Inverted tooth chain output transmission device for snow caster

A technology of transmission device and toothed chain, which is applied in the direction of transmission device, transmission chain, hoisting device, etc. It can solve the problems of easy slipping of V-belt transmission, easy damage of reducer transmission, high maintenance cost, etc., and achieve large torque and stable operation , The effect of large transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

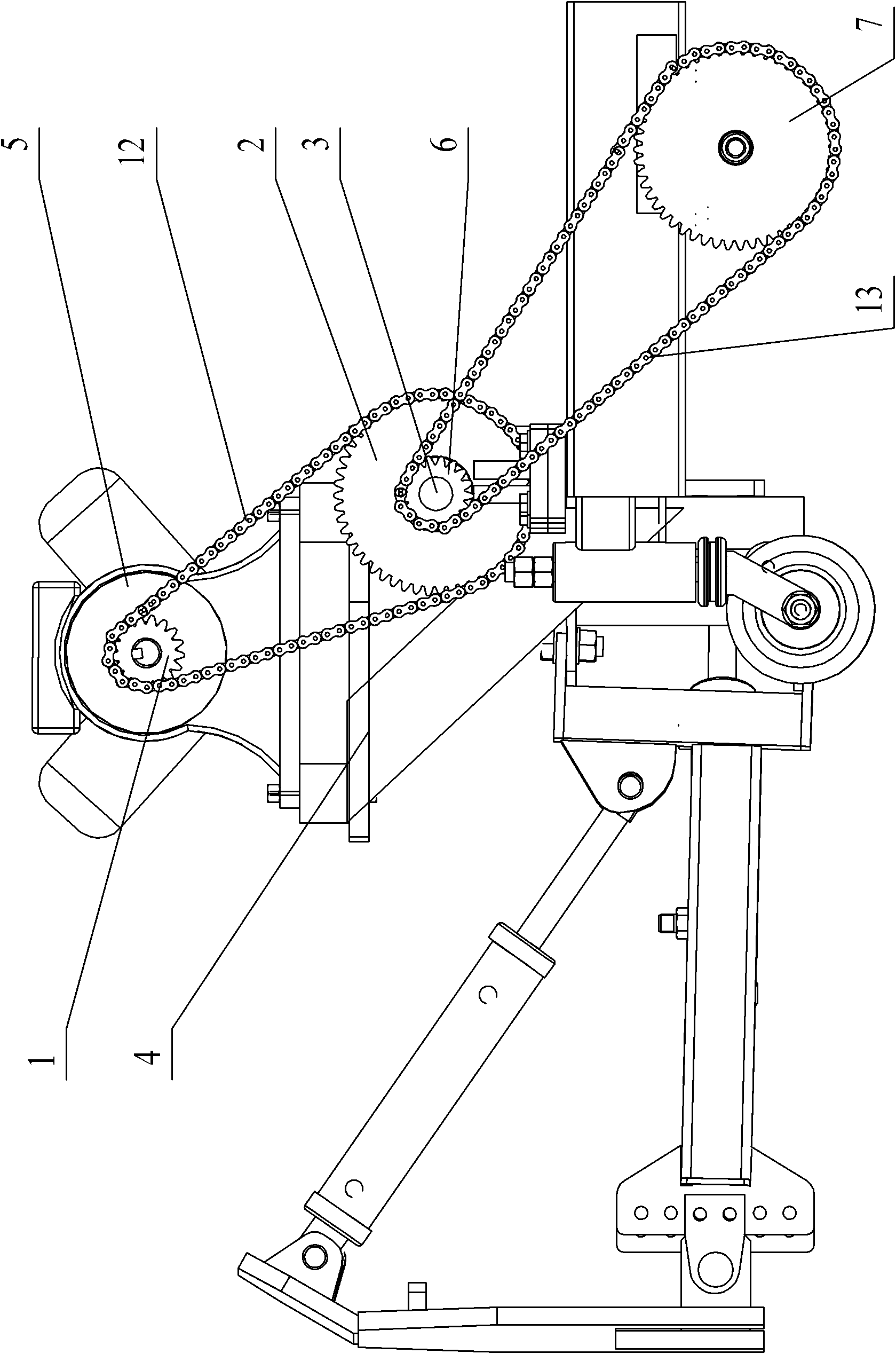

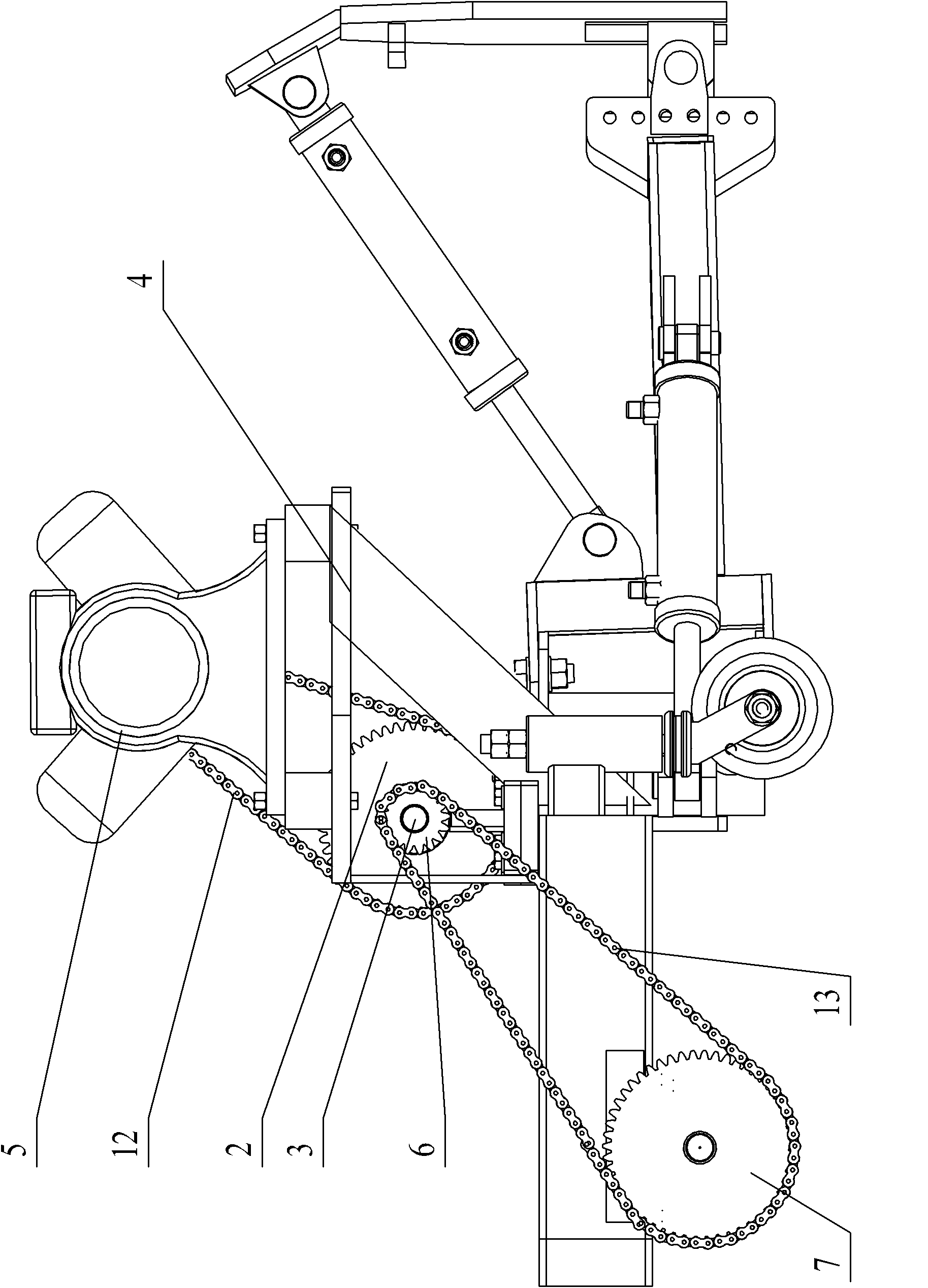

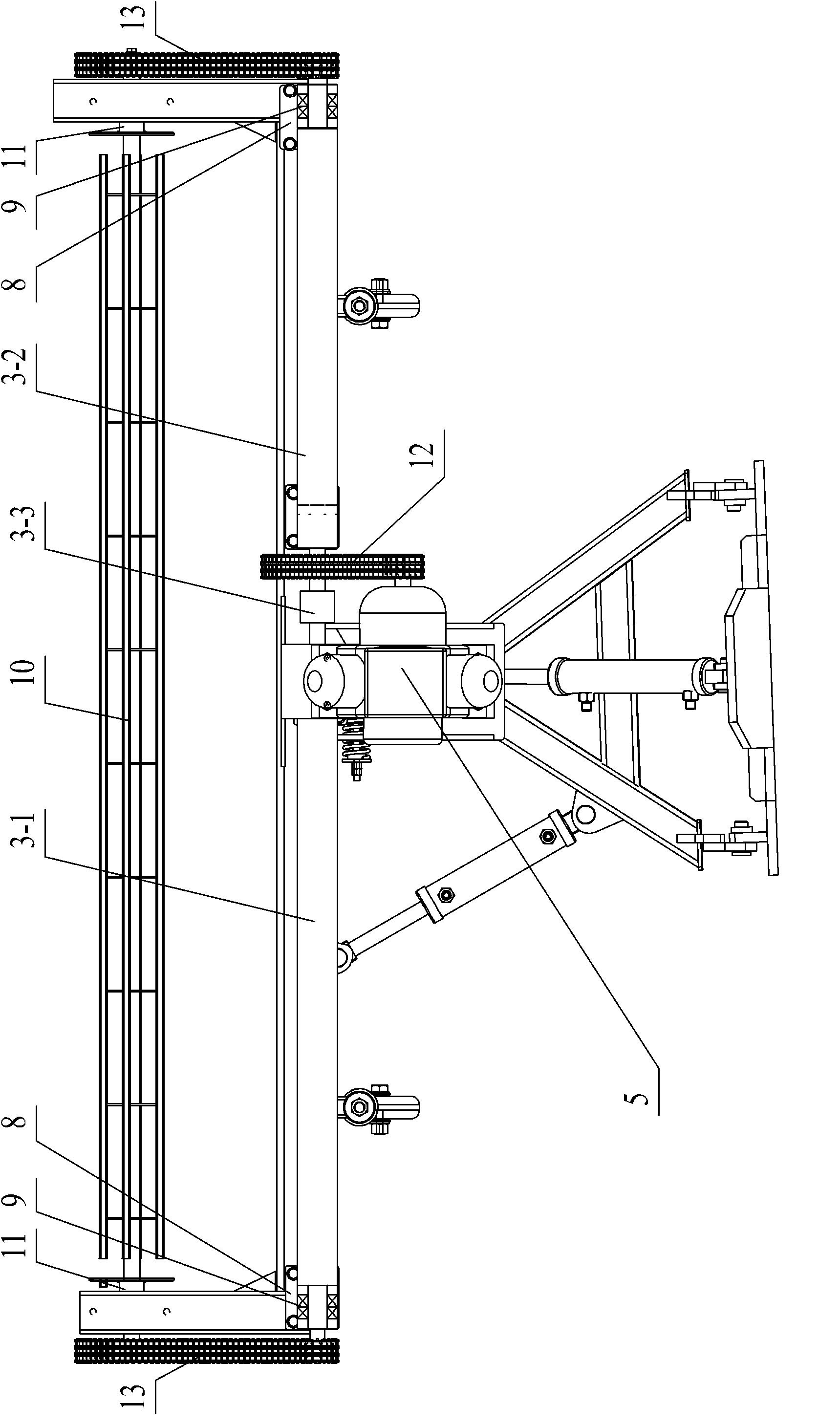

[0007] Specific implementation mode 1: Combination Figure 1-Figure 3 To explain this embodiment, the toothed chain output transmission device of the snow blower of this embodiment includes a main frame 4, and the output transmission device also includes a driving small toothed sprocket 1, a driven large toothed sprocket 2, a transmission shaft 3, Air-cooled dual-cylinder diesel engine 5, roller brush shaft 10, toothed chain 12, two small transmission sprockets 6, two large transmission sprockets 7, two bearing seats 8, two rolling bearings 9, two seated bearings 11 And two drive chains 13, the air-cooled double-cylinder diesel engine 5 is fixedly installed at the upper end of the main frame 4, and the output shaft of the air-cooled double-cylinder diesel engine 5 is fixedly installed with an active small toothed sprocket 1, the main frame 4 A bearing seat 8 is fixedly installed at the left and right ends of the drive shaft 3, and both ends of the transmission shaft 3 pass thro...

specific Embodiment approach 2

[0008] Specific implementation manner two: combination image 3 The present embodiment will be described. The rolling bearing 9 of the present embodiment is a double row rolling bearing. With this setting, the drive shaft has a small jump, running more smoothly, and reducing torque loss. The other composition and connection relationship are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination image 3 The present embodiment will be described. The seated bearing 11 of the present embodiment is a seated spherical ball bearing. This setting has the effect of adjusting the heart. Other components and connection relationships are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com