Superhigh-count compact siro spinning yarn and production technological method thereof

A technology of siro spinning yarn and production process, which is applied in the field of textile fiber spinning, can solve the problems of low strength, less hairiness, and more hairiness, and achieve the effect of high strength and less hairiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The invention discloses an ultra-high-count compact siro-spun yarn and a production process thereof, which are implemented in the steps of opening and cleaning, carding, drawing, roving, spun yarn, and winding.

[0015] Spinning material: 1.1dtex*38mm, 1.33dtex*38mm

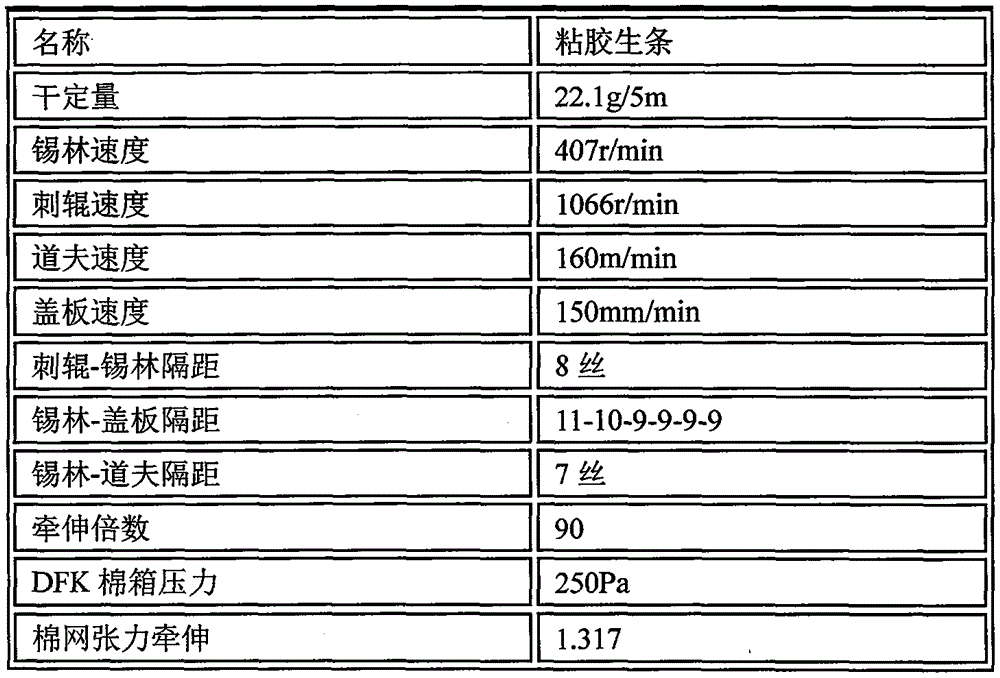

[0016] Blowing-carding unit: enlarged gauge, reduced carding strength, light weight, low output speed;

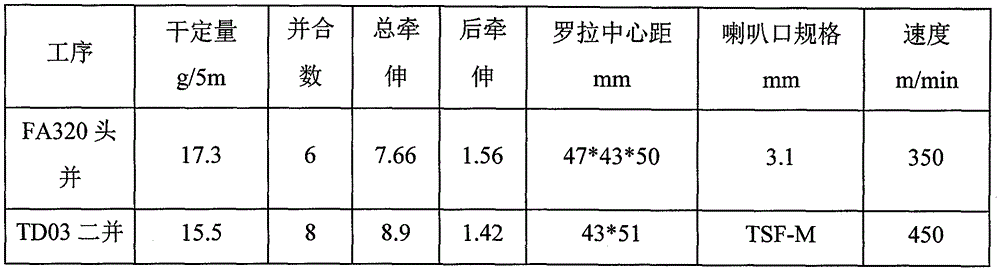

[0017] Drawing frame: low speed, uniform evenness control, small draft roller gauge, adopting the principle of "small gauge, small tension";

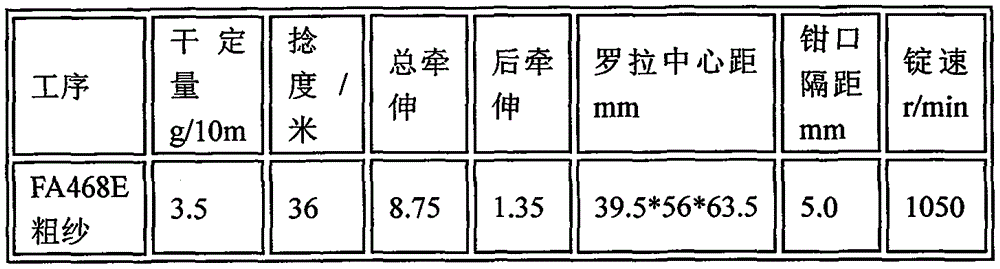

[0018] Roving: low speed, reducing tension difference between spindles;

[0019] Spinning: Optimal air flow, gauge, draft multiple, weight, cradle pressure, spinning twist coefficient, etc., low speed.

[0020] Main technical characteristics of spun yarn:

[0021] 1. It is necessary to control the tension of the equipment in each process to avoid accidental drafting, and the production equipment in the process should be finely leveled;

[0022] 2. Appropriate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com