High-shape-preservation pure cotton yarn of high-density anti-wrinkle fabric and production method thereof

A technology of anti-wrinkle fabric and production method, which is applied in the direction of yarn, textile and papermaking, etc. It can solve the problems of fineness, maturity, mixed long and short piles, and the inability to meet the anti-wrinkle requirements of fabrics, and achieve less hairiness, tight structure, and good hand feeling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] 1. Preparation of each sliver:

[0016] The cotton fiber is picked, carded, and combed to obtain a combed sliver.

[0017] 2. Production of pure cotton yarn:

[0018] Spinning type: 40S compact spinning is adopted.

[0019] The combed cotton sliver is pre-combed in the drawing process, and then mixed and roved in multiple passes to obtain cotton roving sliver.

[0020] Then feed the cotton roving slivers into the spinning frame, through twisting and winding, the twist coefficient of the pure cotton yarn is controlled to be 460-500, and finally go through the winding process to obtain the package yarn, that is, pure cotton yarn.

[0021] 3. Weaving the pure cotton yarn obtained by the above production, such as plain weave, the density of the fabric is 120 threads / inch in the warp direction and 90 threads / inch in the weft direction.

[0022] 4. Optimize the liquid ammonia pretreatment process conditions and resin finishing process through moisture control, uniform dryi...

PUM

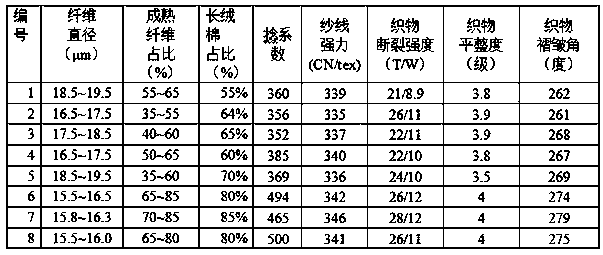

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com