Novel fiber bunching device

A technology of fiber bundles and top rollers, which is applied in textiles and papermaking, drafting equipment, spinning machines, etc., can solve the problems of yarn hairiness, fly, and low fiber strength, and achieve less fly, less broken ends, The effect of high fiber strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

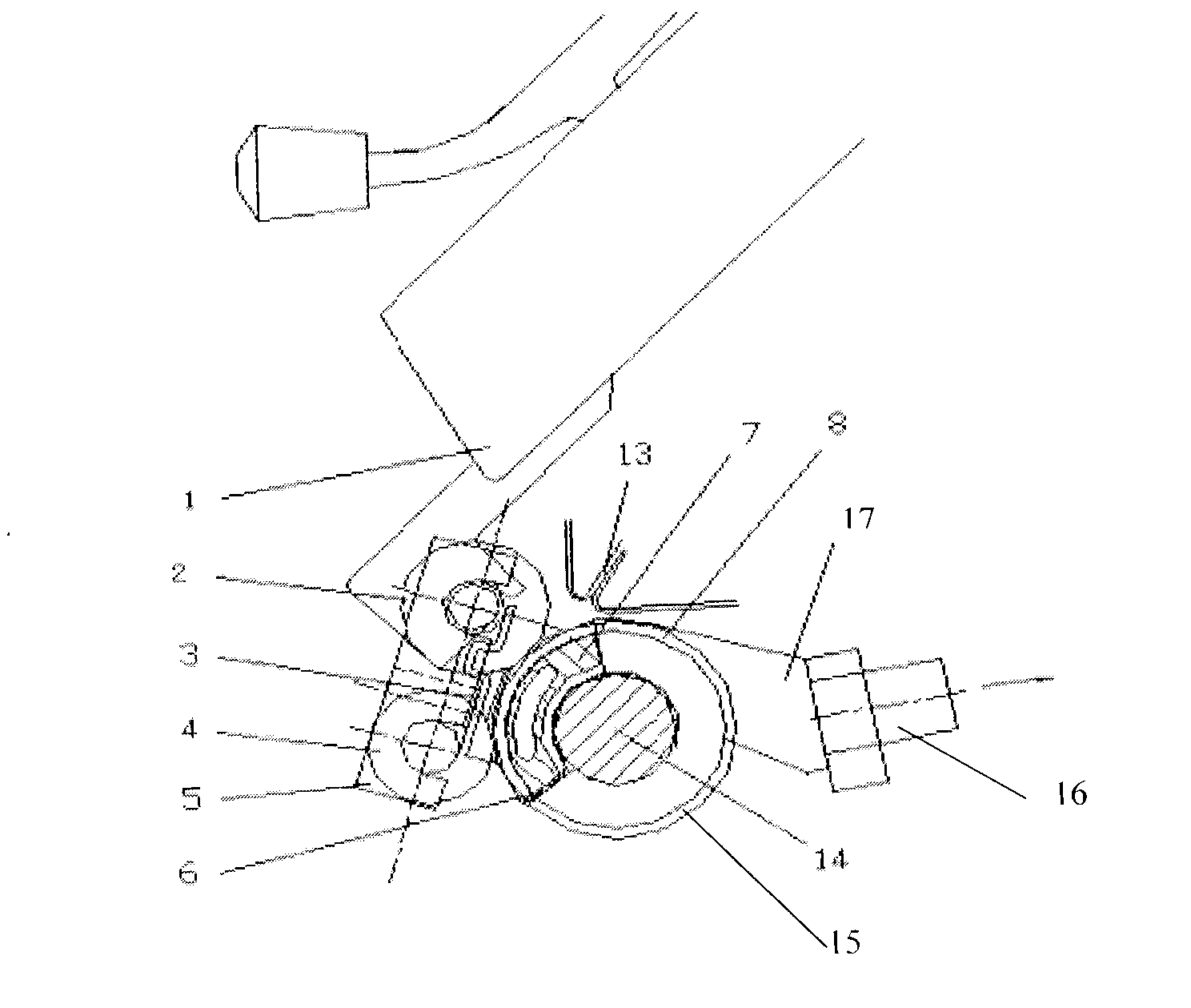

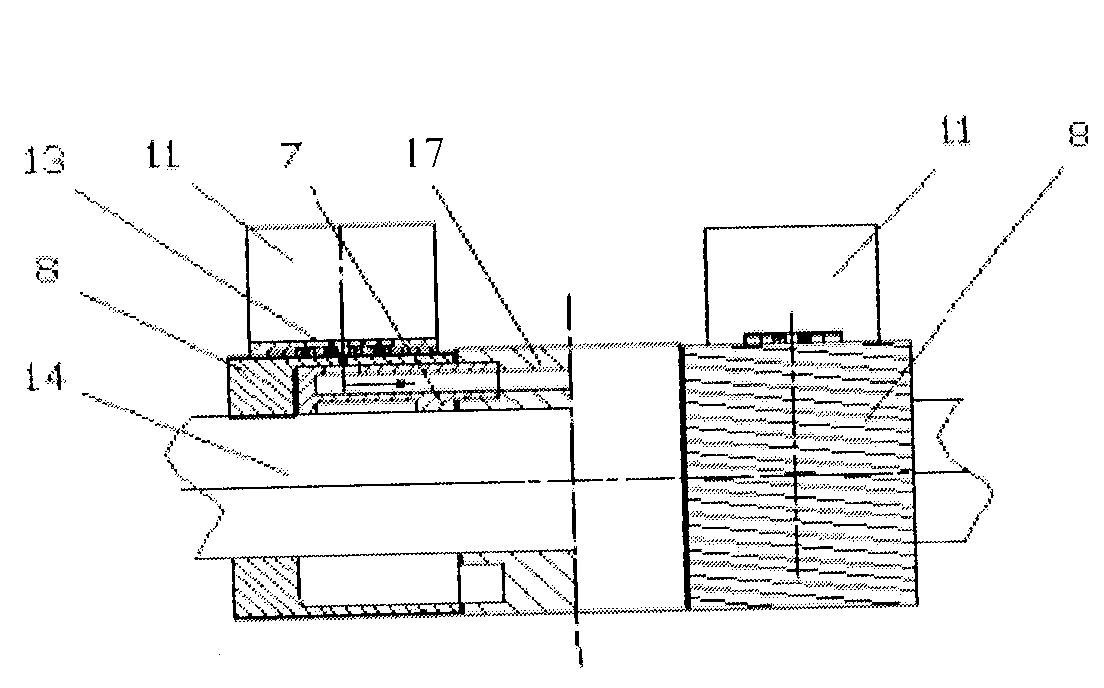

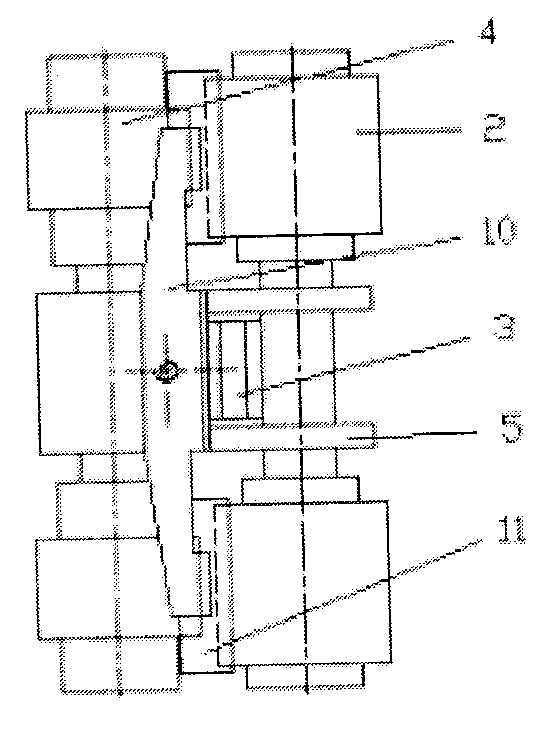

[0014] A fiber bundle device, which is composed of a double top roller assembly and a hollow roller assembly, the double top roller assembly is composed of a top roller frame 5, a spring 3, a positioning plate 10, an air flow orientation block 11, a permanent magnet 12, a first The top roller 2 and the second top roller 4 are composed, the first top roller 2 and the second top roller 4 are arranged on the top roller frame 5, the air flow orientation block 11 is arranged on the top roller frame 5 through the positioning plate 10, and the spring 3 is arranged on the top roller frame 5. On the top roller stand 5, the permanent magnet 12 is arranged on the air flow orientation block 11, the shape of the air flow orientation block 11 is made of a hyperboloid, a groove is opened at the lower end, and a hole is provided at the upper end; the hollow roller assembly is made of a hollow roller Ring 8, baffle plate 6, wide suction nozzle 7, main shaft 14, lower dust cover 15, suction seat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com