Manufacturing method of cotton and wool mixed spinning yarn

A production method, cotton wool technology, applied in the direction of yarn, textiles and papermaking, etc., can solve the problems of difficult spinning and carding into webs and slivers, low yarn quality, poor yarn evenness, etc., to reduce damage and breakage, Intensely mixed results that ensure intrinsic quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

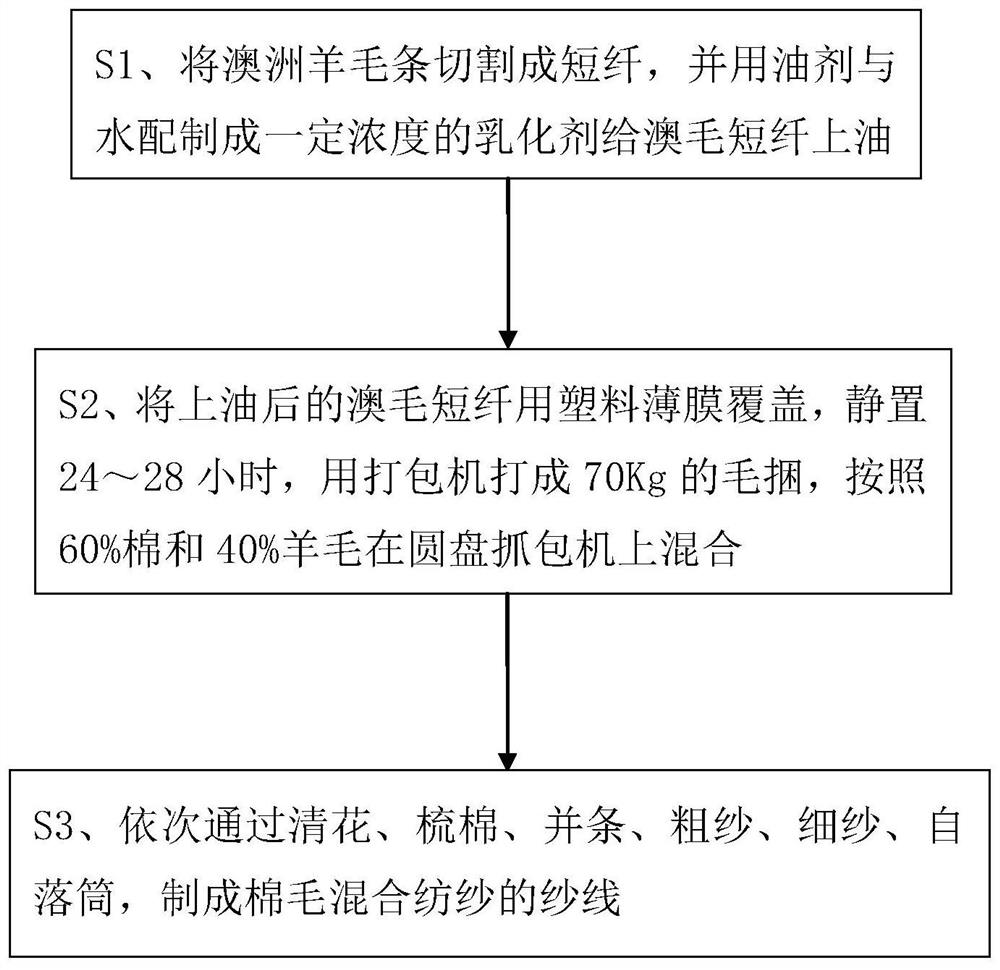

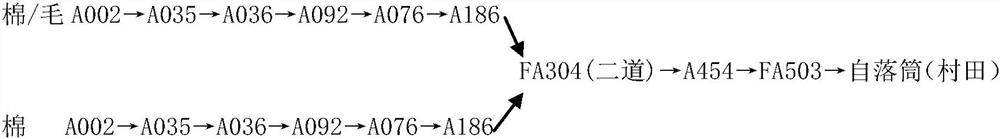

[0021] In order to achieve the purpose of the present invention, as figure 1 As shown, in one of the embodiments of the present invention, a method for making cotton wool blended spinning is provided, comprising the following steps:

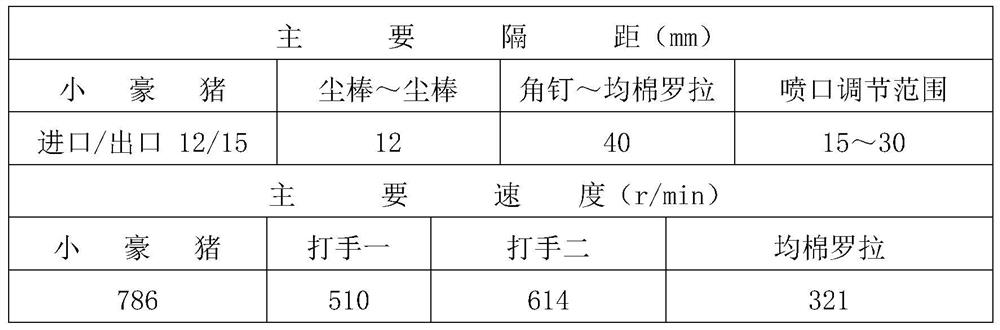

[0022] S1. Cut Australian wool tops into short fibers, and use oil and water to prepare an emulsifier with a certain concentration to oil the Australian wool short fibers. Among them, the public count of Australian wool is 700-740Nm; the Australian wool tops are cut into short fibers with a length of 30-35mm; the ratio of crude oil and water in the oil agent is 1:14, and the moisture regain of Australian wool is controlled at 18%~20%;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com