Dysmorphism rod curved line drafting device

A drafting device and special-shaped rod technology, which is applied in the field of spinning technology, can solve the problems of moving forward, concentrating, and stabilizing the speed change point affecting fibers, and small fiber control force, etc., to achieve reduction Effect of planktonic zone length, enhanced control, yarn evenness and hairiness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

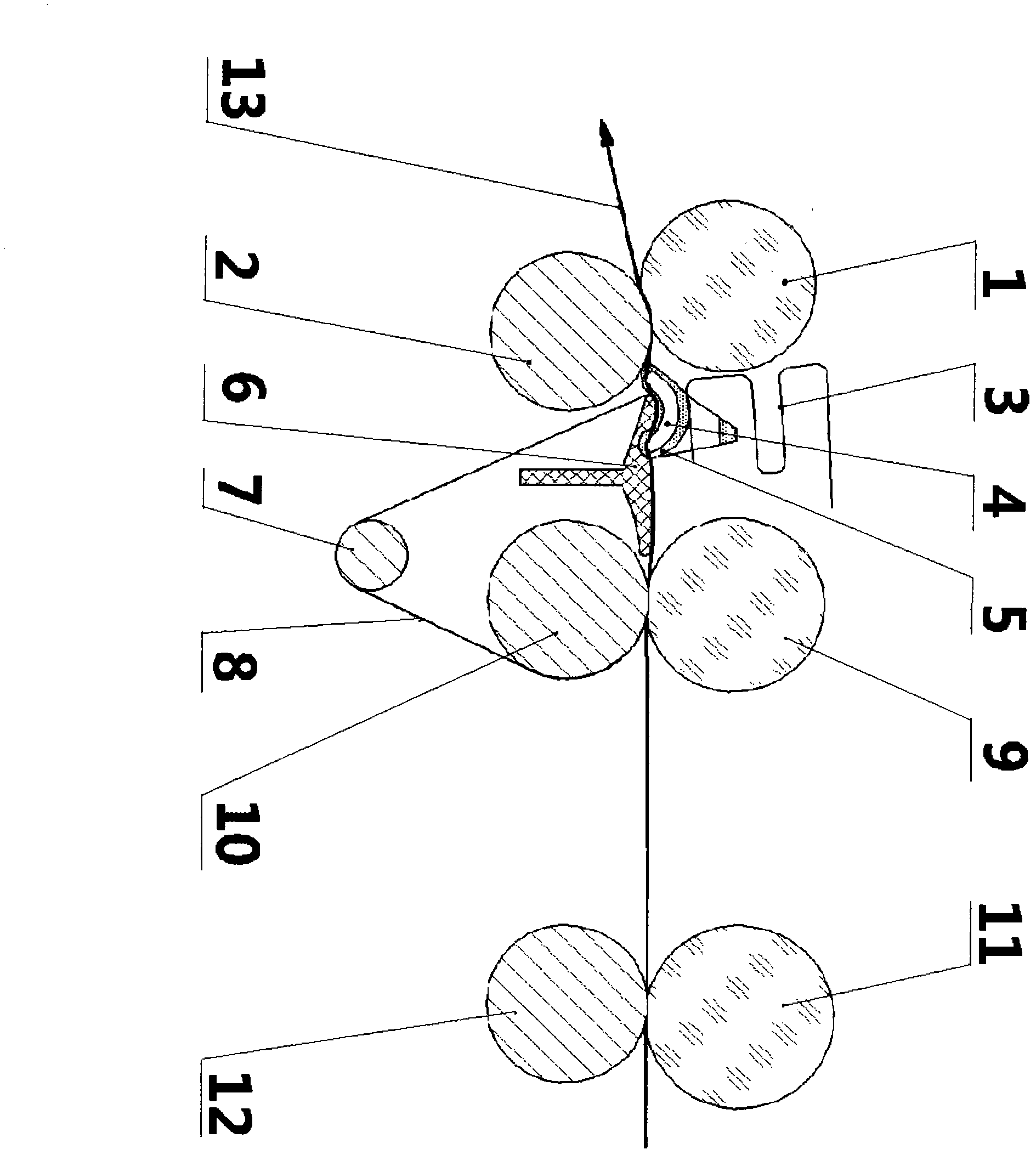

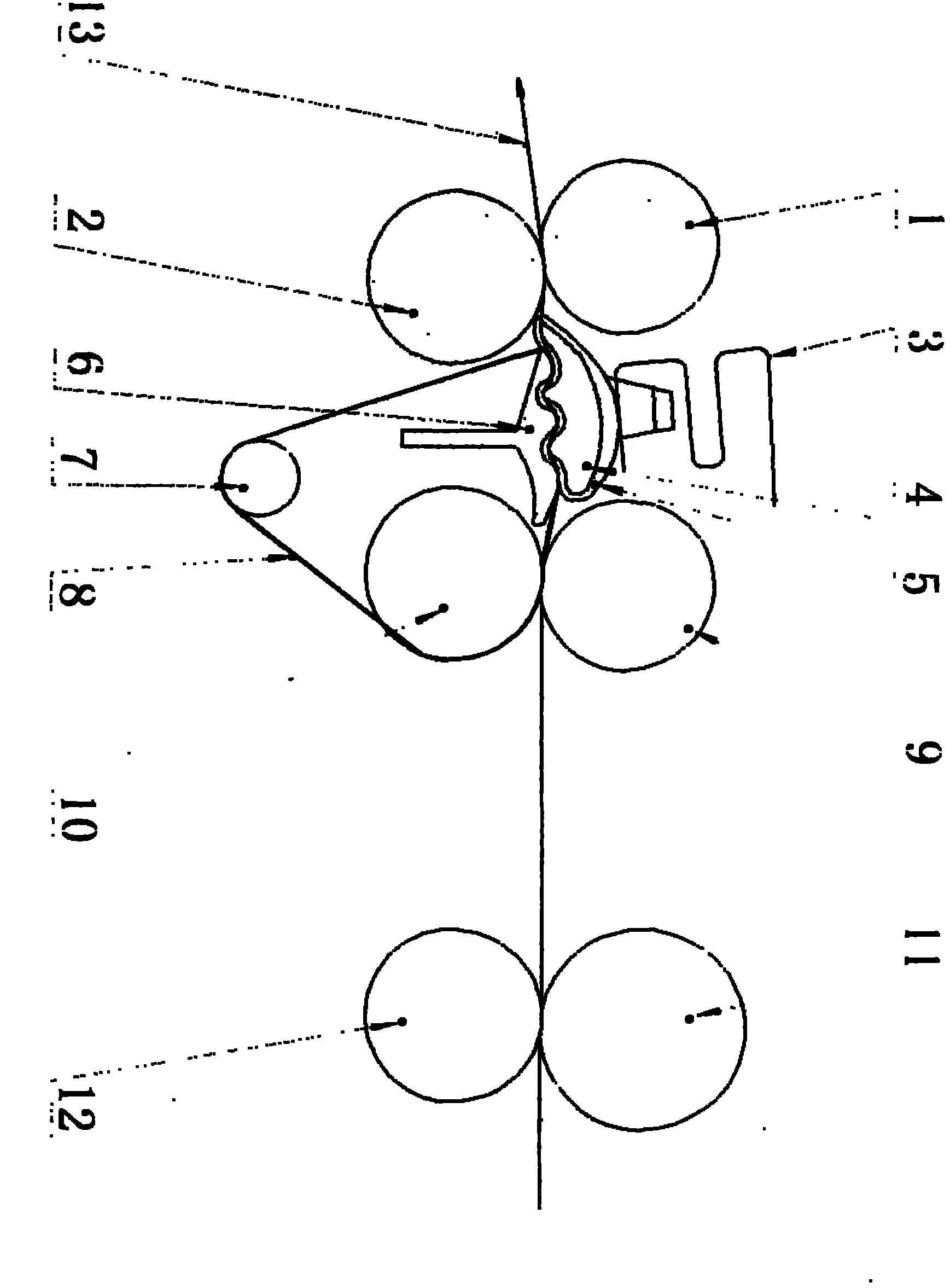

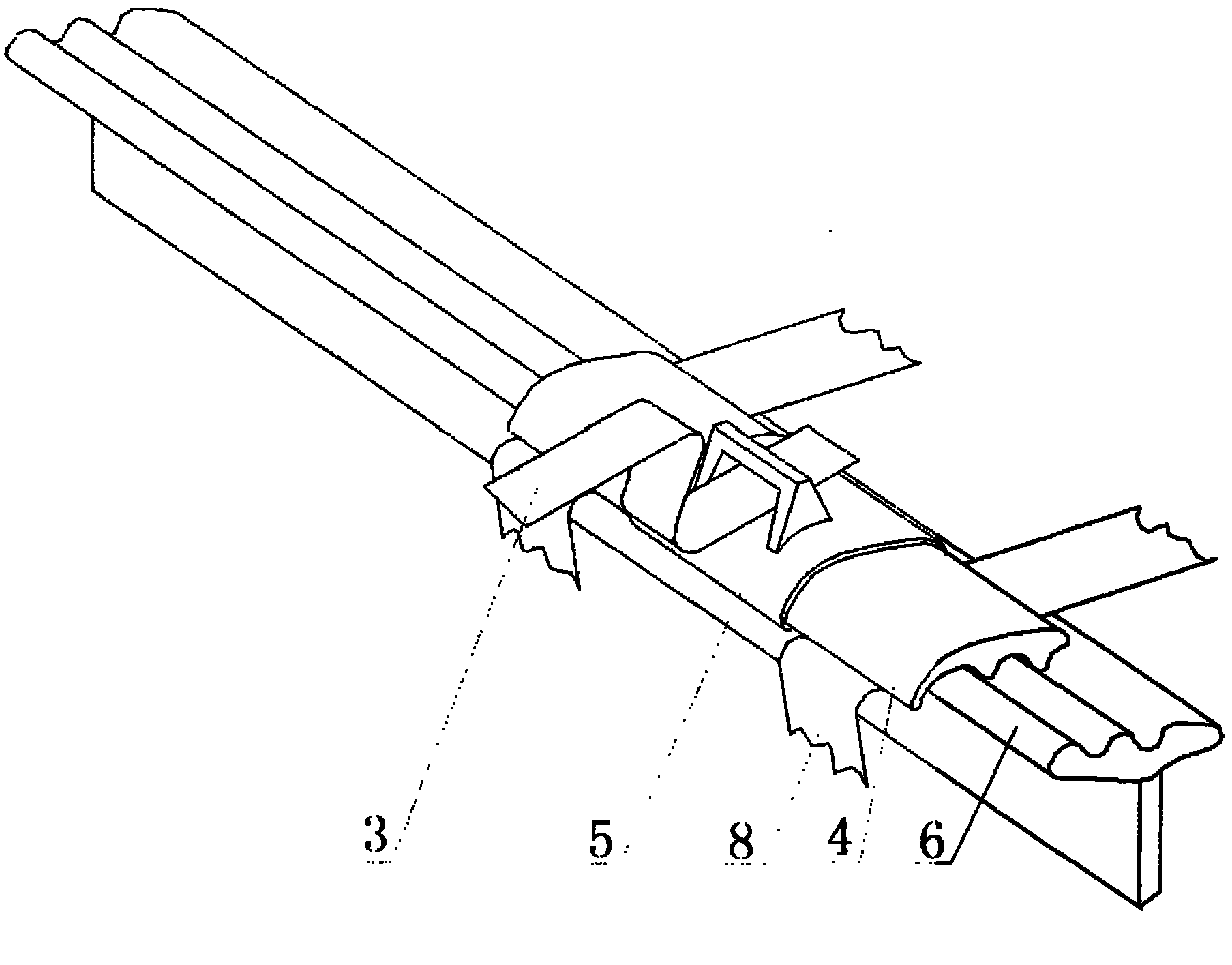

[0013] As shown in the figure, the middle lower ring (8) is sleeved on the concave-convex lower pin (6), the middle roller (10) and the tension device (7). The middle positioning body (5) is in the middle of the special-shaped rod (4), and the middle positioning body ( 5) Under the action of the compression spring (3), it is pressed tightly on the concave-convex lower pin (6), and the intermediate positioning body (5) separates the special-shaped rod (4) from the concave-convex lower pin (6) to form a fiber bundle conveying The curved drafting channel allows the fiber bundle (13) and the lower circle (8) to pass. The fiber bundle (13) passes through the lower surface of the special-shaped rod (4) under the support of the lower ring (8), the upper end of the compression spring (3) is connected with the cradle, the lower end is connected with the intermediate positioning body (5), and the compression spring (3) The special-shaped rod (4) can be easily lifted or pressed on the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com