Soft core yarn and preparation method

A core yarn, cotton spinning technology, applied in the direction of yarn, textiles and papermaking, can solve the problem that the textile technology cannot meet the market requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

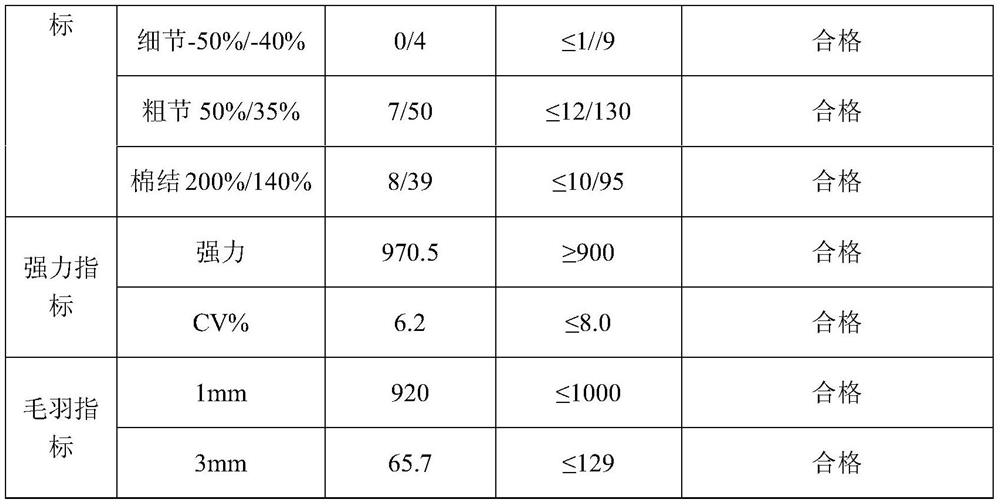

Examples

Embodiment 1

[0029] This embodiment provides a kind of flexible core yarn, a kind of short fiber is covered with a kind of short fiber, wherein one kind of fiber is the core, another kind of fiber is the sheath, the inside core yarn is twisted in the opposite direction to the outer short fiber, during the twisting process In the process, the twist of the core yarn is reduced, and it is close to the untwisted state, so that the core yarn forms a nearly smooth fiber bundle, making the yarn softer. The content of the core yarn is 1-30%, and the balance is the sheath (outsourcing). The core yarn fiber is made of high-quality long-staple cotton.

Embodiment 2

[0031] The present embodiment provides a kind of flexible core yarn preparation method, comprises the following steps:

[0032] Process flow: 1. Core yarn: FA002A automatic plucking machine → FA103 mixed opener → FA022 multi-compartment mixed machine → FA106 opener → FA046 vibrating box feeder → A076F single beater roll Machine → FA201B carding machine → FA305 drawing frame (pre-drawing) → A191B sliver coiler → A201E combing machine → FA317A mixing → FA317A finishing → FA415A roving frame → FA506S spinning frame → NO.21C automatic winder.

[0033] 2. Soft core yarn: FA002A automatic plucking machine → FA103 mixed opener → FA022 multi-compartment blender → FA106 opener → FA046 vibrating cotton box feeder → A076F single hand coiler → FA201B carding machine → FA317A mixing → FA317A finishing → FA415A roving frame → FA506S spinning frame + core yarn plying → NO.21C automatic winding.

[0034] Core yarn production process:

[0035] 1.1- Blowing process:

[0036] For cotton fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com