Spinning system and using method of regenerated polyester yarn

A technology of regenerated polyester and yarn, applied in the field of spinning system of regenerated polyester yarn, which can solve the problems of easy entanglement of card clothing and difficult spinning, and achieve the effect of wide humidification, avoiding static electricity and eliminating static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

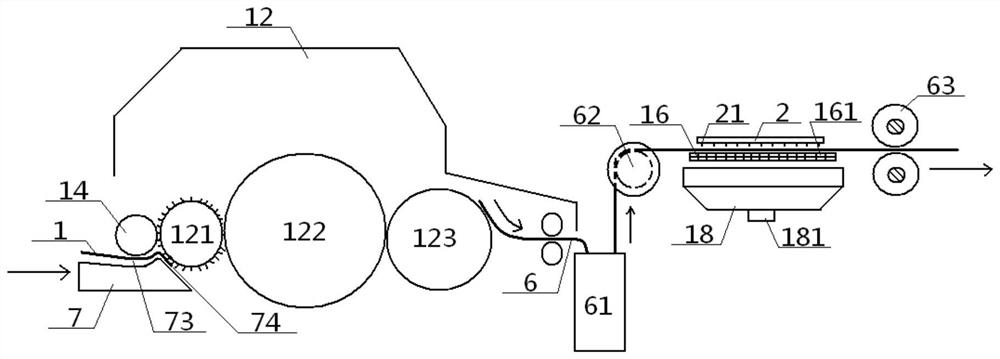

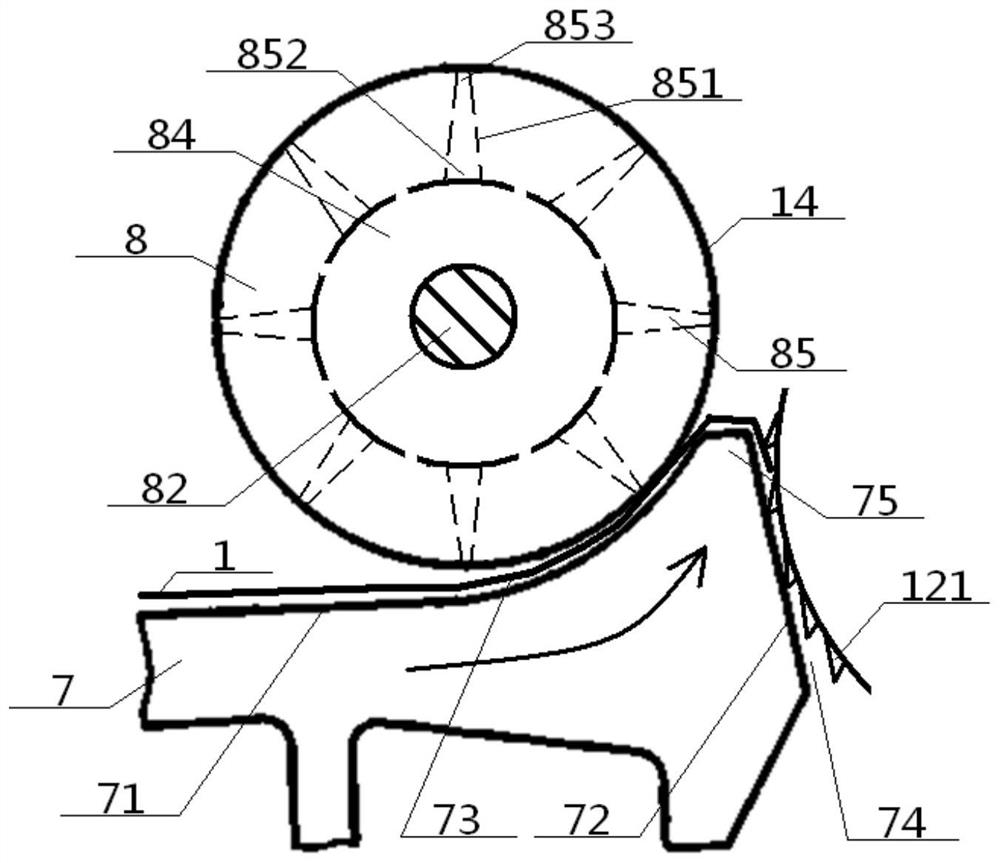

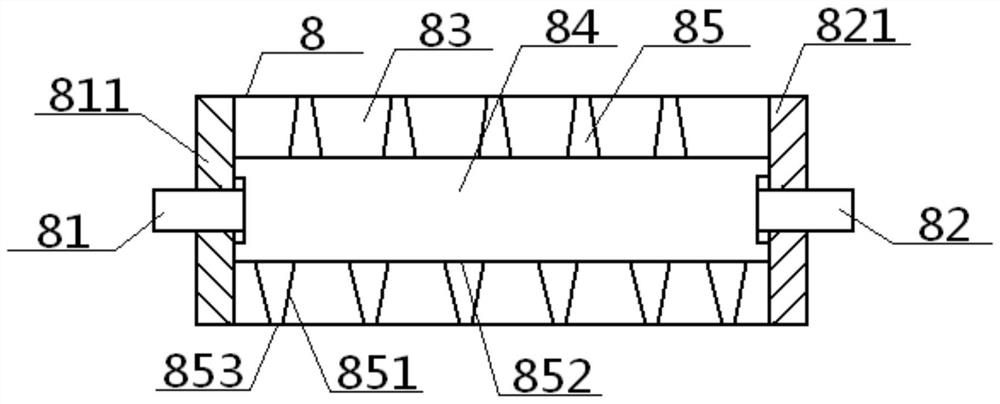

[0068] see Figure 1 to Figure 11 , a spinning system for regenerated polyester yarn, comprising a feeding roller 14, a carding machine 12, a sliver can 61 and a cotton feeding roller 63, and the carding machine 12 includes a licker-in roller 121, a cylinder 122 and a doffer 123 , the cotton-feeding pallet 7 is arranged below the cotton-feeding roller 14, and the cotton-feeding pallet 7 includes a top arc plate surface 71 and a side inclined plate surface 72, and the top arc plate surface 71 and the cotton feed roller 14 are sandwiched into There is a cotton feeding channel 73, and a barbed cotton channel 74 is sandwiched between the side inclined plate surface 72 and the licker-in roller 121. The cotton feeding channel 73 passes through the cotton sliver channel 74, the cylinder 122, the doffer 123 in turn, and the entrance of the sliver can 61 The outlet of the sliver can 61 communicates with the drawing frame through the guide roller 62 and the cotton feeding roller 63 in t...

Embodiment 2

[0071] Basic content is the same as embodiment 1, the difference is:

[0072] Structurally: the inside of the channel side wall 851 is provided with a left support shaft 91, a right support shaft 92 and a rotating body 9, the left end of the rotating body 9 is fixedly connected with one end of the left supporting shaft 91, and the other end of the left supporting shaft 91 One end is rotatably connected to the side wall 851 of the channel, the right end of the rotating body 9 is fixedly connected to one end of the right support shaft 92, the other end of the right support shaft 92 is rotatably connected to the side wall 851 of the channel, and the left fulcrum 91 and the right fulcrum 92 are facing each other. It is provided that the side circumference of the rotating body 9 is connected to the bottom end of the stirring blade 93, and the number of the stirring blade 93 is at least two.

[0073] In terms of method: in the process of spraying the water mist through the spray cha...

Embodiment 3

[0075] Basic content is the same as embodiment 1, the difference is:

[0076] Structurally: the spinning system of the regenerated polyester yarn also includes a plurality of flow-regulating rotary spoons 3 arranged in sequence, the flow-regulating rotary spoons 3 and the air flow nozzles 21 are set up and down one by one, and the flow-regulating rotary spoons 3 are located at the air flow nozzles 21, horizontal Between the supporting plates 16; the flow-adjusting rotating spoon 3 includes a fixed-rotating cylinder 4 and a rotating concave spoon 5, and the fixed-rotating cylinder 4 includes a column side wall 42 and a column top surface 41 and a column bottom surface 43 connected to its two ends, The middle part of the column top surface 41 and the column bottom surface 43 runs through the same column shaft 44. The rotating concave spoon 5 includes a connecting column part 51, a middle waist part 52 and an external pressure part 53. The inner end of the connecting column part 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com