Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Improve hairiness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

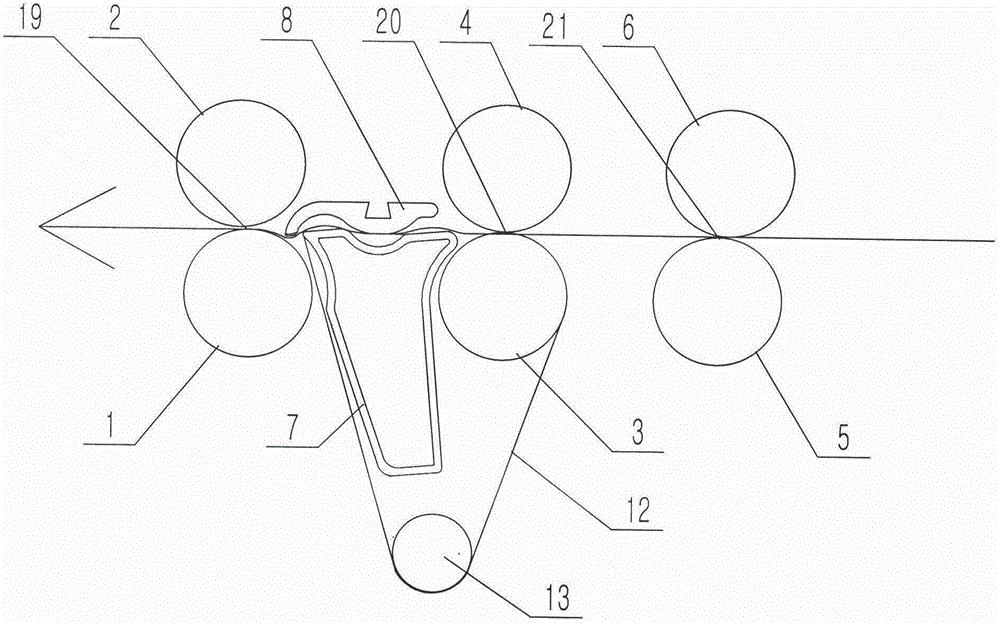

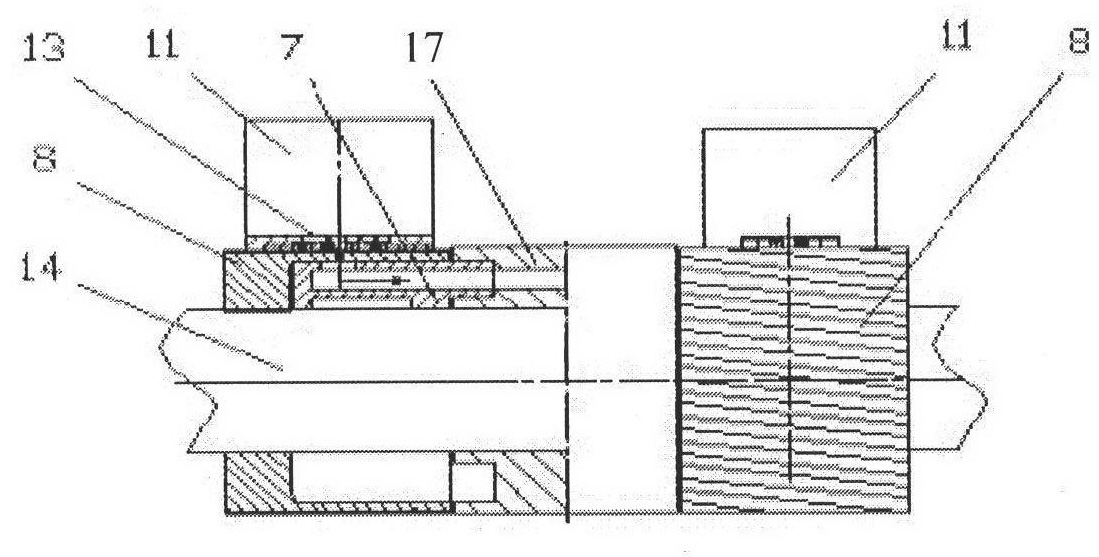

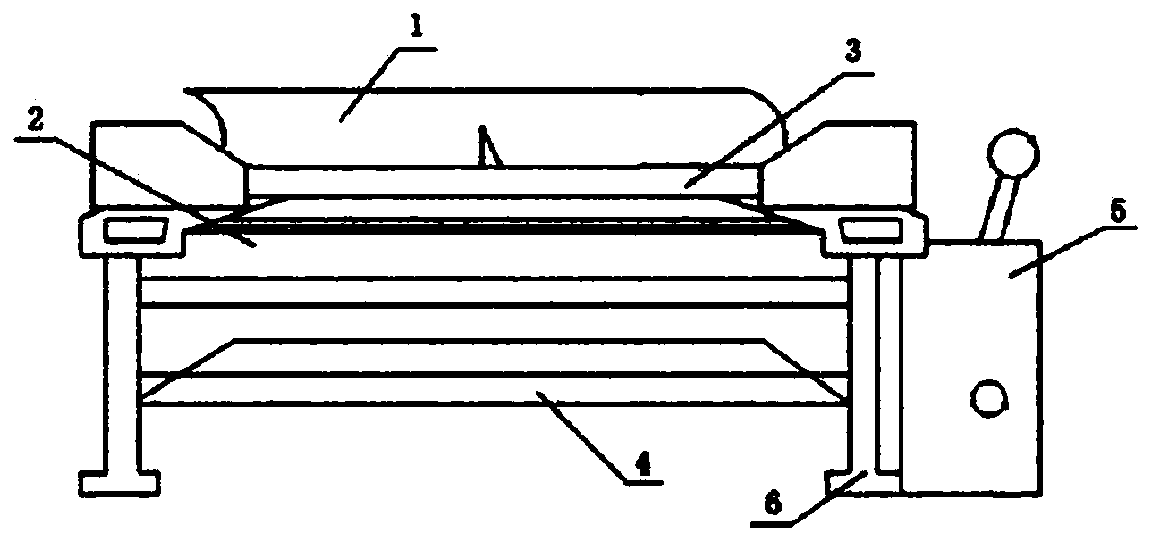

High power drafting device for ring spinning frame

InactiveCN101307515AShorten the lengthExpand the range of the friction fieldDrafting machinesFiberEngineering

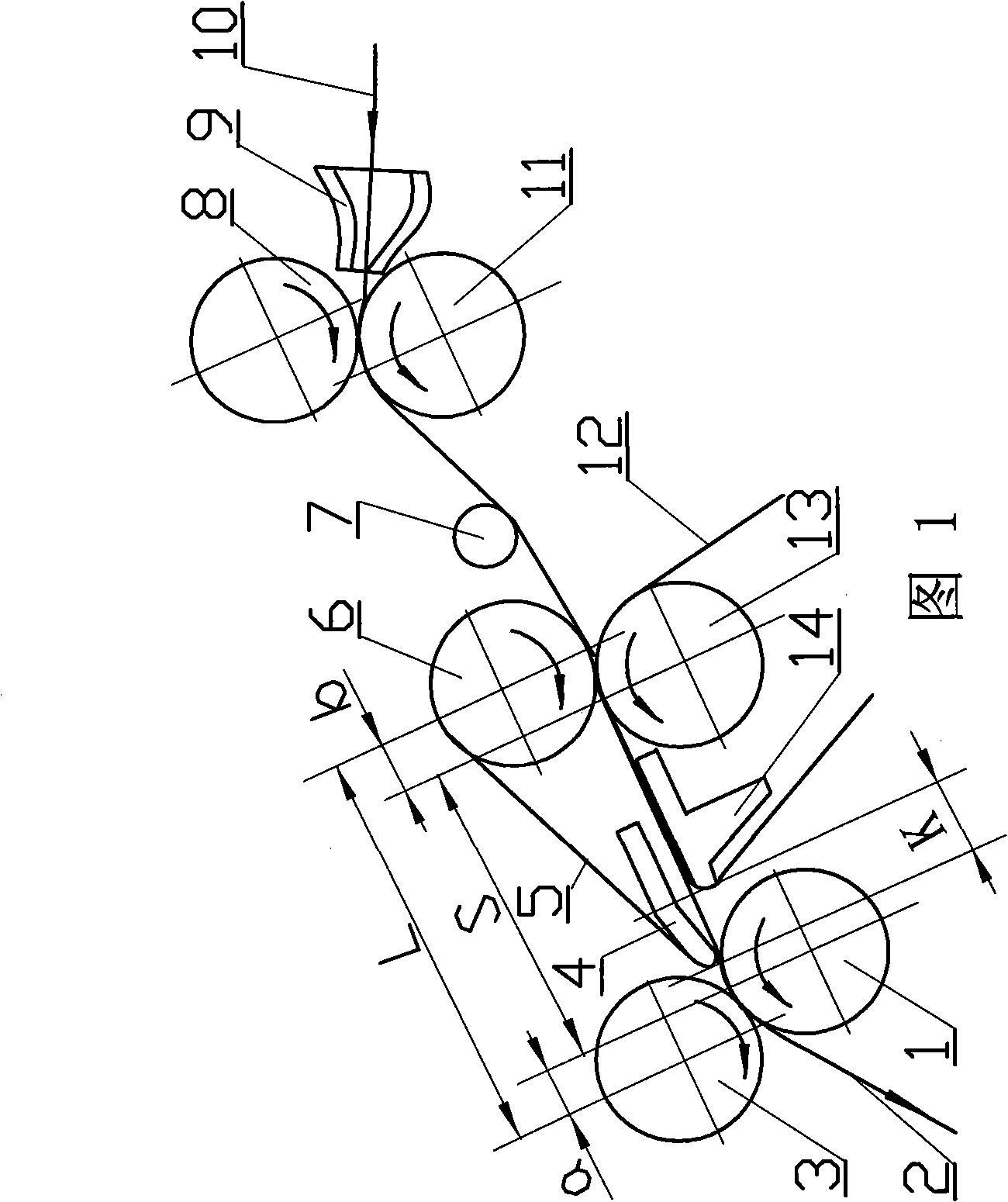

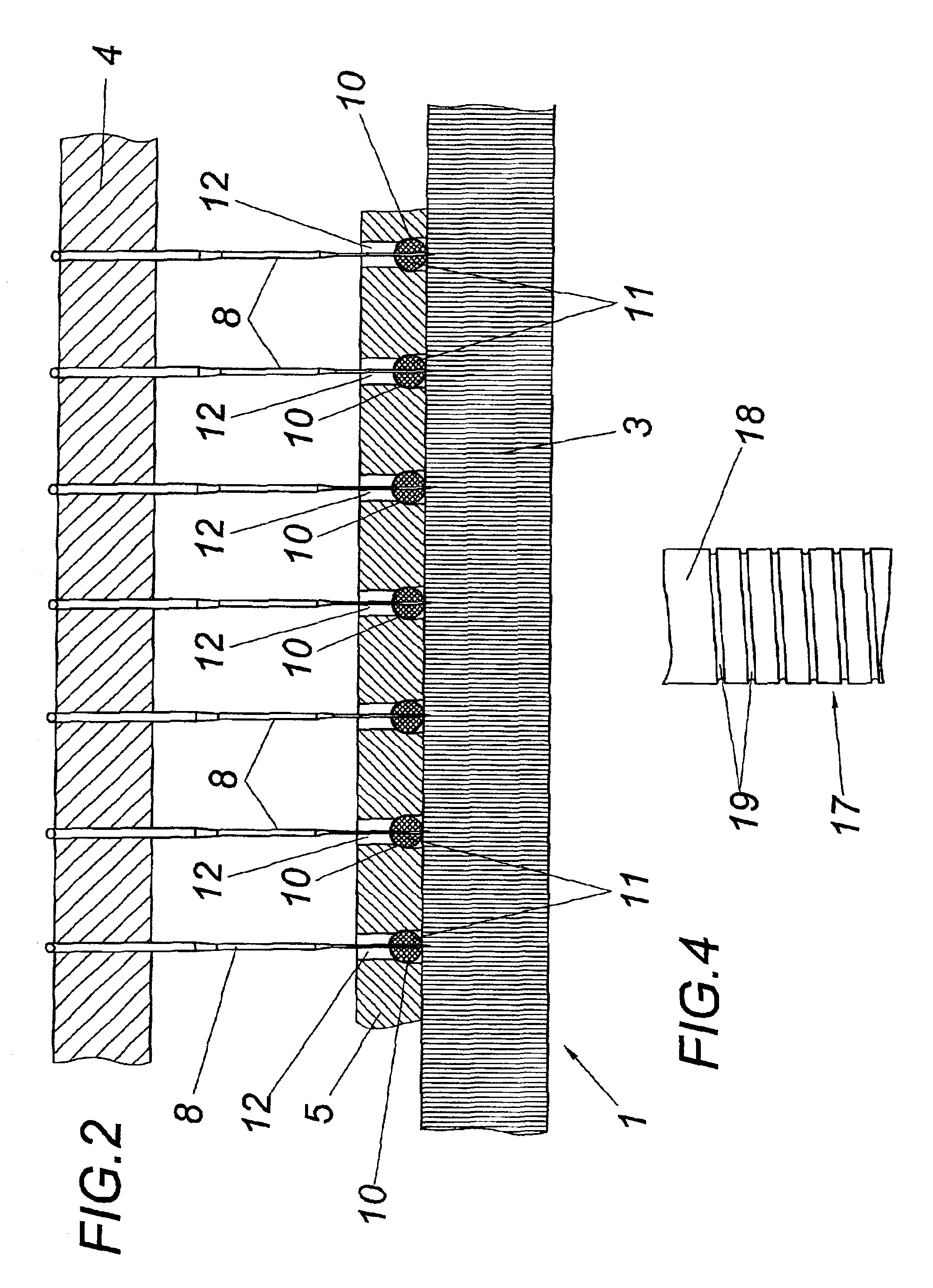

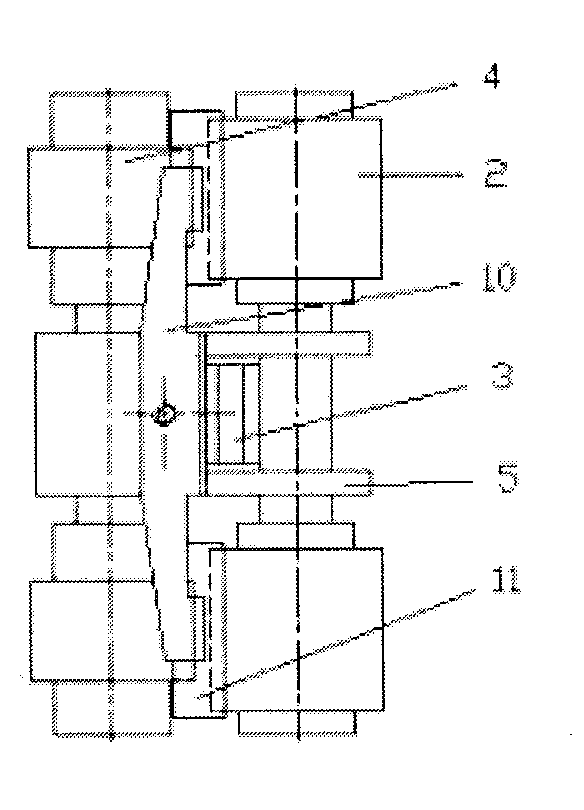

The invention discloses a high-power drafting assembly used for a ring spinner, comprising a front drafting roller pair with a front roller and a front belt roller, and a rear drafting roller pair with a rear roller and a rear belt roller, wherein, a middle roller and an upper middle roller are arranged between the front drafting roller pair and the rear drafting roller pair, an upper pin is arranged between the upper middle roller and the front belt roller, while a lower pin is arranged between the middle roller and the front roller, an upper apron is sleeved on the upper middle roller and the upper pin, a lower apron is sleeved on the middle roller and the lower pin, the forward setting distance K between the upper pin front edge and the lower pin front edge is at least 3 millimeters, the ratio of the setting distance L from the upper middle roller to the front belt roller and the setting distance S from the roller to the front roller is between 1.1 and 1.6. The high-power drafting assembly can shorten the freestream flow zone length to the utmost extent, extend the control area of the apron, effectively increase the drafting multiple of the drafting assembly and guarantees the quality of the completed filament.

Owner:DONGTAI TEXTILE MASCH CO LTD

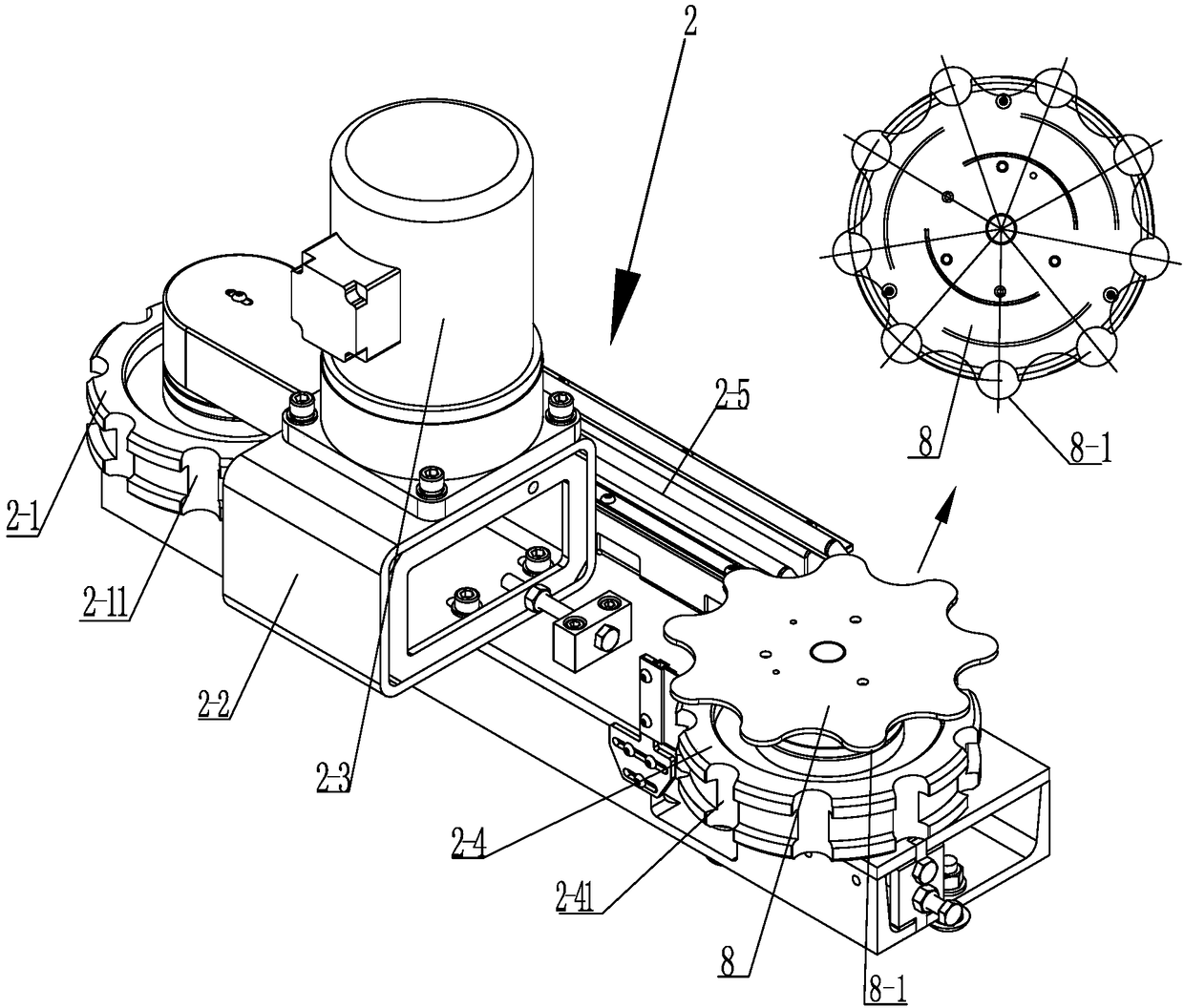

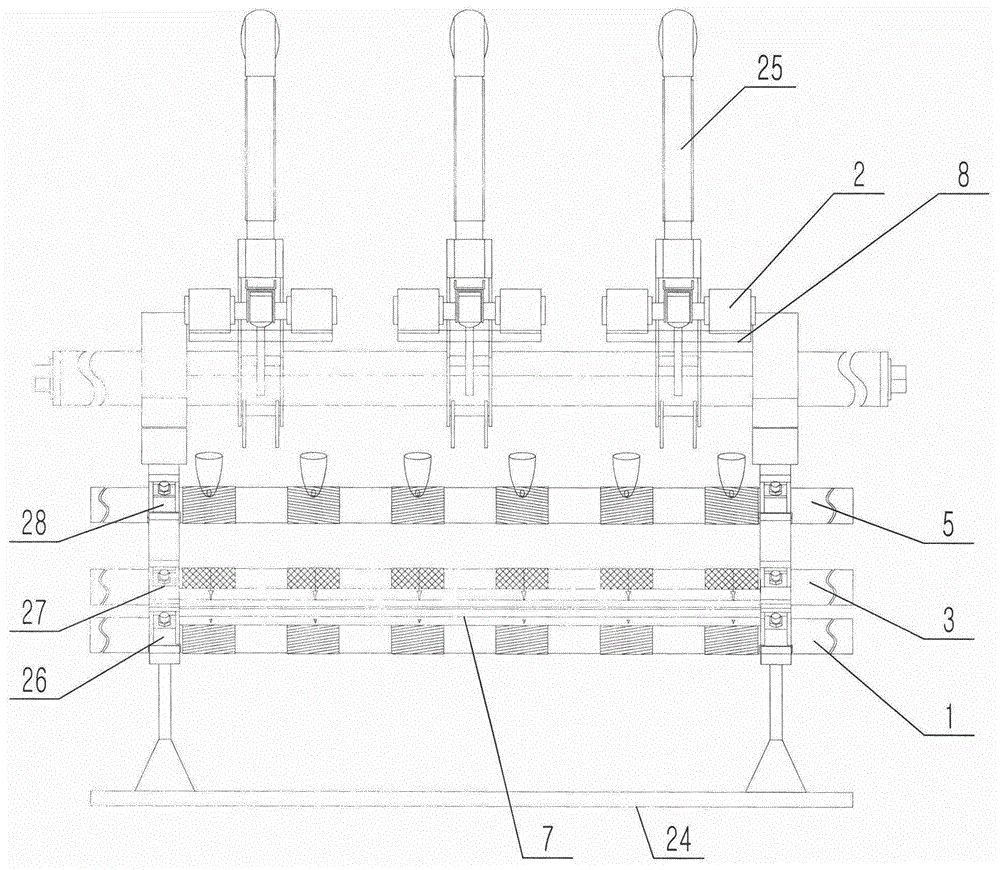

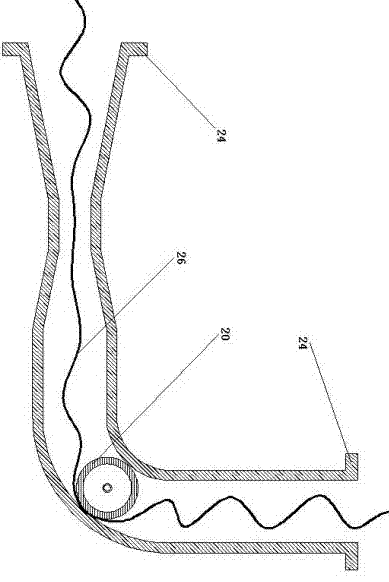

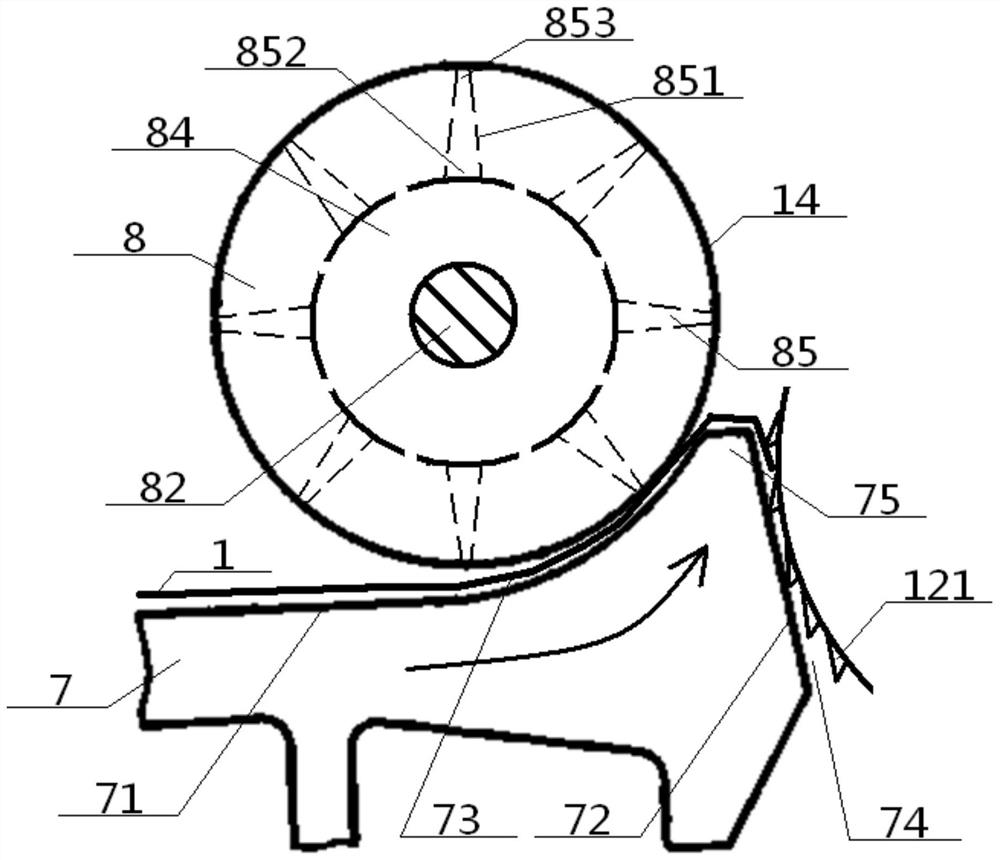

Conveying joint device for cops and bobbins for spinning and doffing connection and conveying method thereof

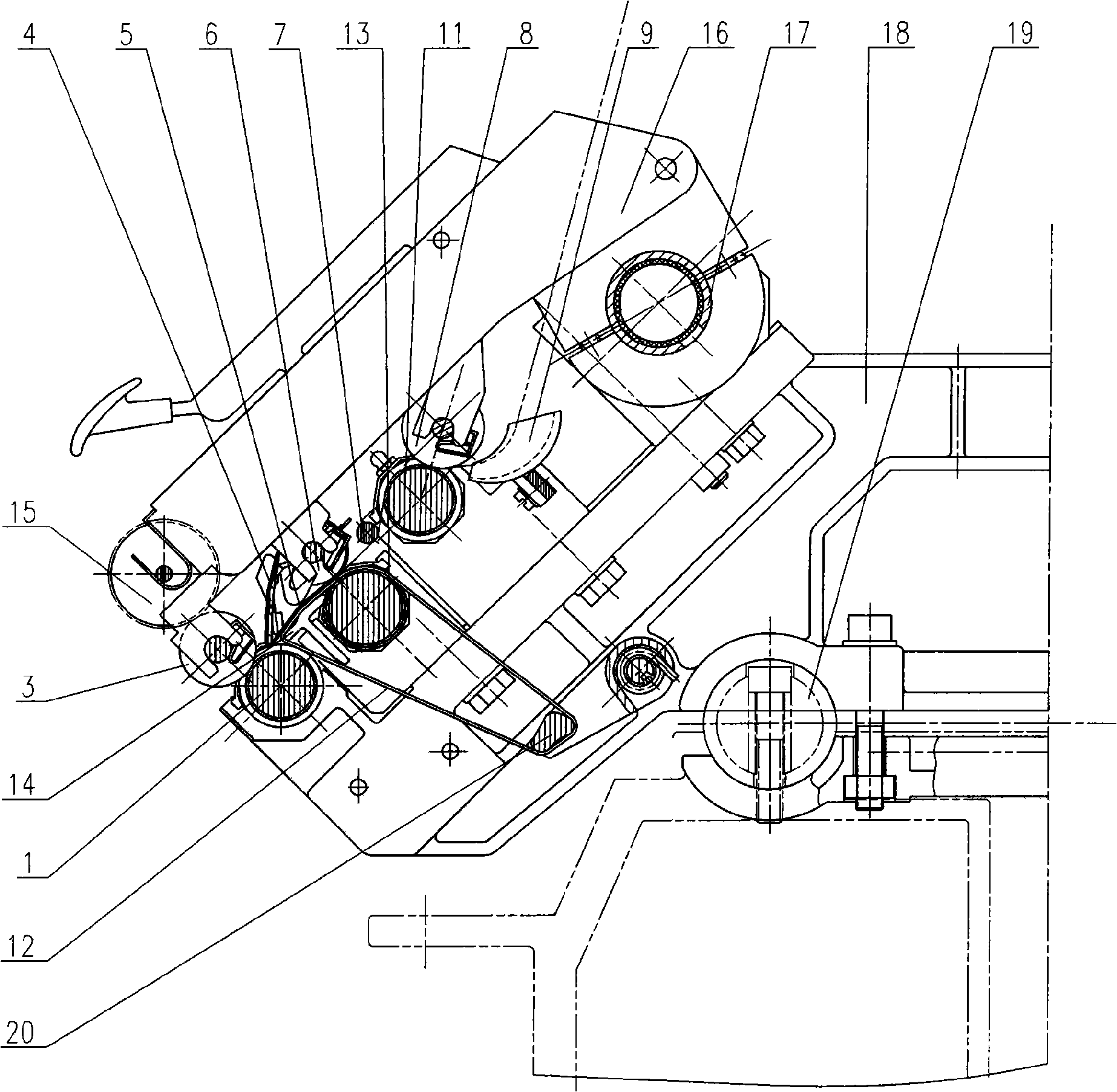

ActiveCN108560088AAchieve automatic round-trip transportationReasonable structureTextiles and paperWinding machineBobbin

The invention relates to a conveying joint device for cops and bobbins for spinning and doffing connection. The device comprises a stirring plate arranged at the joint between first pallet conveying track and a second pallet conveying track, a pallet output mechanism, a pallet input mechanism, multiple pallets and multiple pallet support assemblies. The multiple pallets and the multiple pallet support assemblies are used for placing cops and bobbins. The stirring plate is used for stirring pallets which are conveyed to the joint and. Clamping positioning of the above pallets is released. The stirring plate is coaxially installed onto a guide wheel. The pallet output mechanism is used for automatically conveying all pallets separated from the pallet support assemblies to the second pallet conveying track. The pallet input mechanism is used for automatically conveying all the pallets outputted by the second pallet conveying track to the pallet support assemblies of the first pallet conveying track. Therefore, the purpose of automatically conveying pallets in a reciprocating manner between an automatic winding machine and an automatic doffing and spinning machine is fulfilled. As a result, connection between the automatic doffing and spinning machine and the automatic winding machine is realized. The device is reasonable and compact in structure and helps reduce the conveying process. Spindle speed and production efficiency of the spinning machine can be greatly increased.

Owner:常州市同和纺织机械制造有限公司

Drafting device in spinning frame

The invention relates to a drafting device in a spinning frame. The drafting device in the spinning frame comprises a front roller, a front leather roller, a middle roller and a middle leather roller. A front jaw is formed between the front leather roller and the front roller, a middle jaw is formed between the middle leather roller and the middle roller, and a negative pressure pipe is arranged between the front roller and the middle roller. A groove is formed in the middle of the upper surface of the negative pressure pipe, a front gathering opening and a rear gathering opening are formed in the upper surface of the negative pressure pipe, and a tension device is arranged below the middle roller and the negative pressure pipe. A flexible sleeve ring made of breathable materials bypasses the upper surface of the middle roller, the upper surface of the negative pressure pipe and the tension device and covers the opening parts of the front gathering opening and the rear gathering opening. An upper pin is arranged above the connecting line of the front jaw and the middle jaw and placed between the front leather roller and the middle leather roller. A cambered surface boss is arranged on the lower surface of the upper pin, the end portion, extending downwards, of the cambered surface boss abuts against the flexible sleeve ring on a groove in the upper surface of the negative pressure pipe. The drafting device in the spinning frame is suitable for the spinning frame, and mainly used for orderly and evenly arraying fibers.

Owner:ZHANGJIAGANG GUANGZHONG TEXTILE MACHINERY TECH CO LTD

Dysmorphism rod curved line drafting device

The invention provides a dysmorphism rod curved line drafting device and is suitable for the field of spins. The dysmorphism rod curved line drafting device comprises a front clamping opening composed by a front roller and a front rubber roller, a middle clamping opening composed by a middle roller and a middle rubber roller, a back clamping opening composed by a back roller and a back rubber roller, a dysmorphism rod, a middle positioning body, a concave and a protruding surface lower pin, a pressure spring, a lower ring and a lower ring tension device. The dysmorphism rod, a middle positioning body, a concave surface and a protruding surface lower pin, a pressure spring, a lower ring and a lower ring tension device are arranged between the front clamping opening and the middle clamping opening. The dysmorphism rod curved line drafting device is characterized in that a convex-concave is arranged on the lower surface of the dysmorphism rod perpendicular to the axis line direction and the convex-concave is arranged in a wave shape. A convex-concave is arranged on the surface of the concave and convex lower pin perpendicular to the axis line direction and the convex-concave is arranged in a wave shape. A curved line drafting passage is formed by the coordination of the protruding and concave part of the dysmorphism rod and the concave and the protruding of the concave and protruding lower pin. Restraining force of a fibre bundle in the middle and the back portion of a main drafting area is strengthened. The length of a floating zone in a front drafting area of a spinning machine is reduced. The dysmorphism rod curved line drafting device is beneficial to the forward displacement, focus and stability of a speed changing of the fibre.

Owner:程心一

Method for preparing wula sedge blended fasciated yarn

The invention discloses a preparation method of ulagrass blended wrapping yarn. First, "boiling + carding + three times of alkali boiling + softening treatment" is used to obtain ulagrass fiber; then the ulagrass fiber cut to 45-50 mm and cotton are mixed and opened at a mass ratio of 70 / 30-10 / 90, Carding, drawing, and rotor spinning into core yarn materials, in which a roller carding machine is used for carding, and repeated opening and carding are used to improve the uniformity of subsequent yarns; Cotton blended core yarn is used for wrapping, and two or several pieces of pure cotton yarn, modal yarn, wool yarn, etc. are combined and wound on a bobbin in parallel as outer wrapping yarn. The speed ratio of hollow spindle speed and output roller is 500-900. The preparation of ulagrass blended wrapped yarn will broaden the application field of ulagrass fiber with thermal insulation and antibacterial properties.

Owner:TIANJIN POLYTECHNIC UNIV

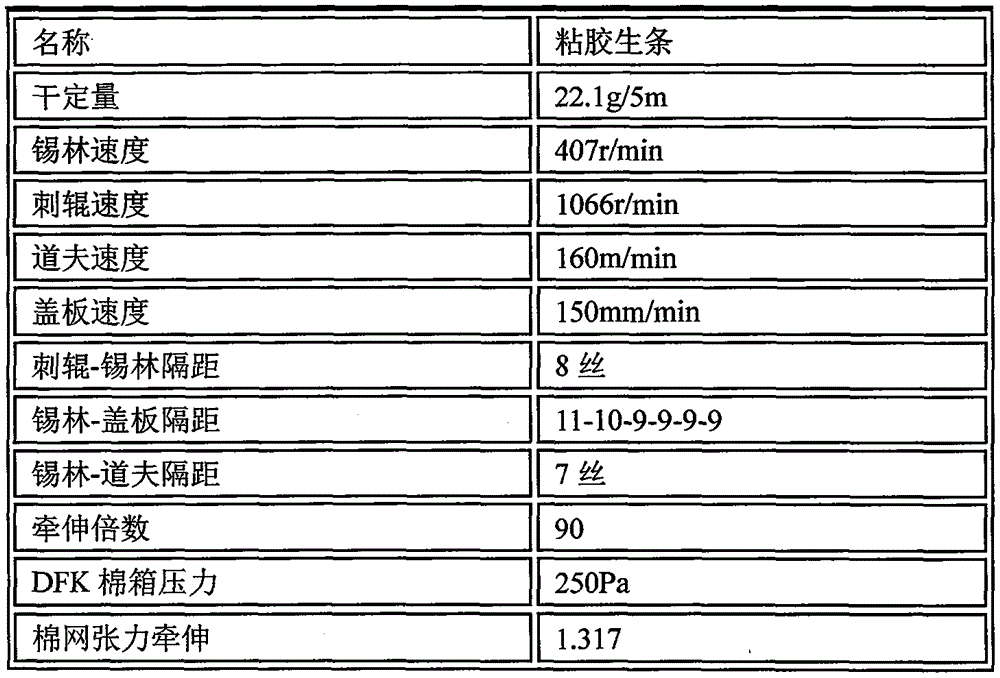

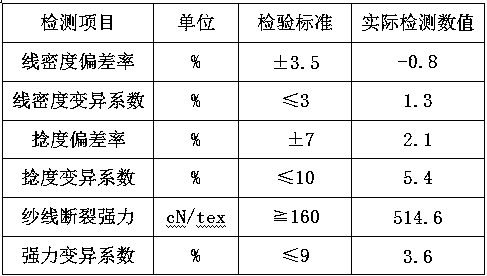

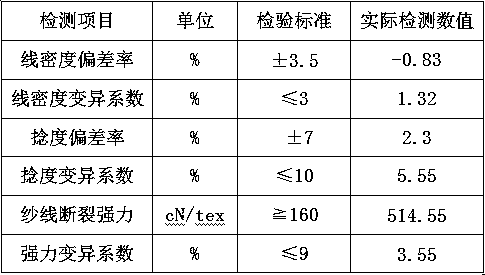

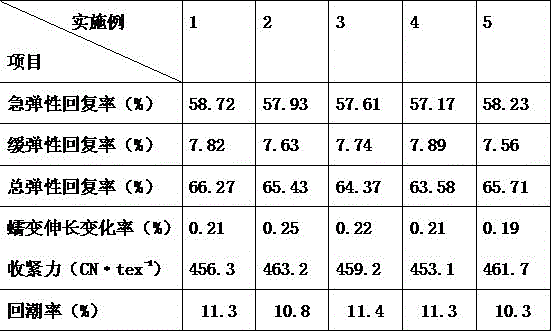

Superhigh-count compact siro spinning yarn and production technological method thereof

InactiveCN106149124AOvercome the disadvantages of multiple and low strengthImprove hairinessYarnTextile fiberYarn

The invention relates to a production technology of a regenerable cellulose fiber knitted material, and particularly relates to a superhigh-count compact siro spinning yarn and a production technological method thereof. The invention aims at providing a superhigh-count compact siro spinning yarn and a production technological method thereof, belonging to the technical field of spinning textile fibers. According to the superhigh-count compact siro spinning yarn and the production technological method thereof, the bad problems that the traditional ring spinning yarns have more feathers, low strength and the like can be overcome, by combining the characteristics of viscose fibers, the yarn has higher strength and fewer feathers, and the product has finer, softer and more comfortable characteristics, and the superhigh-count compact siro spinning yarn is more suitable for producing underwear and high-grade clothes.

Owner:JIANGNAN UNIV

Method for treating a yarn by needling

InactiveUS6857170B2Hairiness can be increasedImprove hairinessLayered productsNeedling machinesYarnFiber

Owner:FEHRER MONIKA

Spinning of lapping yarn

The invention provides the spinning method of a wrap yarn with the yarn core consists of high count yarn. The invention uses pure cotton high count yarn as yarn core and polylactic fiber filament as the outer layer of the wrap yarn; wrap yarn technology is adopted to process the high count spun yarn; wrapping filament wraps the spunbonded fabrics bidirectionally at the outer layer of the spun yarn; due to the adding of the filament, the gained wrap yarn improves the strength of the yarns by reaching the strength to 8 percent through 15 percent; meanwhile the filoplume of the yarns is improved, the weavability of the high count yarn is ensured and the weavability of the high count yarn and the producing value of the products is improved.

Owner:SHENGHONG GRP CO LTD

Air overfeeding tube

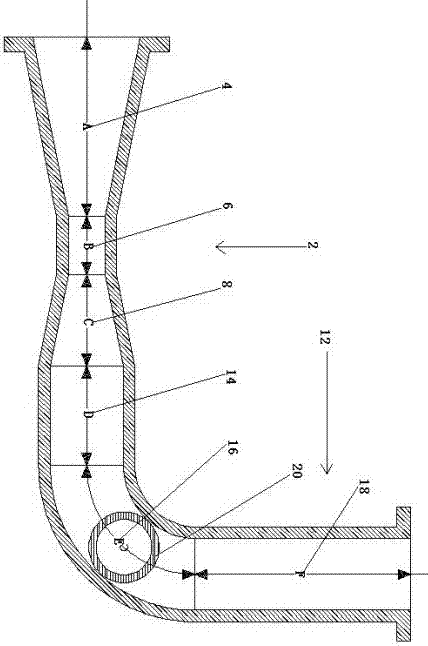

InactiveCN103924332ASimple structureChange direction of motionTextiles and paperYarnAcceleration Unit

The invention relates to an air overfeeding tube which comprises a Venturi tube and a yarn discharging bending tube with a yarn guiding wheel. The Venturi tube is hermetically communicated with the yarn discharging bending tube, a compression section, a throat section and an expansion section are coaxially arranged in the Venturi tube, the yarn discharging bending tube is hermetically communicated with the throat section, and the yarn guiding wheel is located at the turning corner of the yarn discharging bending tube. The role of airflow can be accelerated by the aid of the Venturi tube, the yarn discharging bending tube is innovatively hermetically connected to the rear of the Venturi tube, the motion direction of yarns can be changed, the high-speed airflow integrally performs a certain tractive force upon each point of the yarns, the dispersed tractive force is large as a whole while the tractive force on each point of the yarns is limited, the airflow drives the yarns to move flexibly and cannot cause damages to the yarns and cannot increase yarn hairness on the surfaces of the yarns, and acceleration of the Venturi tube enables the overfeeding effect to be implemented easily.

Owner:WUJIANG MINGJIA WEAVING

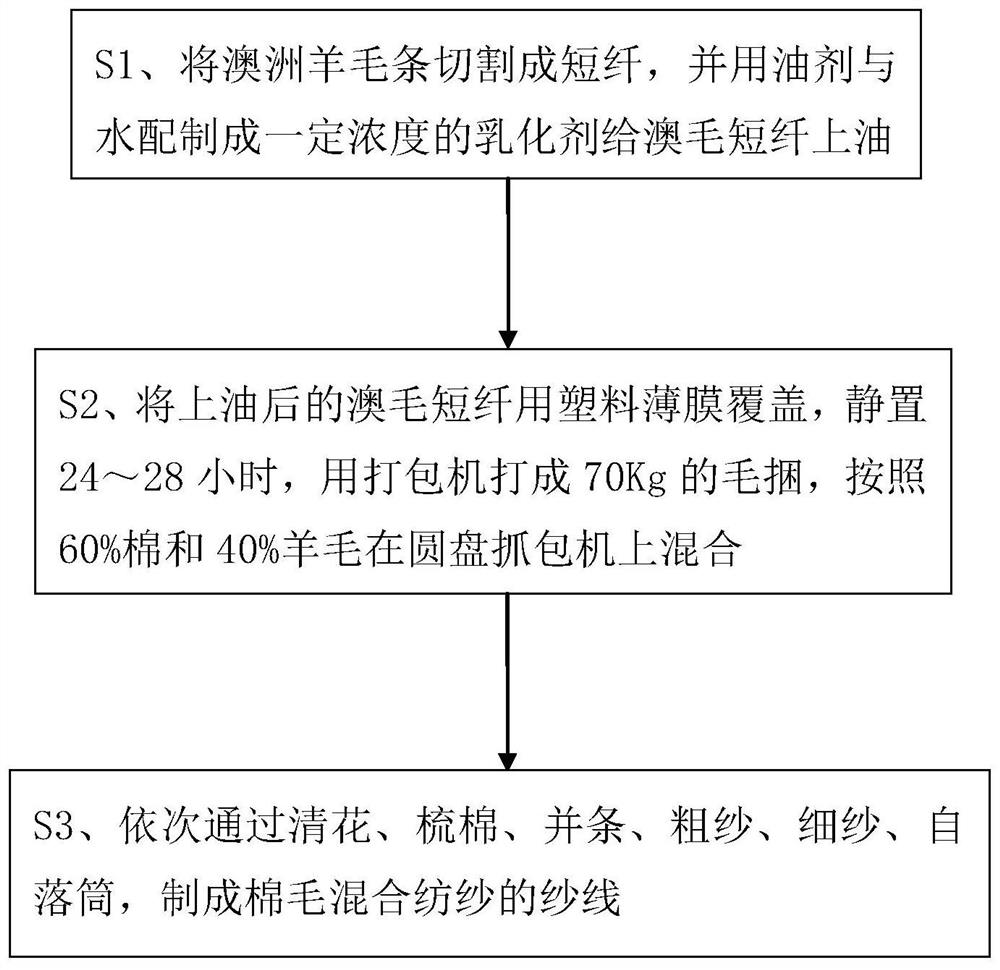

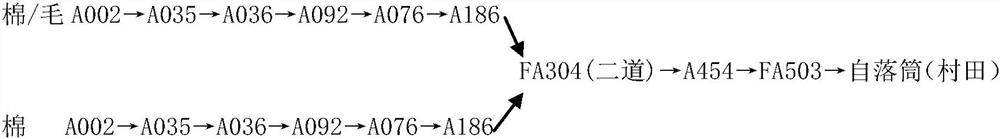

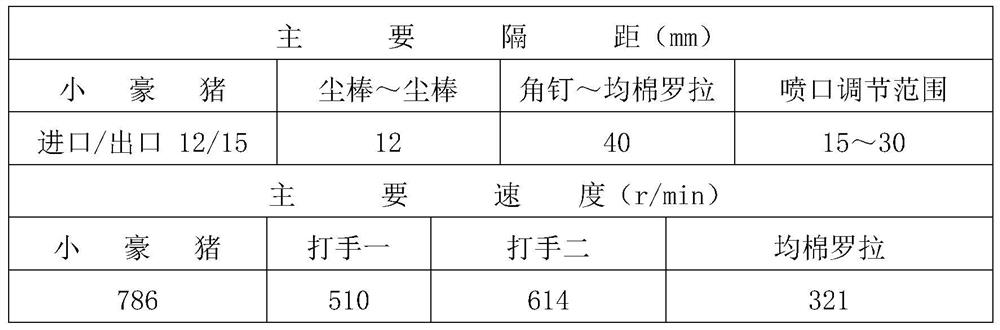

Manufacturing method of cotton and wool mixed spinning yarn

The invention discloses a manufacturing method of cotton and wool mixed spinning yarn. The manufacturing method of the cotton and wool mixed spinning yarn comprises the following steps: S1, cutting Australian wool tops into short fibers, and using oil and water to prepare a emulsifier with a certain concentration to oil the Australian wool short fibers; S2, covering the oiled Australian wool shortfibers with a plastic film, standing for a set time, packing into bales, and then mixing on a disc grabbing machine according to the ratio of 60% cotton and 40% wool; and S3, performing blowing, carding, drawing, roving, spinning, and self-doffing in sequence to obtain the cotton and wool mixed spinning yarn. The invention uses oil and water to prepare the emulsifier with a certain concentrationto oil the Australian wool short fibers, covers the short fibers with the plastic film, and lets the short fibers stand for a certain period of time to make the emulsifier penetrate evenly, so as to reduce the mass specific resistance of the Australian wool fibers, reduce static electricity, improve the lubricity and flexibility of the Australian wool, reduce the friction resistance among the fibers, reduce the damage and breakage of the fibers during the carding process, and improve the spinnability; and therefore, the spinning efficiency is improved.

Owner:NANTONG INST OF FIBER INSPECTION

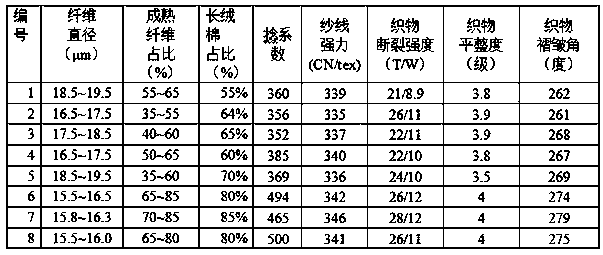

High-shape-preservation pure cotton yarn of high-density anti-wrinkle fabric and production method thereof

High-shape-preservation pure cotton yarn of high-density anti-wrinkle fabric and a production method thereof belong to the technical field of textile and especially to the production of pure cotton yarn. Pure cotton yarn is obtained by performing cotton picking, carding, combing, pre-mixing, multi-pass mixing, roving, spinning and winding on cotton fiber; the diameter of the cotton fiber is 15.5 to 16.5 [mu]m. The mass percentage of mature cotton fibers in cotton fibers is 65-85%, and the mass percentage of long staple cotton is 75-90%; the obtained pure cotton yarn has a strength of 340CN / texor more. The process of the invention does not need to adjust the equipment and is favorable for production, and the obtained pure cotton yarn meets the requirements of the subsequent weaving, and the obtained fabric has the advantages of strong shape retention, small loss of fabric strength after finishing, and good hand feeling.

Owner:HAIAN LIANFA COTTON SPINNING CO LTD

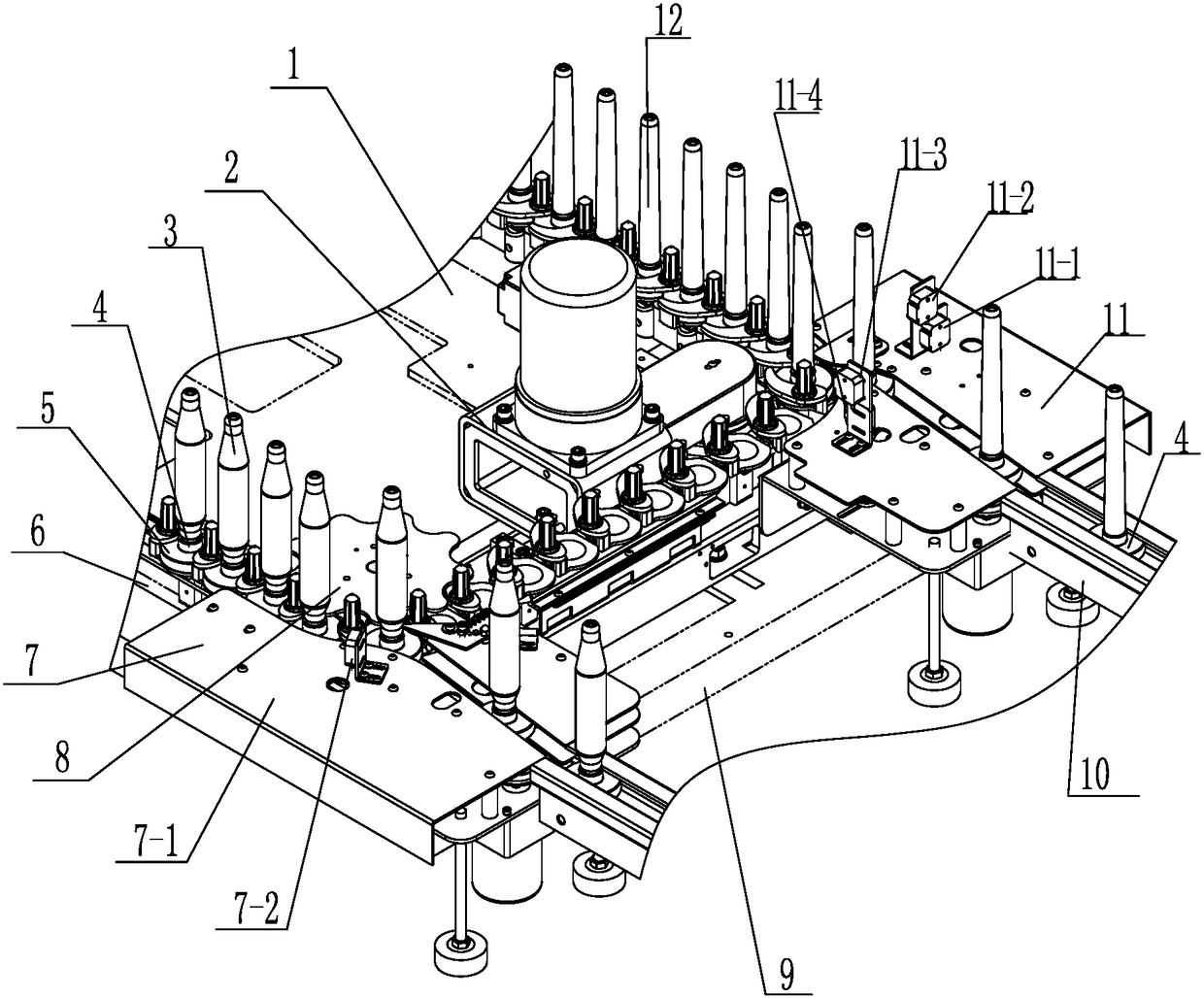

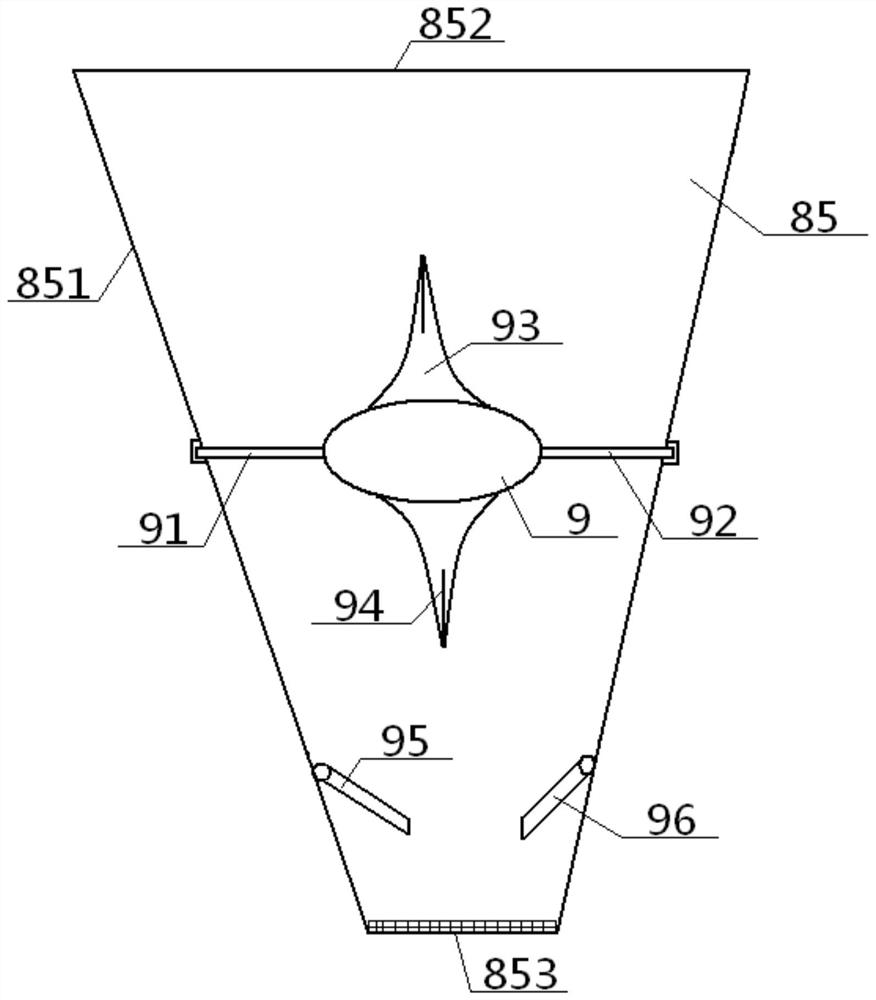

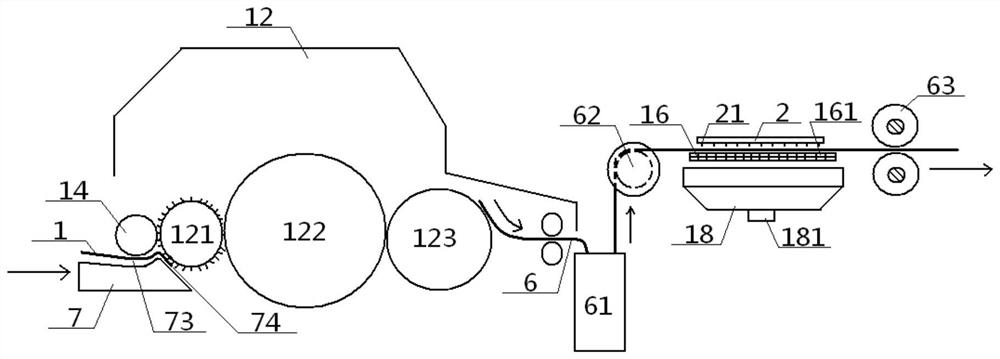

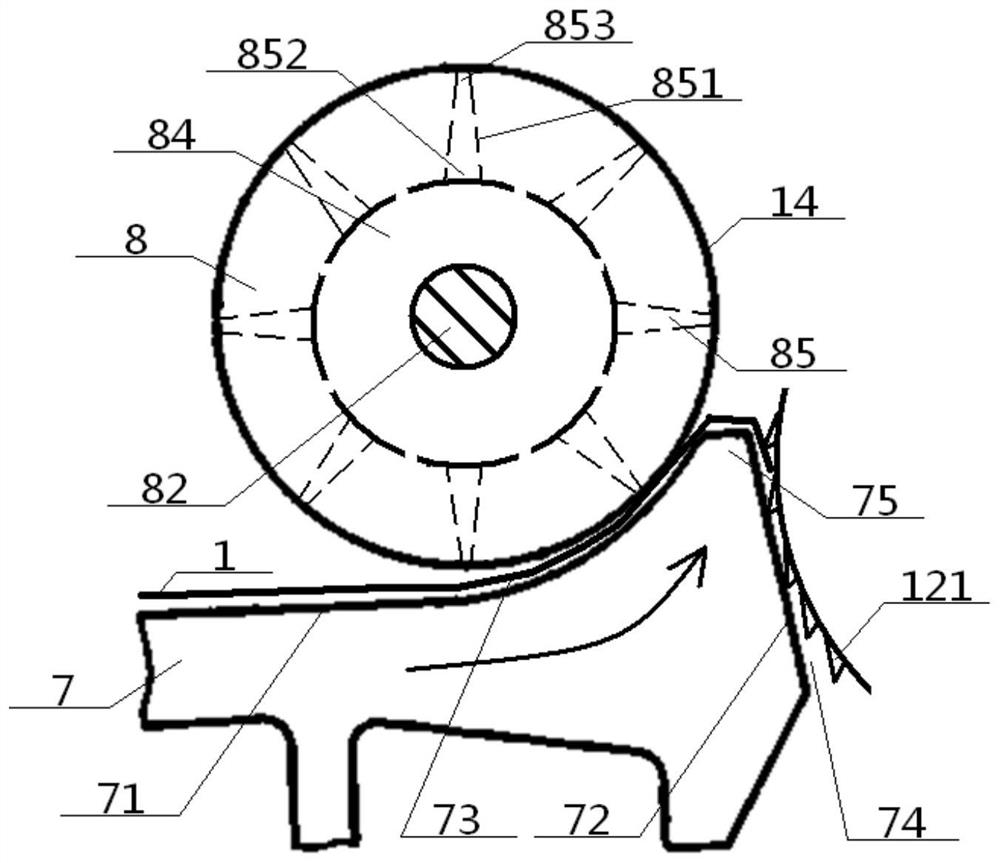

Spinning device for ultra-long and ultra-thin spun polyester threads and spinning process

ActiveCN110172758AHigh strengthIncrease humidityCarding machinesTextile treatment by spraying/projectingFiberPolyester

The invention relates to a spinning device for ultra-long and ultra-thin spun polyester threads and a spinning process. The spinning device comprises a cotton feeding roller and a cotton feeding support plate, wherein the cotton feeding support plate comprises a vertex-arc plate surface and a skew-back plate surface; a cotton feeding passage is formed between the vertex-arc plate surface and the cotton feeding roller in an included manner; an acupuncture cotton passage is formed between the skew-back plate surface and a licker-in in an included manner; the cotton feeding roller comprises a cotton press roller body, and a left drive shaft and a right drive shaft which are connected with the two ends of the cotton press roller body; the cotton press roller body comprises a cotton press outerbody and an inner chamber formed inside the cotton press outer body; a plurality of mist spray passages are arranged inside the cotton press outer body; each mist spray passage comprises a passage side wall, and an inner passage port and an outer passage port which are connected with the two ends of the passage side wall, the inner passage port is communicated with the cotton press inner chamber,the outer passage port is communicated with the outer wall of the cotton press outer body. Through the design provided by the invention, not only electrostatic phenomena are reduced, ultra-long and ultra-thin fiber production is facilitated, and further the production of sewing threads with high strength and good evenness is facilitated, but also outside interferences are decomposed, and smooth production is ensured.

Owner:湖北枫树科技有限公司 +1

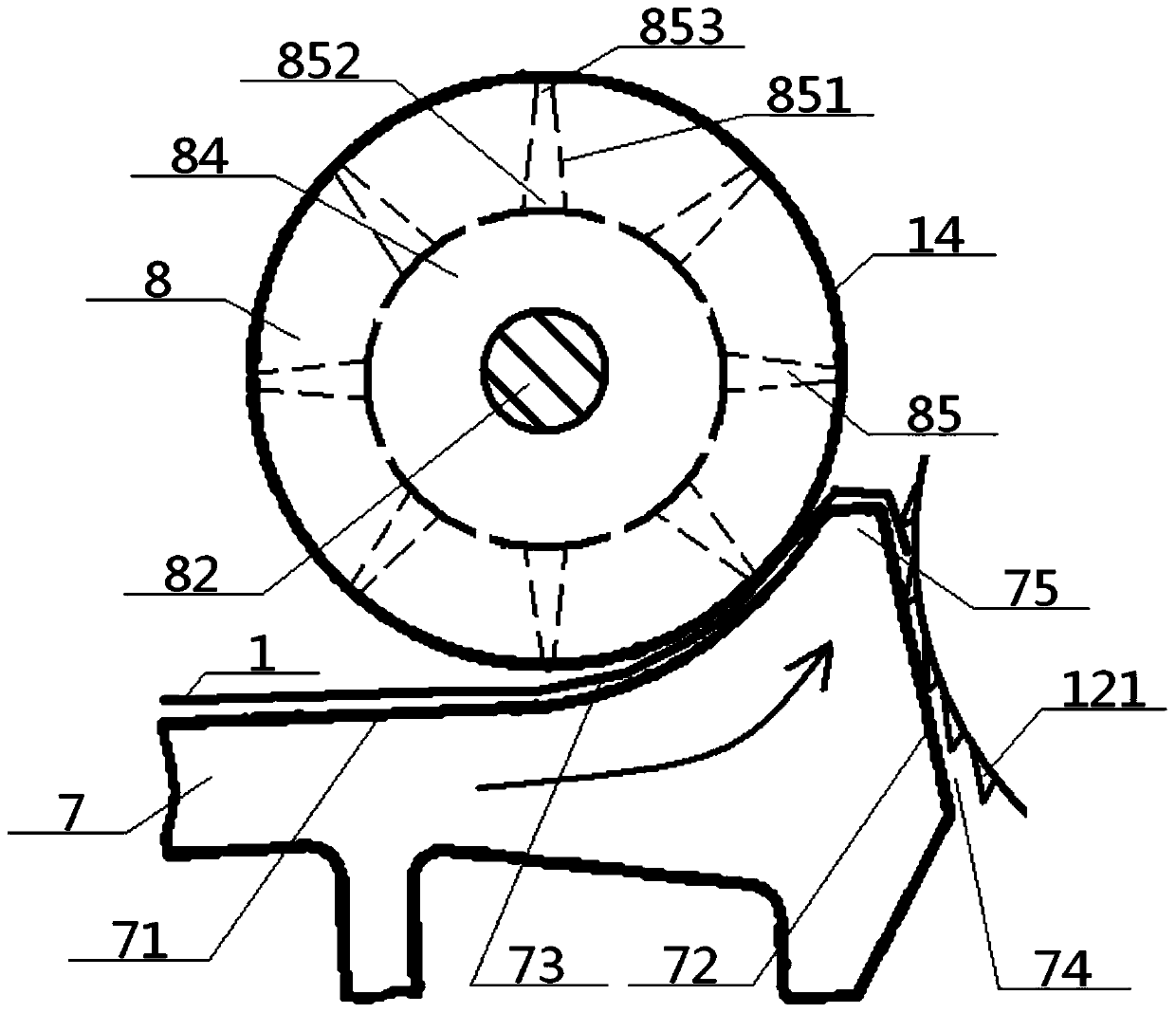

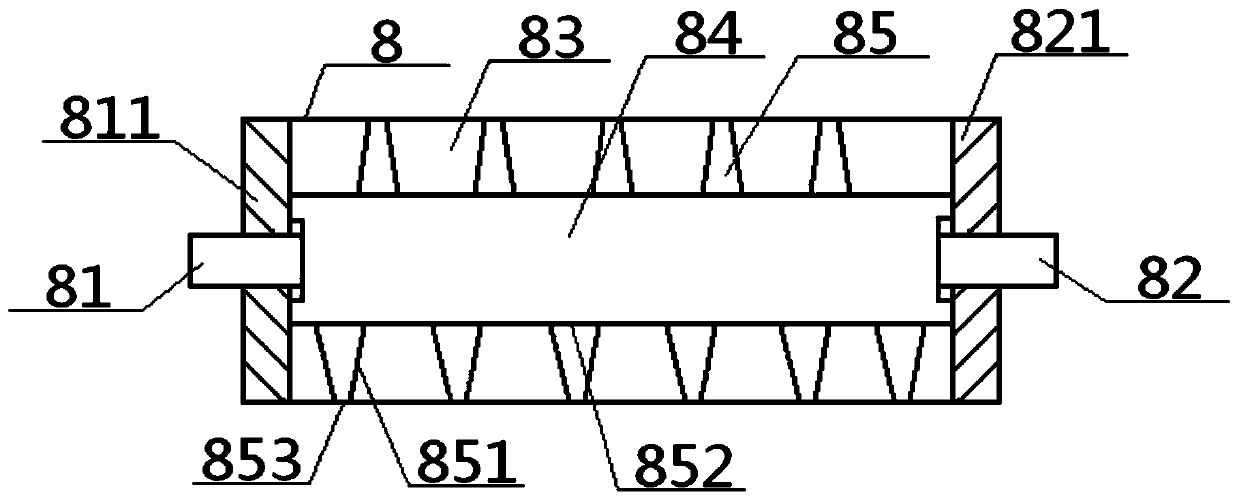

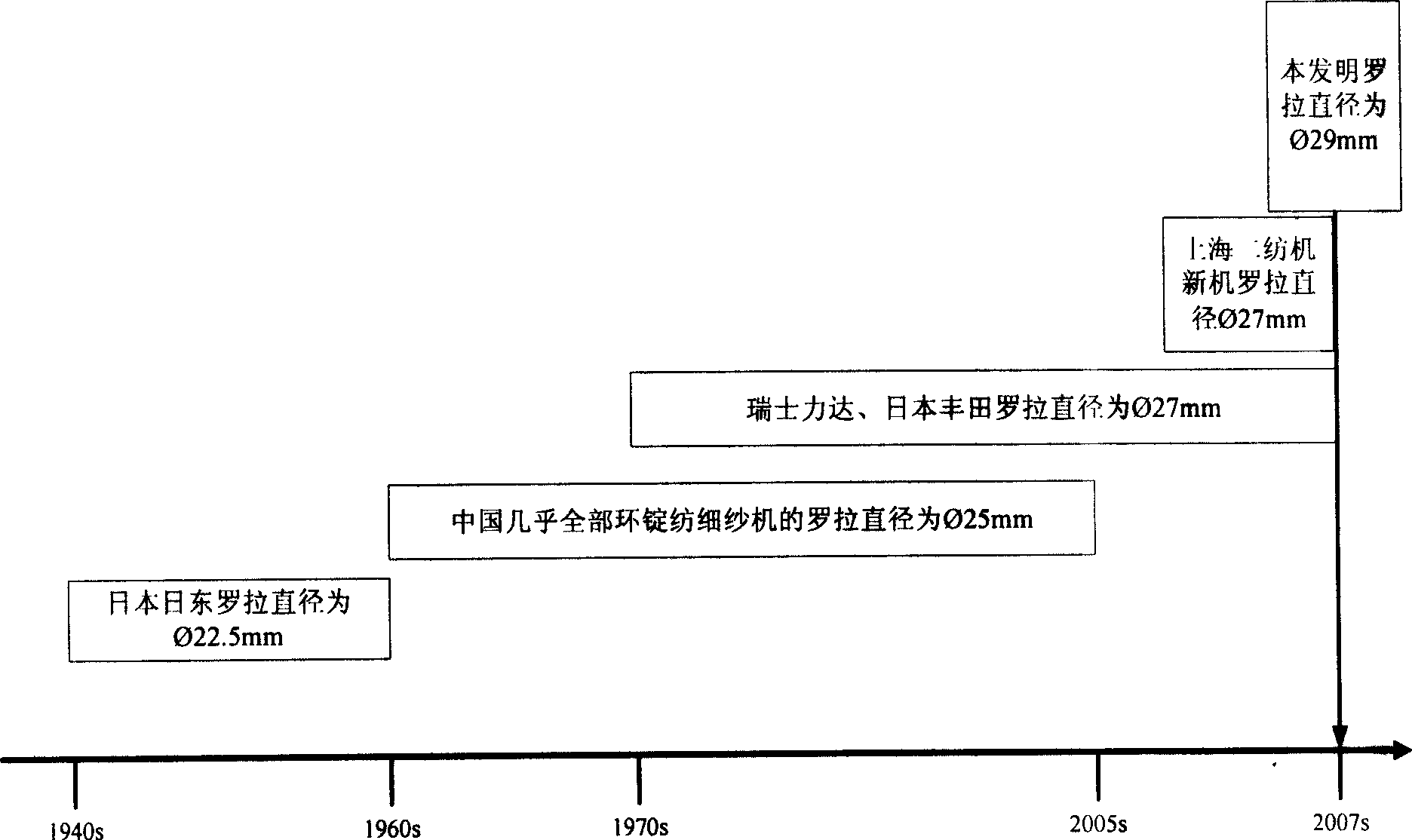

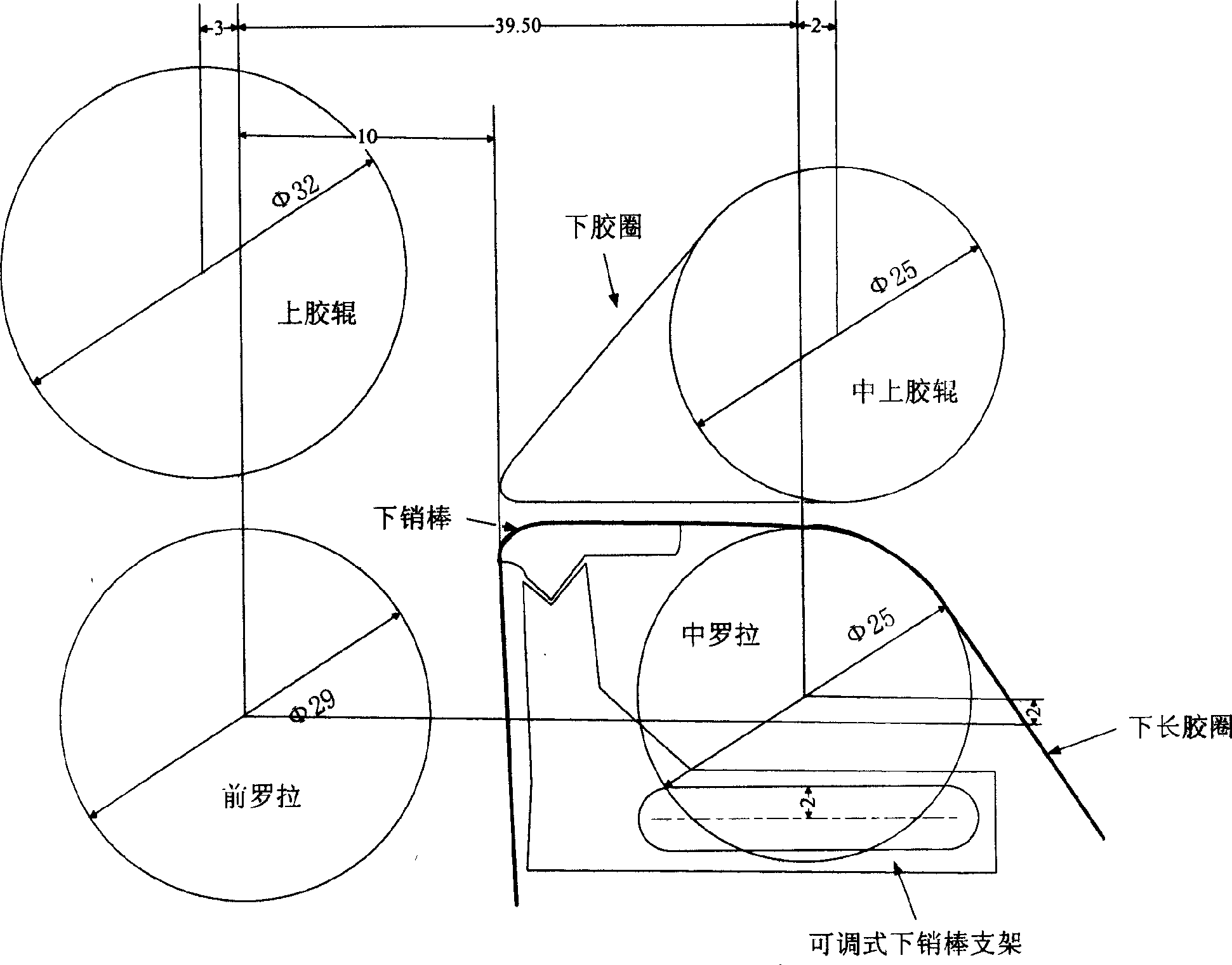

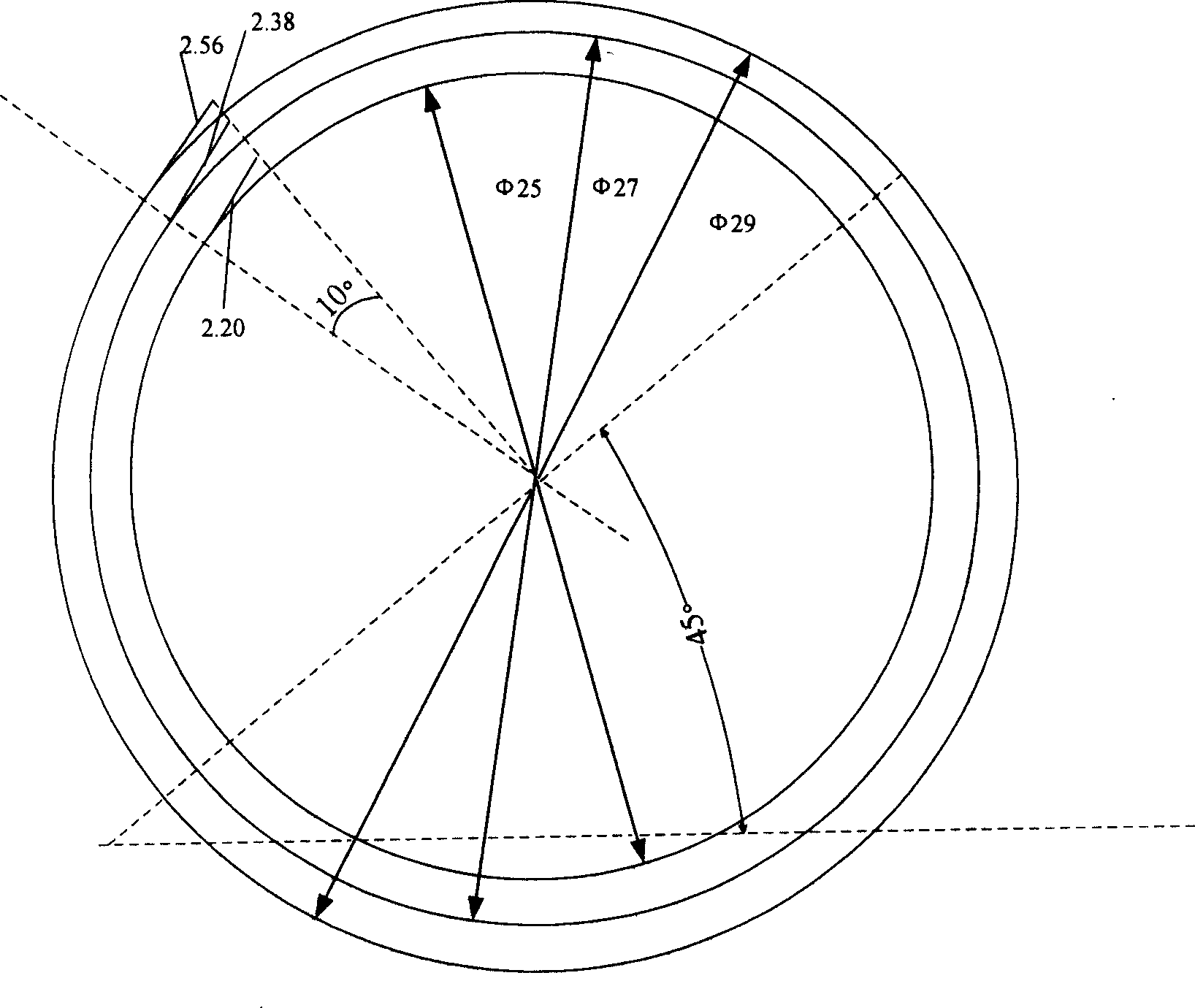

Reaching combination collocation design for increasing front roller diameter (29-31mm) centre distance of spinning frame

The invention relates to a combined optimization design of a core working part of a ring spun yarn machine which draws rough yarn by a front roller to form spun yarn. The combined design comprises two parts: one is to use the technology of an adjustable lower pin support of a spinning machine (the patent of Xu Zhongxiang which is a member of the team members: ZL 200620039228.2); the second is to use the front roller with the diameter of 29mm to 31mm. The combined optimization design of the roller and a cot reduces the spinning holding distance (approach), increases the contact arc length of the roller and an upper rubber roll and moves the acting point (shift point) to the direction of a middle roller, thereby being conductive to reducing the actual holding distance, reducing an untwisting area and reducing the end breakage rate. As the diameter of the roller is increased (the general diameter of the roller is 25mm or 27mm), the rotation speed can be reduced at the same line speed, thereby reducing vibration and wear, enhancing anti-torsion and anti-bending properties, leading the roller to bear greater cradle pressure and being applicable to the re-compression process. The technology can significantly improve the spinning quality of the spun yarn and can be used for designing novel spinning machines and transforming old machines.

Owner:徐明 +2

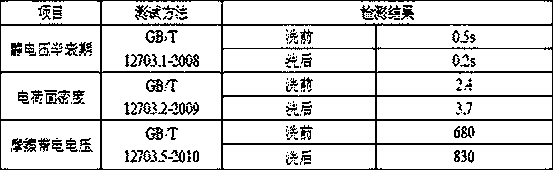

Color-spun polyester-viscose fabric and production method thereof

PendingCN110983573AImprove featuresPromote sheddingWoven fabricsLiquid/gas/vapor textile treatmentPolyesterViscose

The invention provides a color-spun polyester-viscose fabric and a production method thereof. Four-time continuous hair grabbing is adopted in hairiness grabbing and shearing, one-time hairiness shearing is realized, integral molding is realized, the production efficiency is improved, relatively large tension force is used in the first-time hairiness grabbing to facilitate quick fuzzing, relatively small tension force is used in the second-time and third-time hairiness grabbing to avoid damaging the fabric surface, grabbed hairiness is denser and more uniform, relatively large tension force isused in the fourth-time hairiness grabbing to comb the grabbed hairiness so as to facilitate subsequent hairiness shearing, hairiness grabbing and shearing are uniform through control of the tensionforce in the four-time hairiness grabbing, the fabric is good in wool-like effect, is fluffy and soft in hand feel and is resistant to fuzzing and pilling, difficult in hair slip, good in water washing appearance, comfortable to wear and excellent in antistatic property, the method is advanced and reasonable in processing flow, the product quality is stable, the method is simple and reliable, is high in production rate, short in period and high in color fixation rate and reduces sewage discharge from the perspective of energy saving and environmental protection, the product quality can be improved, and the fabric is good in quality sense and excellent in market economic benefit.

Owner:LILANG CHINA

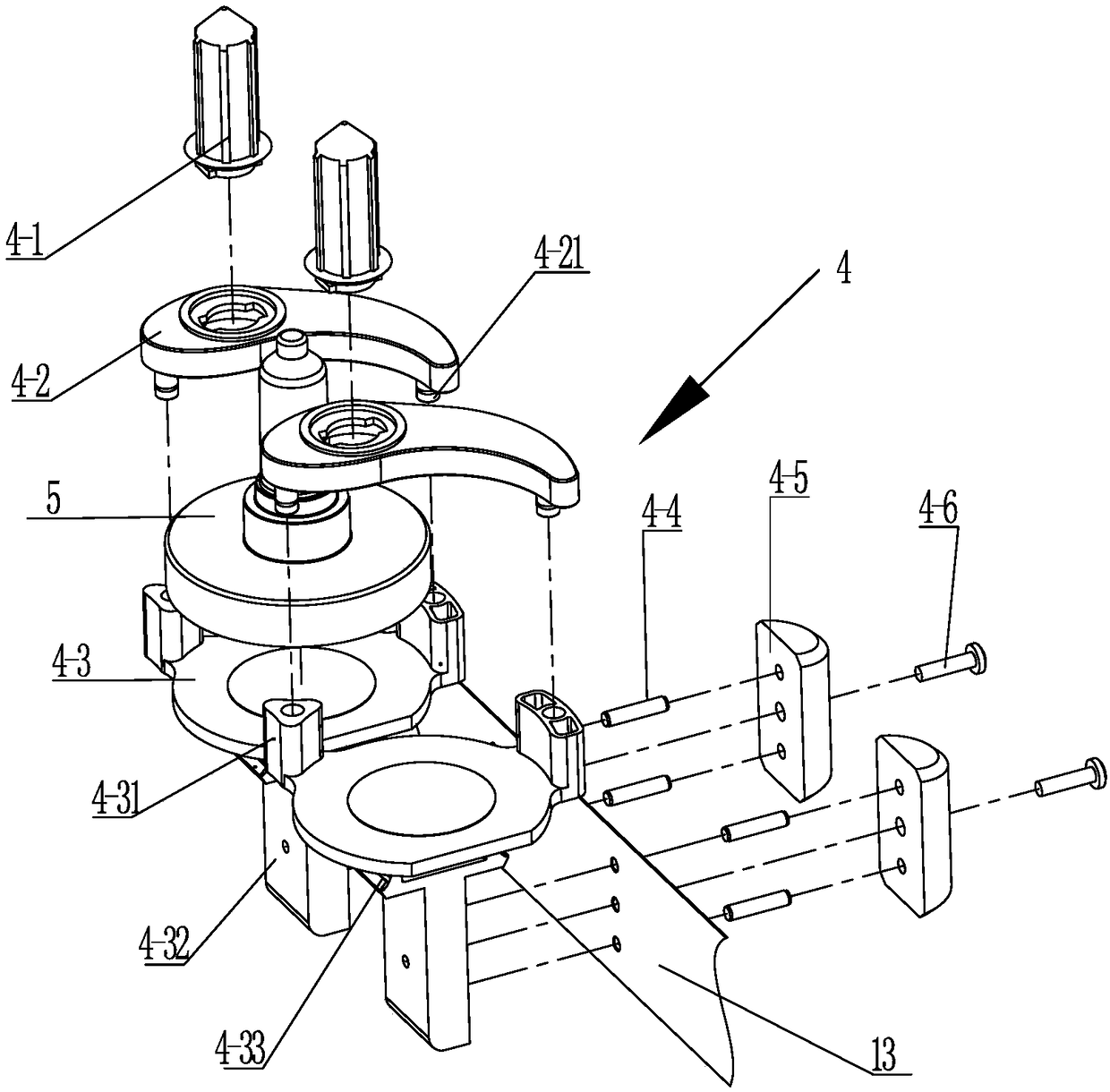

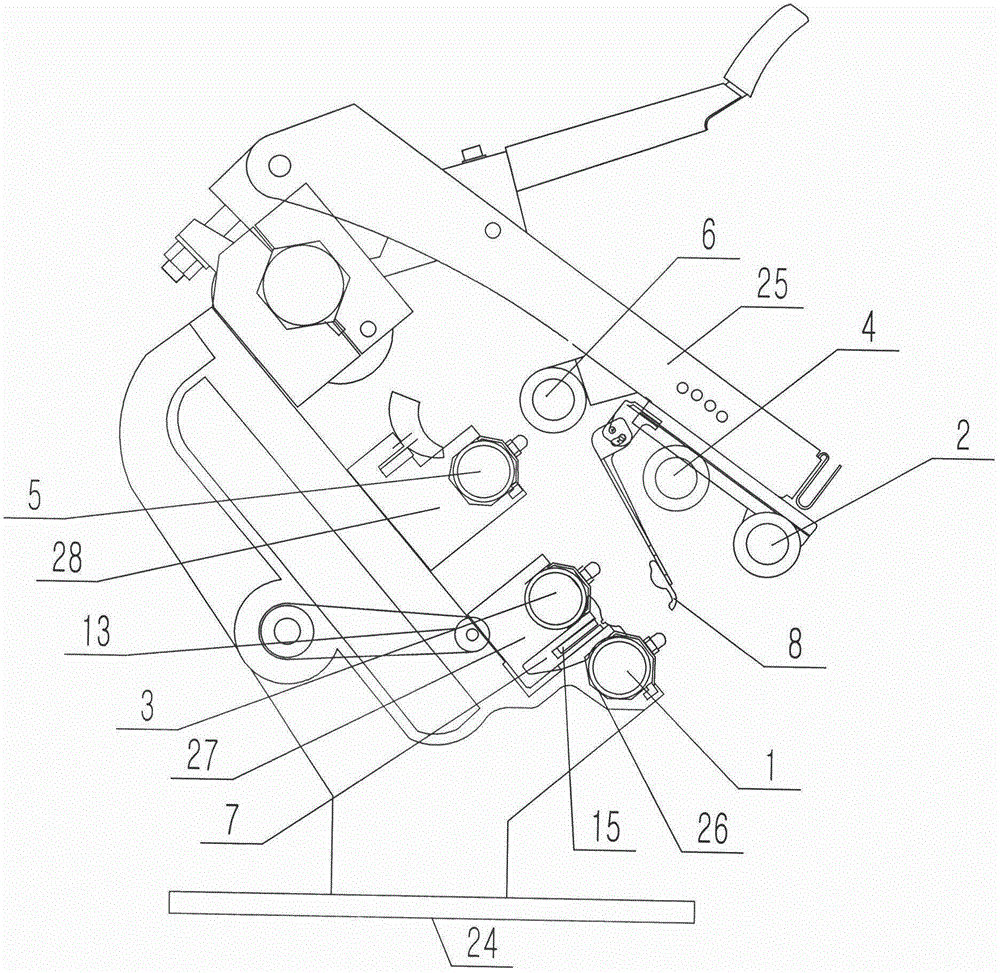

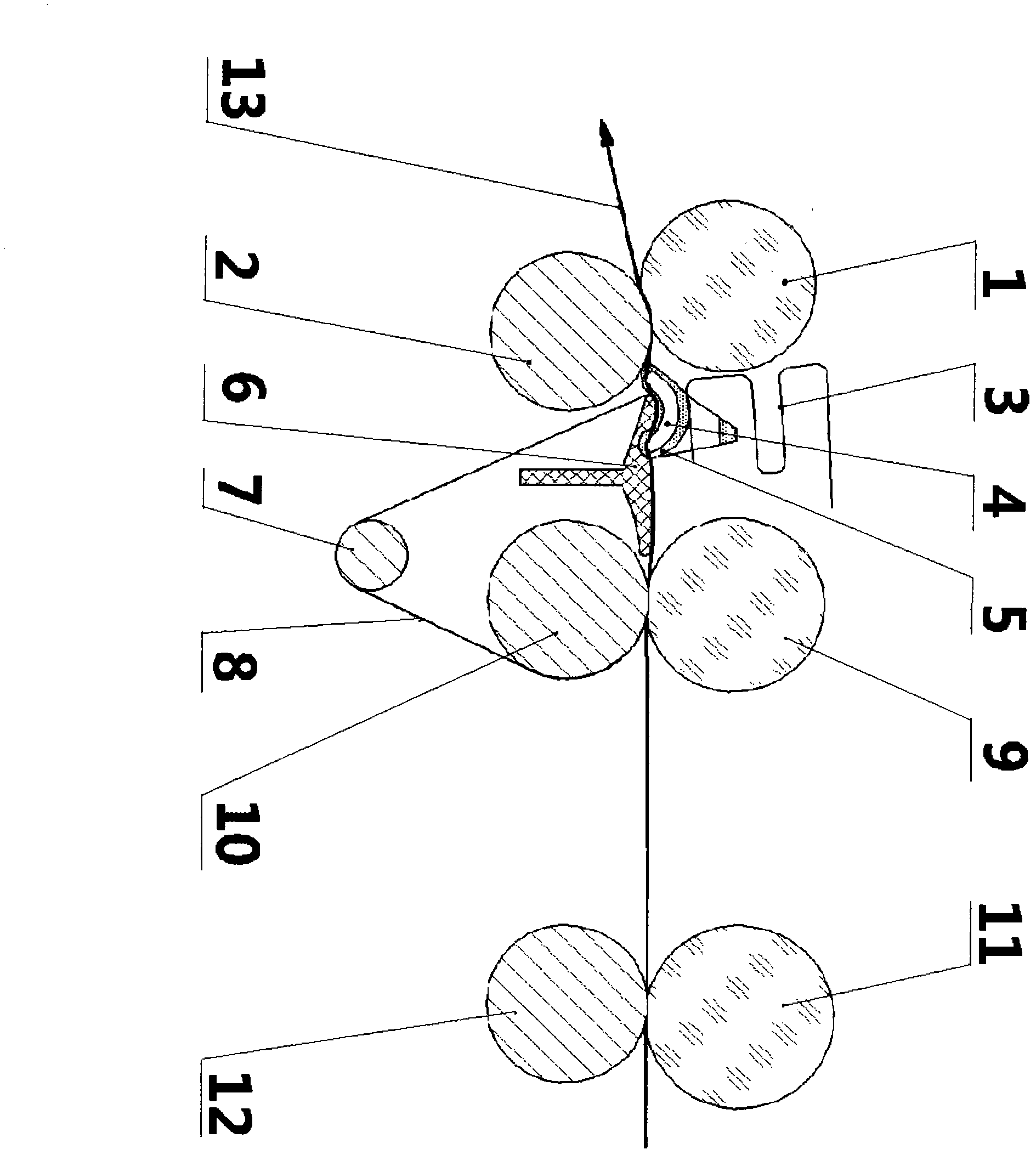

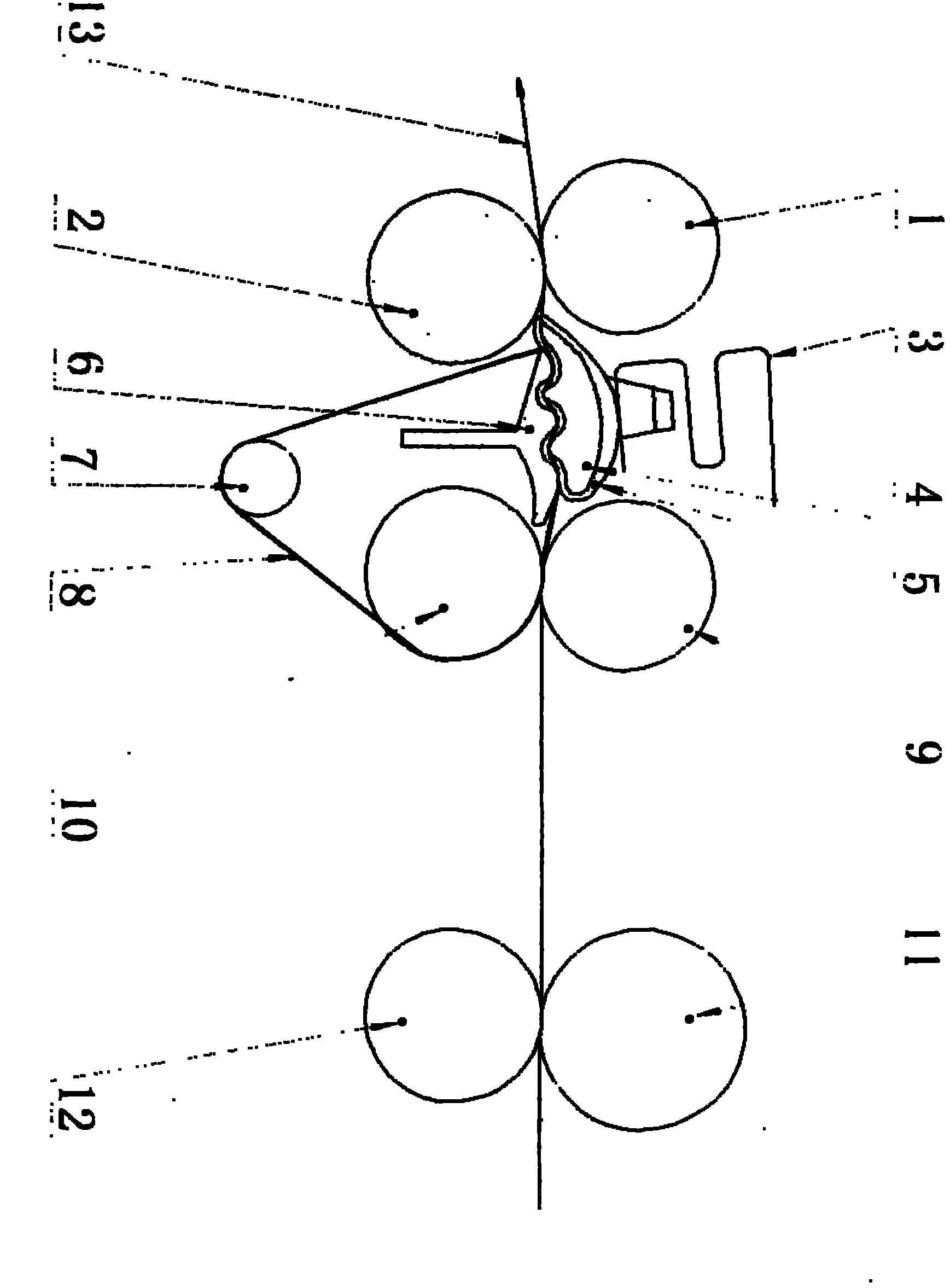

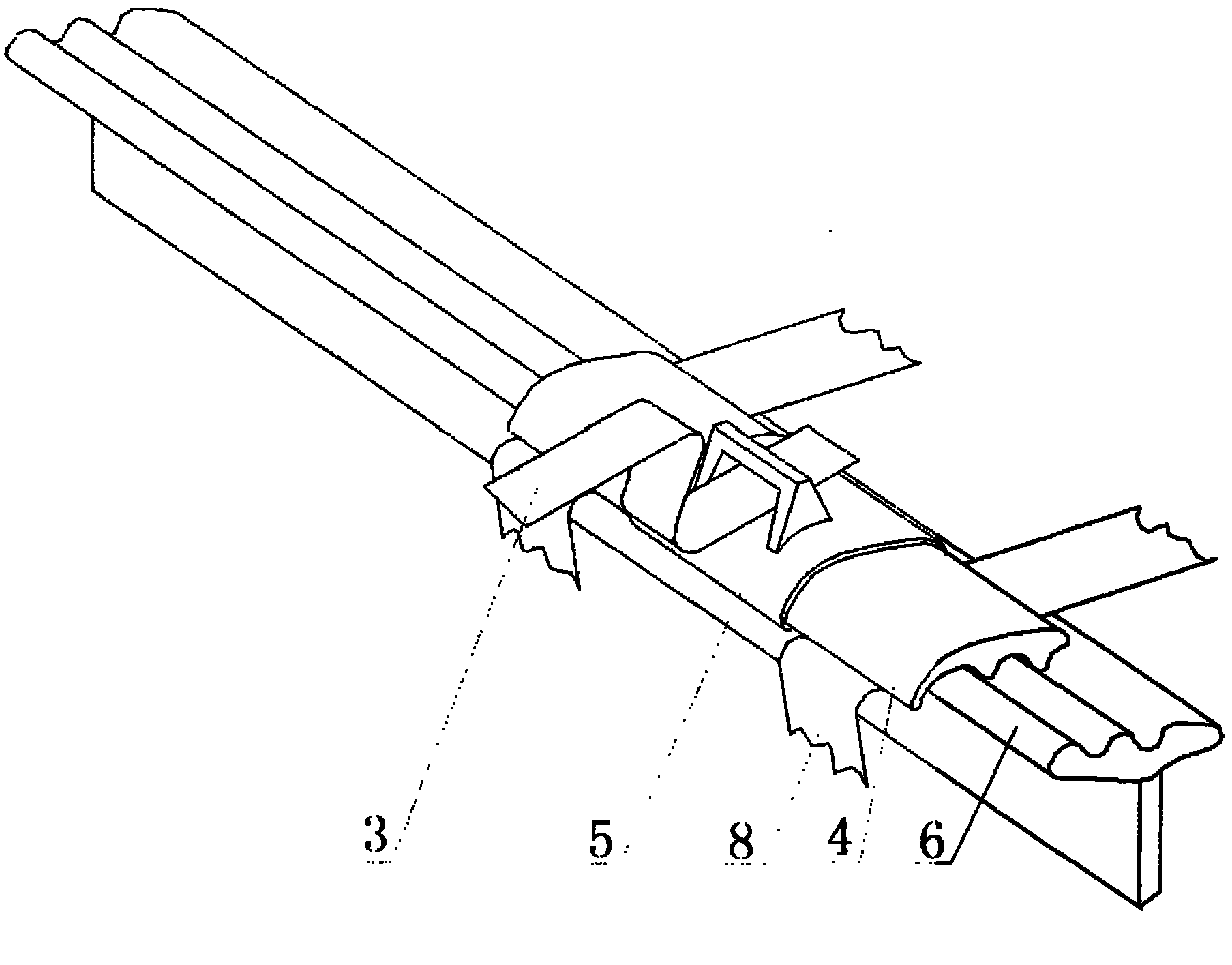

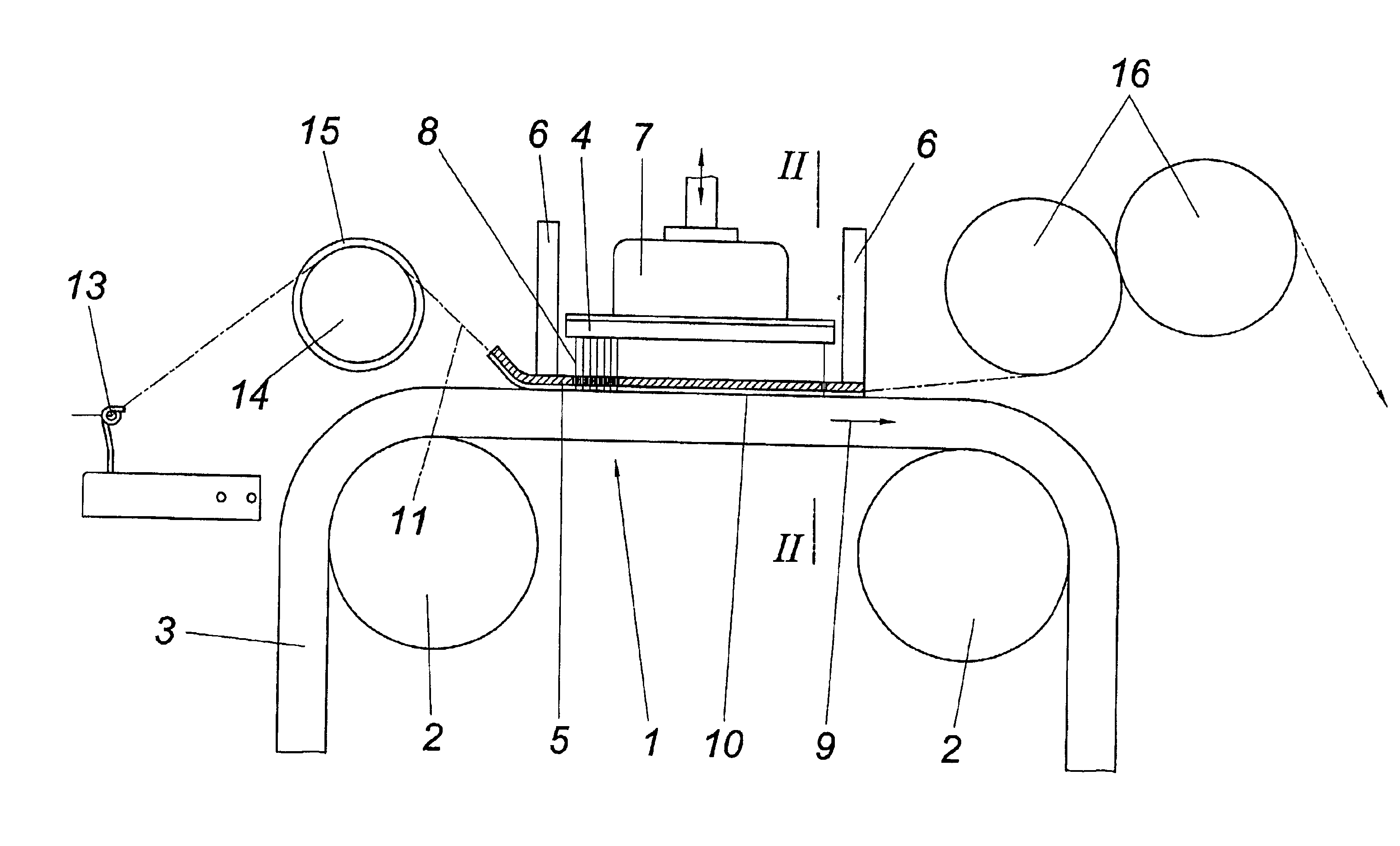

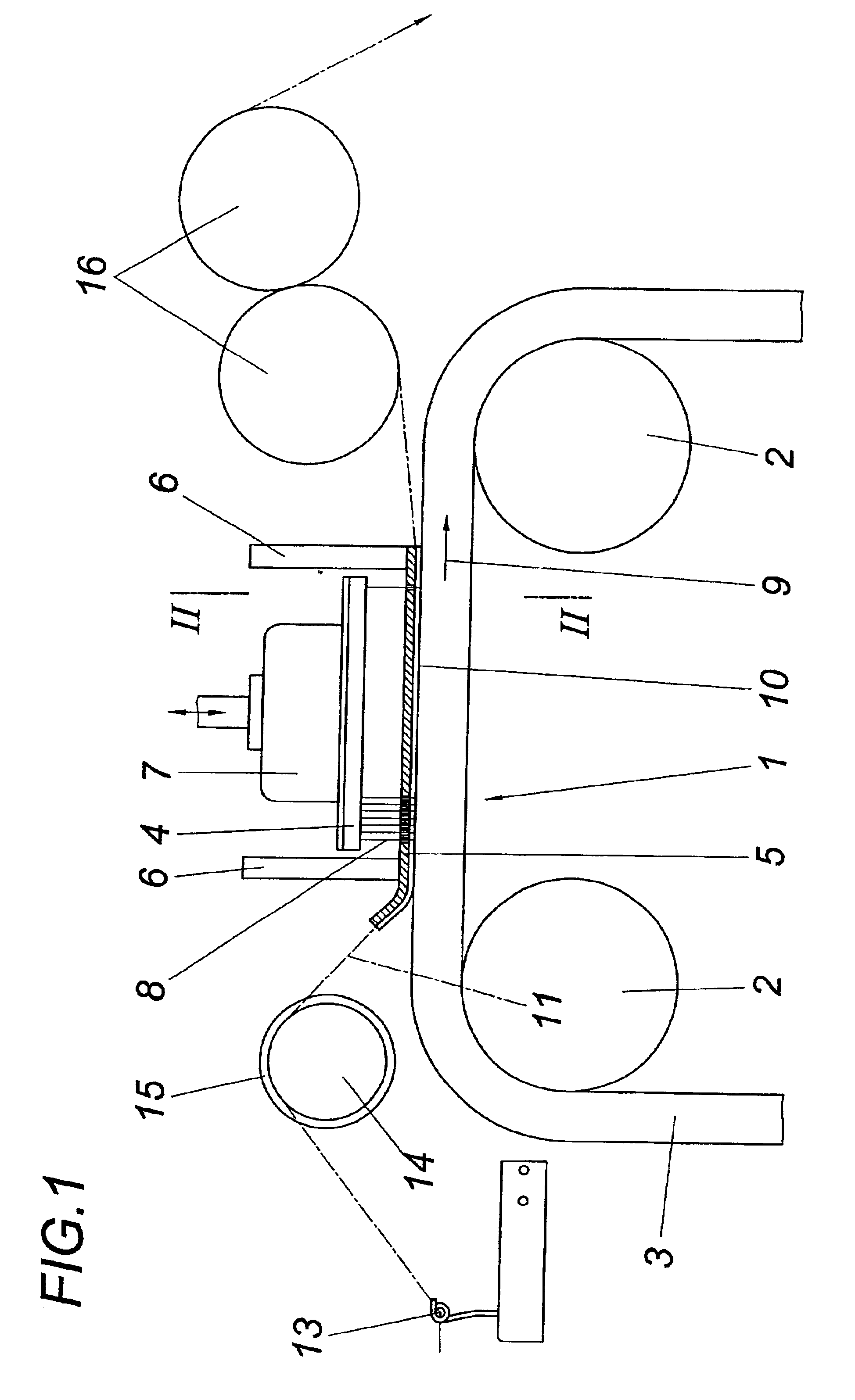

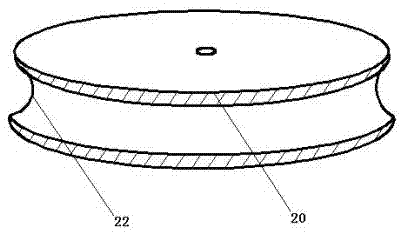

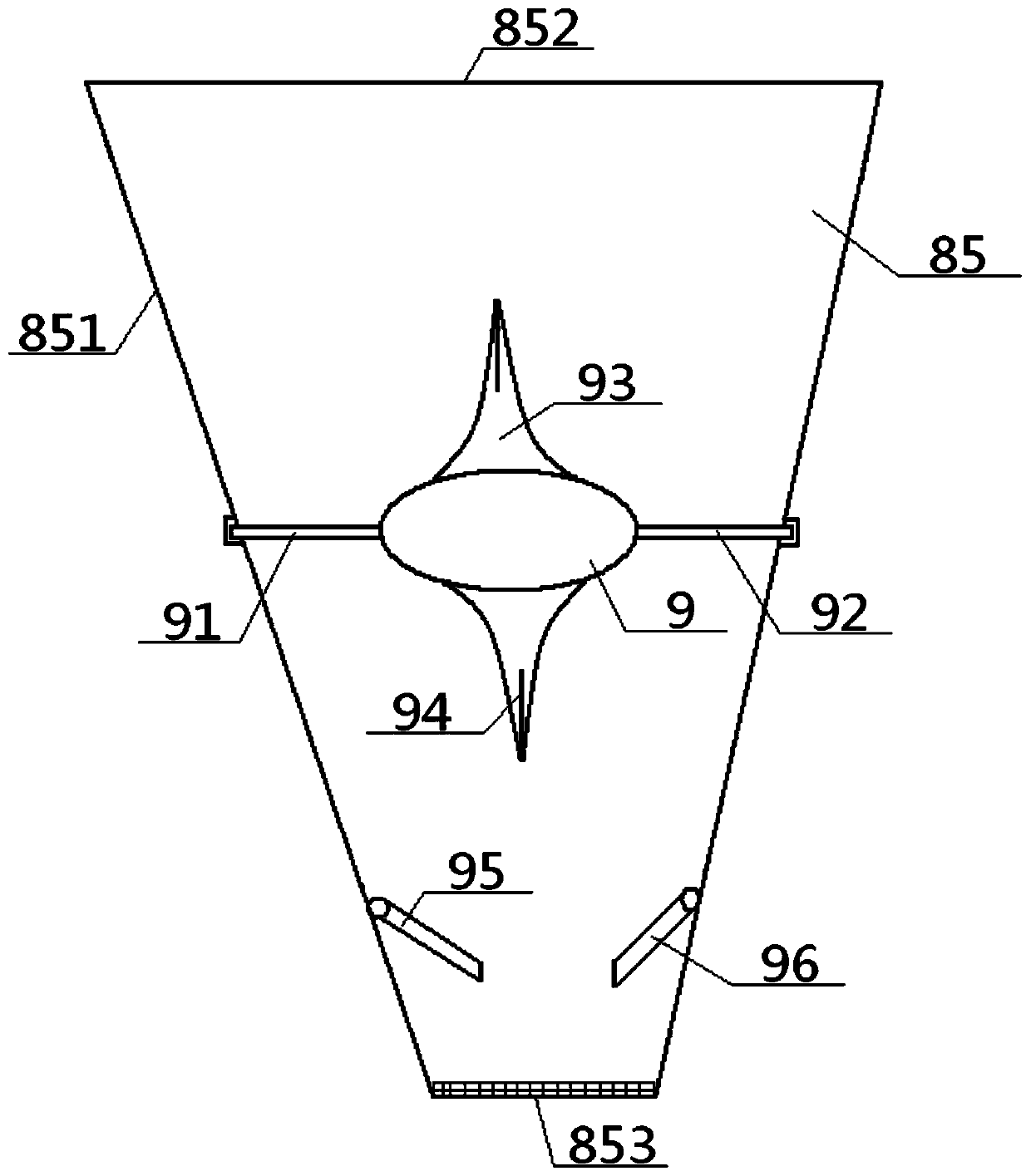

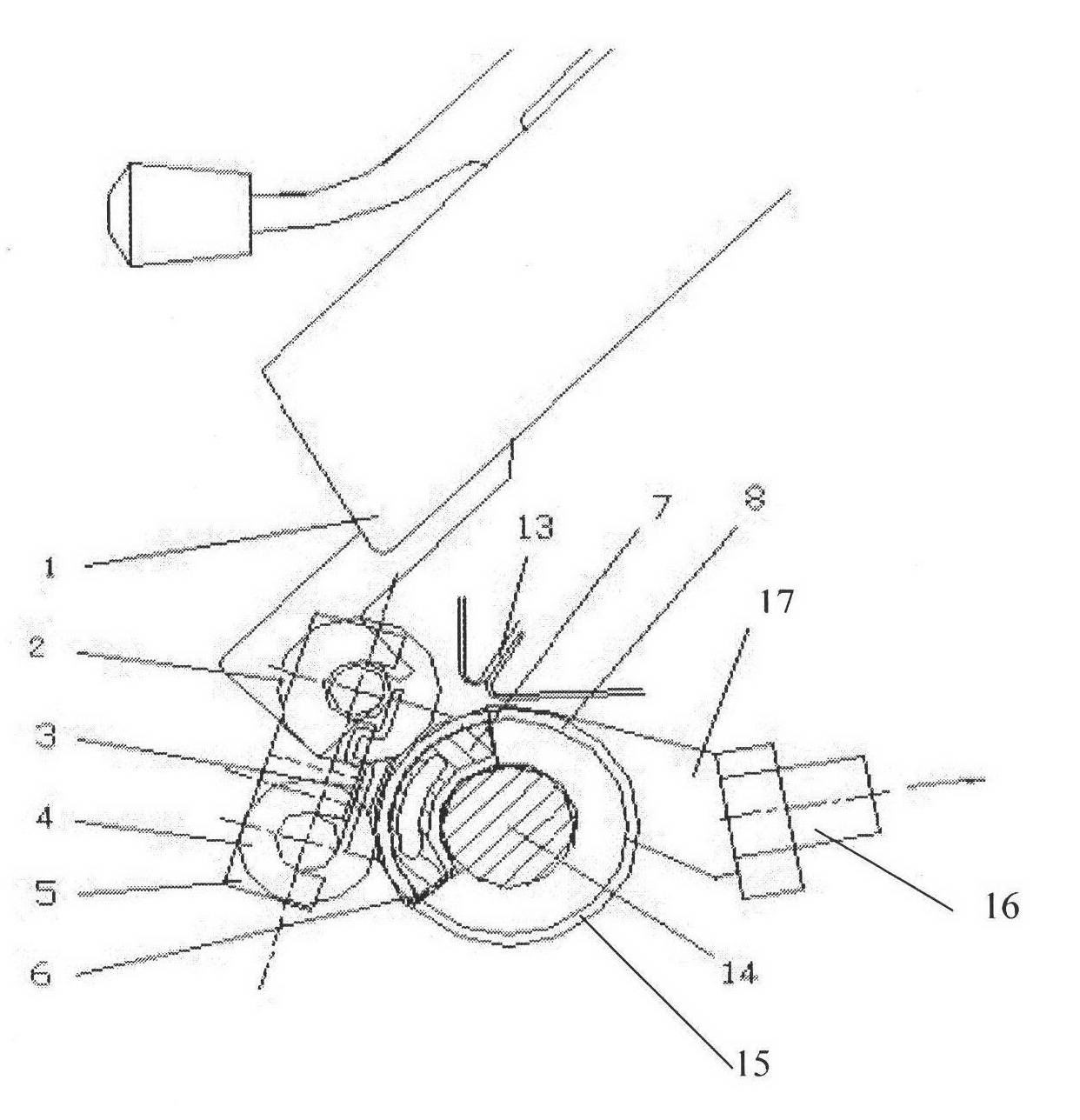

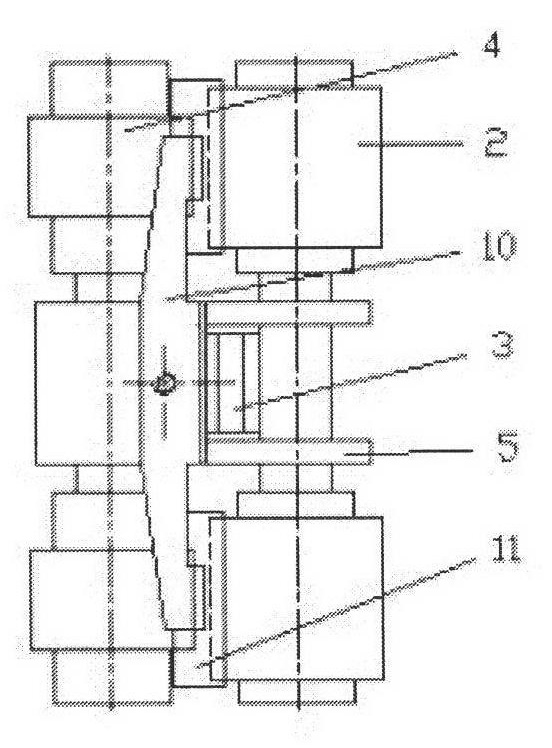

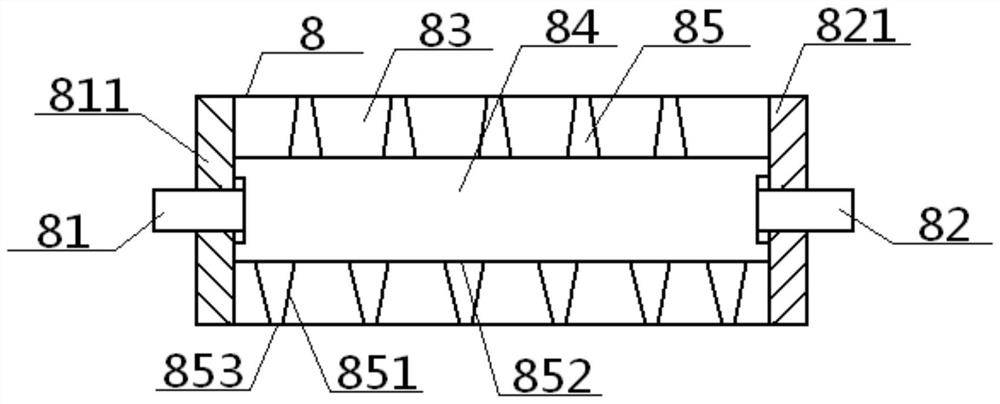

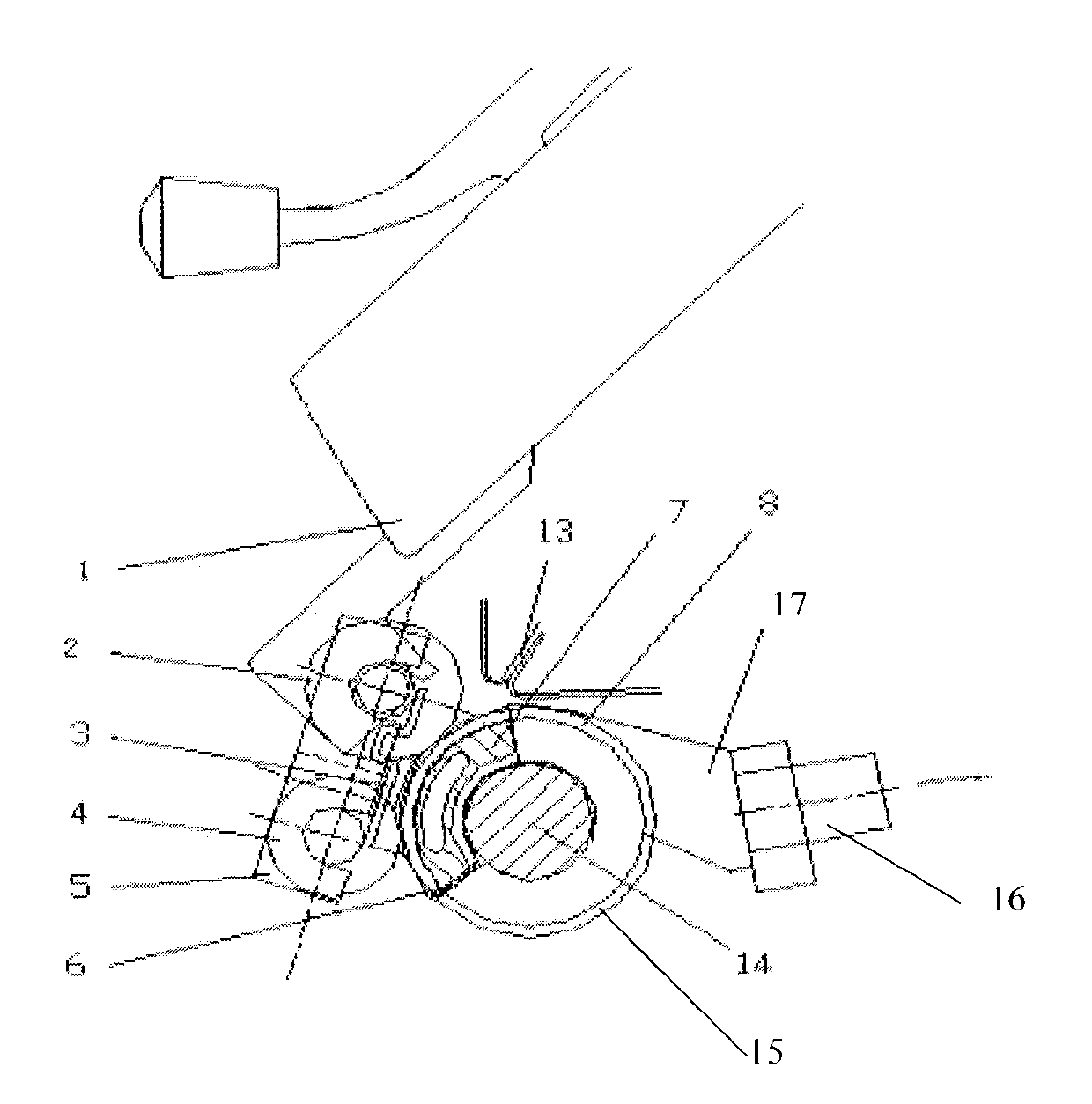

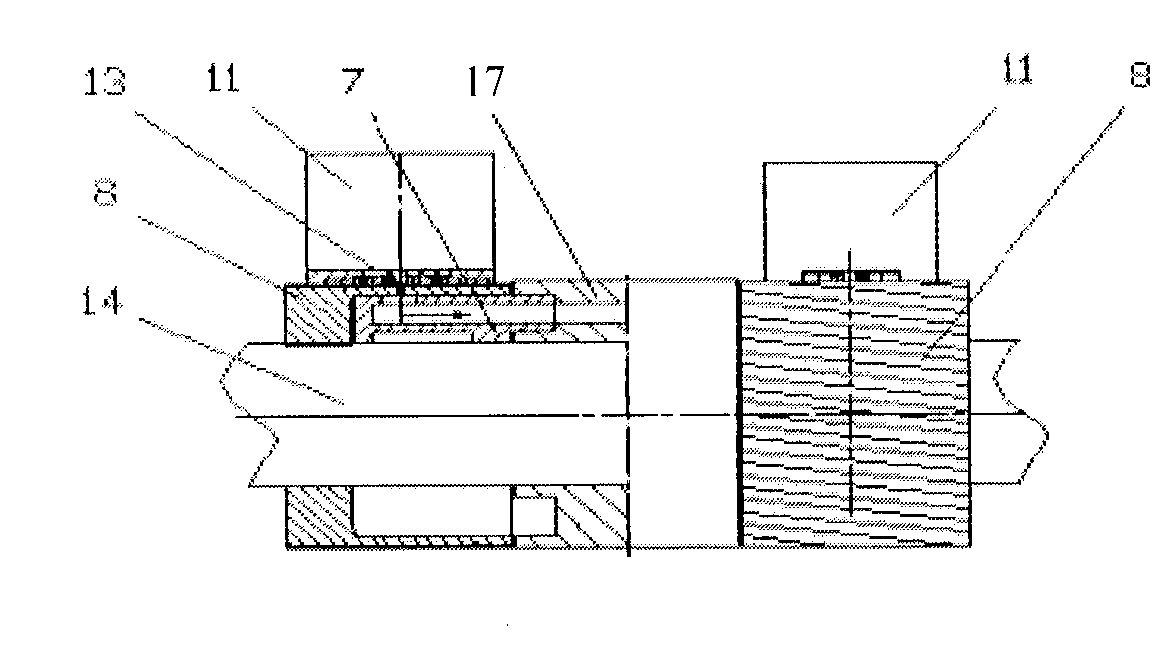

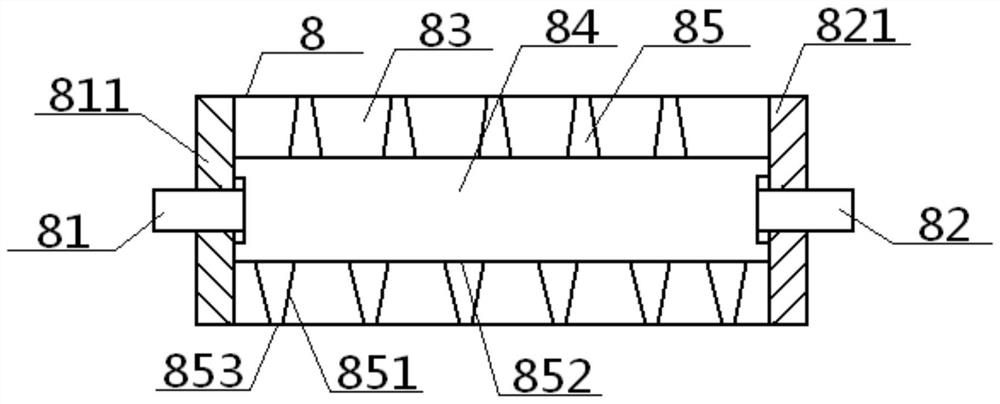

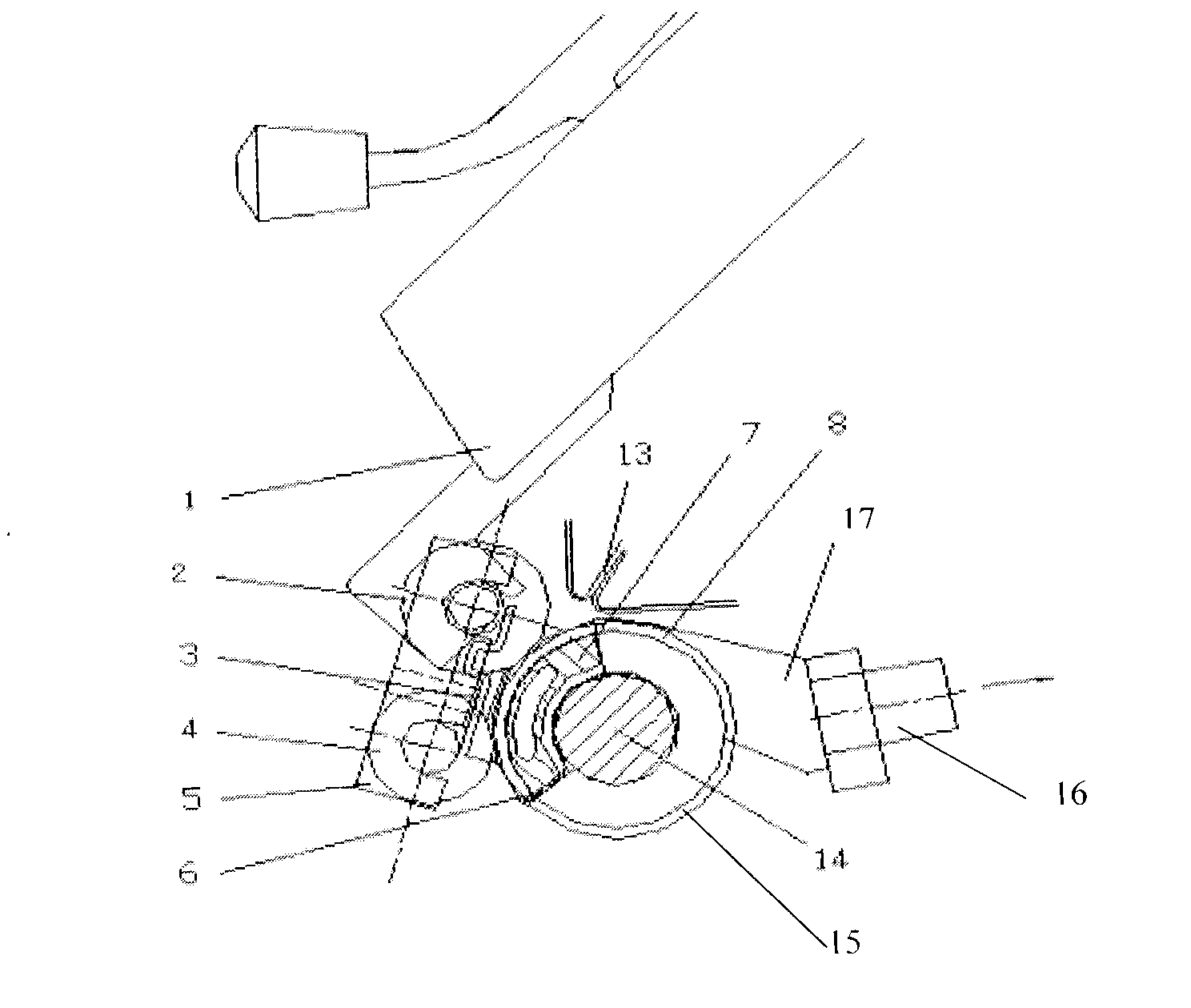

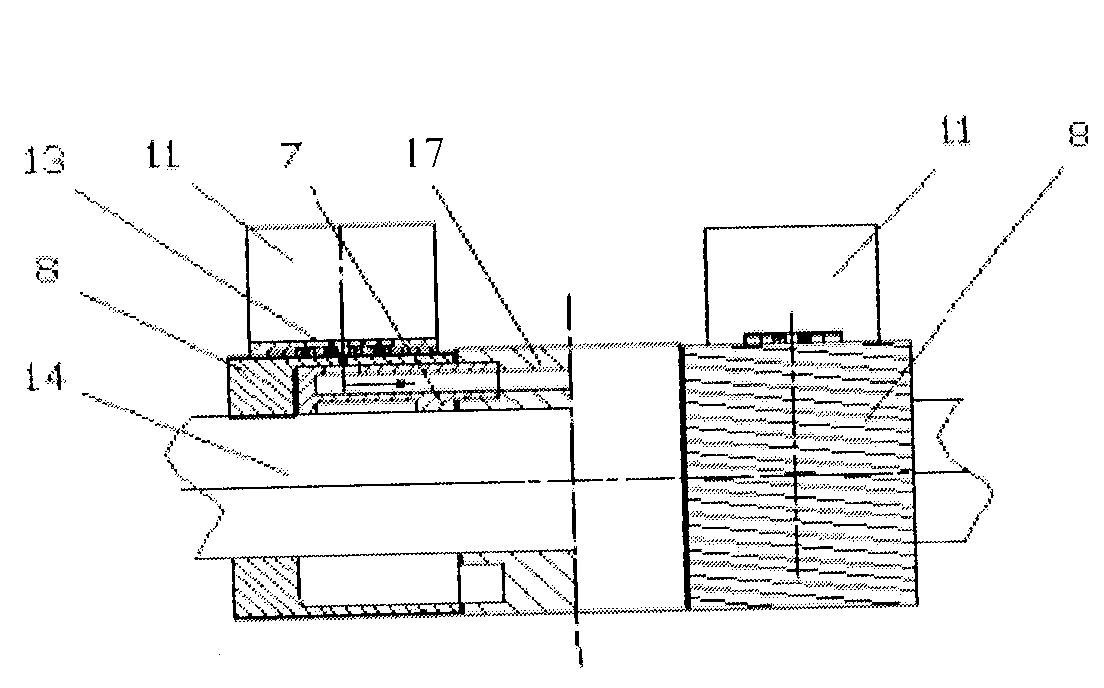

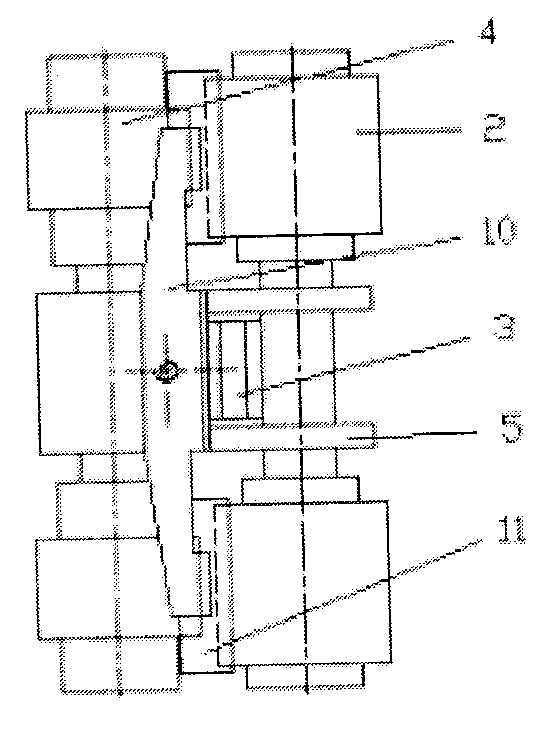

Novel double-fiber bundling device

ActiveCN102304790ARaise the barImprove hairinessDrafting machinesContinuous wound-up machinesYarnFiber bundle

The invention relates to a novel double-fiber bundling device. A first leather roller (2) and a second leather roller (4) are arranged on a leather roller frame (5); an airflow orientating block (11) is arranged on the leather roller frame (5) through a positioning plate (10); a spring (3) is arranged on the leather roller frame (5); a permanent magnet (12) is arranged on the airflow orientating block (11); a wide vacuum nozzle (7), a lower dust cover (15), an air suction base (16), an upper dust cover (17) and a baffle (6) are arranged in hollow roller rings (8); the hollow roller rings (8) are arranged on a main shaft (14) in pairs; the upper dust cover (17) is arranged on the wide vacuum nozzle (7); the lower dust cover (15) is arranged on the lower part of the wide vacuum nozzle (7); and the upper dust cover (17) is connected with the air suction base (16). The device solves the problems of much hair feather, low fiber strength and much flyings of yarns spun by spinning and wool spinning equipment; production cost is reduced; and working efficiency is improved.

Owner:陆节

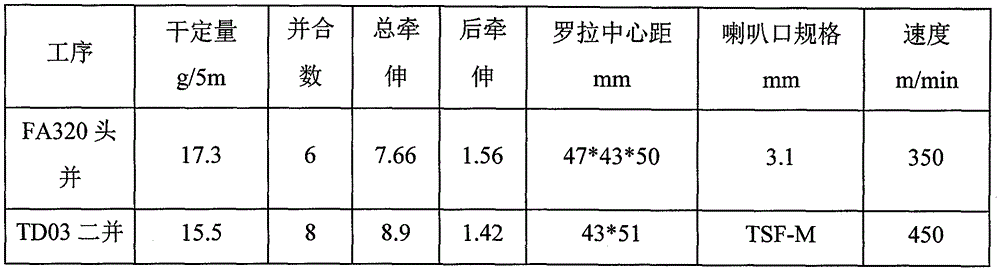

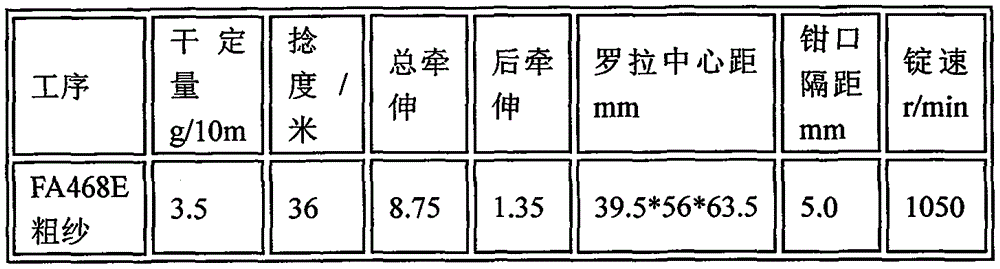

Ring spinning combed cotton 80-roving siro spinning technology

The invention provides a ring spinning combed cotton 80-roving siro spinning technology. The technology is characterized by comprising the steps of drawing and roving; According to the steps of drawing and roving, the end combination quantity is 2.2-2.5 g / m, the front roller speed is 340-360 meter / minute, and the light quantity selected by roving is 3.8-4.2 g / 10m; the roving twist factor is 110-113. The surface fiber of cotton 80-roving siro spun yarn is arranged in order, the structure is compact, the amount of hairiness is small, the fabric touch is soft and full, the fabric is unique in style, and the yarn has the characteristics of threads.

Owner:山东华晨彩装科技有限公司

Method for reducing high count yarns' surface hairiness

The invention discloses a method for reducing high count yarns' surface hairiness. The high count yarns can be cellulose type, protein type, chemical fiber type, or blended yarns of cellulose type, protein type and chemical fiber type. Chitosan and its derivative undergo crosslinking through ultraviolet light and a chemical catalyst to form crosslinked chitosan and its derivative. The crosslinked chitosan and its derivative are used as a sizing agent to penetrate and cover the surface of yarns, thus enhancing cohesive force between yarns' fibers and raising mechanical property of yarns. Then, the yarns can be resistant to repeated washing of hot soap-suds, and has antibacterial property.

Owner:JIANGNAN UNIV

Process for manufacturing anti-bleaching flower gray towel

InactiveCN106491029AReduce dosageReduce processingDomestic applicationsWoven fabricsPulp and paper industryProcess design

The invention discloses a process for manufacturing an anti-bleaching flower gray towel and relates to a process for manufacturing a novel towel. The process comprises the steps of selecting appropriate yarn counts; by blending optimization raw cotton and color fibers according to a certain blending ratio, performing warping and sizing on yarn spun as required, and weaving the yarn into gray fabrics through reasonable weaving process design; scouring and bleaching the gray fabrics, performing loose type hair reversal drying, and finally performing sewing. An anti-bleaching flower gray yarn effect product can be manufactured creatively at a low cost. The product is flexible and fluffy in touch, complete in color scheme and good in color fastness, a production process is simplified, the cost is reduced, and the bleaching resistance of the product is improved.

Owner:SUNVIM GROUP

Spinning device and spinning process for ultra-long ultra-fine polyester yarn

ActiveCN110172758BHigh strengthIncrease humidityCarding machinesTextile treatment by spraying/projectingYarnPolyester

The invention relates to a spinning device for ultra-long and ultra-thin spun polyester threads and a spinning process. The spinning device comprises a cotton feeding roller and a cotton feeding support plate, wherein the cotton feeding support plate comprises a vertex-arc plate surface and a skew-back plate surface; a cotton feeding passage is formed between the vertex-arc plate surface and the cotton feeding roller in an included manner; an acupuncture cotton passage is formed between the skew-back plate surface and a licker-in in an included manner; the cotton feeding roller comprises a cotton press roller body, and a left drive shaft and a right drive shaft which are connected with the two ends of the cotton press roller body; the cotton press roller body comprises a cotton press outerbody and an inner chamber formed inside the cotton press outer body; a plurality of mist spray passages are arranged inside the cotton press outer body; each mist spray passage comprises a passage side wall, and an inner passage port and an outer passage port which are connected with the two ends of the passage side wall, the inner passage port is communicated with the cotton press inner chamber,the outer passage port is communicated with the outer wall of the cotton press outer body. Through the design provided by the invention, not only electrostatic phenomena are reduced, ultra-long and ultra-thin fiber production is facilitated, and further the production of sewing threads with high strength and good evenness is facilitated, but also outside interferences are decomposed, and smooth production is ensured.

Owner:湖北枫树科技有限公司 +1

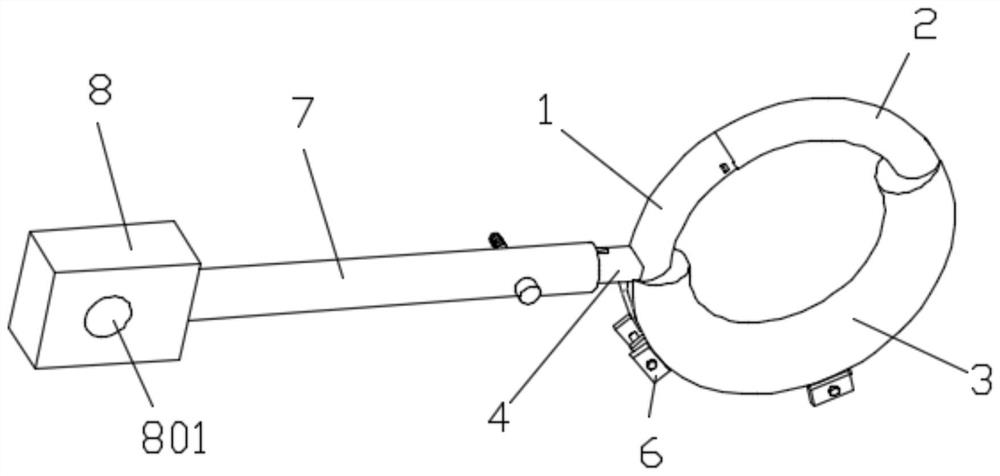

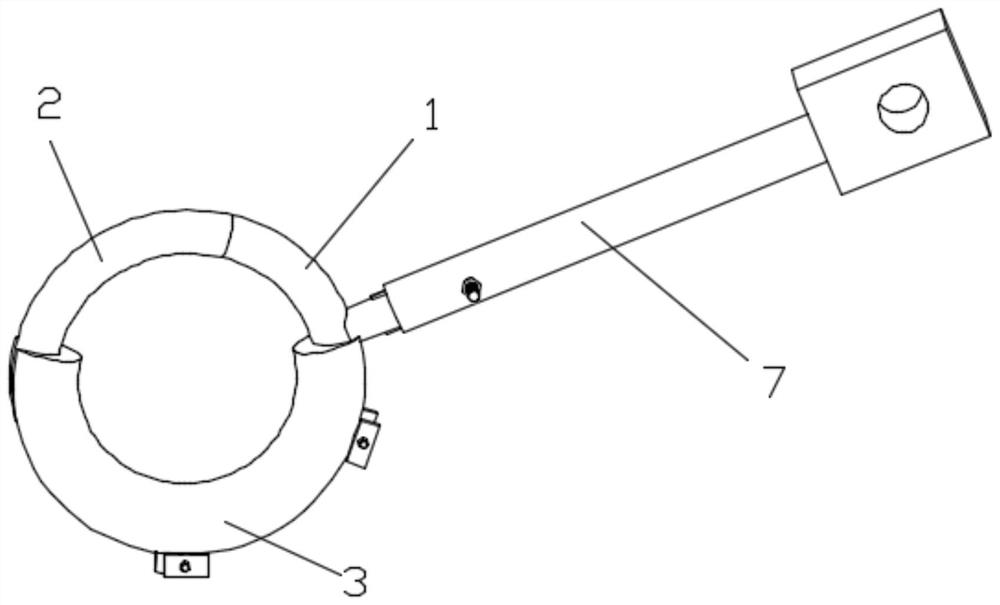

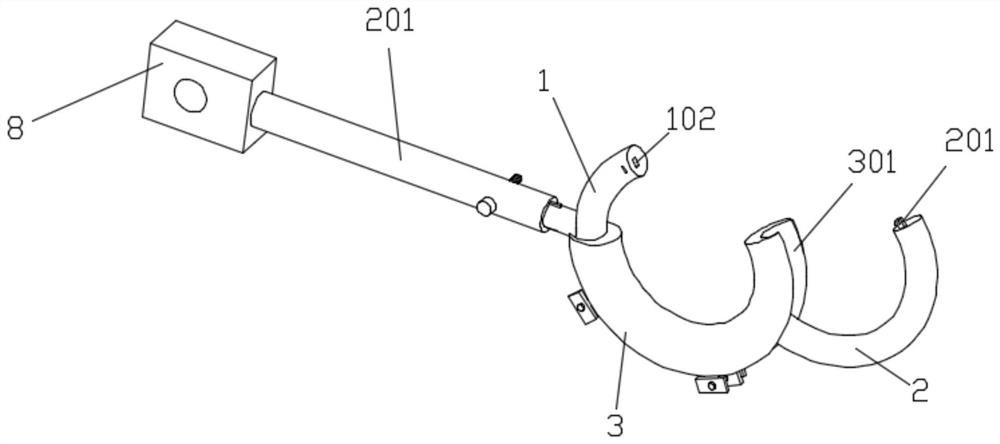

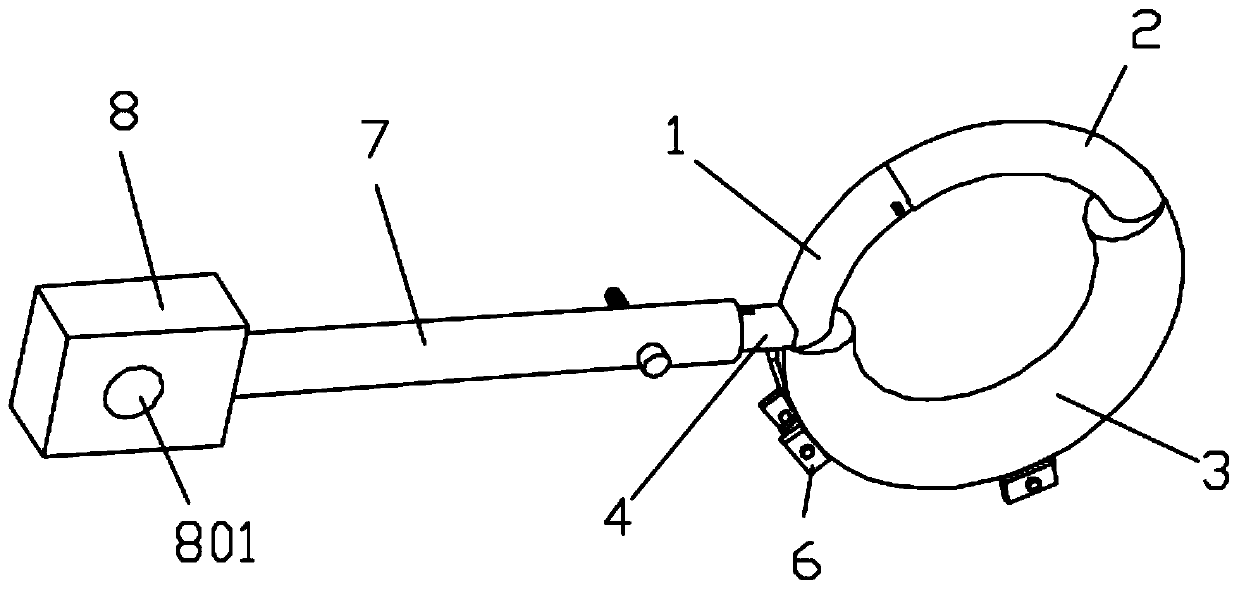

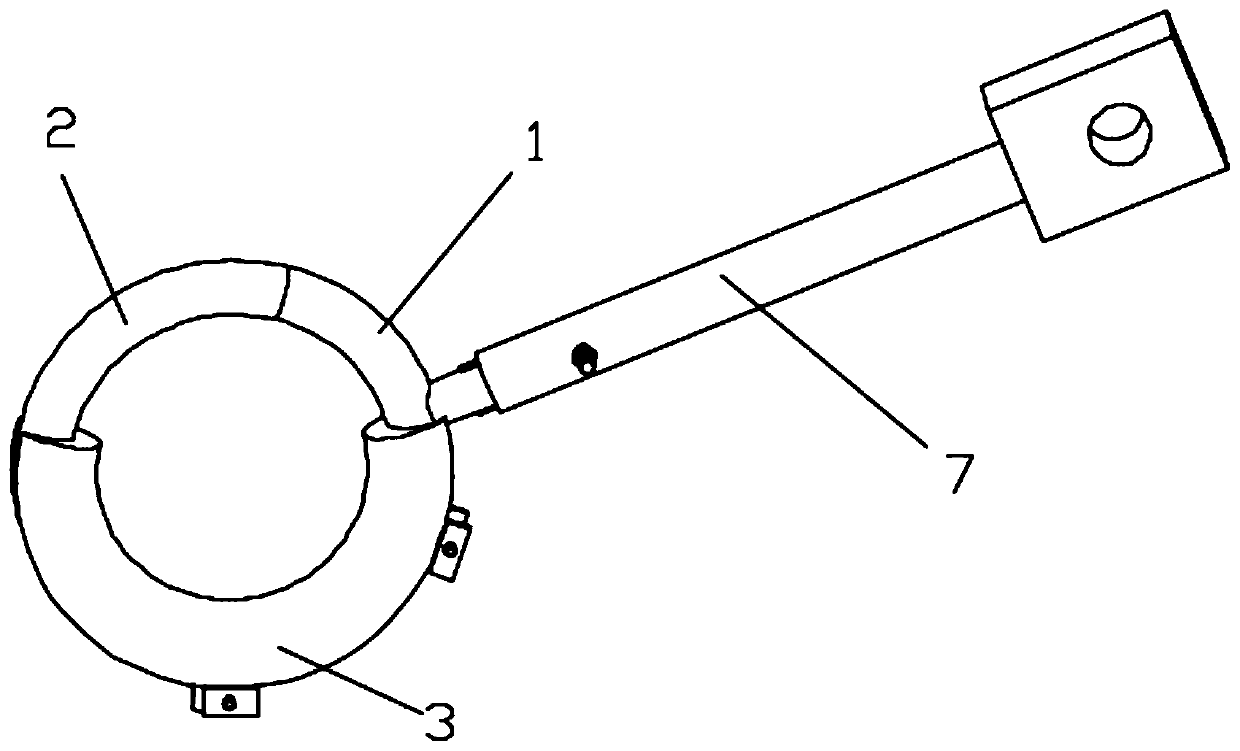

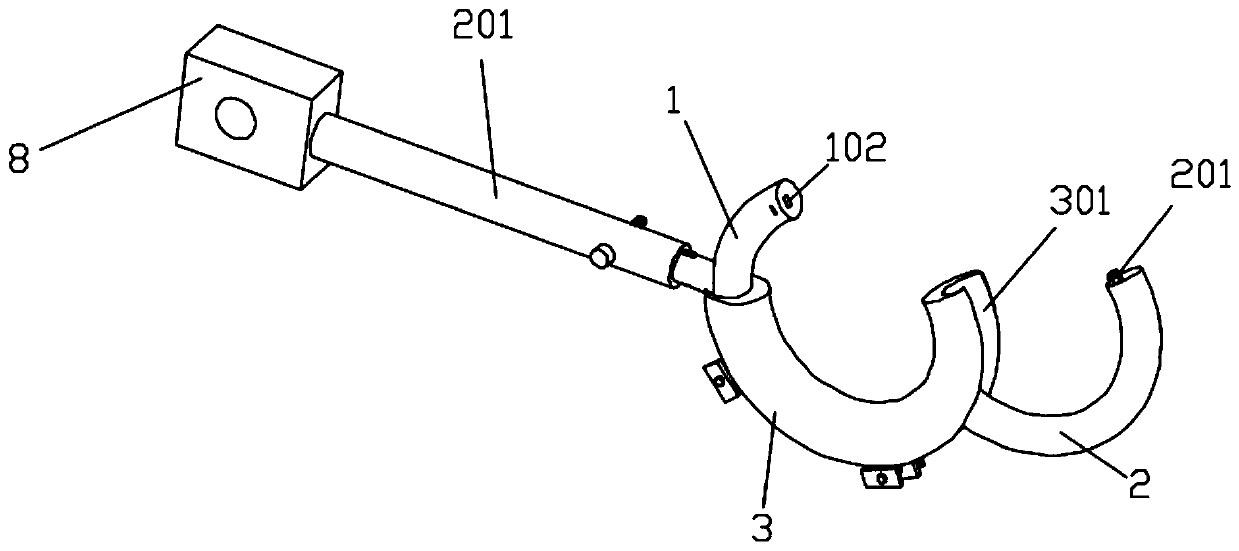

a yarn guiding mechanism

The invention discloses a yarn guiding mechanism and relates to the technical field of textile machinery. The present invention comprises a first arc-shaped rod, a second arc-shaped rod and an arc-shaped yarn guide sleeve; the first arc-shaped rod and the second arc-shaped rod form a yarn guide ring; wherein, the first end of the first arc-shaped rod and the second arc-shaped rod The first ends of the two curved rods are hinged, and the second end of the first curved rod is detachably connected to the second end of the second curved rod; the outer surface of the first curved rod is fixedly connected with a connecting rod; The outer surface of the yarn guide sleeve is provided with a clamping groove matched with the yarn guide ring along the peripheral direction; the arc-shaped yarn guide sleeve is clamped on the inner surface of the yarn guide ring through the clamping groove. The present invention clamps the arc-shaped yarn guide sleeve with the yarn guide ring, and when the surface of the arc-shaped yarn guide sleeve is worn due to long-term use, the arc-shaped yarn guide sleeve can be replaced directly, without the need to replace the yarn guide mechanism as a whole, reducing waste of material.

Owner:ANHUI HANLIAN TEXTILE CO LTD

Yarn guide mechanism

The invention discloses a yarn guide mechanism, and relates to the technical field of textile machinery. The yarn guide mechanism comprises a first arc-shaped rod, a second arc-shaped rod and an arc-shaped yarn guide sleeve. The first arc-shaped rod and the second arc-shaped rod form a yarn guide ring; the first end of the first arc-shaped rod is hinged to the first end of the second arc-shaped rod, and the second end of the first arc-shaped rod is detachably connected with the second end of the second arc-shaped rod; the outer side face of the first arc-shaped rod is fixedly connected with aconnecting rod; the outer side face of the arc-shaped yarn guide sleeve is provided with a clamping groove matched with the yarn guide ring in the circumferential direction; and the arc-shaped yarn guide sleeve is clamped in the inner side face of the yarn guide ring through the clamping groove. The arc-shaped yarn guide sleeve is clamped with the yarn guide ring, when the surface of the arc-shaped yarn guide sleeve is abraded due to long-time use, the arc-shaped yarn guide sleeve can be directly replaced, the yarn guide mechanism does not need to be integrally replaced, and material waste isreduced.

Owner:ANHUI HANLIAN TEXTILE CO LTD

Double-fiber bundling device

ActiveCN102304790BRaise the barImprove hairinessDrafting machinesContinuous wound-up machinesYarnFiber bundle

The invention relates to a novel double-fiber bundling device. A first leather roller (2) and a second leather roller (4) are arranged on a leather roller frame (5); an airflow orientating block (11) is arranged on the leather roller frame (5) through a positioning plate (10); a spring (3) is arranged on the leather roller frame (5); a permanent magnet (12) is arranged on the airflow orientating block (11); a wide vacuum nozzle (7), a lower dust cover (15), an air suction base (16), an upper dust cover (17) and a baffle (6) are arranged in hollow roller rings (8); the hollow roller rings (8) are arranged on a main shaft (14) in pairs; the upper dust cover (17) is arranged on the wide vacuum nozzle (7); the lower dust cover (15) is arranged on the lower part of the wide vacuum nozzle (7); and the upper dust cover (17) is connected with the air suction base (16). The device solves the problems of much hair feather, low fiber strength and much flyings of yarns spun by spinning and wool spinning equipment; production cost is reduced; and working efficiency is improved.

Owner:陆节

Preparation method of composite yarn with glittering effect

The invention relates to the technical field of textile yarn, in particular to a preparation method of a composite yarn with a flash effect. The aim is to provide a preparation method of the compositeyarn with the flash effect, a gorgeous surface, a flashing luster and a strong sense of three-dimension. The preparation method comprises the first step of selection of raw materials, and the secondstep of preparation of pure wool roving; in the first step, the raw materials comprise 80-90% of 90S mercerized Australian wool and 8-20% of metallic yarn, and the total ratio of the 90S mercerized Australian wool and the metallic yarn is 100%; in the second step, the 80-90% of 90S mercerized Australian wool is prepared into the pure wool roving with a ration of 3.5 g per 10 m by means of flock dyeing, wool blending, cotton carding, drawing, and roving (semi worsted process route). The preparation method of the composite yarn with the flash effect utilizes the Siro-Phil technology to combine the metallic yarn with the mercerized Australian wool to make the yarn have better flash effect, the evenness and hairiness performance can be improved, the scratching sensation of the metallic yarn isreduced, and the yarn strength and the pilling performance of fabrics are improved.

Owner:浙江中鼎纺织股份有限公司

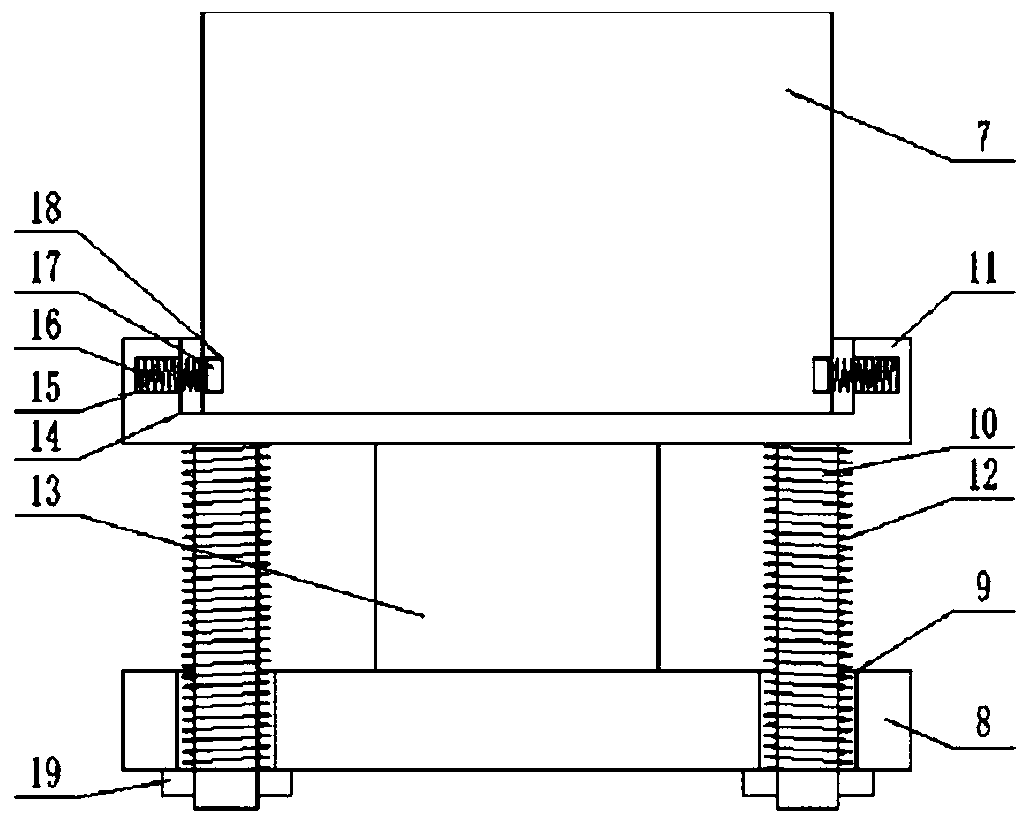

Novel spinning device

InactiveCN108950825AImprove strand styleReduce manufacturing costNon-rotating vibration suppressionLoomsHydraulic cylinderMechanical engineering

The invention discloses a novel spinning device which comprises a spinning machine body. The lower end of the spinning machine body is provided with a retarding vibration mechanism, the retarding vibration mechanism is composed of a base plate, multiple round holes formed in four corners of the base plate, multiple supporting rods, a supporting plate fixed to the upper ends of the multiple supporting rods, multiple hard springs sleeving the supporting rods and located between the supporting plate and the base plate and a hydraulic cylinder vertically arranged on the base plate, wherein one endof each supporting rod is inserted into the corresponding round hole, the spinning machine body is placed on the supporting plate, the supporting plate is provided with a groove, the two opposite side surfaces of the inside of the groove are provided with grooves A, the inner side surfaces of the grooves A are provided with extensible springs, one end of each extensible spring is provided with aclamping block, and the two opposite side surfaces of the spinning machine body are both provided with clamping grooves matched with the clamping blocks. The novel spinning device has the advantages of being simple in structure and high in practicability.

Owner:嘉兴市越实纺织品有限公司

Spinning system and using method of regenerated polyester yarn

ActiveCN110172764BEasy to produceMaintain humidityCarding machinesTextile treatment by spraying/projectingPolyesterYarn

The invention discloses a spinning system for a regenerated polyester yarn. The spinning system comprises a cotton feeding roller, a carding machine and a sliver can, wherein a cotton feeding pallet is arranged below the cotton feeding roller; the cotton feeding pallet comprises a vertex-arc plate surface and a skew back plate surface; a cotton feeding channel is sandwiched between the vertex-arcplate surface and the cotton feeding roller; a cotton puncturing channel is sandwiched between the skew back plate surface and a licker-in roller; the cotton feeding channel communicates with an inletof the sliver can after sequentially passing through the cotton puncturing channel, a cylinder and a doffer; an outlet of the sliver can communicates with a drawing frame after sequentially passing through a guide roller and the cotton feeding roller; the guide roller communicates with the cotton feeding roller through a horizontal pallet; a plurality of air flow nozzles are arranged in a horizontal pressure plate parallel to the horizontal pallet and directly arranged above the horizontal pallet; the cotton feeding roller comprises a cotton pressing outer body and a cotton pressing inner cavity formed therein; a plurality of spray channels are formed in the cotton pressing outer body. The spinning system not only can slow down a static phenomenon, but also facilitates the production of ultra-long and super-fine regenerated polyester fibers, and can decompose external interferences and adjust the humidification amount.

Owner:湖北枫树科技有限公司

Preparation method of Ulagrass blended wrapping yarn

The invention discloses a method for preparing wula sedge blended fasciated yarn. The method comprises the steps that firstly, wula sedge fibers are obtained through boiling, combing, third soda boiling and softening treatment; the clipped wula sedge fibers of 45 mm to 50 mm and cotton are mixed, opened, combed, drawn and subjected to rotor spinning according to the mass ratio being 70 / 30-10 / 90 to form a core yarn material, a roller type combing machine is adopted for combing, and repeated opening and combing are adopted to improve the uniformity of subsequent yarn; finally, a wrapping process is used for wrapping the wula sedge / cotton blended core yarn, two or more pieces of pure cotton yarn, modal yarn, wool yarn and the like are combined and wound around one barrel side by side to serve as external fasciated yarn, and the ratio of the rotating speed of a hollow ingot to output roller speed is 500 to 900. By means of preparation of the wula sedge blended fasciated yarn, the application field of the wula sedge fibers with the heat preservation and bacterium resisting performance can be widened.

Owner:TIANJIN POLYTECHNIC UNIV

A silk viscose chiffon reactive printing process

Owner:ZIBO DARANFANG SILK GRP

Novel fiber bunching device

The invention relates to a fiber bunching device. In the device, a first top roller and a second top roller (4) are arranged on a cap bar (5); an airflow orientation block (11) is arranged on the cap bar (5) through a positioning plate (10); a spring (3) is arranged on the cap bar (5); a permanent magnet (12) is arranged on the airflow orientation block (11); a wide vacuum nozzle (7), a lower dustproof cover (15), a suction base (16), an upper dustproof cover (17) and a baffle plate (6) are arranged in hollow roller rings (8); the hollow roller rings (8) are arranged on a main shaft (14) pairwise; the wide vacuum nozzle (7) is provided with an upper dustproof cover (17); the lower part of the wide vacuum nozzle (7) is provided with a lower dustproof cover (15); the upper dustproof cover (17) is connected with the suction base (16); both sides of the upper dustproof cover (17) are provided with two rows of small holes; and the lower dustproof cover (15) is provided with a net. Due to the adoption of novel fiber bunching device, the problems of large quantity of feathers, low fiber strength and large amount of flies existing in yarns spun by using yarn spinning and wool spinning equipment are solved, the production cost is lowered, and the working efficiency is increased.

Owner:陆节

Silk-viscose chiffon reactive printing process

The invention relates to a silk-viscose chiffon reactive printing process and belongs to the technical field of reactive printing. The process comprises the steps of printing, drying, steaming and washing, wherein for the printing, slurry is added to perform printing, a 180-mesh pattern plate is used, the tension of the pattern plate is 19 -21 N / cm, and the slurry feeding amount of the pattern plate is 0.09 -0.1 kg / m<2>; and the slurry comprises the following components including, by weight, 0.5 -10 parts of reactive dyes, 0.8 -1.5 parts of dye-resistant salt, 1.5 -2 parts of baking soda, 7 -9 parts of urea, 3 -5 parts of thickening agents and 70-85 parts of water. The front printing and back printing of the silk-viscose chiffon obtained by the process of the invention have consistent color, and the printing is clear and white-free.

Owner:ZIBO DARANFANG SILK GRP

A kind of polyester-spandex double core-spun yarn and fabric thereof

The invention discloses a polyester-spandex double core-spun yarn, which comprises a core yarn and an outer fiber. The core yarn is composed of elastic polyester fiber and spandex yarn which are polymerized from polyterephthalic acid and 1,3-propylene glycol ester; The outsourcing fibers are natural fibers or chemical fibers; the mass percentages of the elastic polyester fibers, spandex yarns and outsourcing fibers are 3-9%: 2-8%: 84-94%. Two rovings made of outsourcing fibers are fed into the bell mouth in parallel, and the elastic polyester fiber is introduced into the godet wheel through the tension adjustment device, and the tension value is controlled at 28-30CN. Drafting, after the godet roll and elastic polyester fiber meet, it is fed into the nip of the front roller, merged with the outsourcing fiber, and forms a core-spun yarn under the twisting action of the spinning frame. The invention adopts the elastic polyester fiber and the spandex yarn to prepare the double core-spun yarn, which combines the good elasticity of the spandex yarn and the excellent recovery of the polyester yarn, and the fabric made is comfortable to wear and can keep shape for a long time.

Owner:RUGAO CITY DINGYAN TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com