A kind of polyester-spandex double core-spun yarn and fabric thereof

A core-spun yarn, polyester-spandex technology, applied in yarn, fabric, textile and other directions, can solve the problems of poor weather resistance and temperature resistance of spandex fiber, relaxation deformation, increased elastic residual rate and shrinkage rate, etc. The effect of improving yarn strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

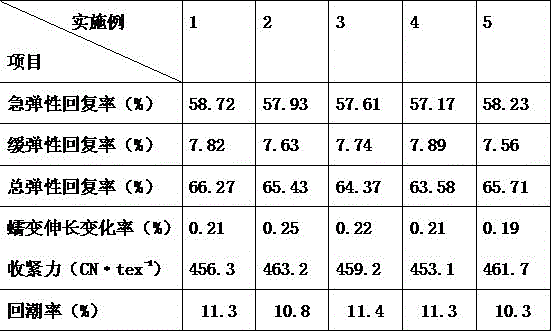

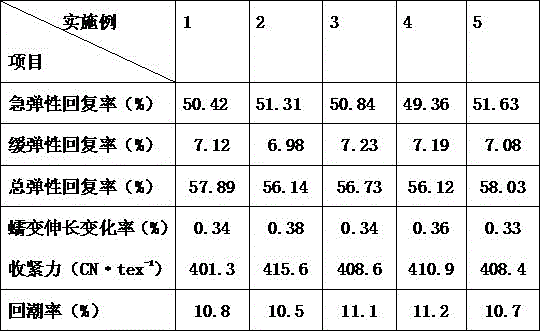

Examples

Embodiment 1

[0017] (1) Yarn specification

[0018] Outsourcing fiber: cotton 229, micronaire value 4.3

[0019] Core yarn: PTT fiber of 72dtex; spandex yarn of 38dtex

[0020] Double core yarn specifications: cotton / PTT fiber / spandex 3 / 2 / 95

[0021] Polyester Spandex Double Core Spun Yarn 27.8tex

[0022] (2) Production process

[0023] Using the Siro spinning process, the roving made of cotton fiber is fed into the bell mouth, and the PTT fiber of 72dtex is introduced into the godet wheel through the tension adjustment device. The tension value of the controller is 28CN, and the 38dtex spandex yarn is placed on the godet roller. Double pre-drafting, after the godet wheel and PTT fibers are combined, they are fed into the nip of the front roller. The core yarn is merged with the core yarn, and the core-spun yarn is formed under the twisting action of the spinning machine. The spinning spindle speed is 8000rpm, and the twist coefficient of the spinning yarn is 320.

[0024] (3) Fabric...

Embodiment 2

[0028] (1) Spinning specifications

[0029] Outsourcing fiber: Bamboo dale fiber 1.33dtex×38mm

[0030] Core yarn: PTT fiber of 82dtex; spandex yarn of 46dtex

[0031] Specifications of double core yarn: bamboo dyer fiber / PTT fiber / spandex 5 / 4 / 91

[0032] Polyester Spandex Double Core Spun Yarn 24.3tex

[0033] (2) Production method:

[0034] Spinning process method is the same as embodiment 1

[0035] (3) Fabric

[0036] The warp yarn adopts the polyester-spandex double core-spun yarn of 24.3tex in the present embodiment, the weft yarn adopts the polyester-spandex double core-spun yarn of 27.8tex in embodiment 1, adopts the above two lower twill weaving on the ZAX-N air-jet loom, and the width The warp density of the woven fabric is 376 threads / 10cm, and the weft density is 212.5 threads / 10cm.

[0037] The fabric of this embodiment has good resilience, high yarn strength, long-lasting shape retention, excellent moisture absorption and air permeability, and elasticity in...

Embodiment 3

[0039] Outsourcing fiber: Modal 1.33dtex×38mm

[0040] Core yarn: PTT fiber of 76dtex; spandex yarn of 42dtex

[0041] Double core yarn specification: Modal / PTT fiber / Spandex 4 / 3 / 93

[0042] Polyester Spandex Double Core Spun Yarn 48tex

[0043] (2) Production method:

[0044] The spinning process is the same as in Example 1.

[0045] (3) Fabric

[0046] The warp yarn adopts the polyester-spandex double core-spun yarn of 27.8tex of embodiment 1, the weft yarn adopts the polyester-spandex double core-spun yarn of 48tex, adopts upper and lower twill weaving on the ZAX-N air-jet loom, and the width is 160cm. The density is 378 threads / 10cm, and the weft density is 214.5 threads / 10cm.

[0047] The fabric of this embodiment has good resilience, high yarn strength, long-lasting shape retention, excellent moisture absorption and air permeability, and elasticity in warp and weft directions, making it comfortable to wear.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com