Spinning device for ultra-long and ultra-thin spun polyester threads and spinning process

A technology for ultra-fine polyester and yarn, which is applied in deburring devices, yarn, textiles and papermaking, etc. It can solve the problems of easy entanglement of card clothing and difficulty in spinning, so as to improve yarn strength, prevent static electricity, and achieve high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

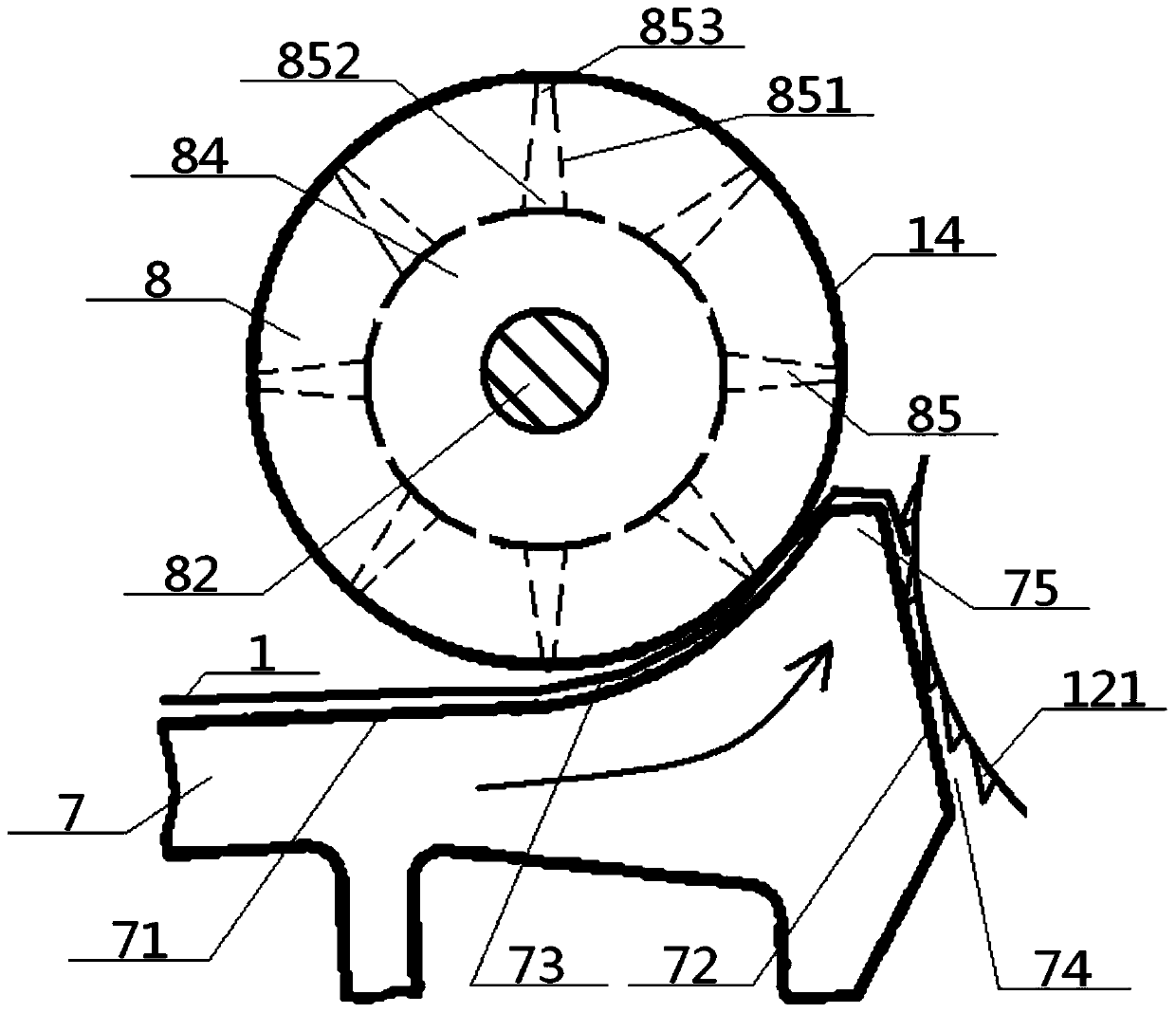

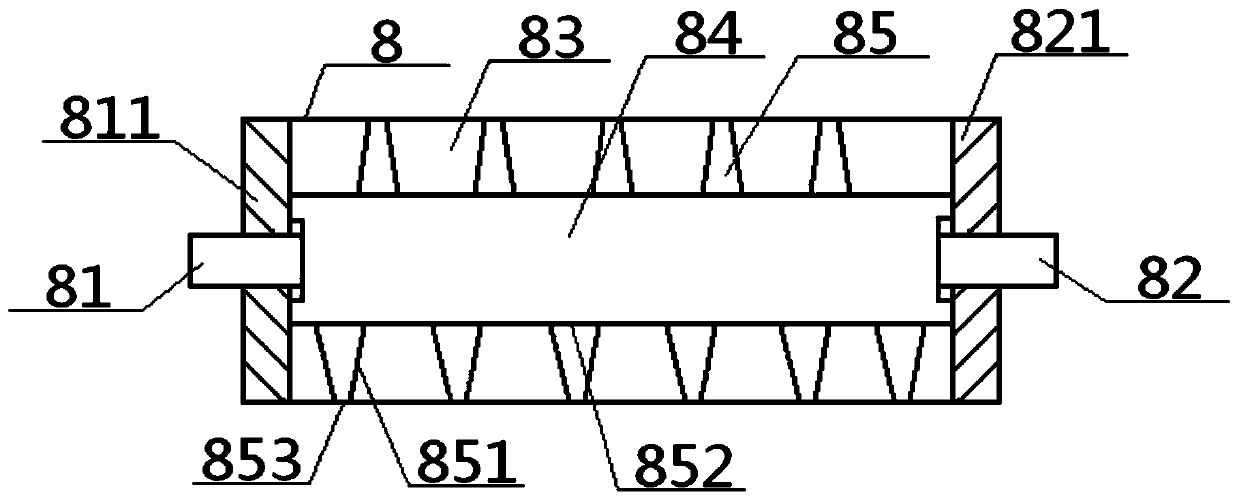

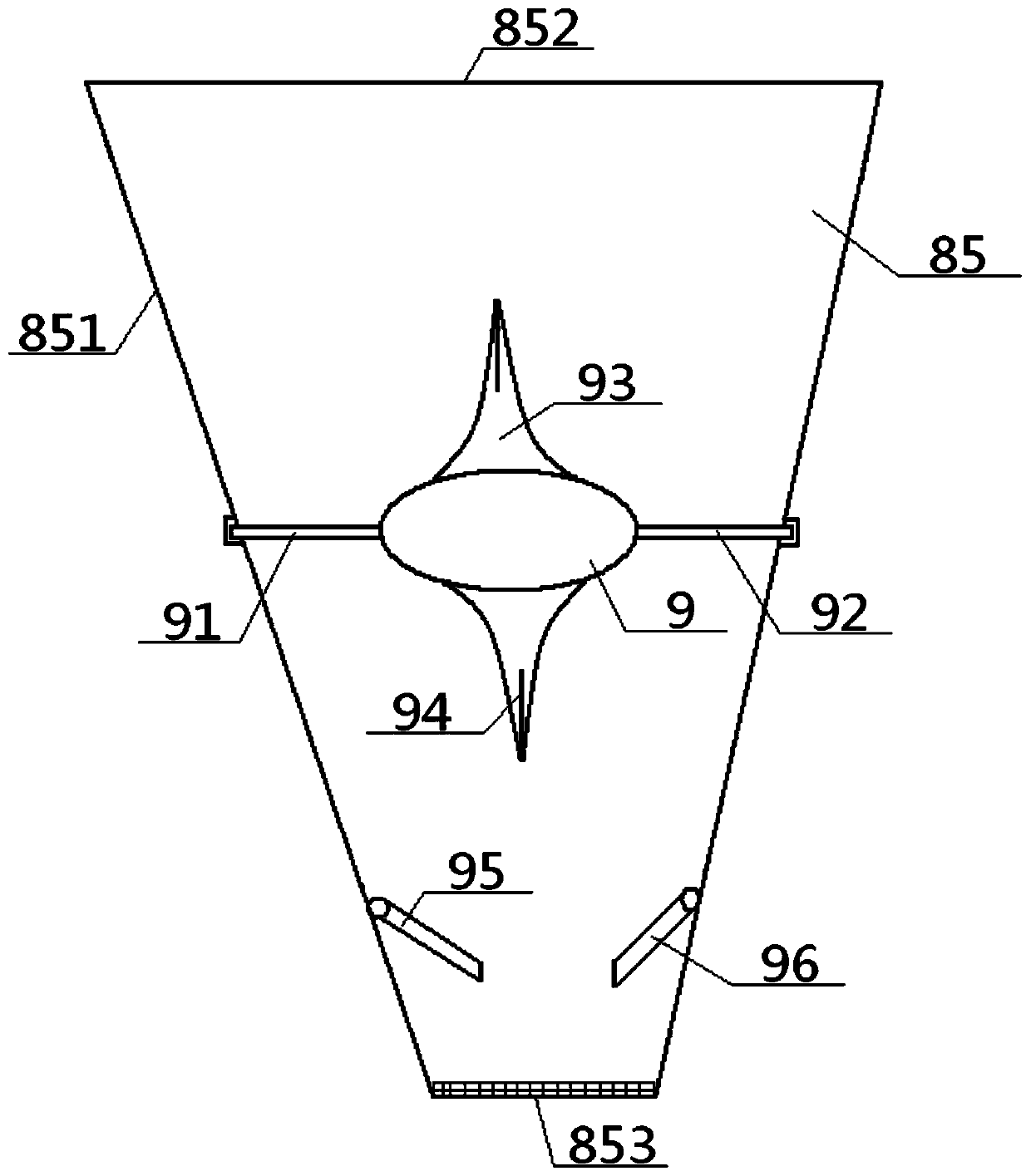

[0050] see figure 1 - Figure 6 , a spinning device for ultra-long and ultra-fine polyester yarns, comprising a cotton feeding roller 14 and a cotton feeding pallet 7, the cotton feeding pallet 7 includes a top arc plate surface 71 and a side inclined plate surface 72, the side The side of the inclined plate surface 72 is provided with a licker-in roller 121, and the top of the top arc plate surface 71 is provided with a cotton feeding roller 14, and a cotton feeding channel 73 is sandwiched between the top arc plate surface 71 and the cotton feeding roller 14. There is a barbed cotton channel 74 sandwiched between the sloping plate surface 72 and the licker-in roller 121; the cotton feeding roller 14 includes a pressing roller body 8 and a left drive shaft 81 and a right driving shaft 82 connected to its two ends. The cotton roller body 8 includes a cotton pressing outer body 83 and a cotton pressing inner cavity 84 opened inside the cotton pressing outer body 83, and a plur...

Embodiment 2

[0053] Basic content is the same as embodiment 1, the difference is:

[0054] The height of the top curved plate surface 71 is gradually increasing from left to right, and the width of the cotton feeding channel 73 is gradually decreasing from left to right. The right end of the top arc plate surface 71 is connected to the top of the side inclined plate surface 72 through the plate nose tip 75, and the distance between the plate nose tip 75 and the cotton feeding roller 14 is less than or equal to the minimum width of the cotton feeding channel 73.

Embodiment 3

[0056] Basic content is the same as embodiment 1, the difference is:

[0057] The inner passage 852 is in contact with the inner cavity 84 of the pressed cotton, and the outer passage 853 is in contact with the outer wall of the outer body 83 of the pressed cotton. The inner passage 852 is wider than the outer passage 853, and the diameter of the side wall 851 of the channel is determined by the inner passage. 852 to the outer crossing 853 are gradually narrowed. This design can make the path of the mist pass through gradually narrowing, which is beneficial to increase the speed of the mist and prevent the mist from staying near the inner crossing 852 to hinder the spraying operation of the mist.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com