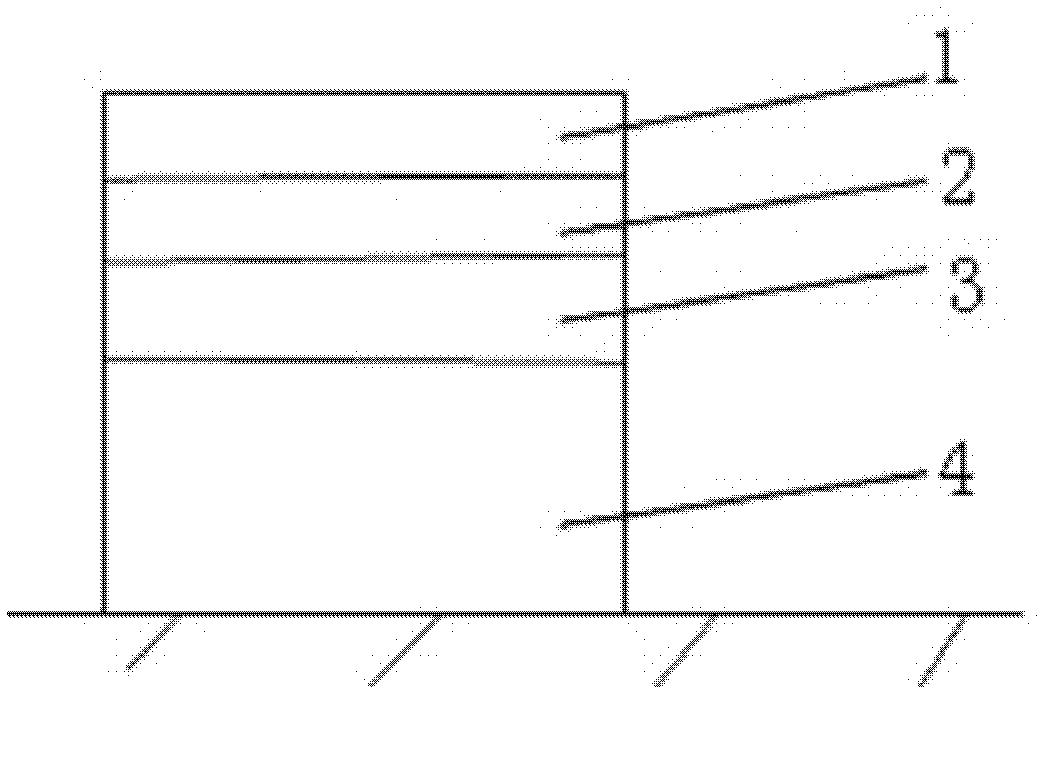

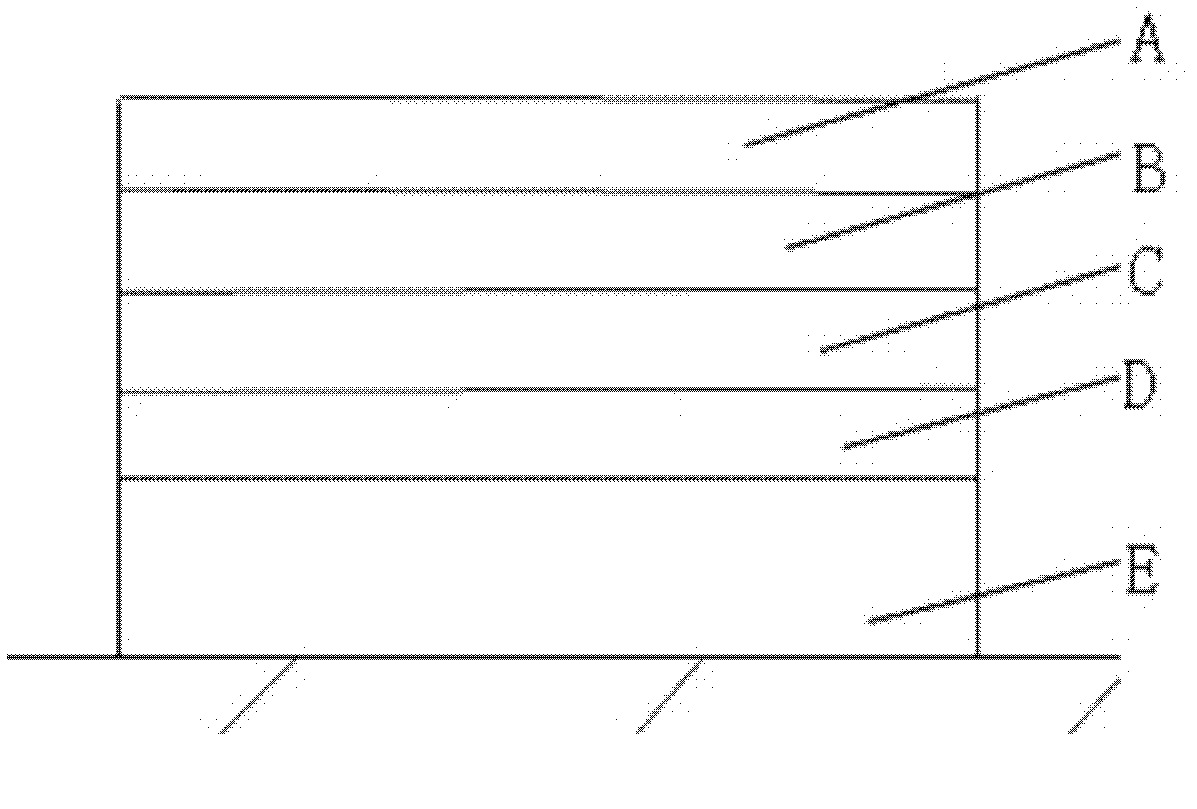

Rotary hearth furnace hearth structure

A rotary hearth furnace bottom, multi-layer structure technology, applied in the direction of manufacturing converters, etc., can solve the problems of hearth uplift, blade life reduction, furnace bottom refractory brick expansion, etc., to solve the problem of dimensional stability, resistance to slag corrosion Performance Effect of metal and liquid slag adhesion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0044] It is applied in a rotary hearth furnace with a diameter of 10 meters in the Joint Laboratory of Energy Conservation and Low Carbon Technology of Beijing Shenwu Environmental Energy Technology Group Co., Ltd., and the temperature in the furnace is 1480°C. The integrated furnace bottom technology of the present invention solves the problem of furnace bottom hardening, Higher growth and burn-through problems, continuous and stable operation, used to deal with the reduction of vanadium-titanium magnetite, etc., and achieved good benefits.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com