Color-spun polyester-viscose fabric and production method thereof

A production method and fabric technology, applied in the field of fabrics, can solve the problems of reduced pilling performance, easy to generate static electricity, etc., and achieve the effects of improved color fastness, less hair shedding, and better wool-like effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0030] The invention discloses a color spinning polyester viscose fabric and a production method thereof. The production method comprises the following steps:

[0031] Step S1: Yarn preparation, blending dope dyed polyester staple fiber and colored viscose staple fiber to form a single yarn; due to the better performance of compact siro spinning in terms of hairiness, evenness and strength, the spinning process adopts compact Siro spinning; preferably, the fiber fineness of polyester staple fiber and / or viscose staple fiber is 1.2D-1.8D, and the fiber length is 30mm-50mm; the single yarn is twisted and lined by S / Z twisting A double-ply yarn of (35-45) S / 2 is formed; the double-ply yarn includes 60-70% polyester and 30-40% viscose, and the twist is 630-670 twists / meter; preferably, the double-ply yarn Also includes spandex, the (35-45) S / 2 double-ply yarn packs 30D-50D spandex, and the drafting ratio of spandex is 2.5-3 times;

[0032] Due to the follow-up need to carry out t...

specific Embodiment 2

[0051] The present invention discloses a color-spun polyester viscose fabric and its production method. The production method changes the production plan of step S4 water washing and segmental water washing in pre-setting on the basis of the above-mentioned specific embodiment 1, and can realize the above-mentioned All the details of the specific embodiment one;

[0052] The segmented water washing in step S4 includes washing with overflow tank, heating up to 72-78 °C at a rate of (1.2-1.8) °C / min, washing with water for 20-30 min, and then washing at (2.2-2.8) °C / min The speed of min is reduced to room temperature, and hot water washing is carried out at room temperature, and then cold water washing is carried out; the washing force of overflow washing is stronger, which can make the gray fabric fully shrink during washing, and better control the dimensional stability of the fabric.

experiment example 1

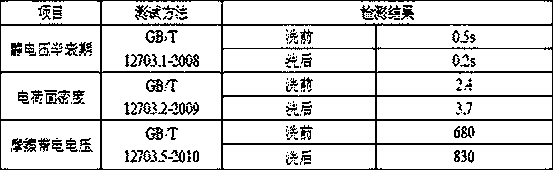

[0054] The antistatic performance of the color spinning polyester viscose fabric that concrete embodiment one makes is tested, test adopts three kinds of test methods of GB / T12703.1, GB / T12703.2 and GB / T12703.5, and test result is as table 1 shown.

[0055] Table 1 Test results of antistatic properties of colored spun polyester viscose fabrics

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com