Conveying joint device for cops and bobbins for spinning and doffing connection and conveying method thereof

An interface device and fine-bonding technology, which is applied in the direction of textiles and papermaking, can solve the problems of hairiness damage, yarn pollution, high labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

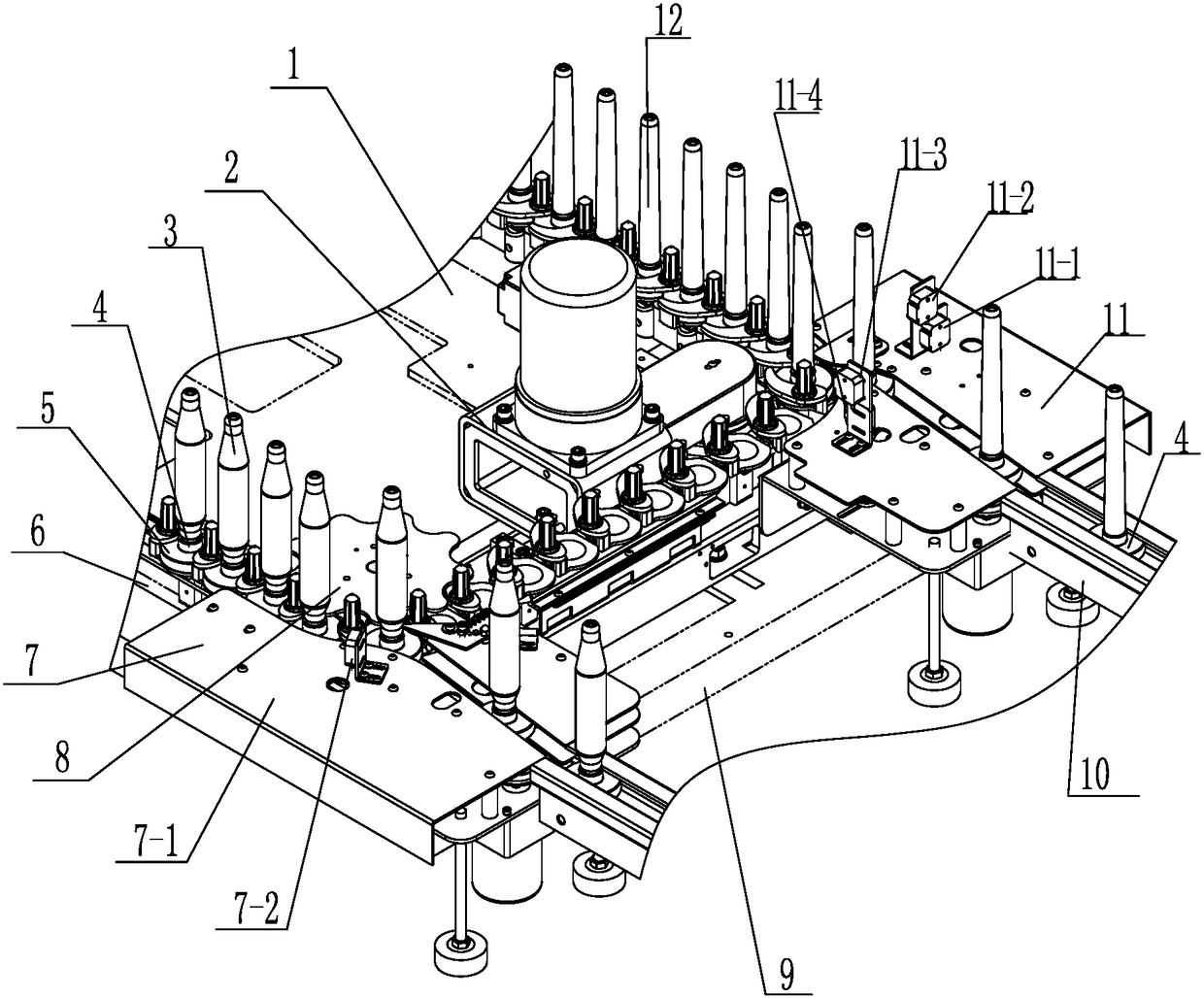

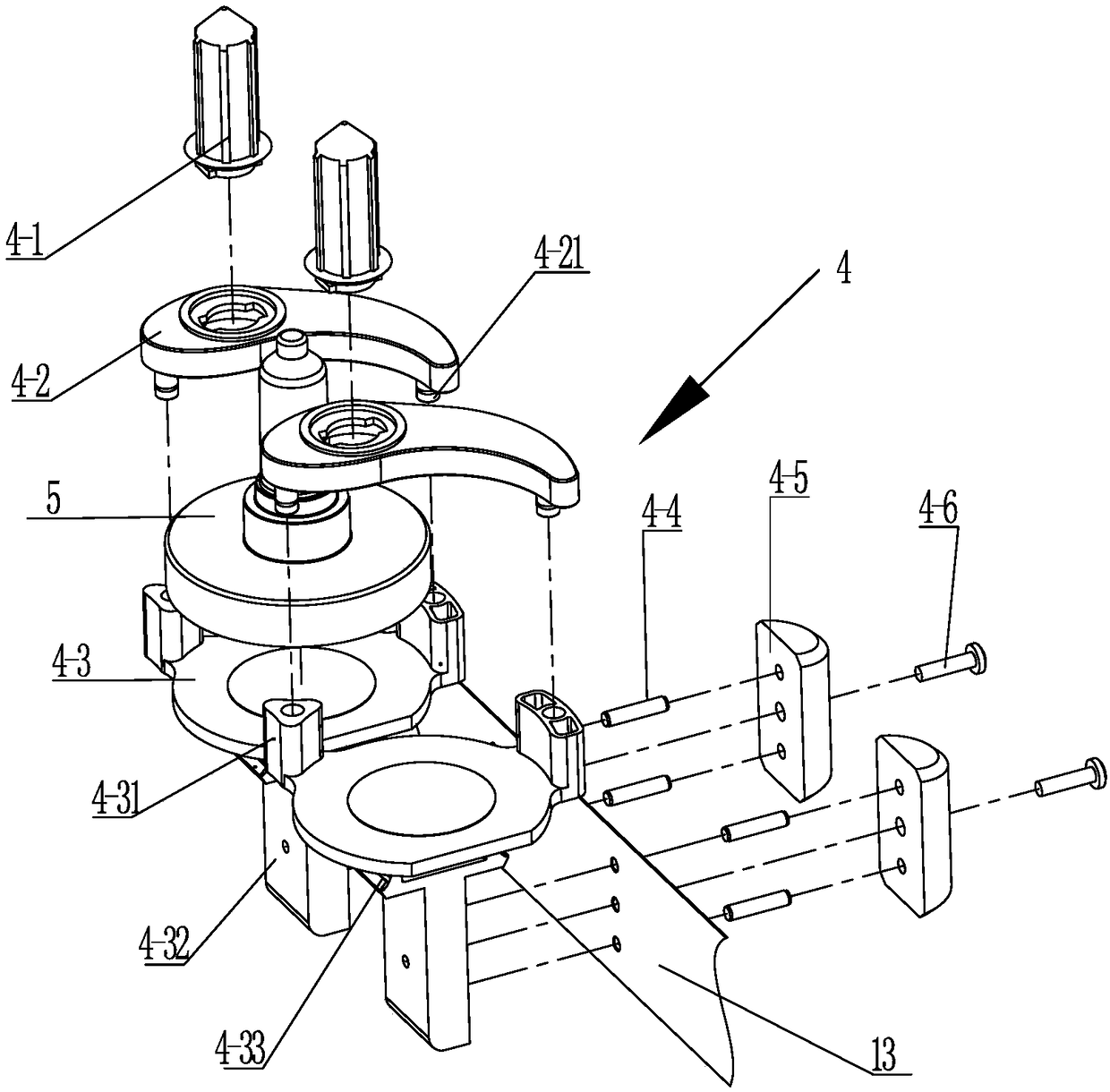

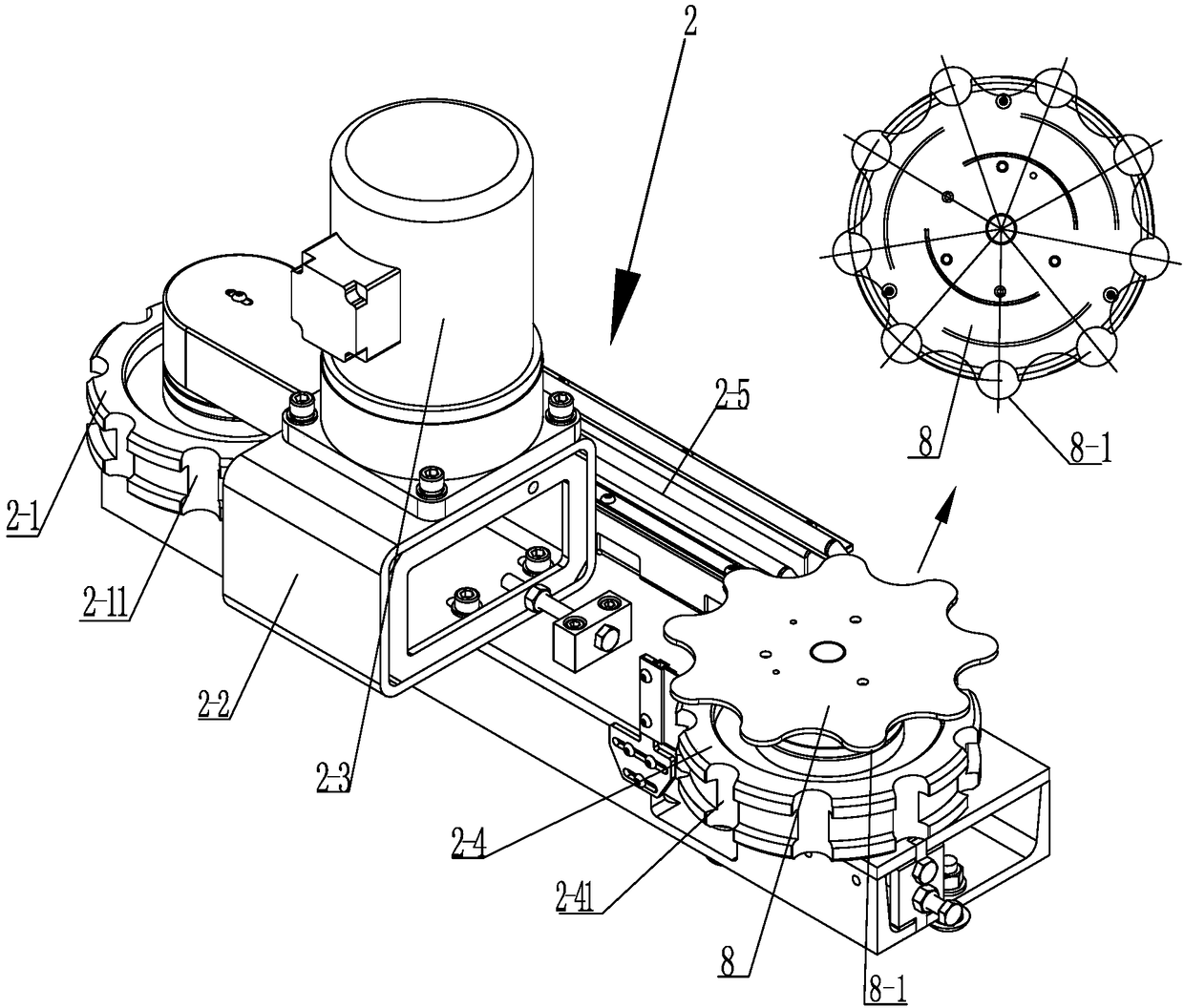

[0022] See Figure 1~5 As shown, the conveying interface device of the present invention, which connects bobbins and bobbins, includes a dial placed at the interface of the first pallet conveying track 6 of the automatic doffing spinning frame and the second pallet conveying track 10 of the automatic winding machine. Disc 8, tray output mechanism 7, tray input mechanism 11, multiple trays 5 and multiple tray support assemblies 4 for placing bobbins and bobbins. The automatic doffer spinning frame tray delivery system 1 of the present invention includes two long strokes on the left side and the right side corresponding to the spindle group and two short strokes on the head and the rear of the car, so that the first tray delivery track 6 moves along the two sides. One long stroke and two short strokes are set, and the base of the headstock or / and the rear of the car is equipped with a tensioning mechanism 2, through the driving wheel 2-1 of the tensioning mechanism 2, a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com