Drafting device in spinning frame

A drafting device and spinning frame technology, applied in spinning machines, drafting equipment, textiles and papermaking, etc., can solve the problems of uneven fiber movement, affecting the strength of spinning yarn, and increasing yarn hairiness, so as to improve the strength and Surface smoothness, reduction of single fiber breakage, and improvement of evenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The drafting device in the spinning frame according to the present invention will be further described in detail through specific examples below.

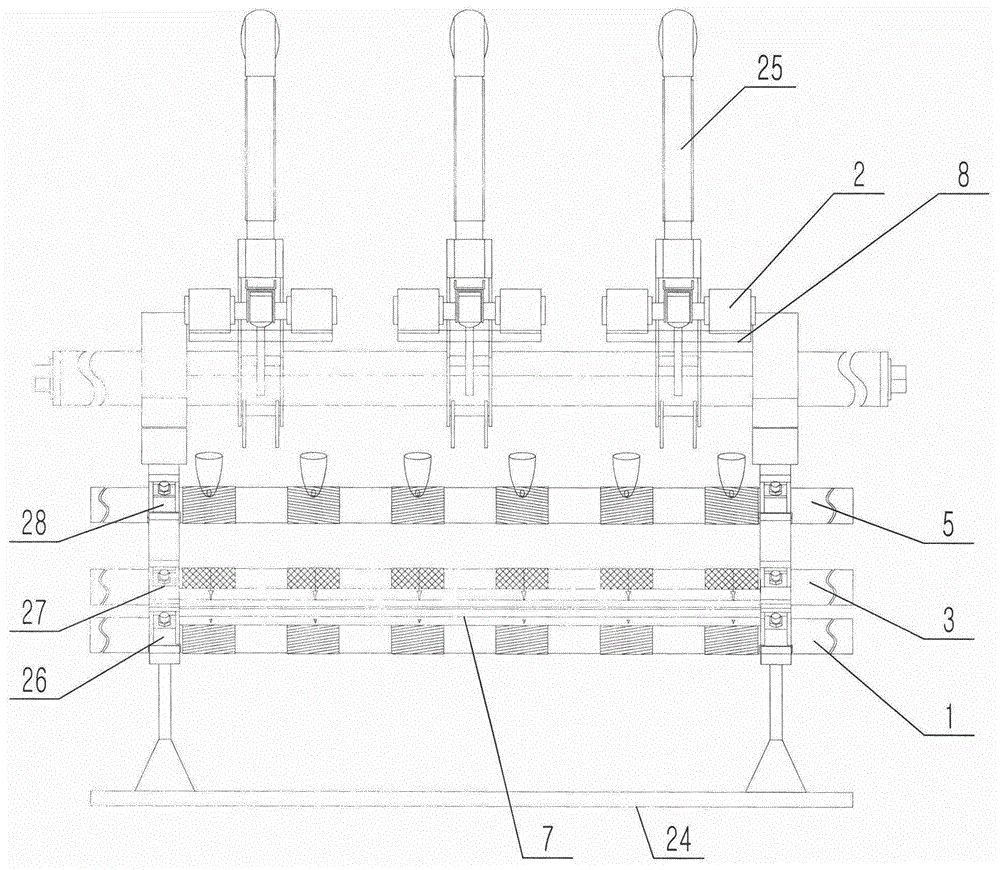

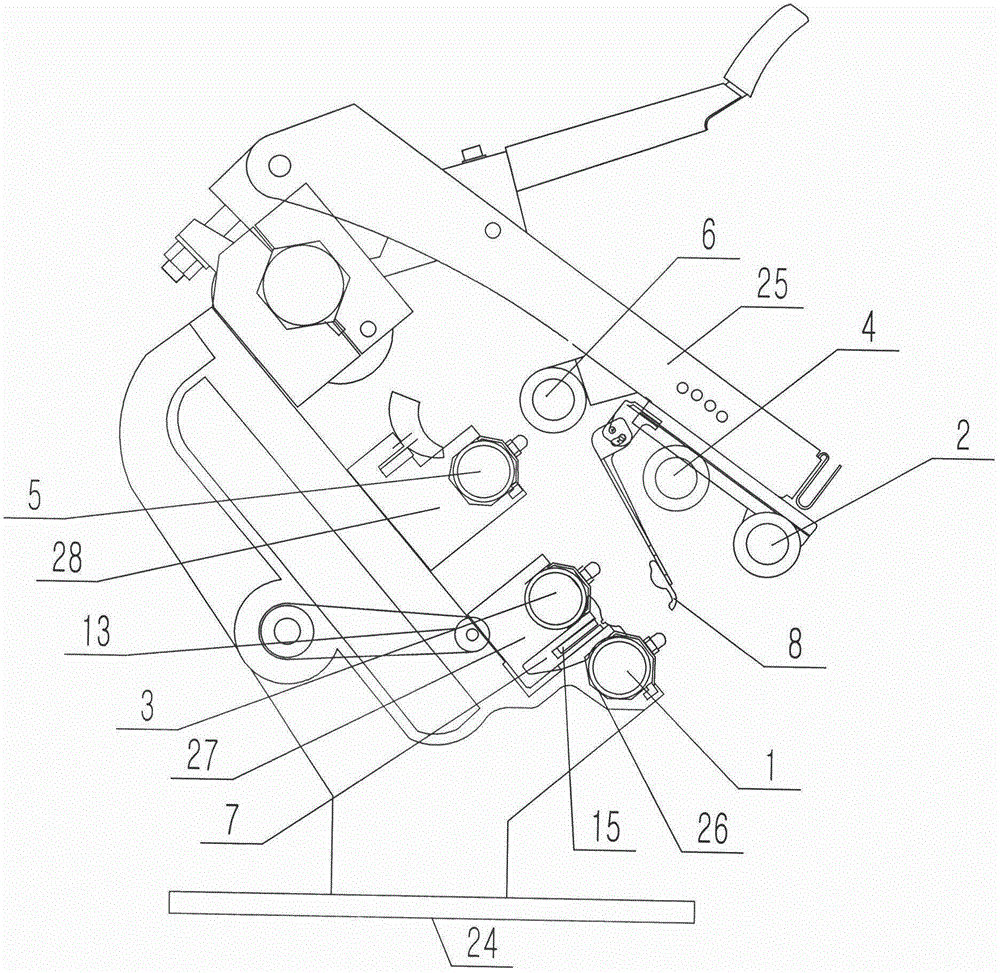

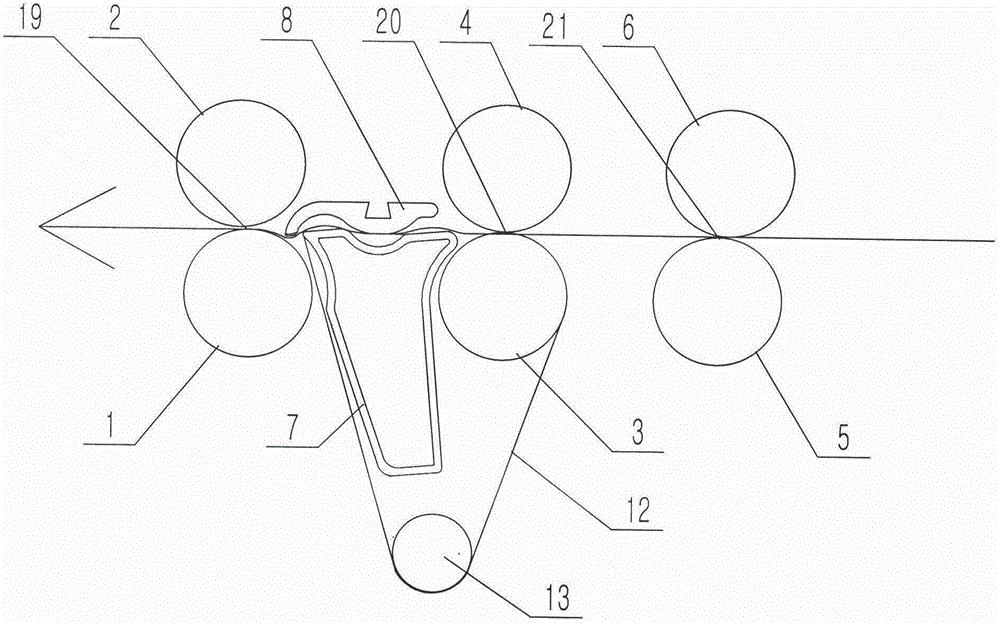

[0031] Such as figure 1 , figure 2 , image 3 As shown, the drafting device in the spinning frame includes the frame 24 of the spinning frame, and the three rows of roller seats arranged on the frame 24 are respectively the front roller seat 26, the middle roller seat 27 and the rear roller seat 28, and each row The roller seats in the row are all lined up and evenly distributed; at the same time, the front roller seats 26, middle roller seats 27 and rear roller seats 28 in each row of roller seats correspond to each other and are located in the same plane; the front roller seats 26, middle roller seats Front roller 1, middle roller 3 and rear roller 5 are respectively arranged on seat 27 and rear roller seat 28, and the central axes of front roller 1, middle roller 3 and rear roller 5 are all parallel to each other; fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com