Preparation method of composite yarn with glittering effect

A yarn and mercerizing technology, which is applied in the field of composite yarn preparation, can solve the problems of dull yarn, poor three-dimensional effect, dull fabric, etc., achieve less scratchy feeling, better flash effect, and improve evenness and hairiness performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

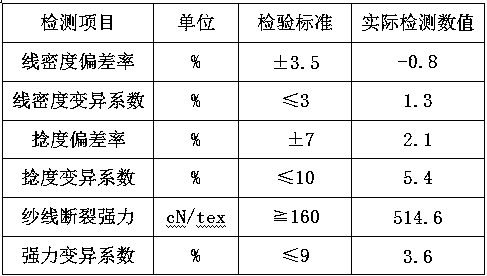

Embodiment 1

[0017] A preparation method of a composite yarn with flash effect described in this embodiment, the steps are as follows:

[0018] The first step is the selection of raw materials: it is composed of 88% 90S mercerized Australian wool and 12% 46D gold and silver wire;

[0019] The second step is the preparation of pure wool roving: 88% of 90S mercerized Australian wool is prepared into a pure wool with a quantitative weight of 3.5g / 10m through dyeing of loose wool → blending → carding → drawing → roving (semi-worsted process route). Wool roving; wherein in the process of wool blending, water, hair oil DH-601 and antistatic agent DK-103 are mixed to form a mixed solution and sprayed on 90S mercerized Australian wool with a spray volume of 35g / min, and then heated at room temperature Place it under the ground for 24 hours, and the amount of water accounts for 6% of the total amount of 90S mercerized Australian wool, the water temperature is controlled at 40°C, and the amount of c...

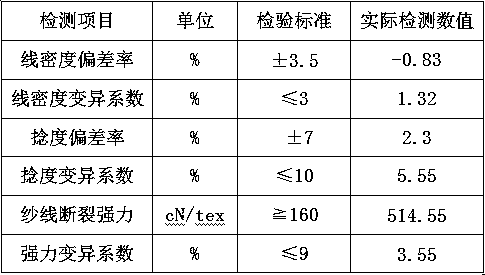

Embodiment 2

[0026] A preparation method of a composite yarn with flash effect described in this embodiment, the steps are as follows:

[0027] The first step is the selection of raw materials: it is composed of 84% 90S mercerized Australian wool and 16% 46D gold and silver wire;

[0028] The second step, the preparation of pure wool roving: 84% of 90S mercerized Australian wool is prepared into a pure wool with a quantitative weight of 3.5g / 10m through dyeing of loose wool → blending → carding → drawing → roving (semi-worsted process route). Wool roving; wherein in the process of wool blending, water, hair oil DH-601 and antistatic agent DK-103 are mixed to form a mixed solution and sprayed on 90S mercerized Australian wool with a spray volume of 35g / min, and then heated at room temperature Place it under the ground for 24 hours, and the amount of water accounts for 6% of the total amount of 90S mercerized Australian wool, the water temperature is controlled at 40°C, and the amount of cru...

Embodiment 3

[0035] A preparation method of a composite yarn with flash effect described in this embodiment, the steps are as follows:

[0036] The first step is the selection of raw materials: it is composed of 90% 90S mercerized Australian wool and 10% 46D gold and silver wire;

[0037] The second step is the preparation of pure wool roving: 90% of 90S mercerized Australian wool is prepared into a pure wool with a quantitative weight of 3.5g / 10m through dyeing of loose wool → blending → carding → drawing → roving (semi-worsted process route). Wool roving; wherein in the process of wool blending, water, hair oil DH-601 and antistatic agent DK-103 are mixed to form a mixed solution and sprayed on 90S mercerized Australian wool with a spray volume of 35g / min, and then heated at room temperature Place it under the ground for 24 hours, and the amount of water accounts for 6% of the total amount of 90S mercerized Australian wool, the water temperature is controlled at 40°C, and the amount of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com