Novel spinning device

A new type of textile equipment and technology, applied in the field of new textile equipment, can solve the problems of low profit point of veil selling price, difficult operation and life, poor preventability, etc., and achieve the effect of reducing the weight CV value, improving the strength, and reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

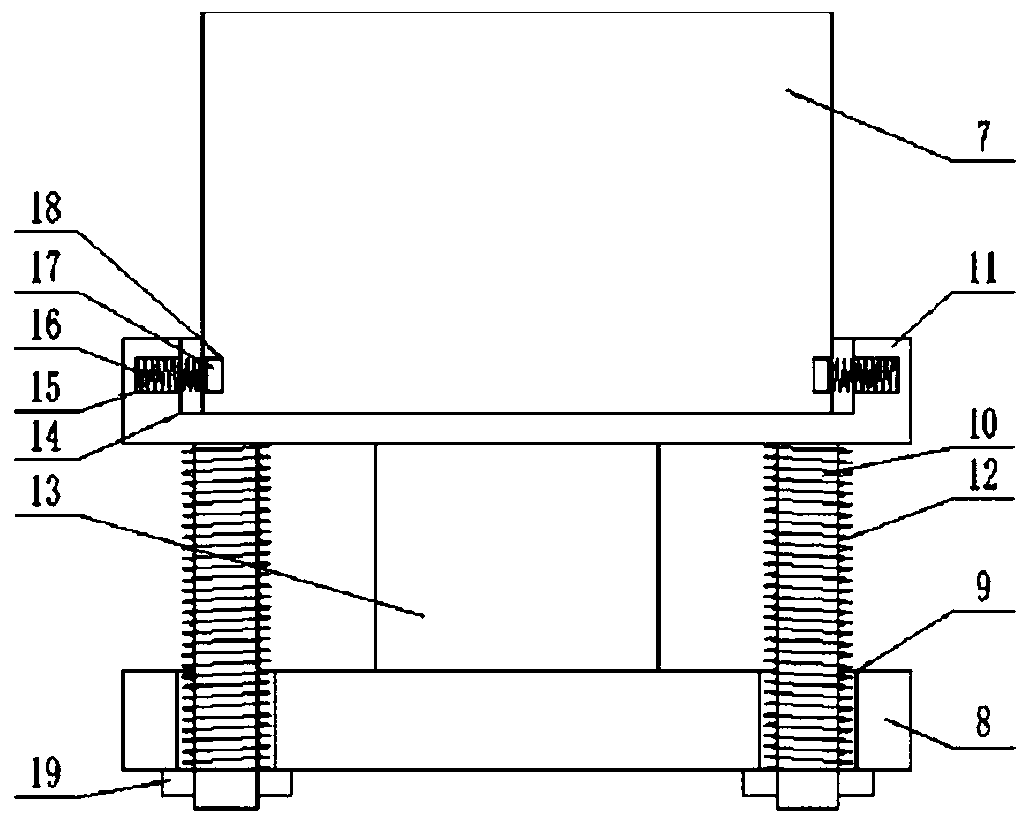

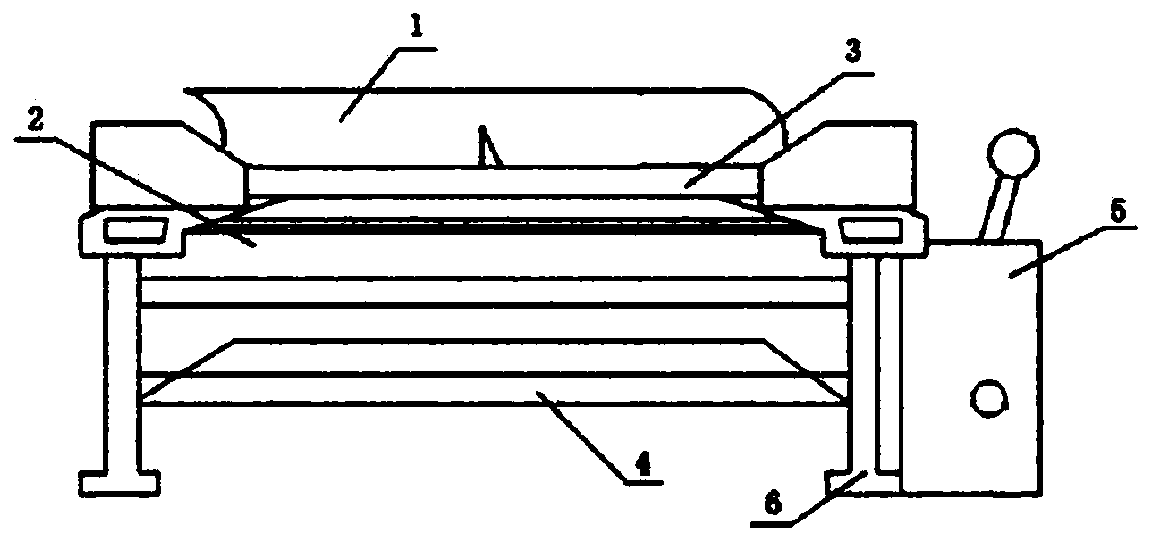

[0015] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-2 As shown, a new type of textile equipment includes a textile machine body (7), the lower end of the textile machine body (7) is provided with a vibration-reducing mechanism, and the vibration-reducing mechanism is opened on the base plate (8) by a base plate (8). A plurality of round holes (9) at the four corners, a plurality of support rods (10) inserted into the round holes (9), a support plate (11) fixed on the upper ends of the plurality of support rods (10), sleeved on the support rods (10) ) and a plurality of rigid springs (12) between the support plate (11) and the base plate (8) and a hydraulic cylinder (13) vertically arranged on the base plate (8), the textile machine body (7) Placed on the support plate (11), the support plate (11) has a groove (14), and the opposite side surfaces of the groove (14) have grooves A (15) inward, and the The inner sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com