Patents

Literature

34results about How to "High transmission torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

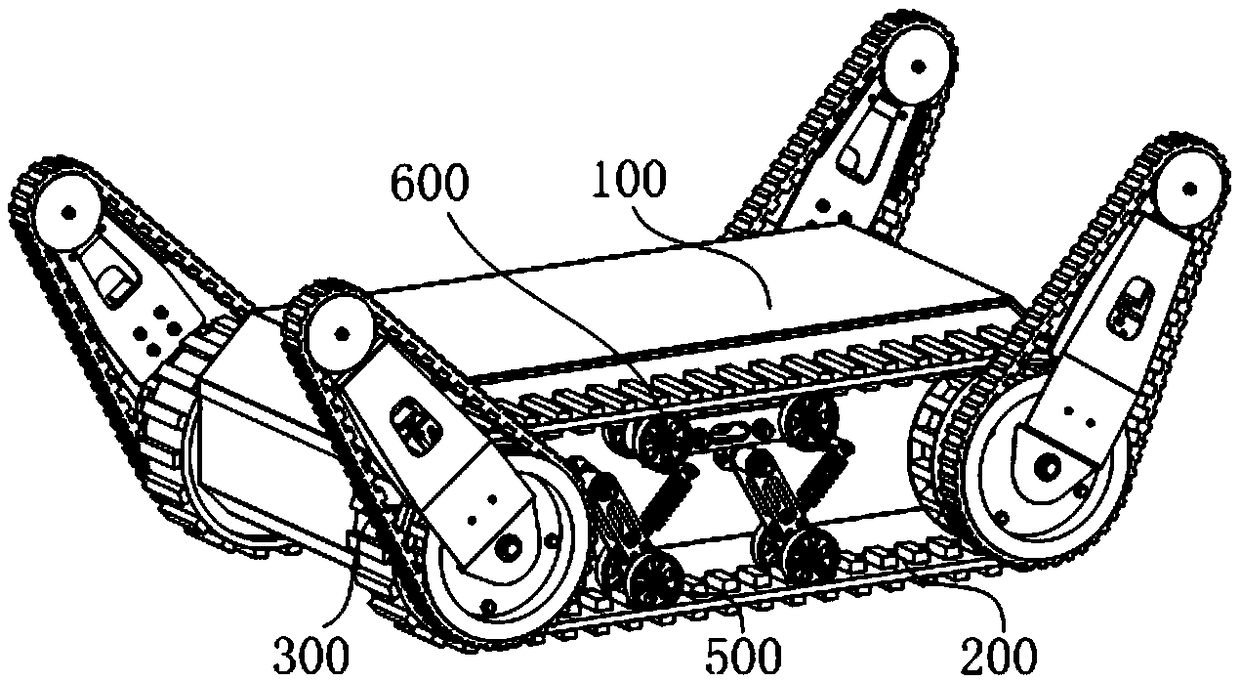

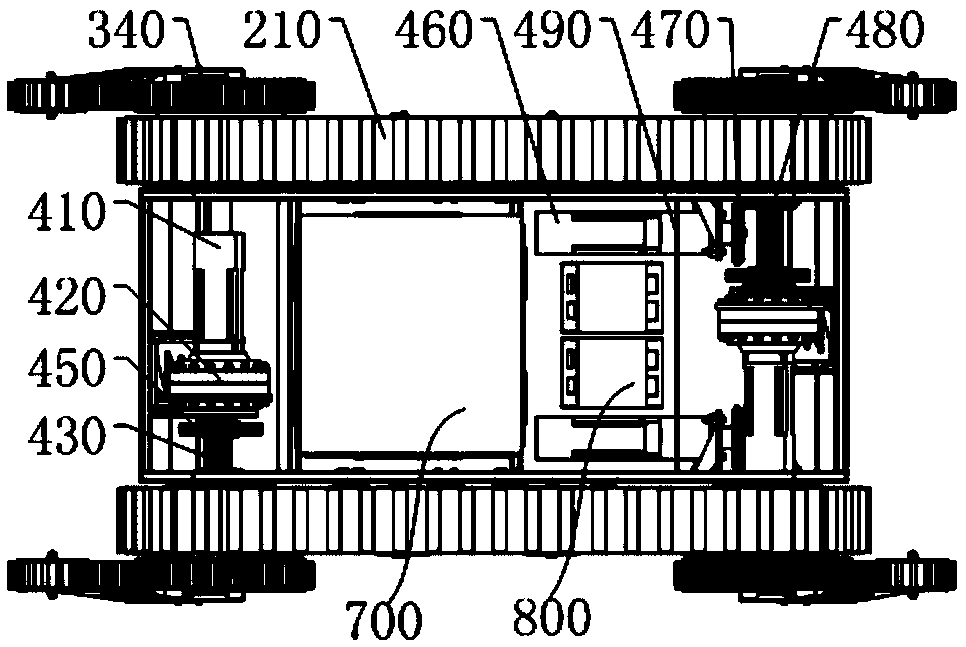

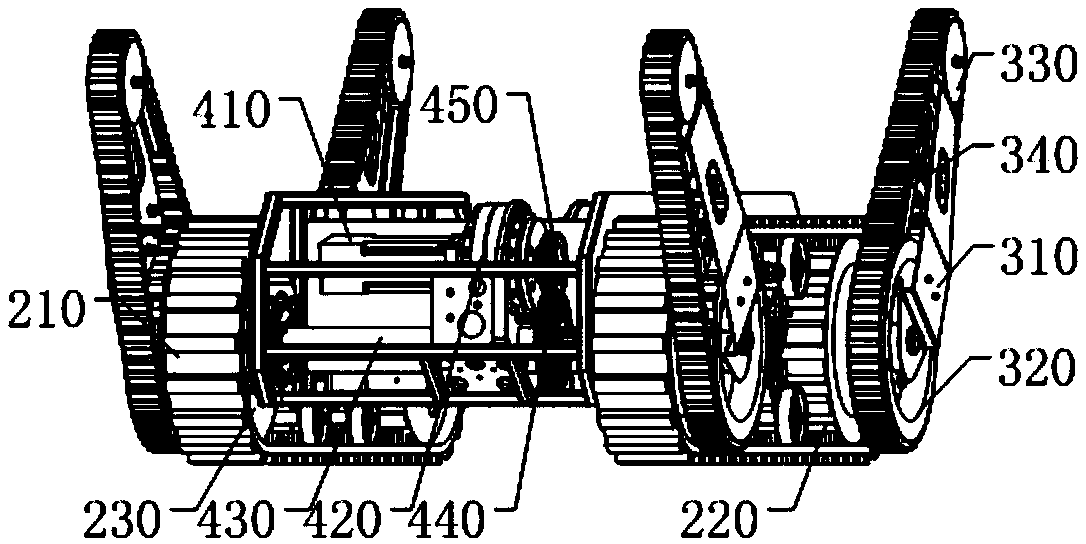

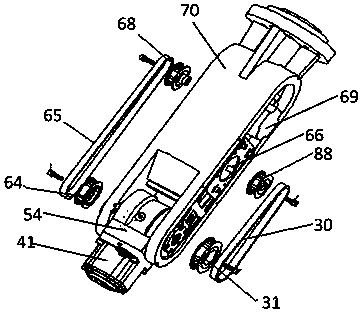

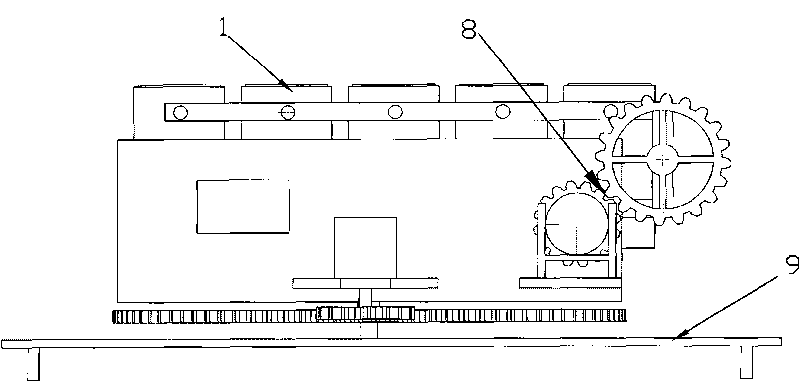

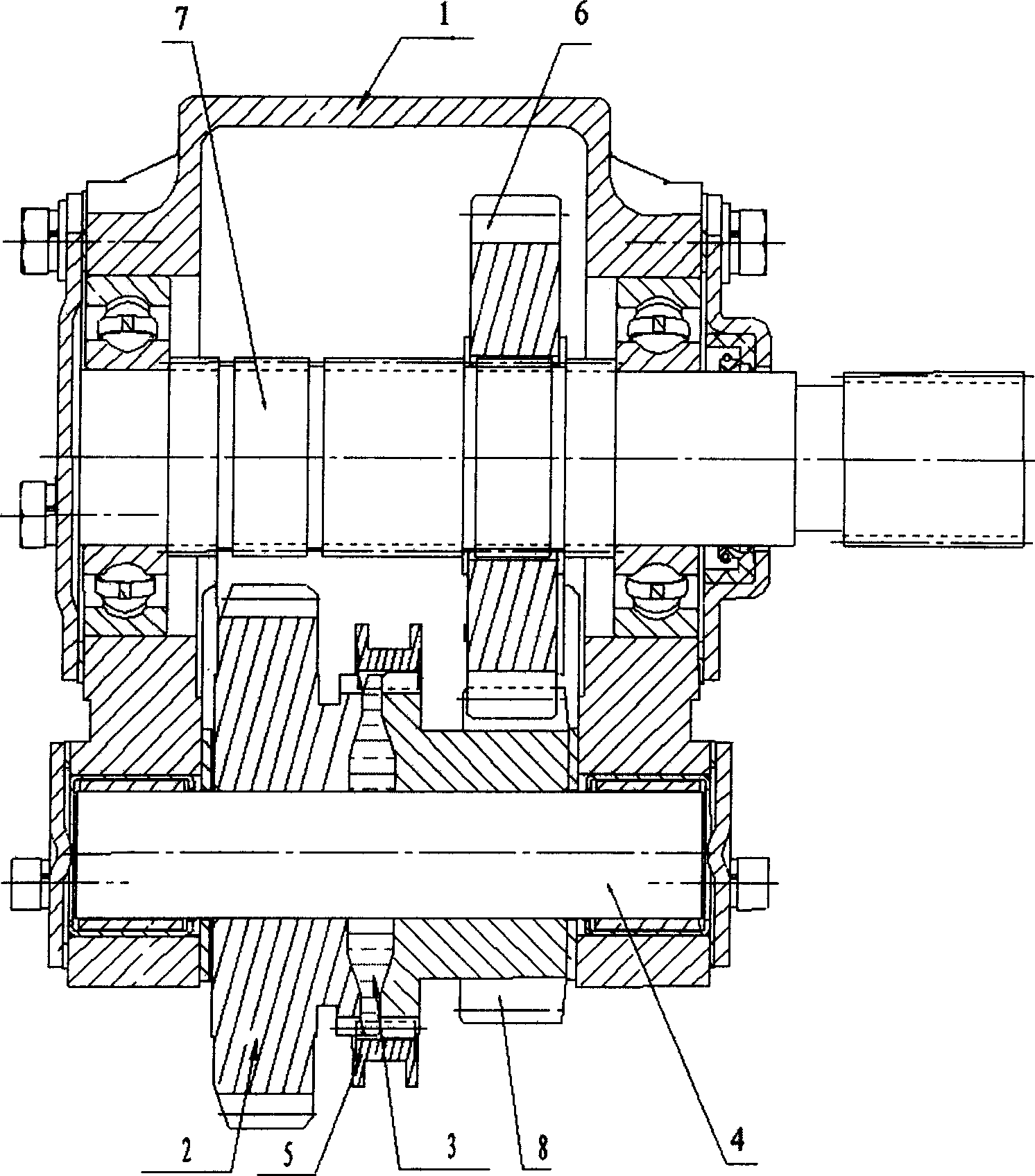

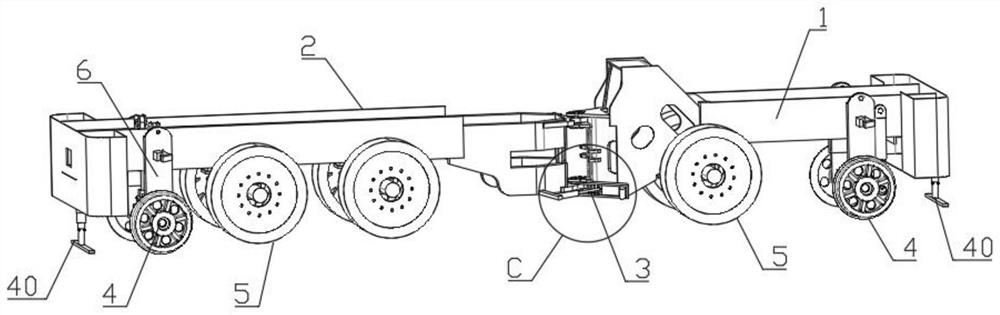

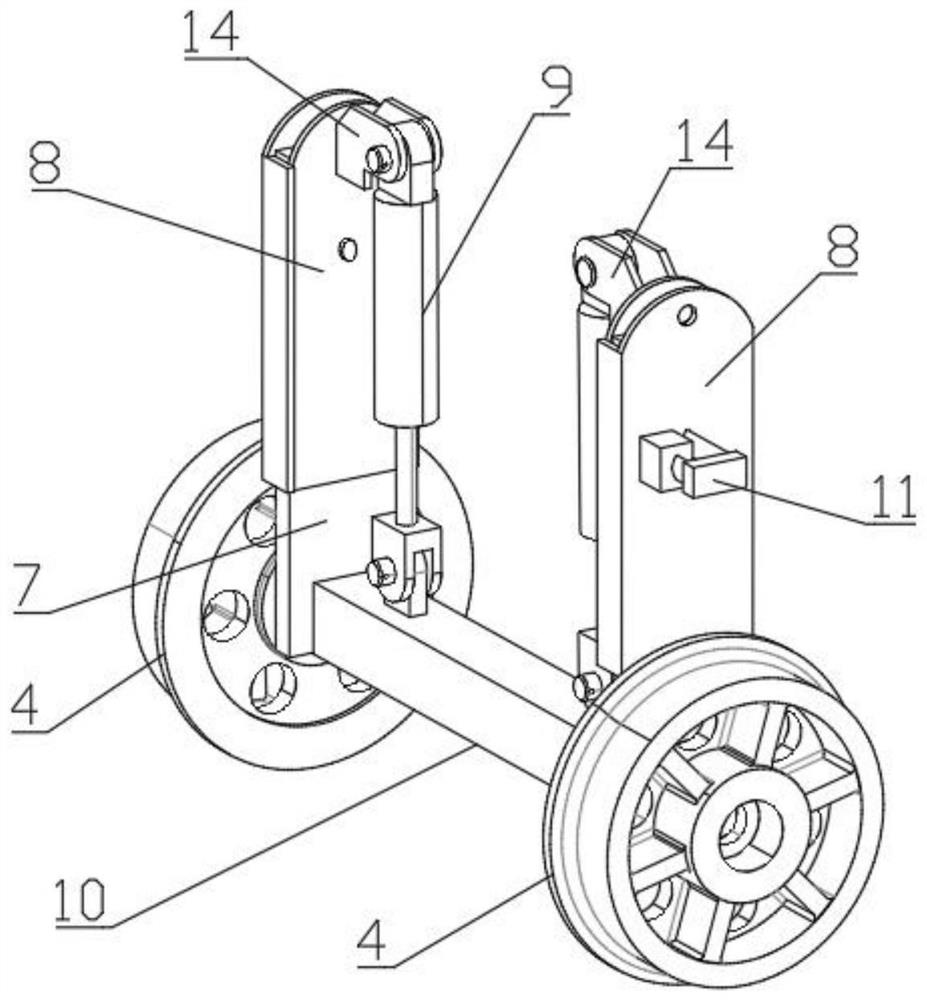

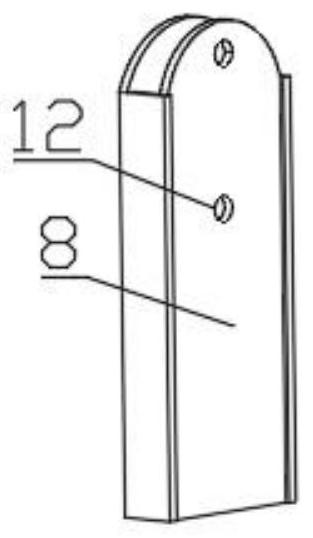

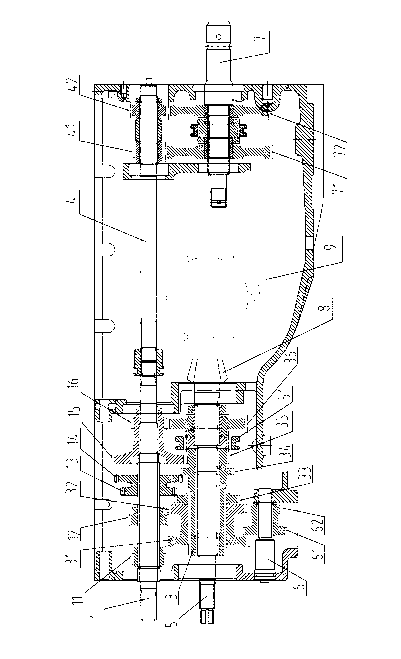

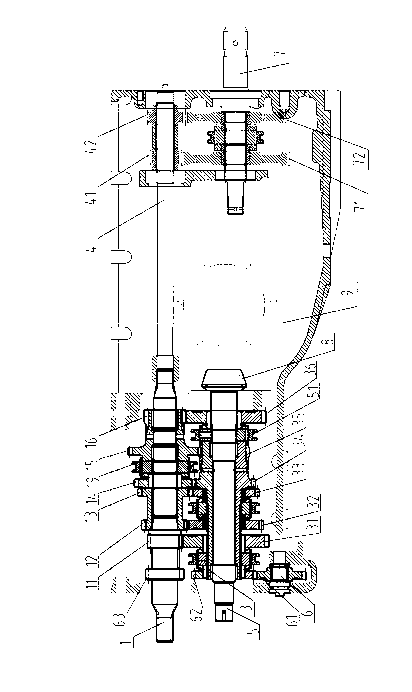

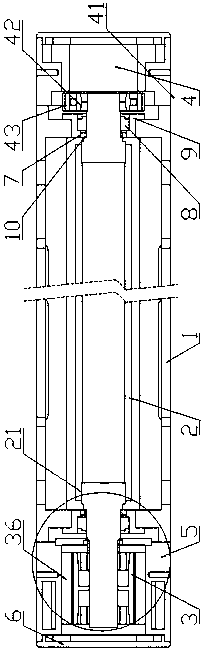

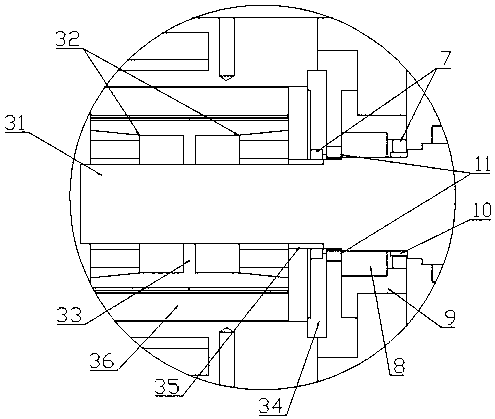

Tracked traveling device and obstacle-surmounting robot

PendingCN109436112AWalking strongImprove obstacle performanceEndless track vehiclesDrive shaftEngineering

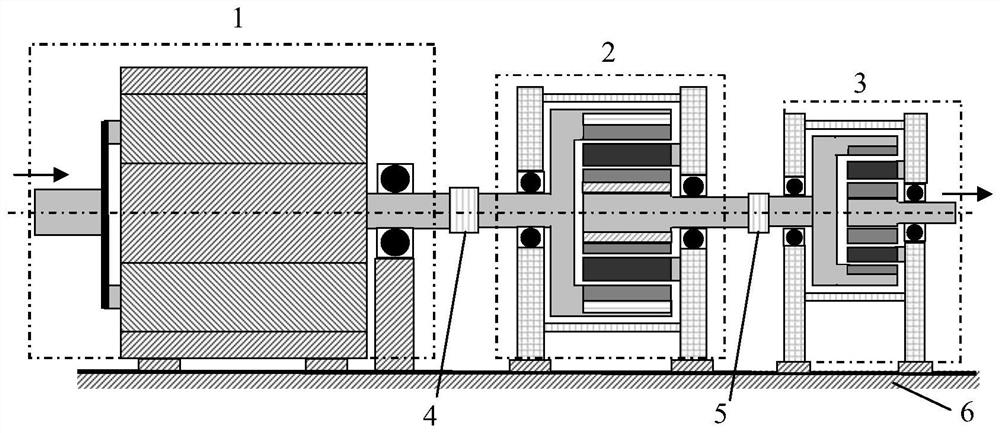

The invention provides a tacked traveling device and an obstacle-surmounting robot and relates to the technical field of tracked obstacle-surmounting robots. The tracked traveling device comprises a body, track mechanisms and at least one pair of rocker mechanisms; the track mechanisms are arranged on the two sides of the body respectively; the rocker mechanisms are arranged on at least one end ofthe body; each rocker mechanism includes a rocker body; the rocker bodies of the pairs of rocker mechanisms are connected through transmission shafts; the transmission shafts are in transmission connection with a cycloidal pin gear speed reducer; the cycloidal pin gear speed reducer is in transmission connection with a first driving mechanism; the first driving mechanism can drive the transmission shafts to rotate through the cycloidal pin gear speed reducer; the transmission shafts drive the rocker bodies in the pairs of rocker mechanisms to rock so that the rocking angles of the rocker mechanisms are adjusted. The obstacle-surmounting robot comprises the tracked traveling device. The problems are alleviated that, for instance, the obstacle-surmounting robot of the prior art has poor obstacle-surmounting capacity.

Owner:杭州白泽新能科技有限公司

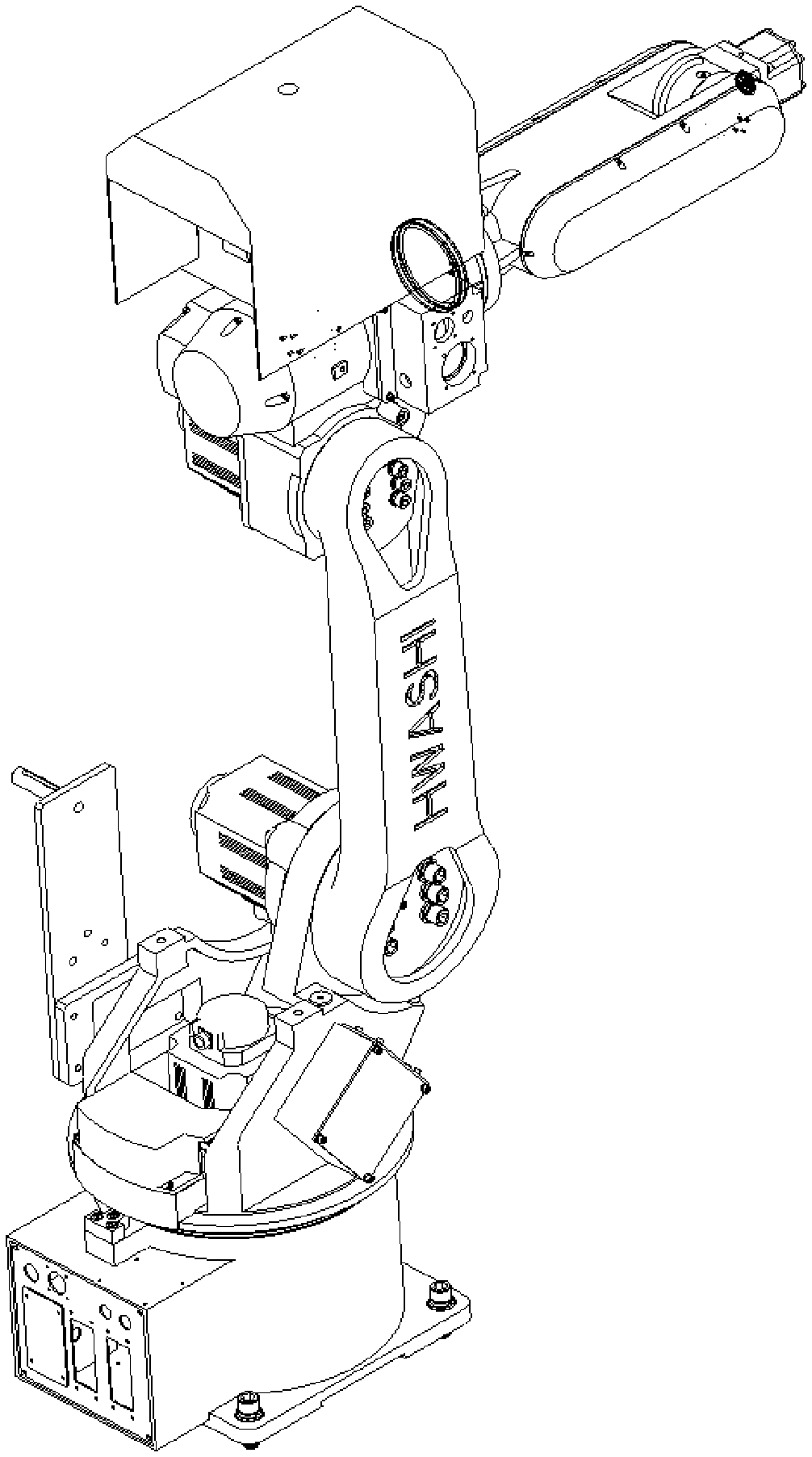

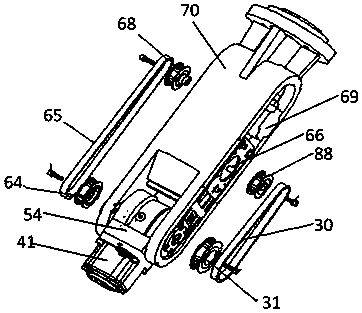

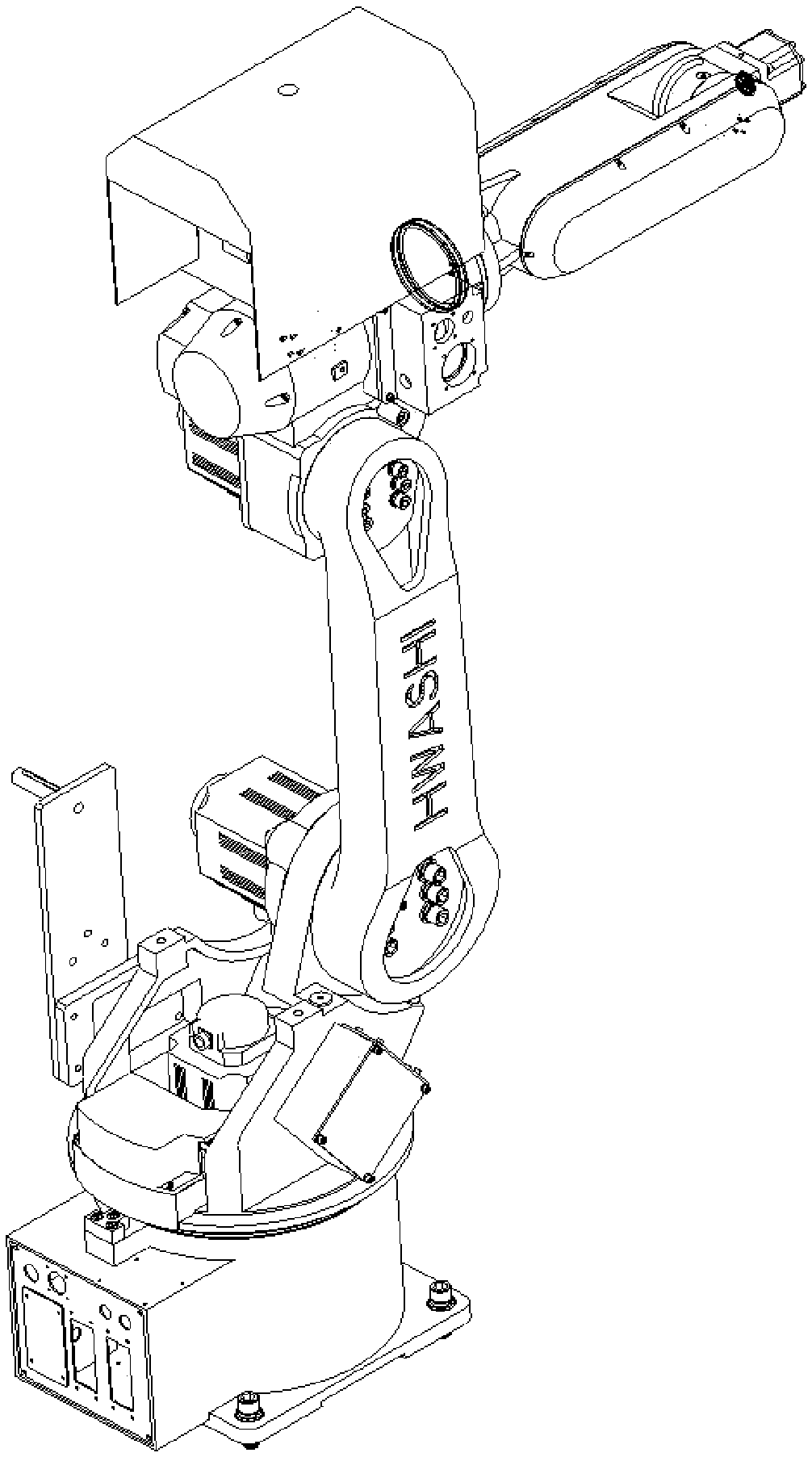

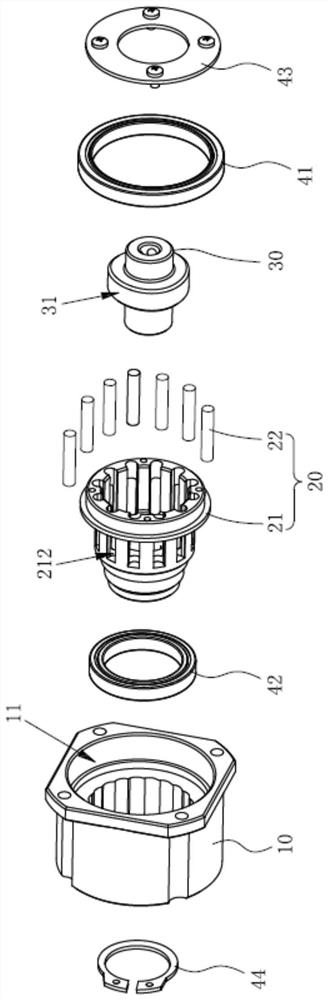

Six-axis robot

ActiveCN108312134ARealize no dead angle workRealize automatic and intelligent workProgramme-controlled manipulatorJointsAngular degreesReducer

The invention discloses a six-axis robot which comprises a first joint structure, a second joint structure, a third joint structure, a fourth joint structure, a fifth joint structure and a sixth jointstructure. When the six-axis robot is under operation, each of the joint structures can rotate around one axis direction; and the six joint structures can independently rotate in the six axis directions, so that a robot control terminal can reach any angle and position to realize working without the dead angle in industrial application; in addition, six servo motors are adopted as drive sources,and a plurality of reducers are also introduced to enable the operating motion of the robot to be smoother, steadier and more controllable; and precise control over the robot can be realized through setting the deceleration proportion of each reducer and the working procedure of each servo motor. Moreover, a plurality of bearing pedestals and the corresponding bearing structures are arranged, so that undamped transmission and stable power transmission of all joints of the robot are realized, and the robot has high operational stability and working continuity.

Owner:HUASHI POWER SUPPLY TECH JIANGXI CO LTD

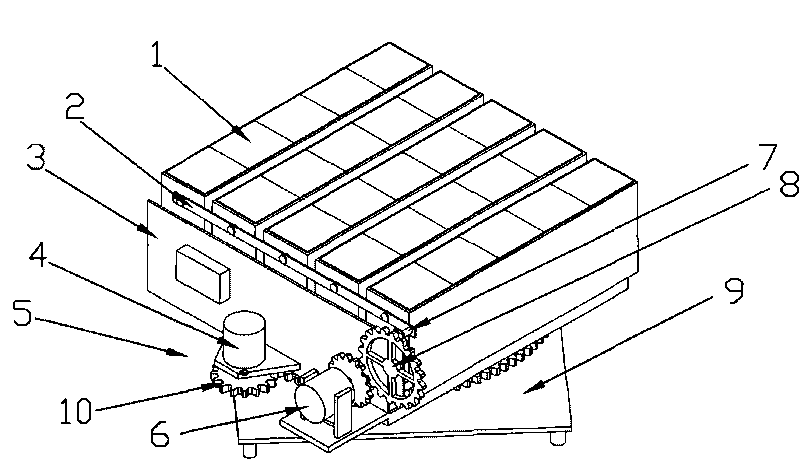

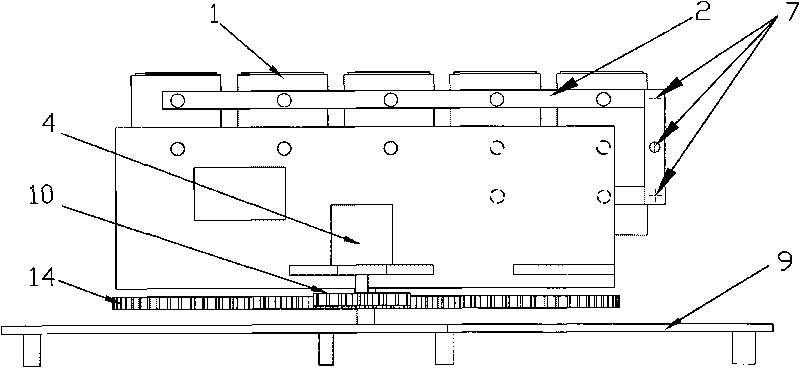

Roof solar double-shaft auto-tracking system

InactiveCN101694589ASimple facilitiesSolve the deficiencies in the scope of application and application methodsPhotovoltaic supportsPhotovoltaic energy generationGear transmissionDual axis

The invention discloses a roof solar double-shaft auto-tracking system, comprising a horizontal base, a framework, a set of photovoltaic module frame, wherein the framework is positioned on the horizontal base, and the set of photovoltaic module frame is arranged in the framework. The roof solar double-shaft auto-tracking system is characterized by comprising a horizontal tracking mechanism and a pitching tracking mechanism, wherein the horizontal tracking mechanism and the pitching tracking mechanism are arranged on the sides of the framework in flush system, and the framework drives the set of photovoltaic module frame to rotate. By two independently set motors, a double-shaft gear transmission is controlled to change and decrease the rotation speed, and the purpose of tracking the sun is realized by controlling the motors. By setting the structure combing the horizontal tracking and the pitching tracking, the roof solar double-shaft auto-tracking system has the advantages of simplifying unnecessary equipment, changing a vertical structure to a horizontal structure, being suitable for roofs as well as most environments, solving the problems of traditional tracking system on application range and insufficient application patterns as well as convenient installation, debugging and maintenance.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Robot

PendingCN110238834ARealize no dead angle workRealize automatic and intelligent workProgramme-controlled manipulatorElectric power transmissionReducer

The invention provides a robot. The robot comprises a first joint structure, a second joint structure, a third joint structure, a fourth joint structure, a fifth joint structure, a sixth joint structure and a manipulator, wherein each joint structure can rotate around an axis direction during operation of the robot, the six joint structures can independently rotate in six axis directions, the manipulator can perform telescopic movement along a straight line so that the robot can reach any angle and position, and dead-angle-free work in industrial application is realized; six servo motors are adopted as driving sources, and a plurality of speed reducers are introduced, so that the operation action of the robot is more stable and controllable; the automatic precise control of the robot can be achieved through setting the speed reduction ratios of all the speed reducers and setting the working procedures of all the servo motors and the oil cylinder air cylinders; and no damping transmission and stable power transmission are ensured through a plurality of bearing seats and a bearing structure, so that the robot has good operation stability and work automation.

Owner:贾培军

Synchronous power takeoff

There is disclosed a synchronous power take-off means, which can realize to take out power from vehicle engines ( speed variators or transfercases ) for driving a generator, a gear pump, a water pump, a vacuum pump, an air compressor and the like. It consists of toothed gearing and gear shift operating parts. Between the power take-off gear disposed on the countershaft and the countershaft gear is mounted a synchronous gear ring, which is inserted in the countershaft gear.

Owner:威海西立电子股份有限公司

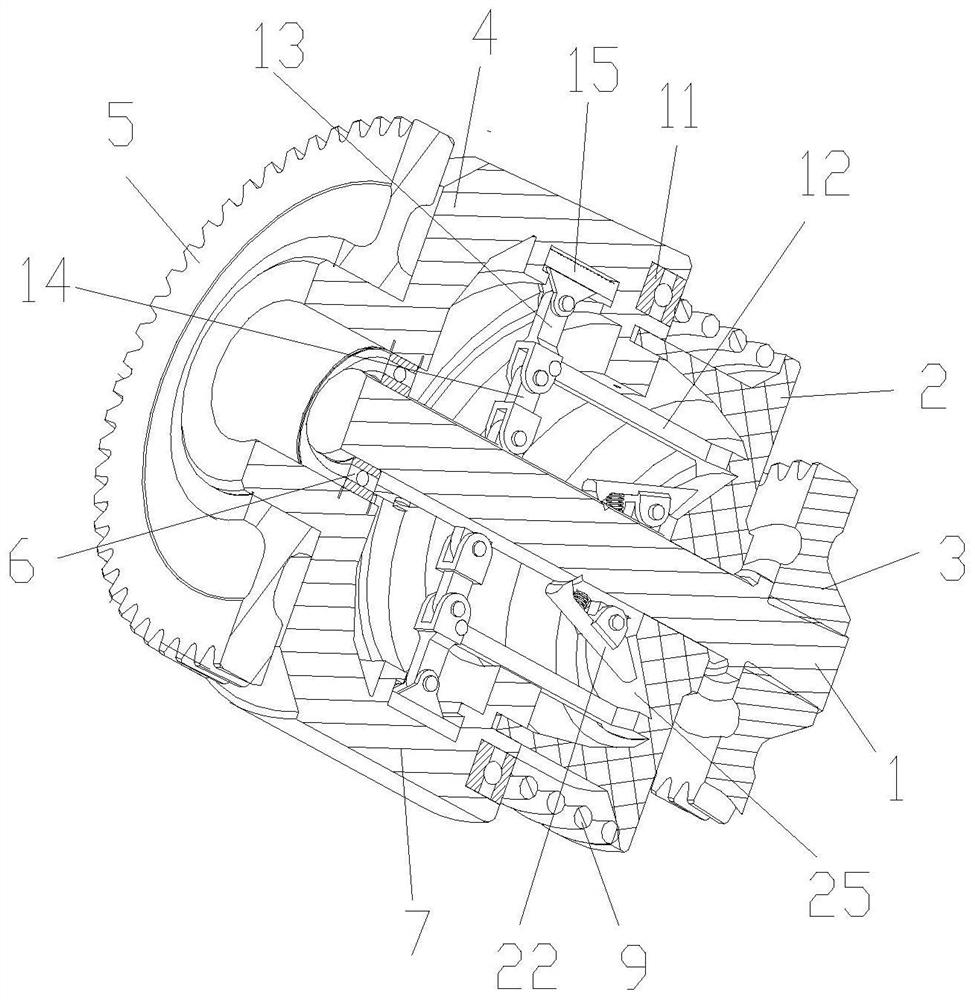

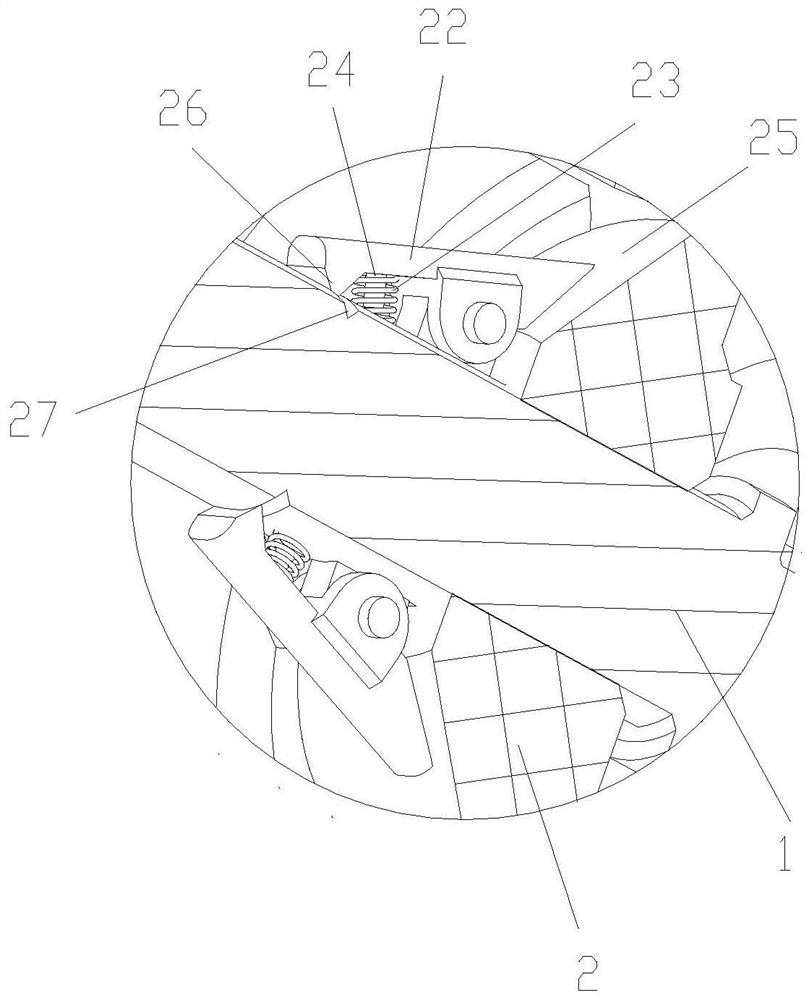

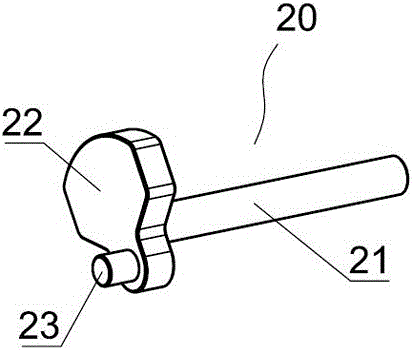

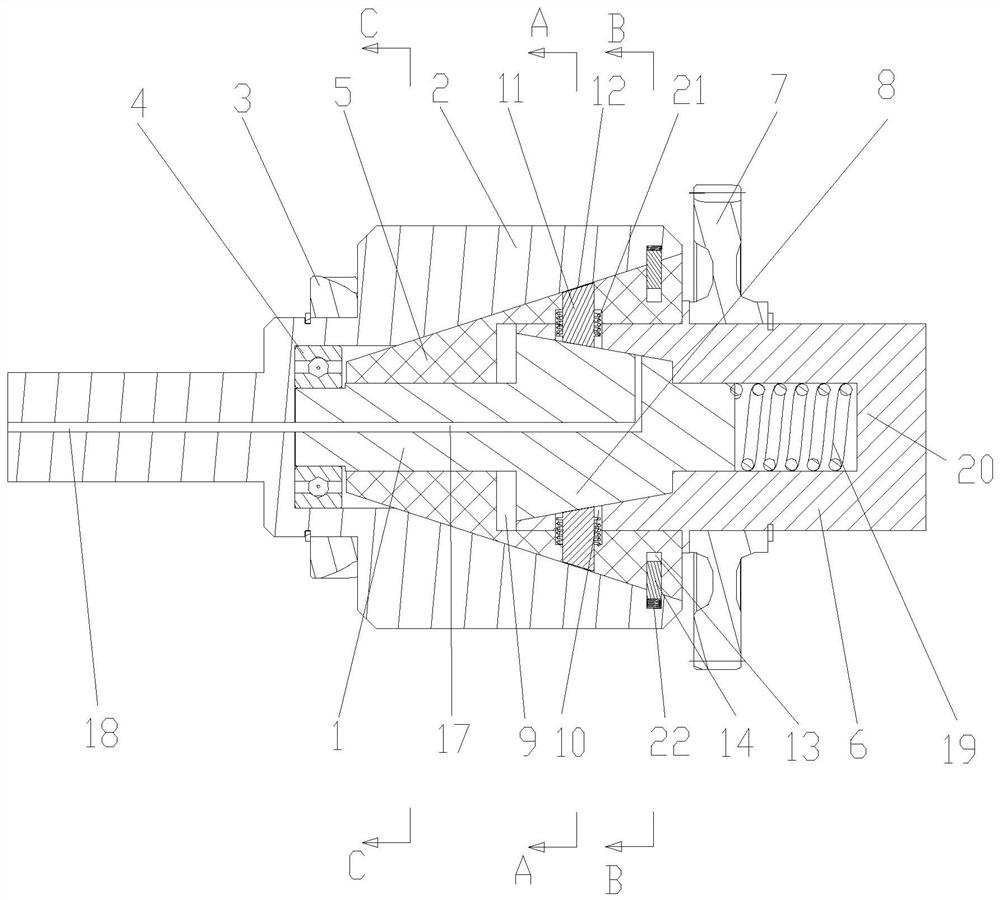

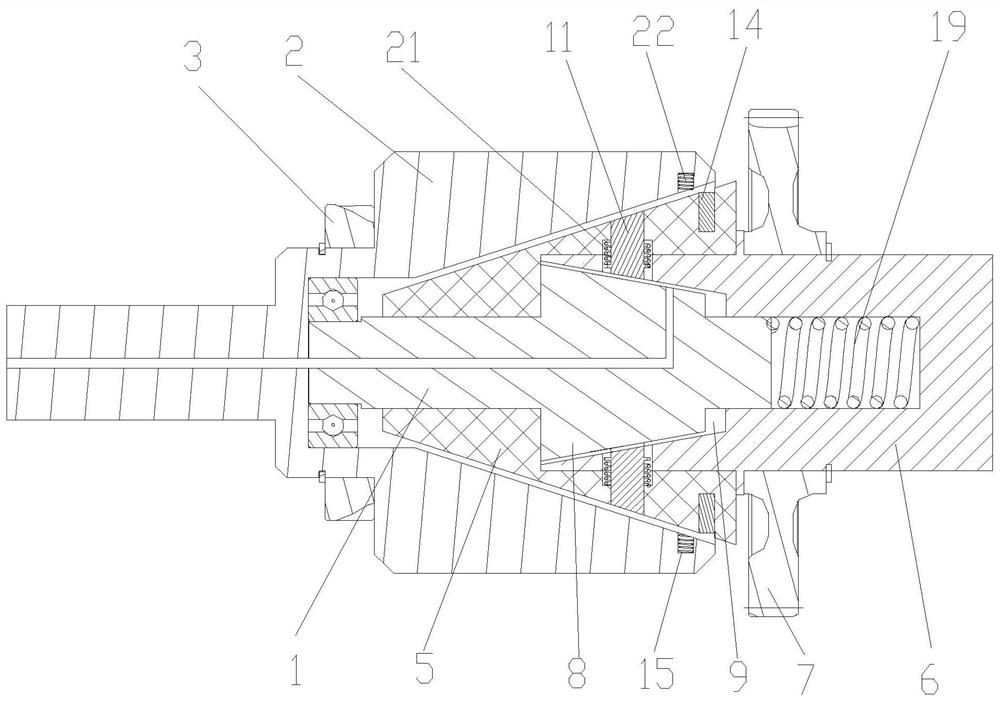

Engine synchronizer mechanism

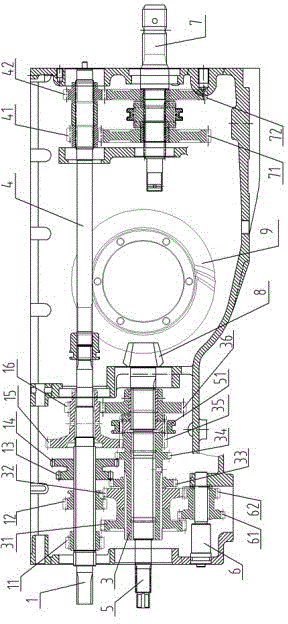

PendingCN111810551AImprove stabilityImprove reliabilityMechanical actuated clutchesDrive wheelDrive shaft

The invention provides an engine synchronizer mechanism which includes a transmission shaft. A driving part, a movable seat and a driven part sequentially sleeve the transmission shaft from left to right in the axial direction, the driving part includes a driving shaft sleeve and a driving wheel, one end of the driving shaft sleeve rotatably sleeves the transmission shaft, and the other end of thedriving shaft sleeve extends to the right to form an extension cylinder; the movable seat slidably sleeves the transmission shaft, the movable seat and the inner wall of the extension cylinder are connected or disengaged through a plurality of connecting rod assemblies, when the movable seat moves to the left to a left limit position, the movable seat drives the connecting rod assemblies to act to enable the connecting rod assemblies to be connected with the extension cylinder, and the left limit position of the movable seat is positioned and locked through a positioning and locking device; and when the movable seat moves to the right to a right limit position, the movable seat drives the connecting rod assemblies to move to enable the connecting rod assemblies to be disengaged from the extension cylinder, and the movable seat is maintained at the right limit position through a reset device. The engine synchronizer mechanism has the advantage that quick connection or disengagement canbe realized.

Owner:ANHUI JIANGHUAI NAVISTAR DIESEL ENGINE CO LTD

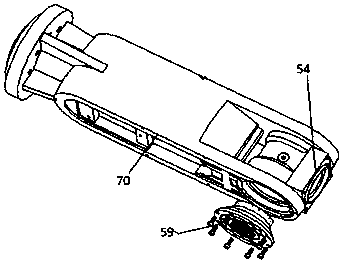

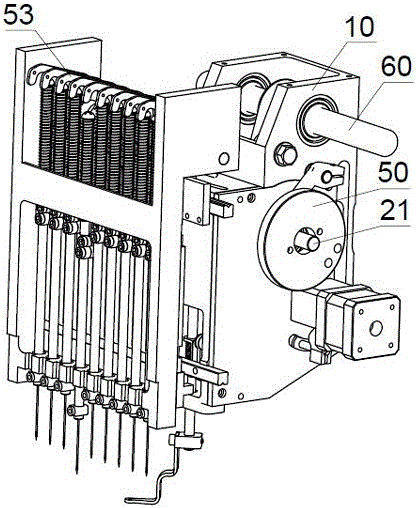

Ultrahigh-speed embroidery machine head

PendingCN106811880ALittle drive lossImprove balanceAuxillary devicesFeedersUltra high speedDynamic balance

The invention relates to the technical field of embroidery machines, and particularly discloses an ultrahigh-speed embroidery machine head. The ultrahigh-speed embroidery machine head is characterized in that a case is provided with a left chamber and a right chamber, a dynamic balance cam, a presser foot cam and a take-up-lever cam are positioned in regions on the outer sides of the left chamber, the right chamber and a right cover plate, a spindle between the dynamic balance cam and the presser foot cam is rotationally movably connected with a partition plate, and the presser foot cam and the take-up-lever cam are rotationally movably connected with the right cover plate. The ultrahigh-speed embroidery machine head has the advantages that the dynamic balance cam, the presser foot cam and the take-up-lever cam are isolated in the three regions by the partition plate and the right cover plate, every two adjacent regions are connected with each other by the spindle and the case in a supported manner, and accordingly resonance effects due to centrifugal force generated by various components can be prevented; the dynamic balance cam is integrally formed by a balance block and an eccentric column, the eccentric column can drive needle bars to move via a needle bar driving connecting rod assembly, centrifugal force generated by the balance block is used for offsetting the centrifugal force generated by the other components, accordingly, vibration can be eliminated, and the spindle can rotate at the high speeds.

Owner:诸暨市驰龙科技有限公司

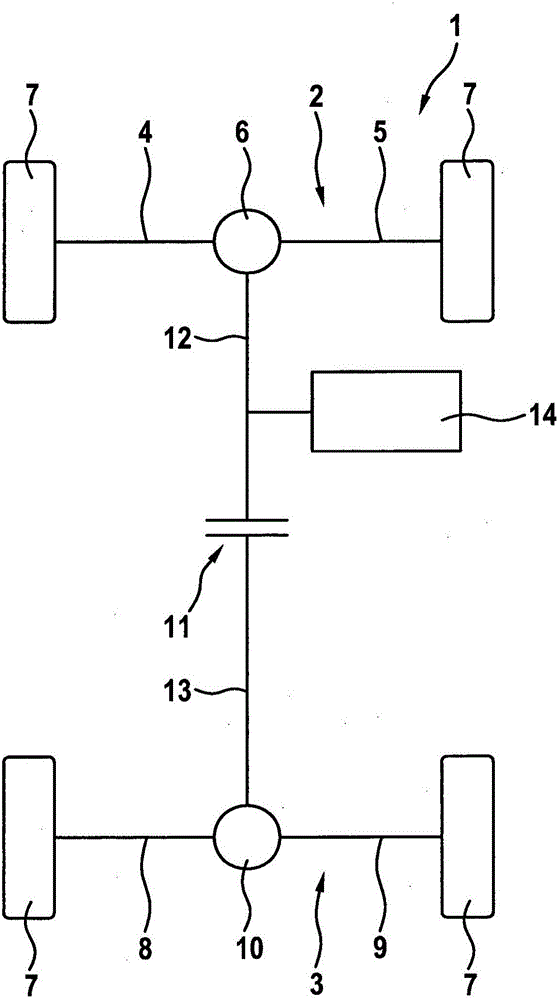

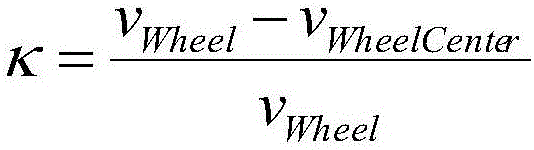

Method for operating a drive train for a motor vehicle and corresponding drive train

ActiveCN106458025ARegulating the desired transmission torqueReduce speedClutchesControl devicesClutch

The invention relates to a method for operating a drive train (1) for a motor vehicle, comprising at least one primary drive axle (2) and at least one secondary drive axle (3) which are operatively interconnected to an adjustable transmission torque by means of a clutch (11). According to the invention, the transmission torque is reduced when wheel slip exceeding a determined slip threshold value is detected on the secondary drive axle (3). The invention also relates to a drive train (1) for a motor vehicle.

Owner:AUDI AG

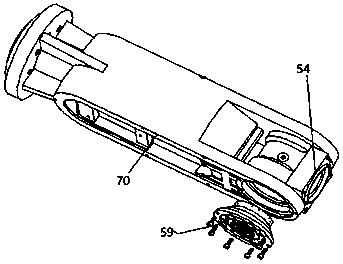

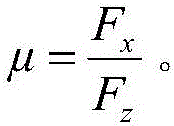

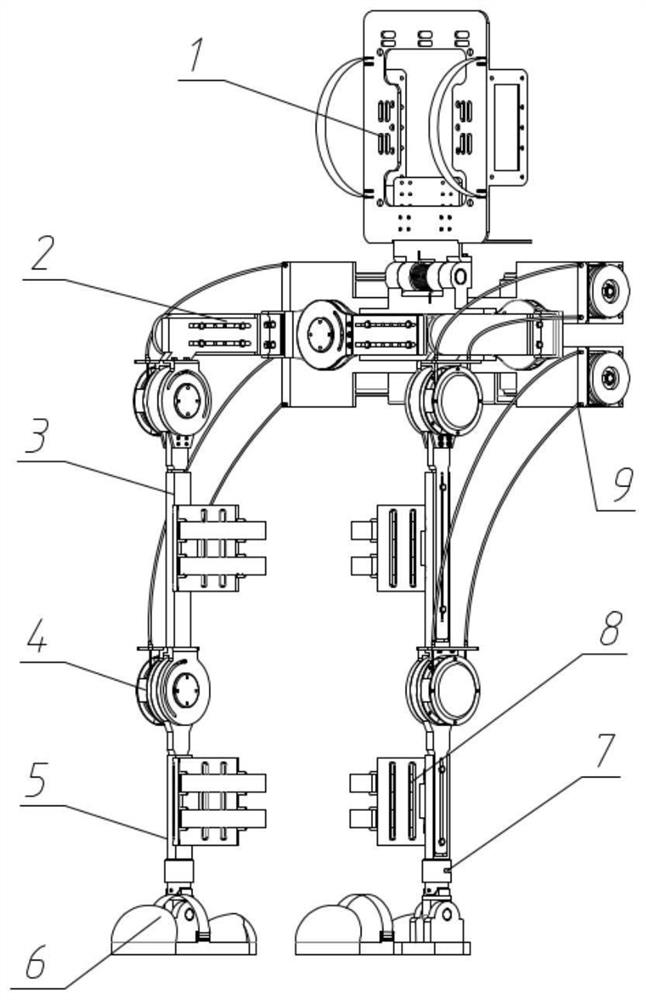

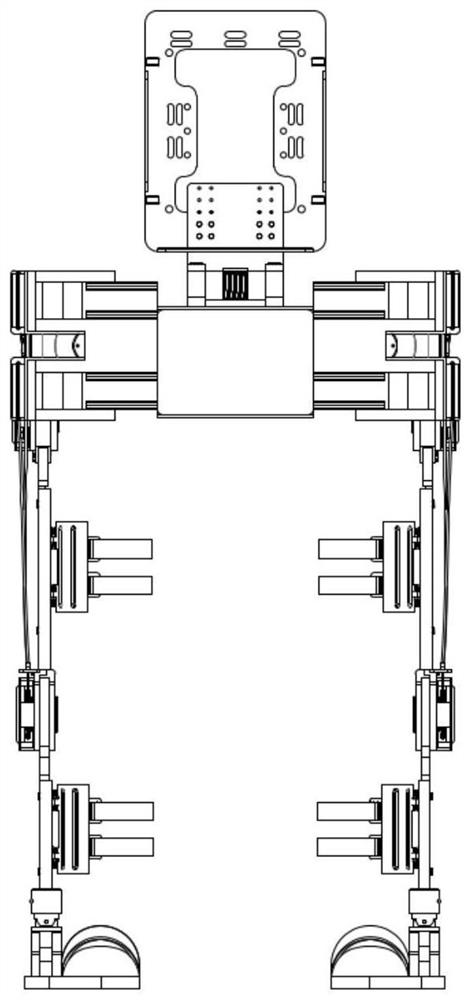

Wearable flexible lower limb assisting exoskeleton robot

PendingCN114474021AReduce the moment of inertia of motionAvoid secondary damageProgramme-controlled manipulatorJointsHuman bodyThigh

The invention relates to a wearable flexible lower limb power-assisted exoskeleton robot, which belongs to the technical field of exoskeleton robots and comprises a back component, hip joint components, thigh components, knee joint components, shank components, foot components, ankle joint components, a floating binding device and a transmission-driving system. The invention has the following beneficial effects: the driving system is integrated on the waist to a certain extent to realize the light weight of the equipment, the deflection inertia of the joint is reduced, the power transmission torque is large through the rope, and the transmission is stable. A rigid-flexible mixed limiting mode is adopted at the joint, rigid impact is reduced, secondary damage to a user caused by mistaken rotation of the motor is prevented, energy is stored when the limiting spring is pressed, and the restoring force of rebounding plays a role in saving labor. The sizes of the thighs, the shanks and the hip joints can be continuously adjusted, and the device is suitable for users of different figures and high in wearing universality. The setting of the degree of freedom of the joints conforms to the actual situation of the human body, the consistency of exoskeleton and user movement is guaranteed, and the movement flexibility is improved.

Owner:SHANDONG JIANZHU UNIV

Engine driving device

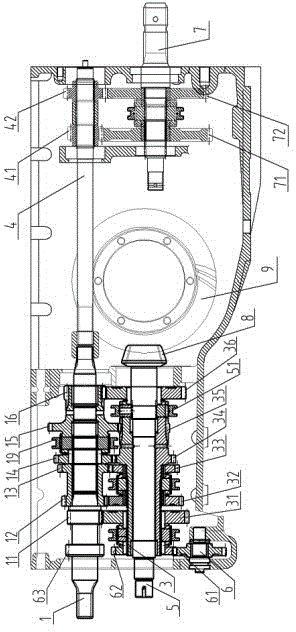

PendingCN111828503AImprove reliabilityQuick engagementFriction clutchesAutomatic clutchesExtreme positionDrive wheel

The invention discloses an engine driving device. The engine driving device comprises a driving part and a driven part, wherein the driving part comprises a driving shaft, a driving shaft sleeve, anda driving wheel; the inner hole of the driving shaft sleeve is a conical inner hole; the driven part comprises a driven shaft sleeve, and a driven wheel; the driven shaft sleeve is arranged on the driving shaft in a sleeving and sliding manner; the outer side wall of the left section of the driven shaft sleeve is matched with the shape of the conical inner hole of the driving shaft sleeve; a conical limited convex ring is arranged on the middle section of the driving shaft; a limited groove is formed in the inner hole of the driven shaft sleeve; a plurality of radial through holes are formed in the driven shaft sleeve; a short shaft is arranged in each radial through hole; a plurality of radial locking inner holes are also formed in the outer side wall of the left section of the driven shaft sleeve; a lock pin is arranged in each radial locking inner hole; a plurality of radial locking outer holes are formed in the wall of the conical inner hole of the driving shaft sleeve; and when adriven bearing is located at the left extreme position, the plurality of radial locking outer holes are connected to the plurality of radial locking inner holes in an abutting joint manner. The enginedriving device has the advantage that the quick connection or disconnection of the driving part and the driven part can be realized.

Owner:ANHUI JIANGHUAI NAVISTAR DIESEL ENGINE CO LTD

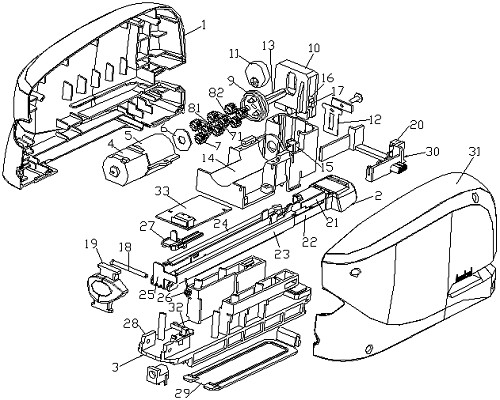

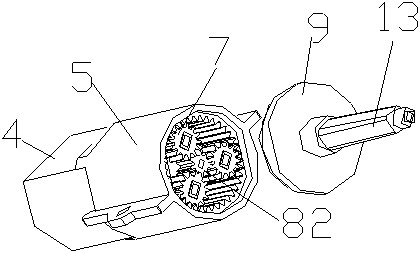

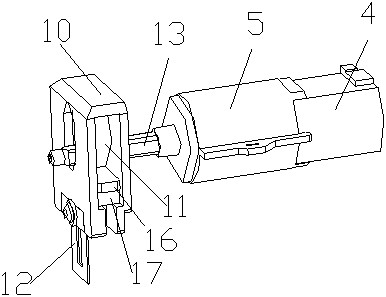

Electric stapler

InactiveCN111645034AChange distanceHigh transmission torqueStapling toolsNailing toolsStructural engineeringMechanical engineering

Owner:EAGLE SHAOGUAN STATIONERY TECH LTD

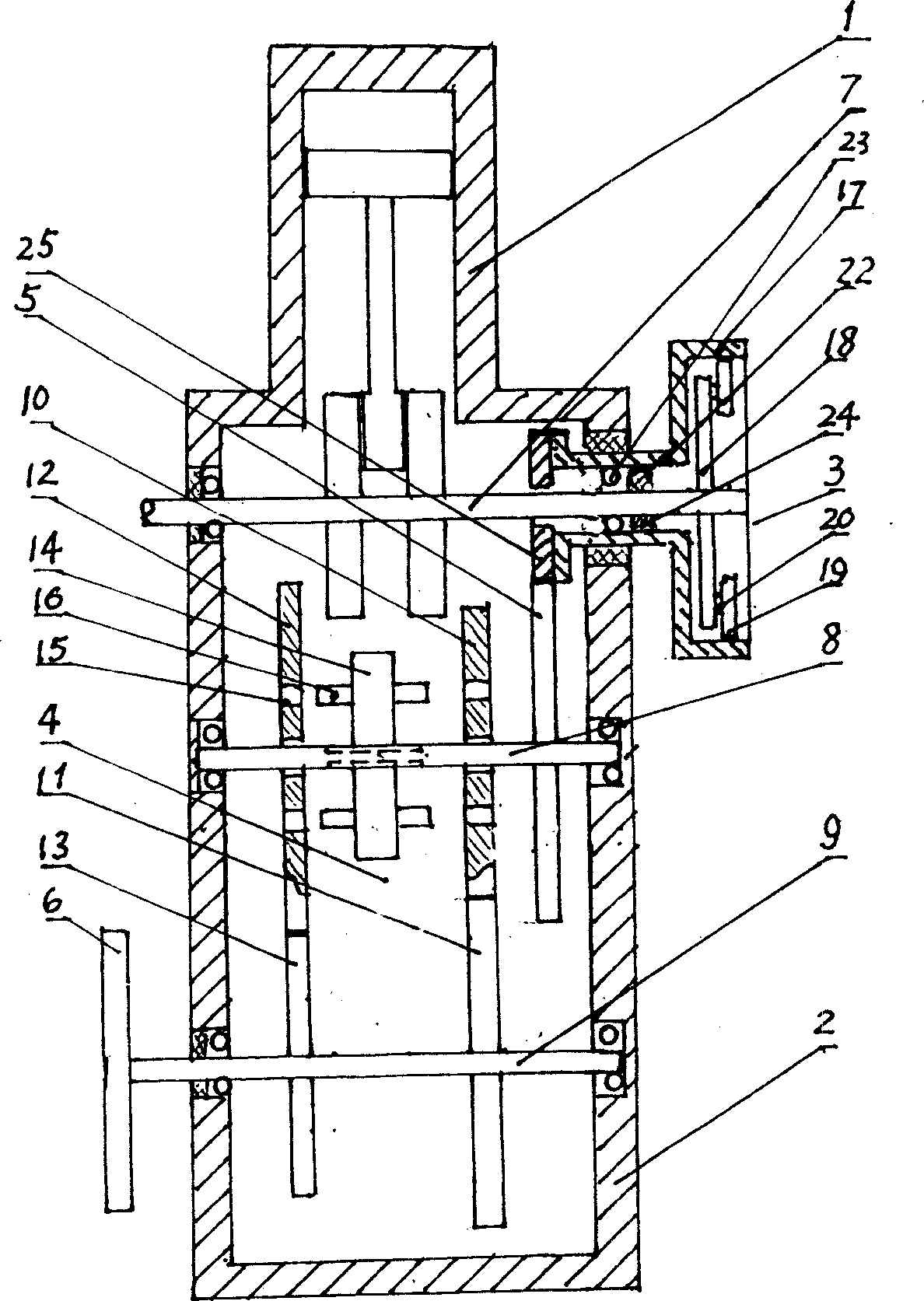

Externally arranged automatic clutch engine

InactiveCN1704570AIncrease frictionHigh transmission torqueGearing controlMachines/enginesGear driveCylinder head

This invention relates to an automatic clutch engine, comprising belonging to engine technology field, which can solve the technology problem by providing an external automatic clutch engine conveying huge force moment. The technical project goes as follows: the engine comprises cylinder and cylinder head association, housing, clutch, changeable cluster gear, selector, drive gear and pinion, wherein, the cylinder and its head association are mounted on the housing; bent axis, auxiliary axis and main axis are locate in the housing; the clutch is one the right section of bent axis, drive gear contacting with external gear of clutch is located in the main axis, the main gear of changeable cluster gear and selector are mounted in the main axis, and the secondary gear and pinion are mounted in the auxiliary axis; the bent axis drives the drive gear through clutch and the driven gear and pinion through master gear in each level. The invention is used in motorbicycle engine and has the advantage of large output torque.

Owner:重庆锦宏摩托车有限公司

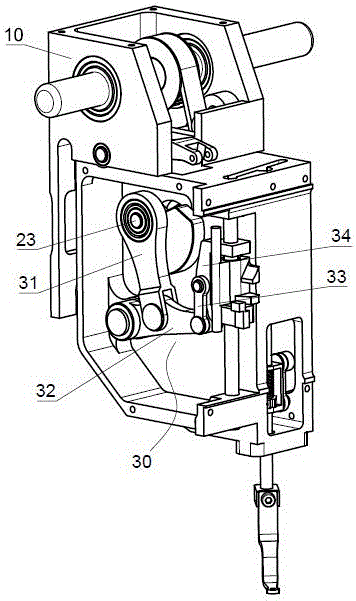

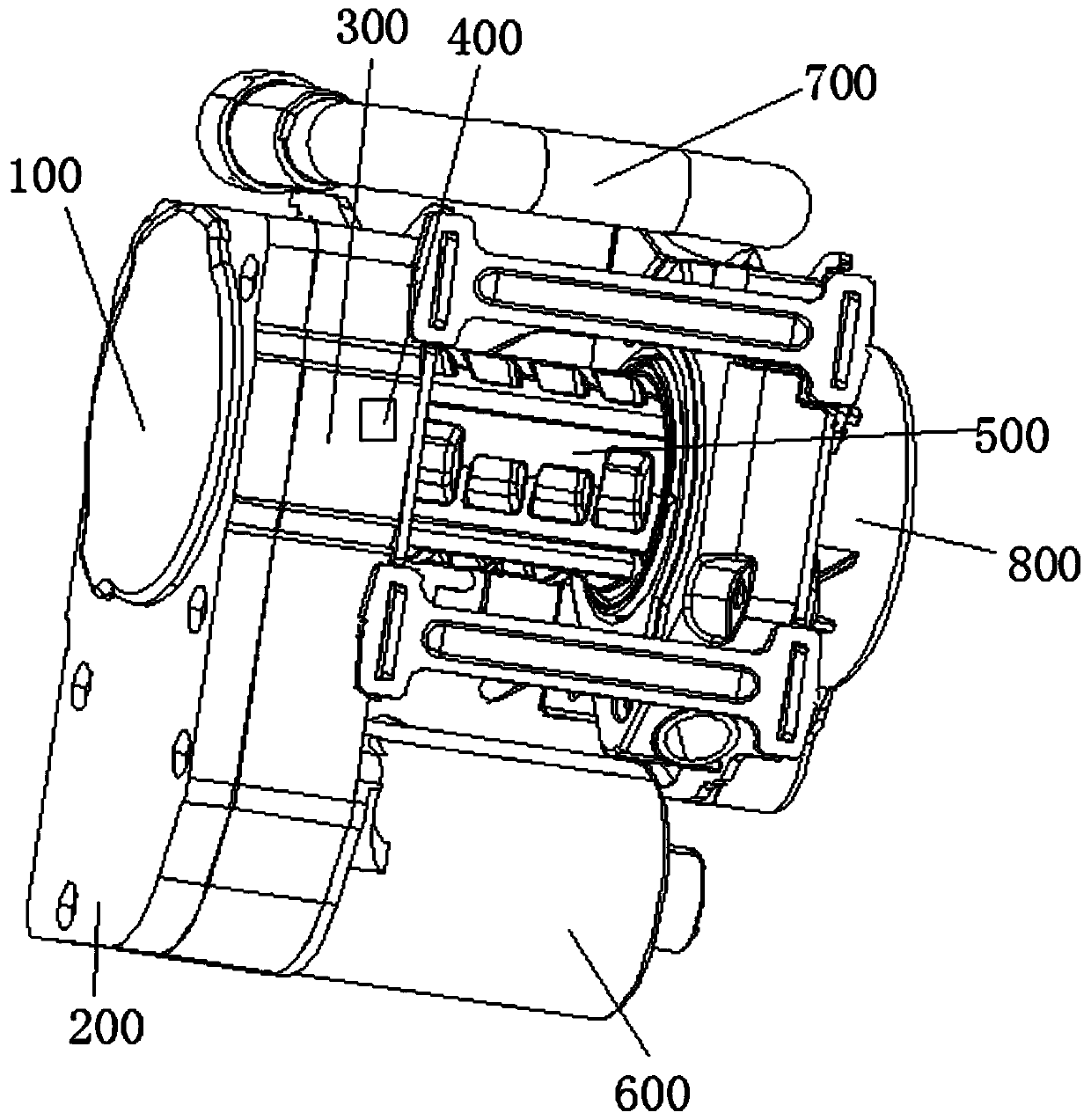

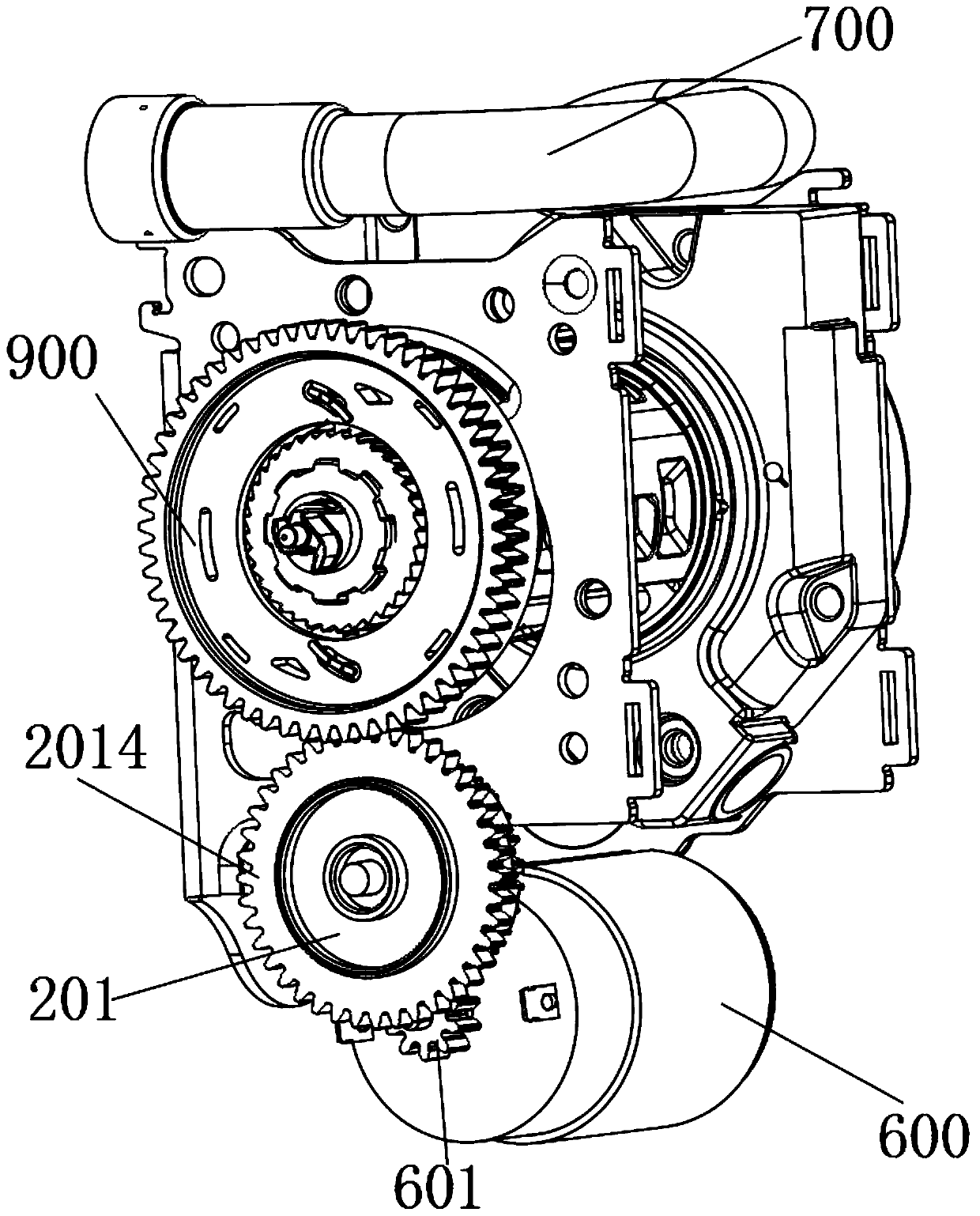

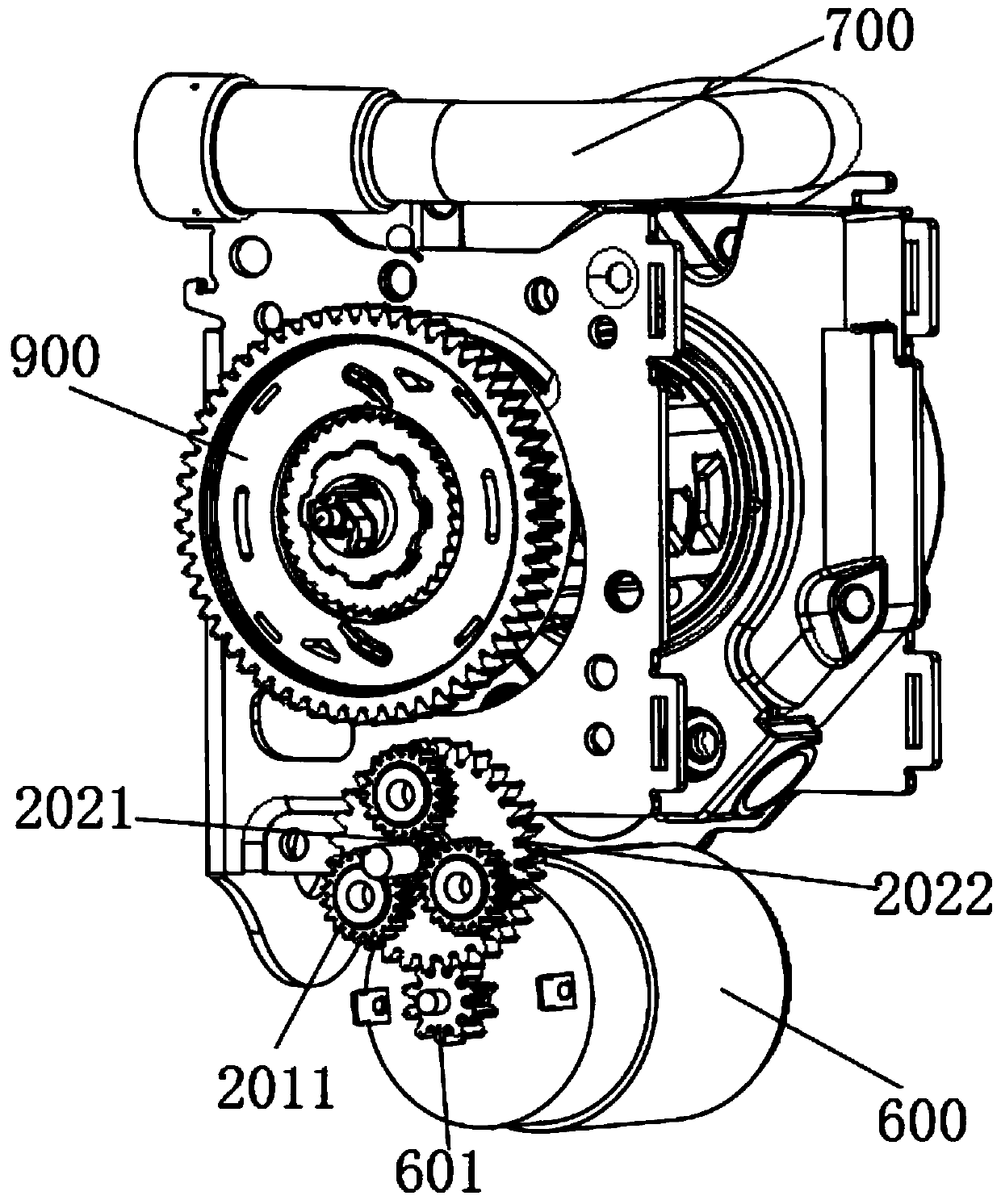

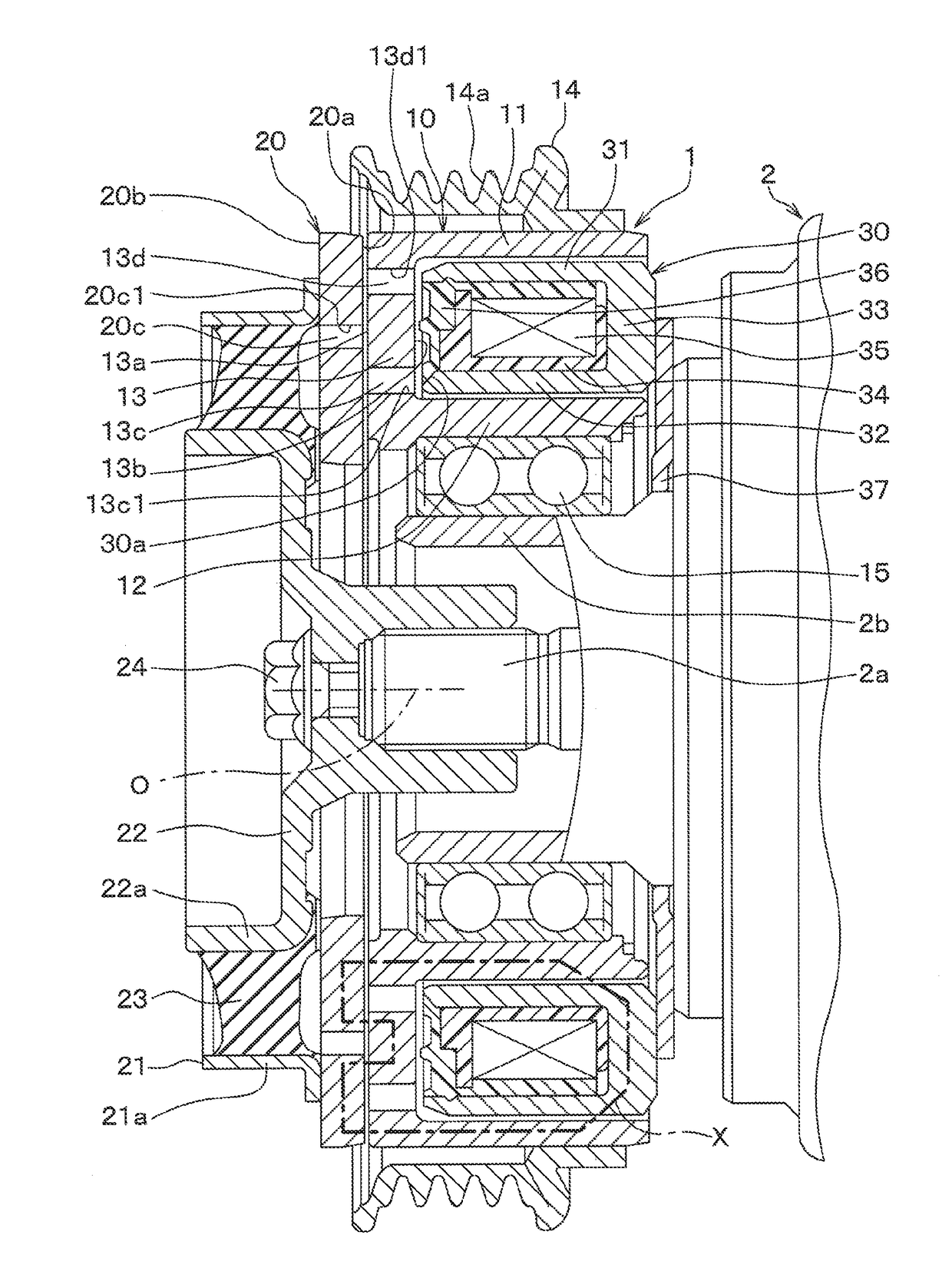

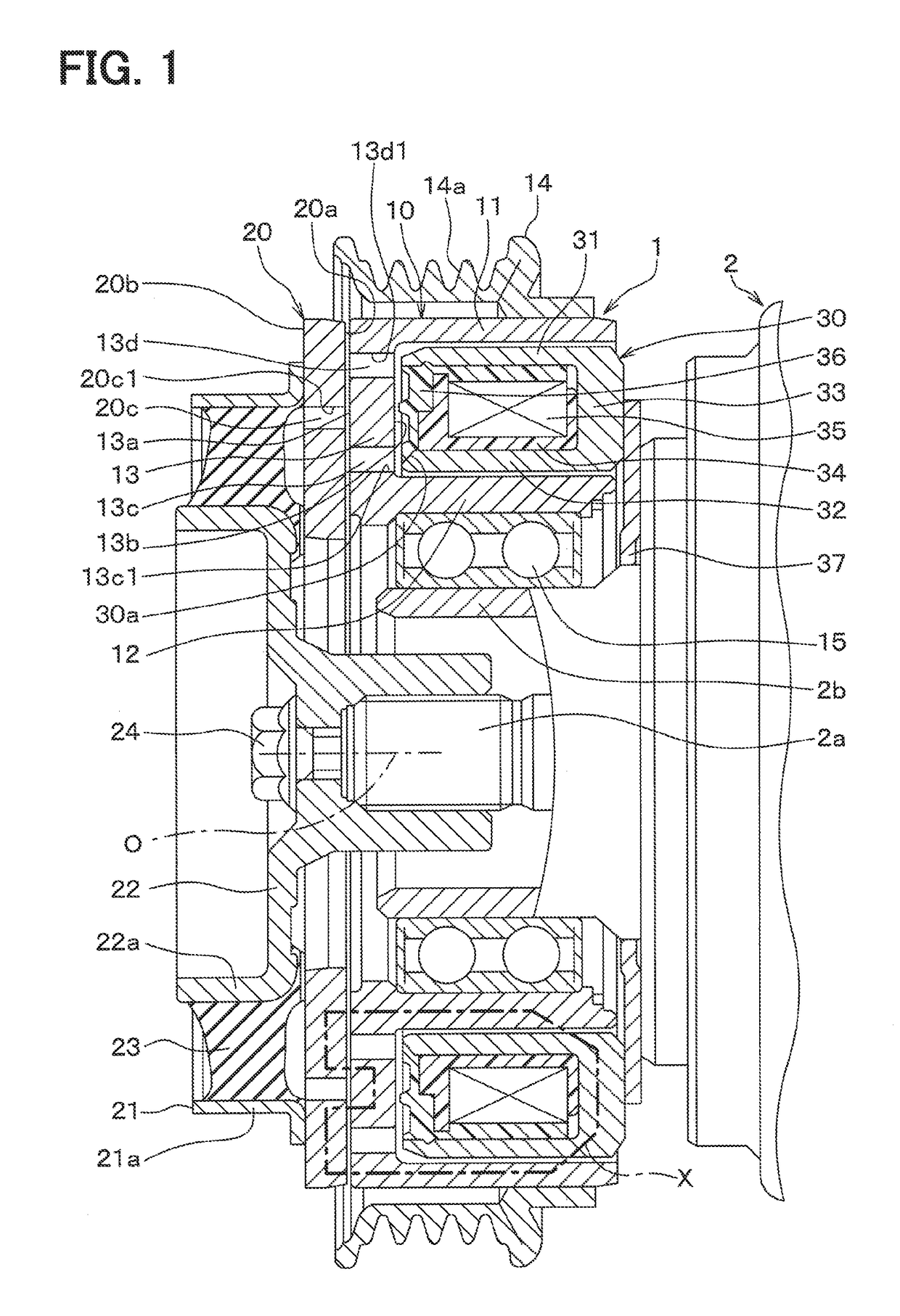

High-torque motor drive structure for safety belt, and safety belt winder

PendingCN111306261AForward and reverseSimple structureBelt retractorsToothed gearingsClutchElectric machinery

The invention discloses a high-torque motor drive structure for a safety belt, and a safety belt winder. The high-torque motor drive structure for the safety belt comprises a motor, a speed reductionmechanism assembly, a main gear, a clutch assembly and a mandrel assembly, wherein an output end of the motor is connected with the speed reduction mechanism assembly, an output end of the speed reduction mechanism assembly is in engagement connection with the main gear, the main gear is connected with the mandrel assembly through the clutch assembly, and the mandrel assembly is driven to rotate through the motor; a drive gear is arranged at an output end of the motor, the speed reduction mechanism assembly comprises a swing gear assembly, an eccentric structure assembly and a second-stage transmission gear, the eccentric structure assembly comprises an eccentric shaft and a first-stage transmission gear, and the eccentric shaft and the first-stage transmission gear are integrally arranged; the drive gear is in engagement connection with the first-stage transmission gear, the eccentric shaft is connected with the swing gear assembly, and the swing gear assembly is connected with the second-stage transmission gear; and during rotation of the drive gear, the drive gear is connected with the mandrel assembly through the clutch assembly, and the operation of driving the mandrel assembly to rotate through the motor is realized.

Owner:SHENYANG JINBEI JINHENG AUTOMOBILE SAFETY SYST CO LTD

Tractor for rail and road

PendingCN114132128AImprove operational performanceImprove stabilityBraking element arrangementsRail and road vehiclesDisc brakeVehicle frame

The invention relates to the technical field of rail-road dual-purpose traction locomotives, in particular to a rail-road dual-purpose tractor which comprises a front frame and a rear frame. The front frame and the rear frame are hinged and are self-locked through a steering self-locking device; a guide wheel and a driving wheel are respectively arranged on the front frame and the rear frame; a guide wheel self-locking device is arranged on the guide wheel, and the axle of the front frame and the axle of the rear frame are split type axles. The self-locking function after lifting of the guide wheels is achieved through the guide wheel self-locking device, the self-locking function after steering of the tractor is achieved through the steering self-locking device, snow removal is conducted on a steel rail through the tractor snow removal device, meanwhile, the split type axle is adopted, a disc brake mode is adopted, heat dissipation is facilitated, a force transmission structure is changed through the differential mechanism assembly, and the traction effect is improved. The transmission torque is increased, and the traction force of the tractor is improved. Through the design, the operation is simpler, and the safety performance and the working efficiency are improved.

Owner:山东智捷专用车制造有限公司

Speed changer used for tractor

ActiveCN103161888AImprove athletic abilityTransmission of large torque increasesToothed gearingsGearing detailsGear wheelControl theory

The invention discloses a speed changer used for a tractor. The speed changer used for the tractor comprises a speed changer body, a cone gear I (8), a two-tap position installing-changing device and a cone gear II (9), wherein the speed changer body is provided with a tap position gear (25), the cone gear I (8) is connected with a speed-changing tap position gear shaft of the speed changer body, the two-tap position installing-changing device is connected with an range shift device and the cone gear II (9) is connected with an input shaft of the two-tap position installing-changing device in a meshed mode. The cone gear I (8) is installed to be connected with cone gear II (9) in a meshed mode. Deceleration is achieved on the speed-changing tap position gear shaft of the speed changer body. The cone gear I (8) and the cone gear II (9) can be used as intermediate gears so as to enlarge a transmitting torsion of the speed changer and improve a movement performance of the speed changer.

Owner:泰安泰山国泰拖拉机制造有限公司

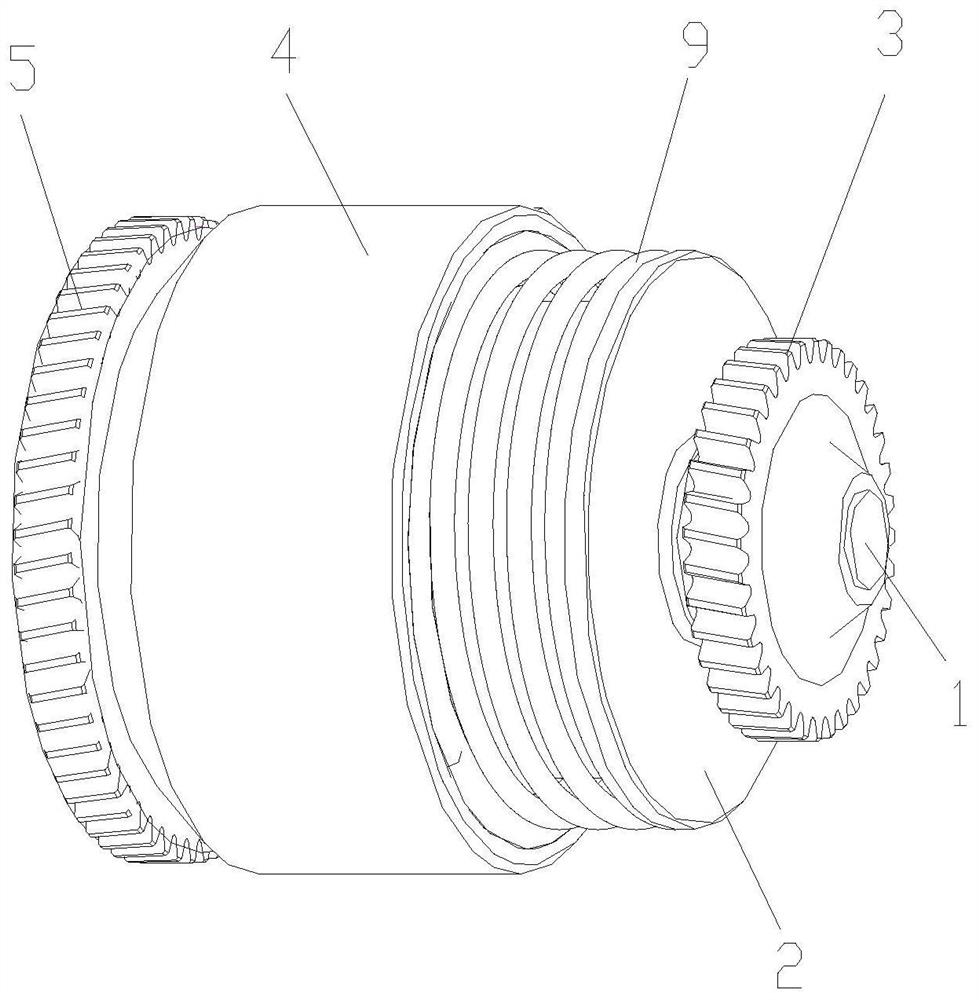

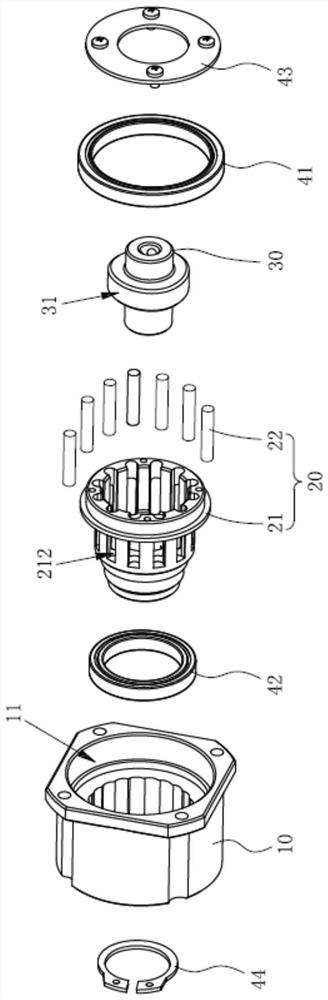

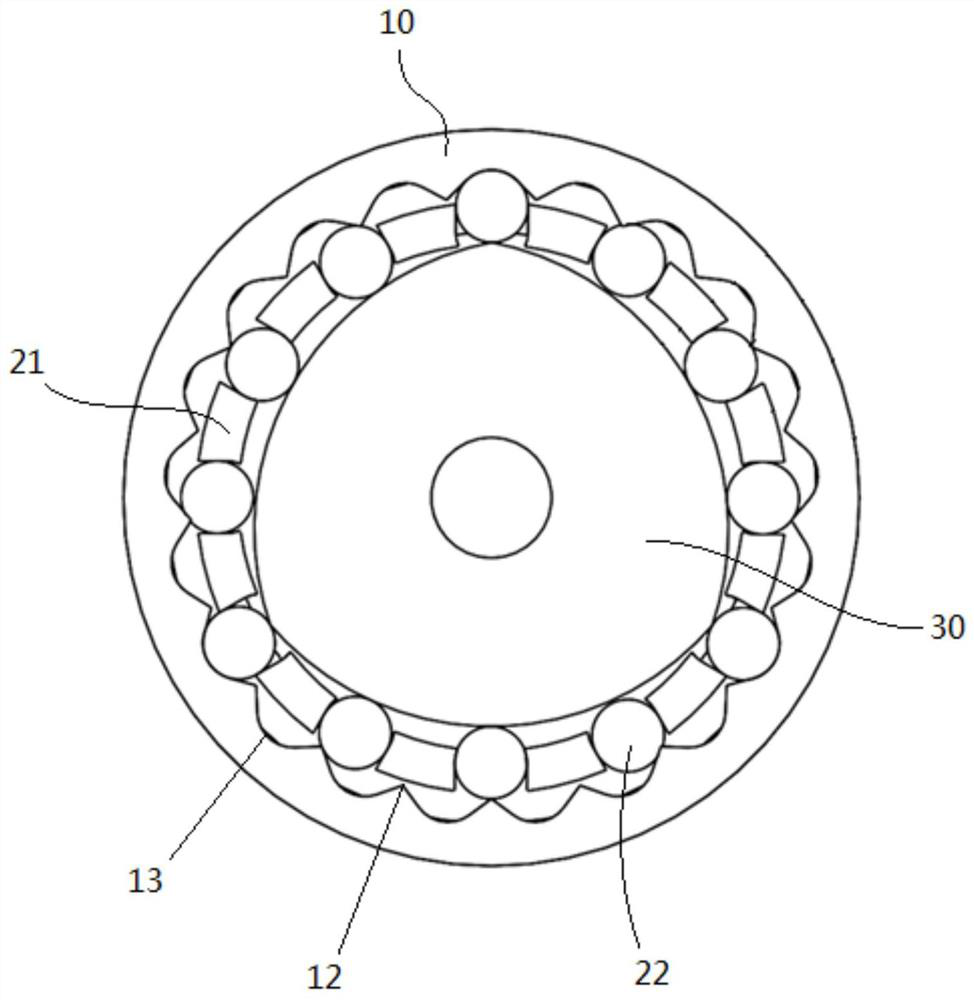

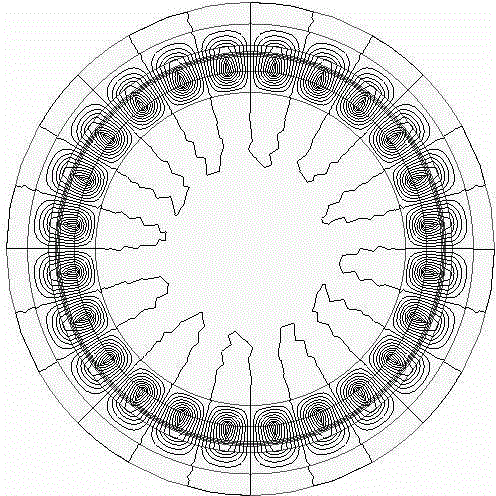

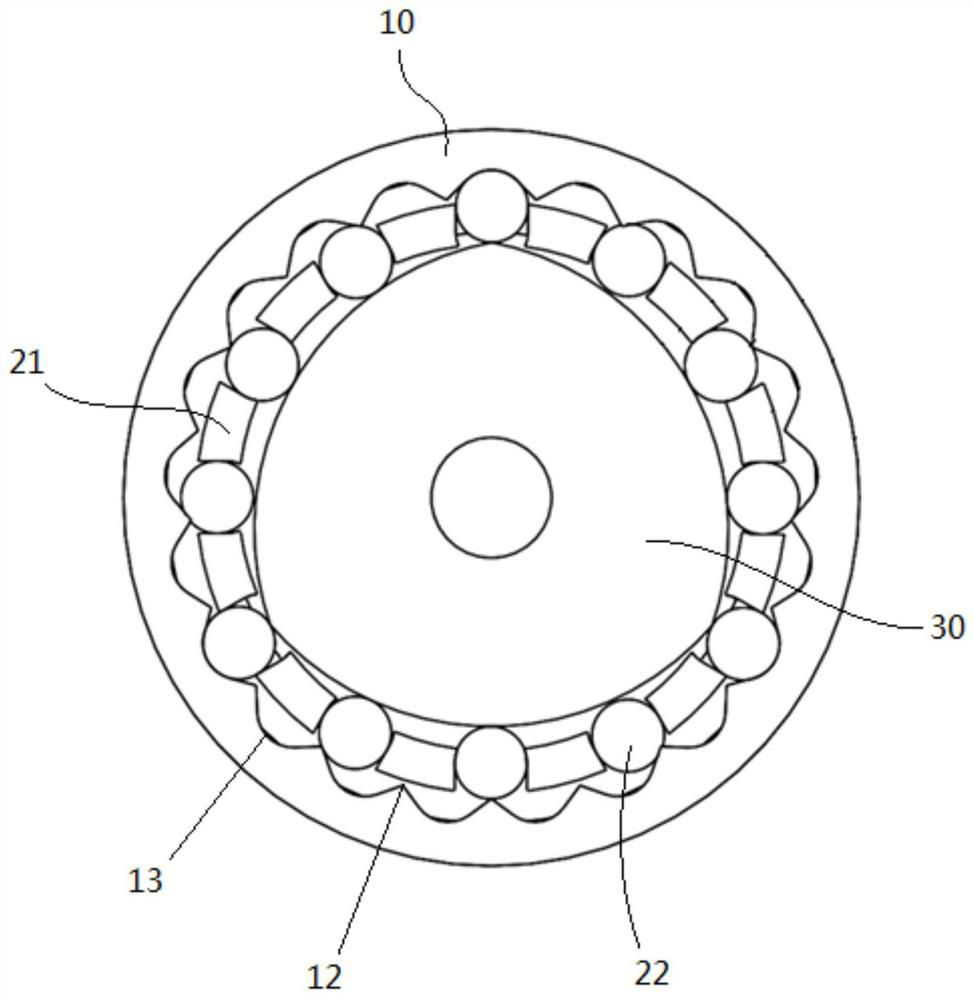

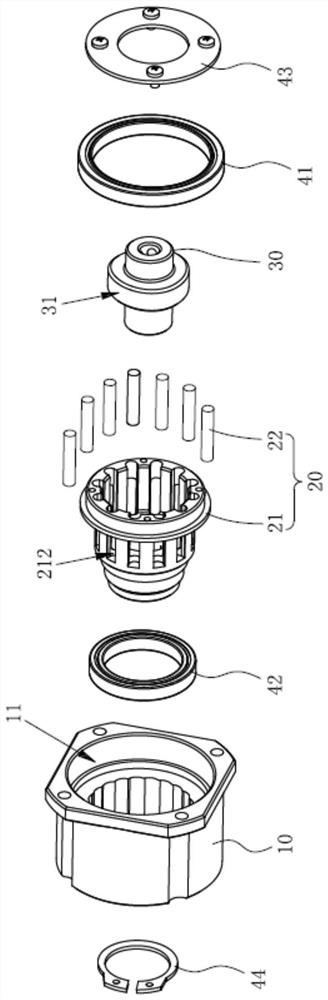

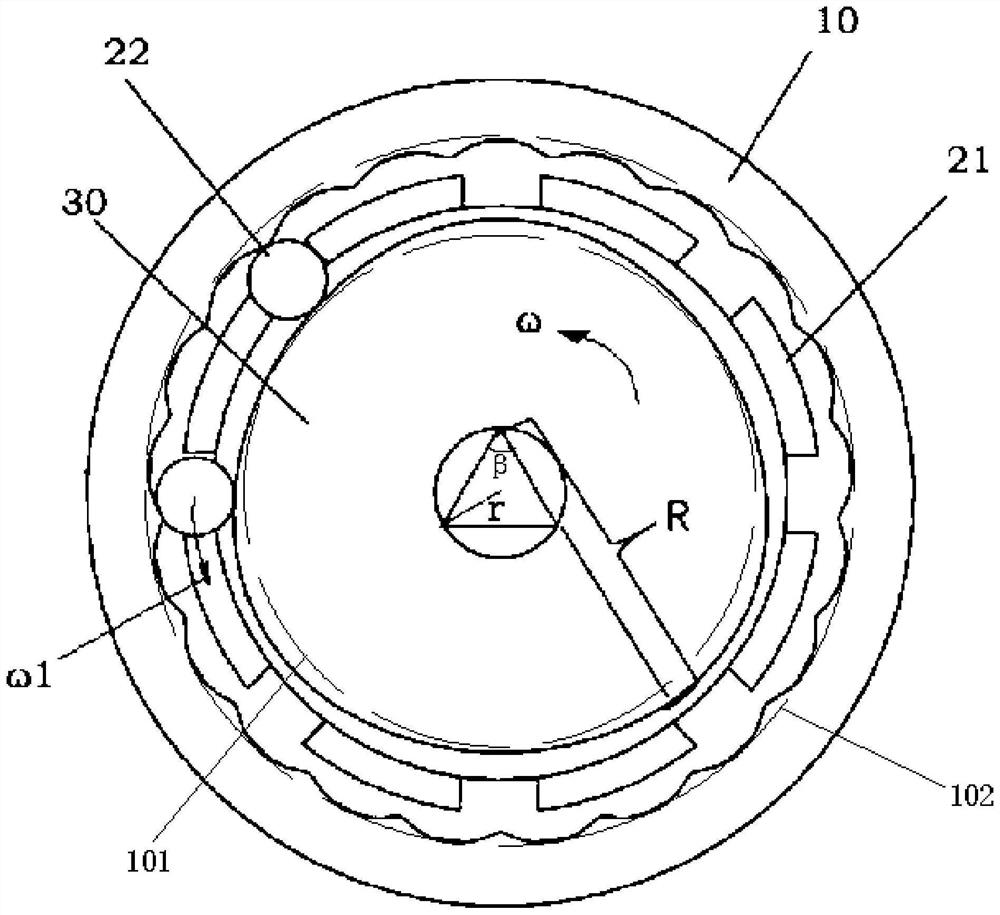

Forming design method for speed reducer

ActiveCN111895058AFlexible sizeReduce manufacturing costDesign optimisation/simulationCAD circuit designReduction driveDrive shaft

The invention belongs to the technical field of speed reducers, and particularly relates to a forming design method for a speed reducer. The speed reducer designed through the forming design method comprises an outer gear ring, rollers and a driving shaft, wherein the outer gear ring is a stator, the driving shaft rotates on its axis and drives the rollers to rotate, the rollers revolve around thedriving shaft, and the contour line of the cross section of the driving shaft is an equal-width curve. The above data are customized according to actual needs: m, n, r, R and Q, the multiple rollersare arranged on a grid, and then design calculation is carried out by using the parameters to obtain the tooth profile of the outer gear ring. By applying the technical scheme of the forming design method for the speed reducer, the novel planetary gear speed reducer can be designed and obtained, so that the problem of lack of a speed reducer which not only meets the requirements of simple design structure and small size, but also realzies flexible speed reduction ratio matching design in the prior art is solved.

Owner:深圳市泉锲科技有限公司

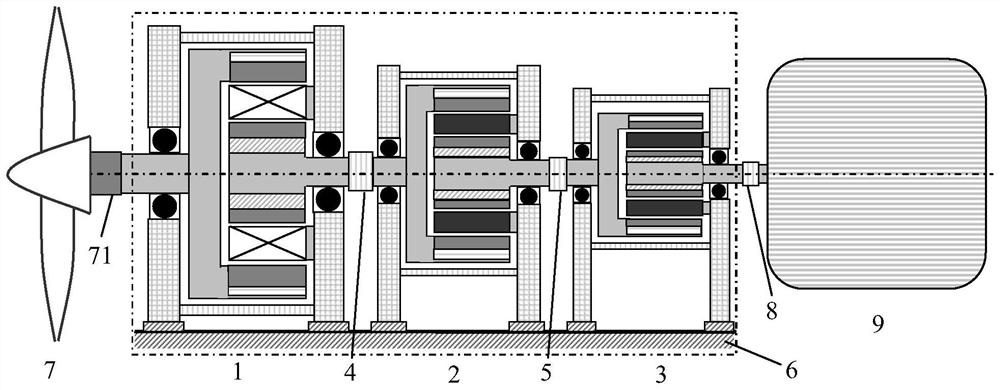

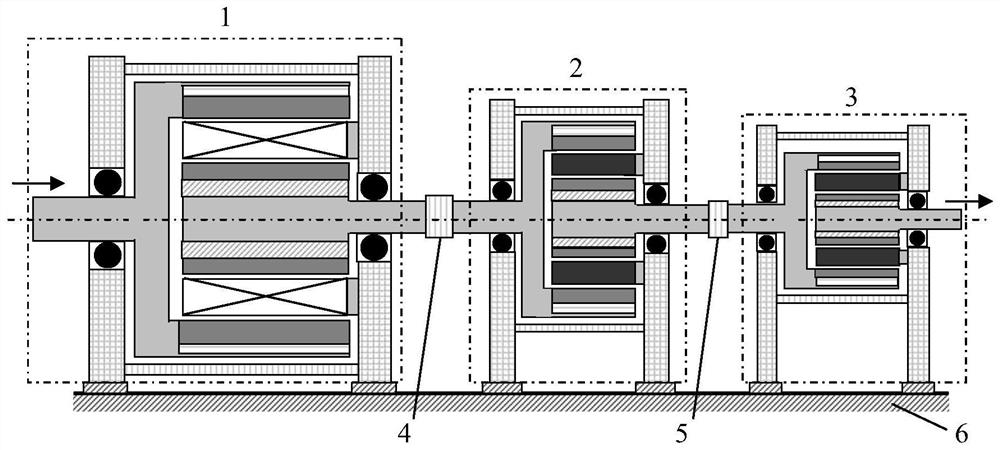

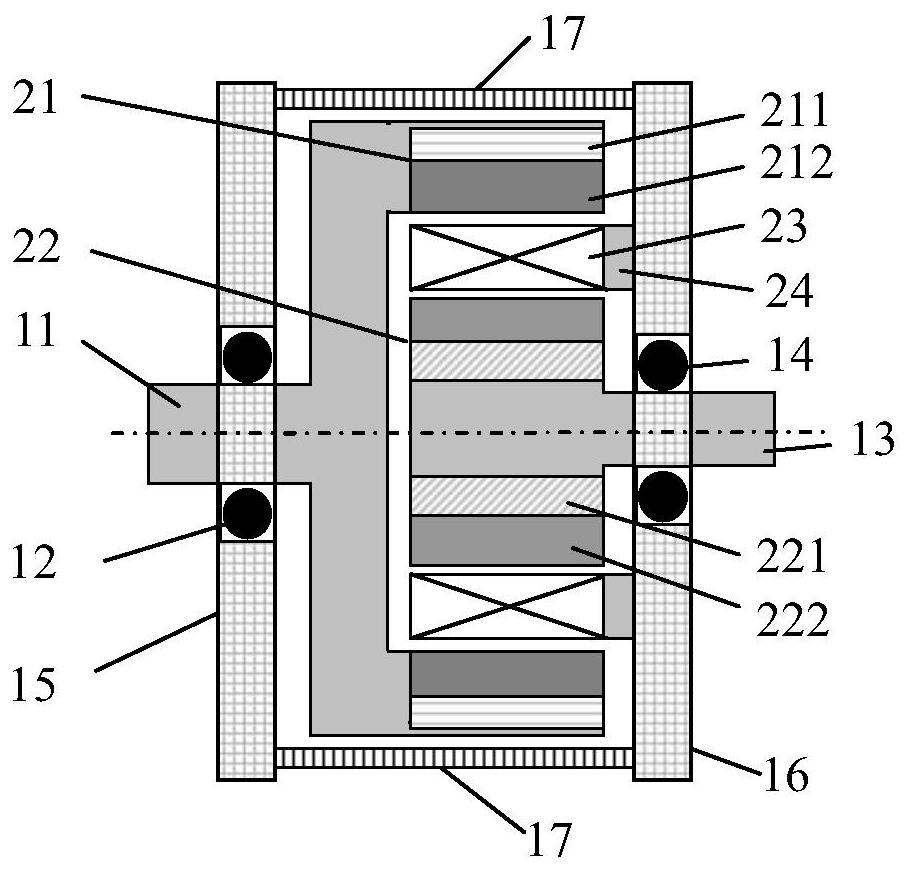

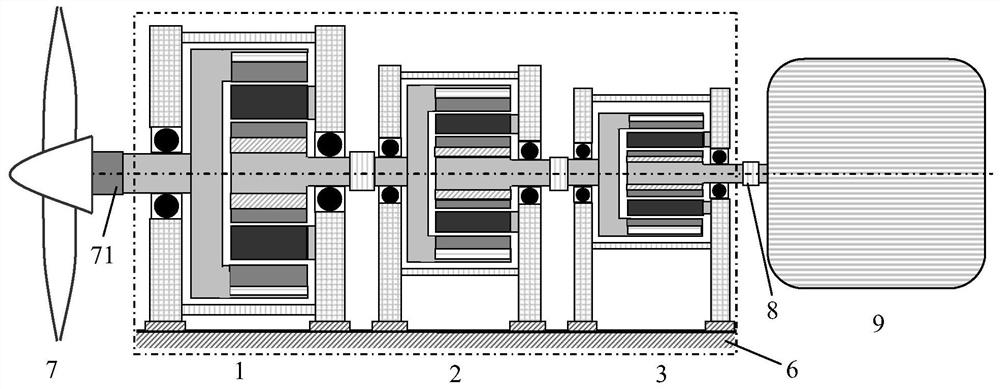

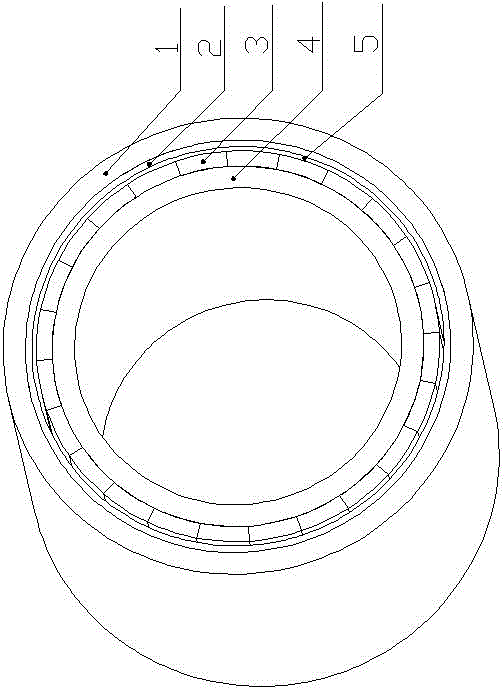

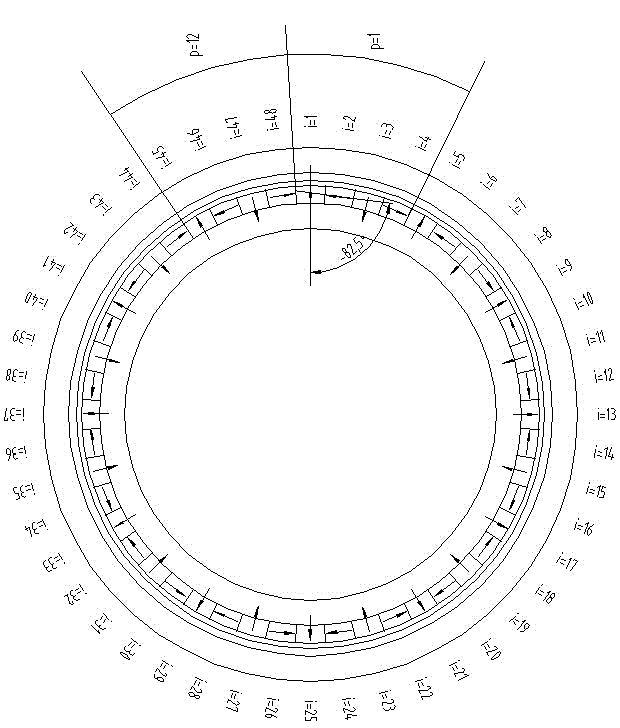

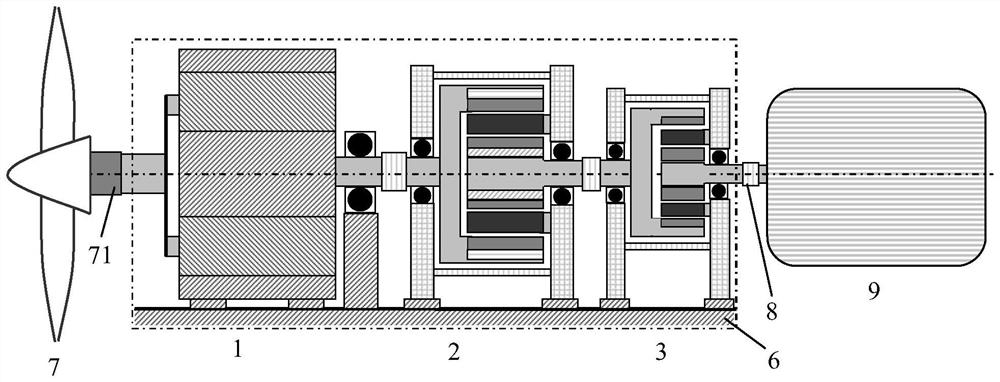

Controllable integrated magnetic gear box for high-power wind driven generator

InactiveCN113659798ASolving resonance problemsAchieve mechanical isolationPermanent-magnet clutches/brakesMechanical energy handlingGear wheelDrive shaft

The invention relates to a controllable integrated magnetic gear box for a high-power wind driven generator, which belongs to the field of wind power. The controllable integrated magnetic gear box comprises a first-stage controllable integrated coaxial magnetic gear, a second-stage coaxial magnetic gear, a third-stage coaxial magnetic gear and the like. The first-stage controllable integrated coaxial magnetic gear comprises a first driving shaft, a first driven shaft, a first outer rotor magnetic gear, a first inner rotor magnetic gear and a magnetic adjusting stator; the magnetic adjusting stator comprises a magnetic adjusting iron core block and an armature winding; each of the second-stage coaxial magnetic gear and the third-stage coaxial magnetic gear comprises a driving shaft, a driven shaft, an outer rotor magnetic gear, an inner rotor magnetic gear and a magnetism adjusting ring; the first driving shaft is connected with the wind wheel main shaft; the first driven shaft is connected with a driving shaft of the second-stage coaxial magnetic gear; the driven shaft of the second stage is connected with the driving shaft of the third stage; and the driven shaft of the third stage is fixed with the rotating shaft of the generator. The device is free of lubrication, light in weight, low in operation and maintenance cost, large and controllable in transmission torque and capable of assisting in controlling the rotating speed of a generator and prolonging the service life of a unit.

Owner:QUFU NORMAL UNIV

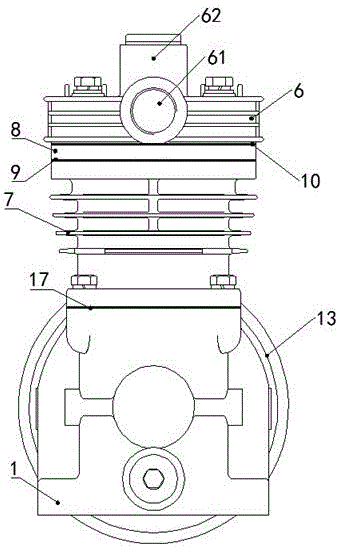

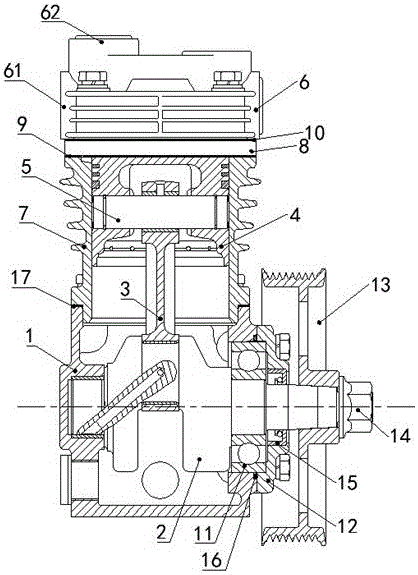

Air compressor for vehicle

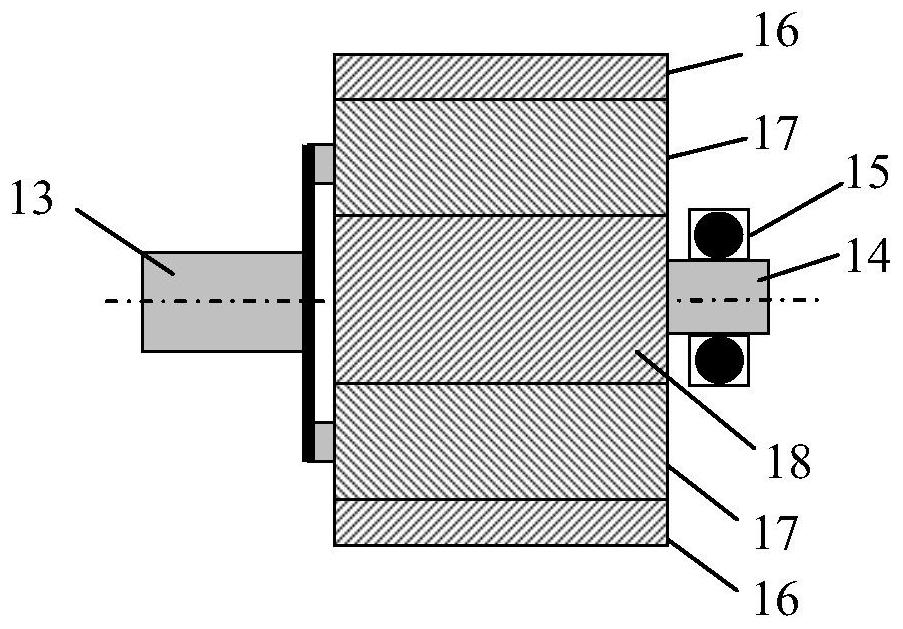

InactiveCN105927501AAvoid scorchingHigh transmission torqueEngine sealsPositive displacement pump componentsPistonGraphite composite

The invention discloses an air compressor for a vehicle. The air compressor comprises a crankcase (1), a crankshaft (2), a connecting rod (3), a piston (4), a piston pin (5), an air cylinder cover (6) and an air cylinder body (7). One side of the crankcase (1) is provided with a bearing (11) and is fixed through a bearing gland (12). One end of the crankshaft (2) penetrates the bearing (11) and the bearing gland (12) and is fixedly connected with a multi-wedged pulley (13) through a hexagonal flange nut (14). An oil seal (15) is arranged at the connecting position of the bearing gland (12) and the crankshaft (2). A notch is formed in a cooperative compressing face of the crankcase (1) and the bearing gland (12). An O-shaped rubber sealing ring (16) is arranged in the notch. By means of the air compressor, the multi-wedged pulley is adopted, the transmission torque is large, the service life of a belt is long, and running is stable; and a flexible graphite composite reinforcement plate is adopted for a cylinder cover gasket, and therefore the gasket is prevented from being coked after being subjected to the high temperature.

Owner:DANYANG CHANGSHENG MACHINERY

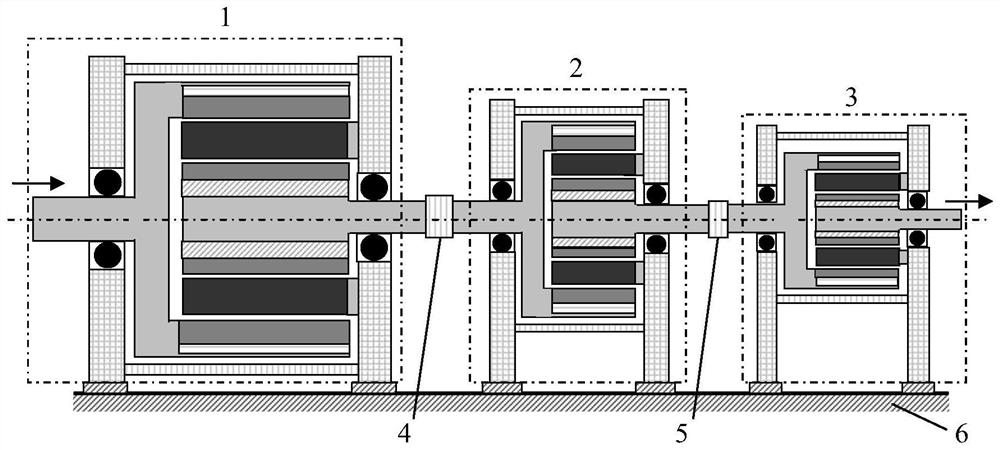

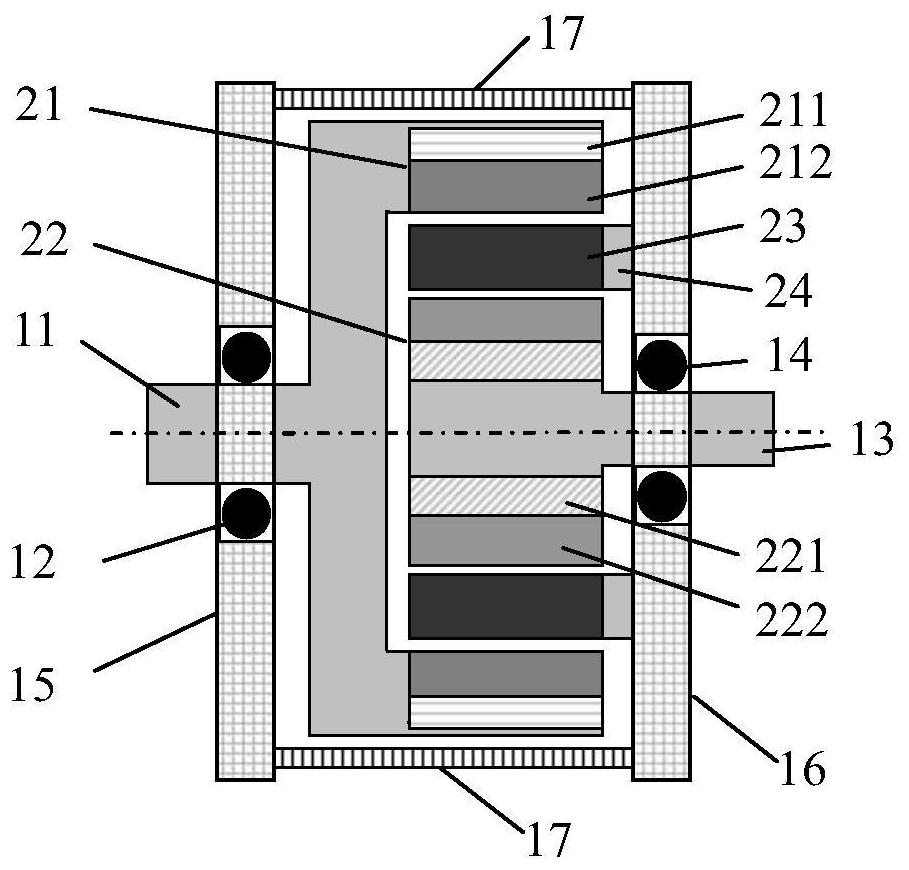

Magnetic gear box for high-power wind driven generator

InactiveCN113659799AAchieve mechanical isolationSolving resonance problemsPermanent-magnet clutches/brakesMechanical energy handlingDrive shaftGear wheel

The invention relates to a magnetic gear box for a high-power wind driven generator, awhich belongs to the field of wind power. The magnetic gear box comprises a first-stage coaxial magnetic gear, a second-stage coaxial magnetic gear, a third-stage coaxial magnetic gear, a first coupler, a second coupler and the like. Each coaxial magnetic gear comprises a driving shaft, a driving shaft bearing, a driven shaft, a driven shaft bearing, a left end plate, a right end plate, a plurality of brackets, an outer rotor magnetic gear, an inner rotor magnetic gear and a magnetic adjusting ring; a driving shaft of the first-stage coaxial magnetic gear is connected with the wind wheel main shaft through a shrinkage sleeve; a driven shaft of the first-stage coaxial magnetic gear is connected with a driving shaft of the second-stage coaxial magnetic gear through a first coupler; a driven shaft of the second-stage coaxial magnetic gear is connected with a driving shaft of the third-stage coaxial magnetic gear through a second coupler, and a driven shaft of the third-stage coaxial magnetic gear is fixed to a rotating shaft of the wind driven generator through a coupler. The device is free of lubrication, small in size, light in weight, large in transmission torque and capable of greatly reducing the operation and maintenance cost and improving the reliability.

Owner:QUFU NORMAL UNIV

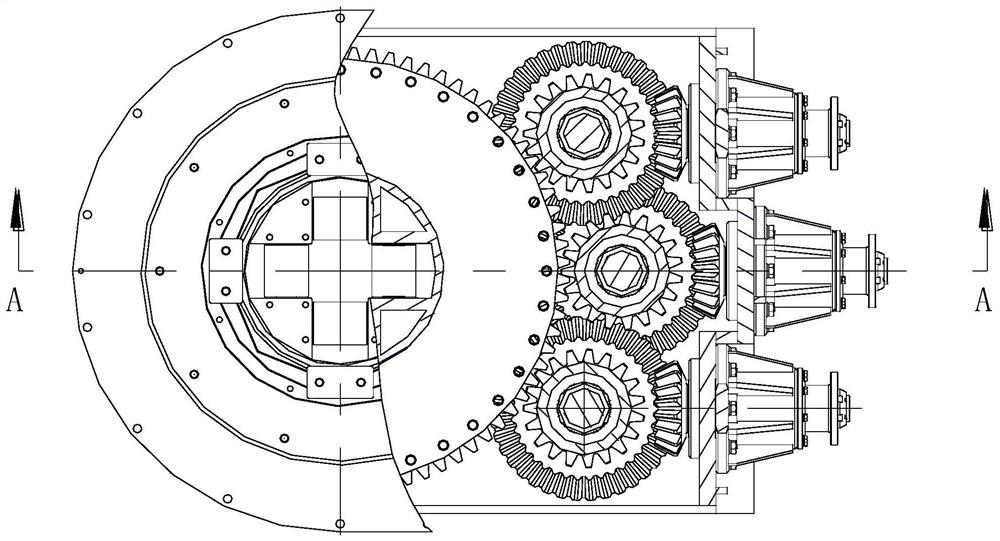

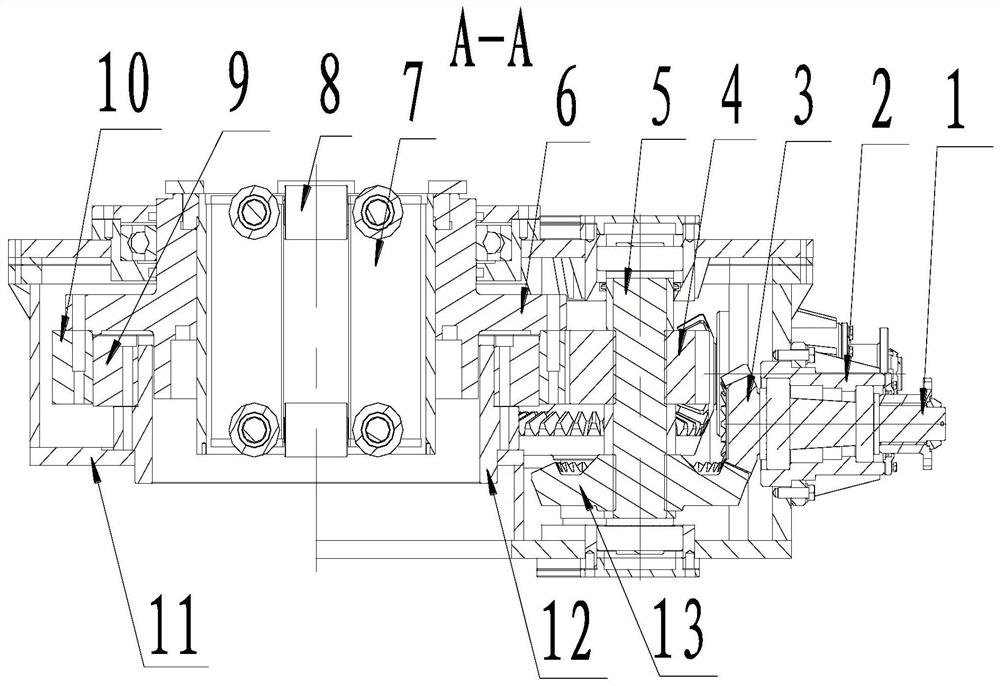

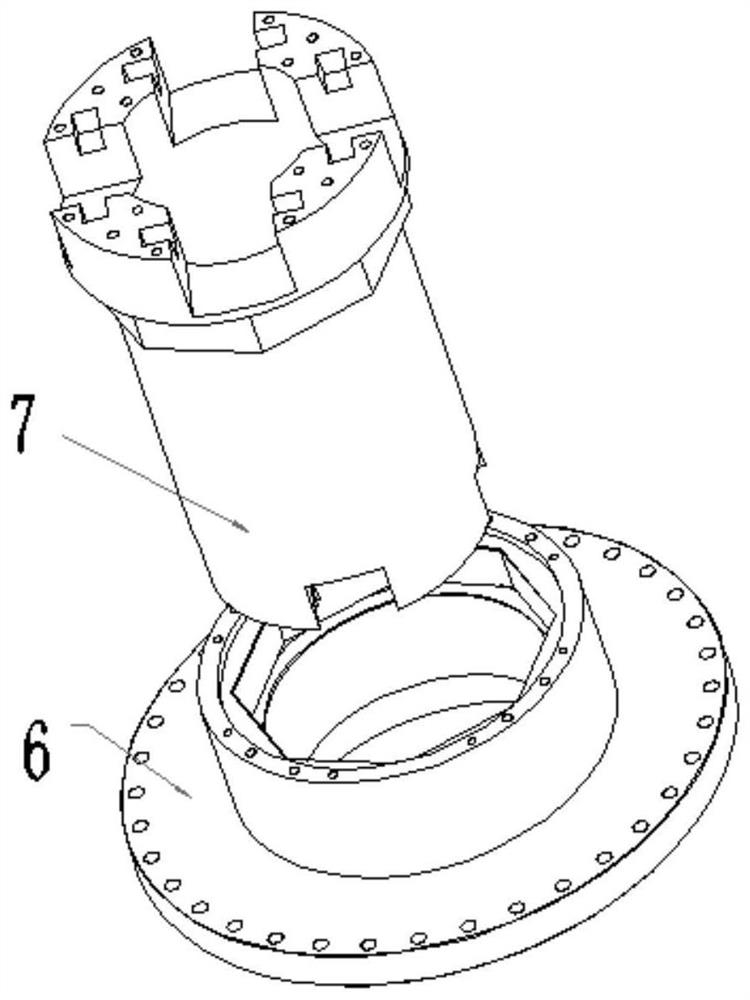

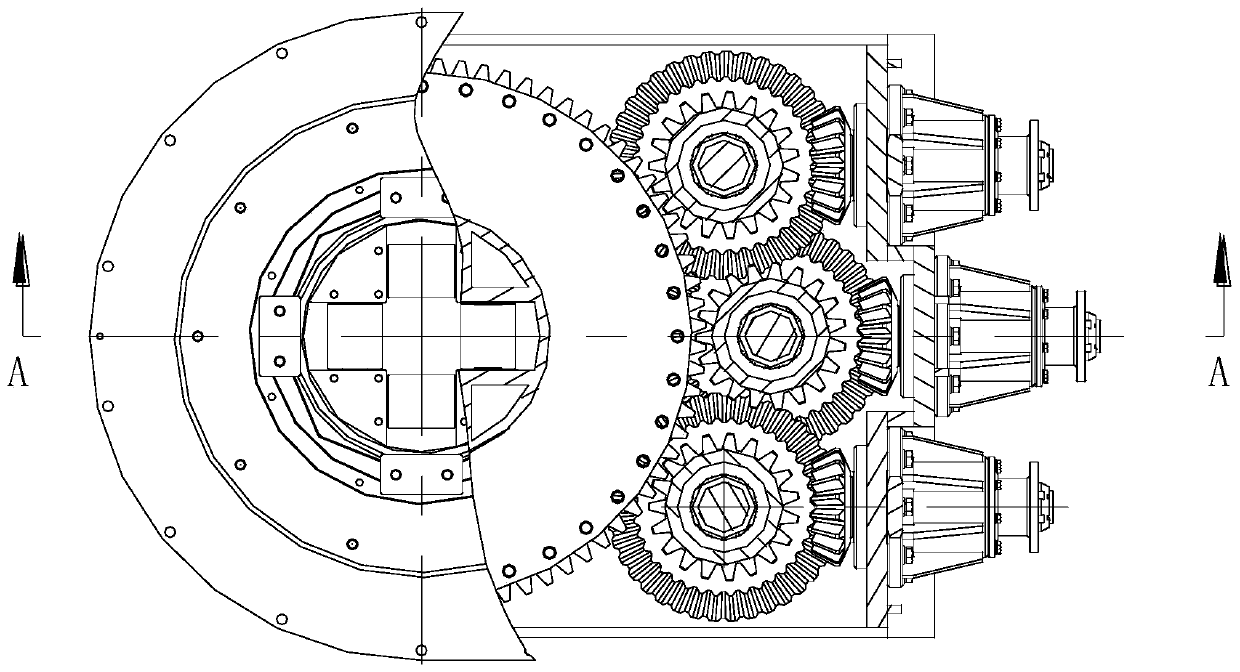

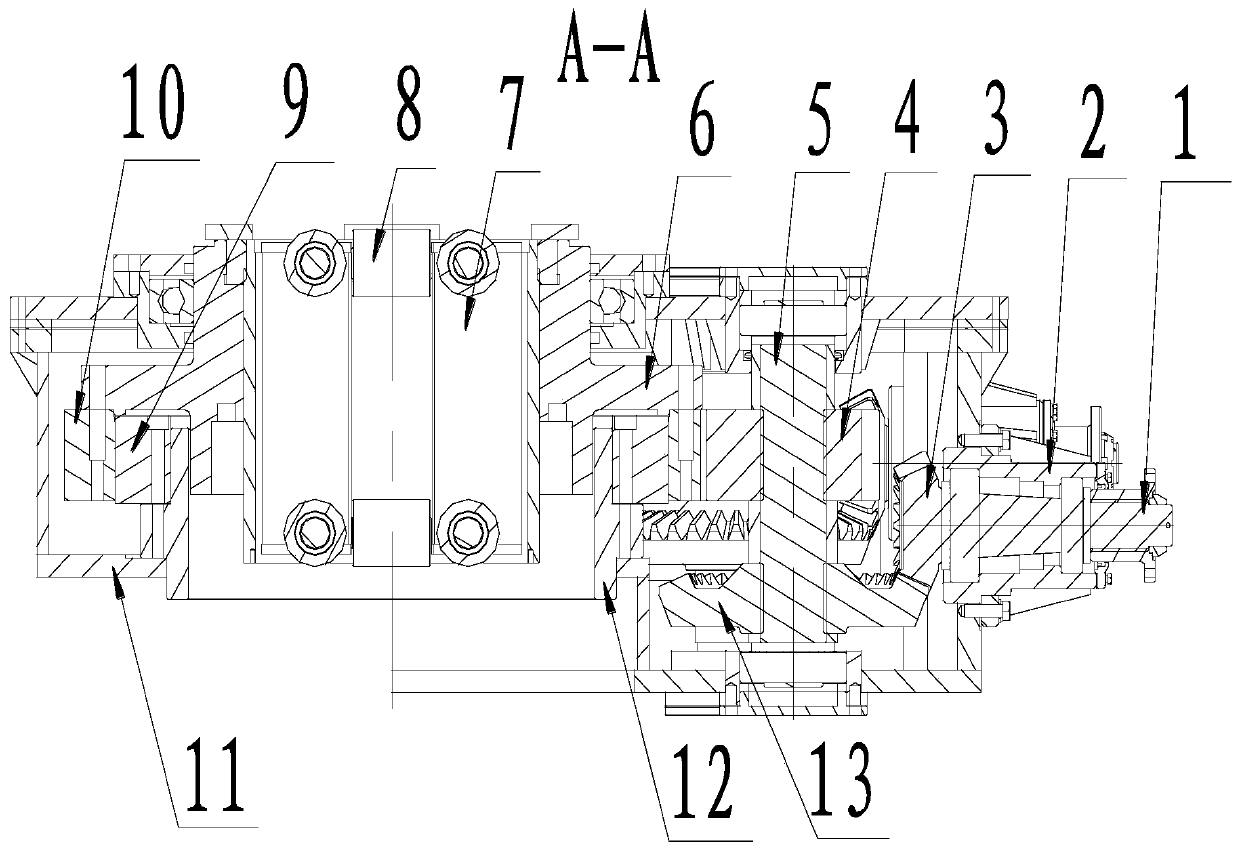

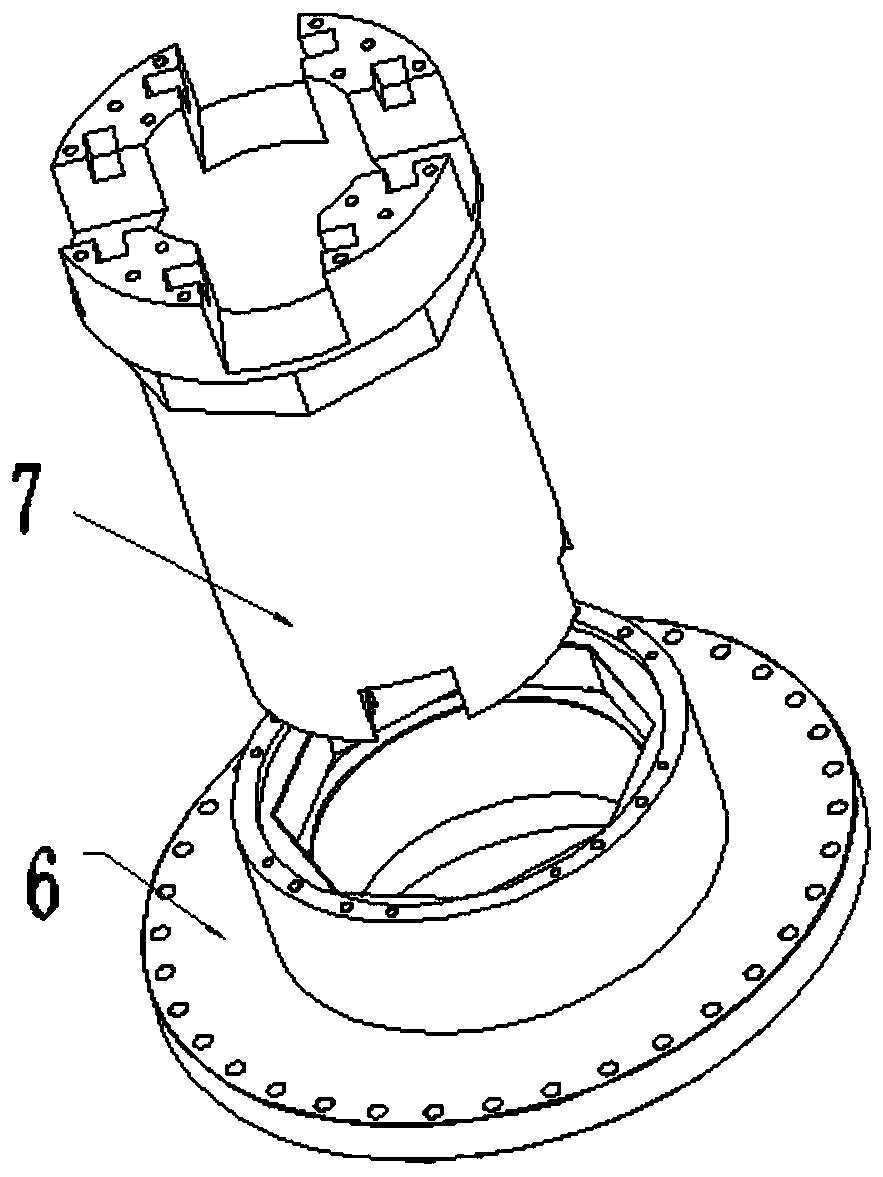

A bottom-mounted multi-input rotary turntable device

InactiveCN110685595BSmall footprintEasy to installDrilling machines and methodsGear wheelEngineering

The invention relates to the technical field of engineering machinery, particularly to an underneath type multiple-input rotation rotating table device. According to the invention, a power system is meshed with a second shaft bevel gear wheel through a bevel gear wheel at the front end of a first shaft, so as to transmit power to the second shaft and realize reversing from the vertical rotation tohorizontal rotation; a spur gear on the second shaft is used for transmitting power to a slewing bearing spur gear, horizontal rotation of the slewing bearing spur gear is used for driving a force taking table fixed on the slewing bearing spur gear to rotate horizontally; the force taking table is hollow, and an inner octangle is arranged at the upper part of the force taking table; an outer octangle at the upper part of a core supplementing wheel carrier is embedded inside the force taking table; drill pipe core supplementing wheels are mounted at the inner upper part and the lower part of the core supplementing wheel carrier, so as to drive a drill pipe inserted therein to complete rotation of the drill pipe. The underneath type multiple-input rotation rotating table device has the characteristics of stable running, big driving torque, long service life, flexible operation and the like.

Owner:陈腊根

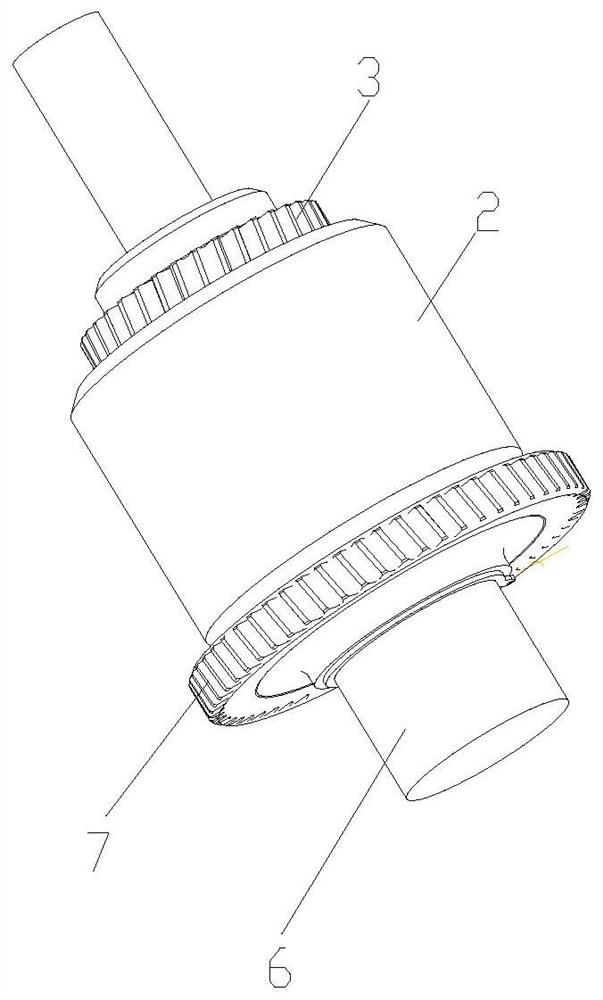

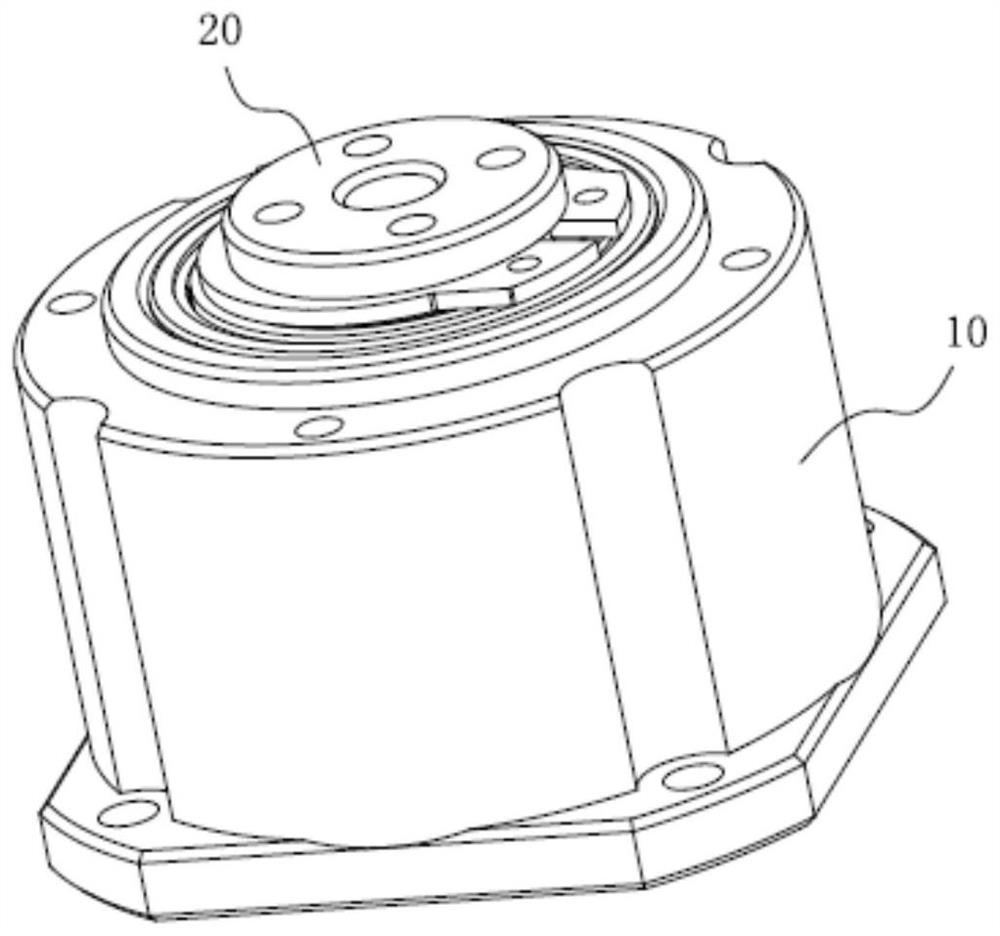

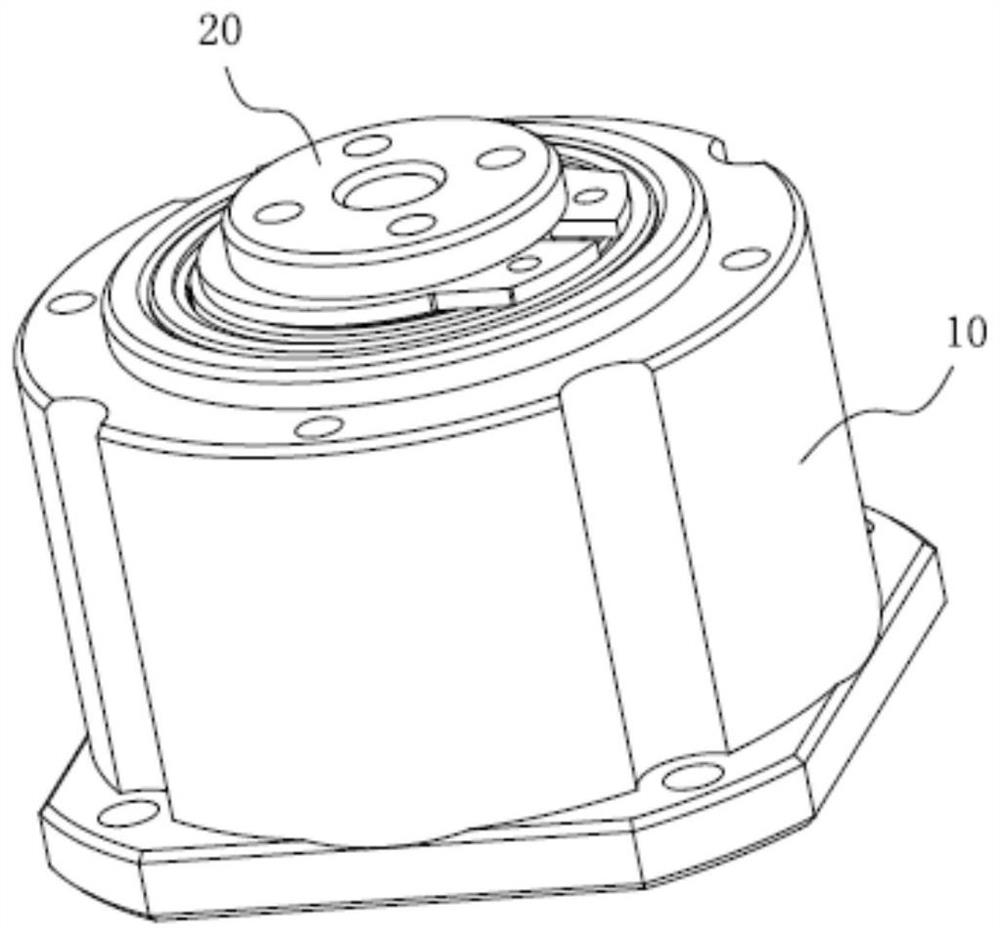

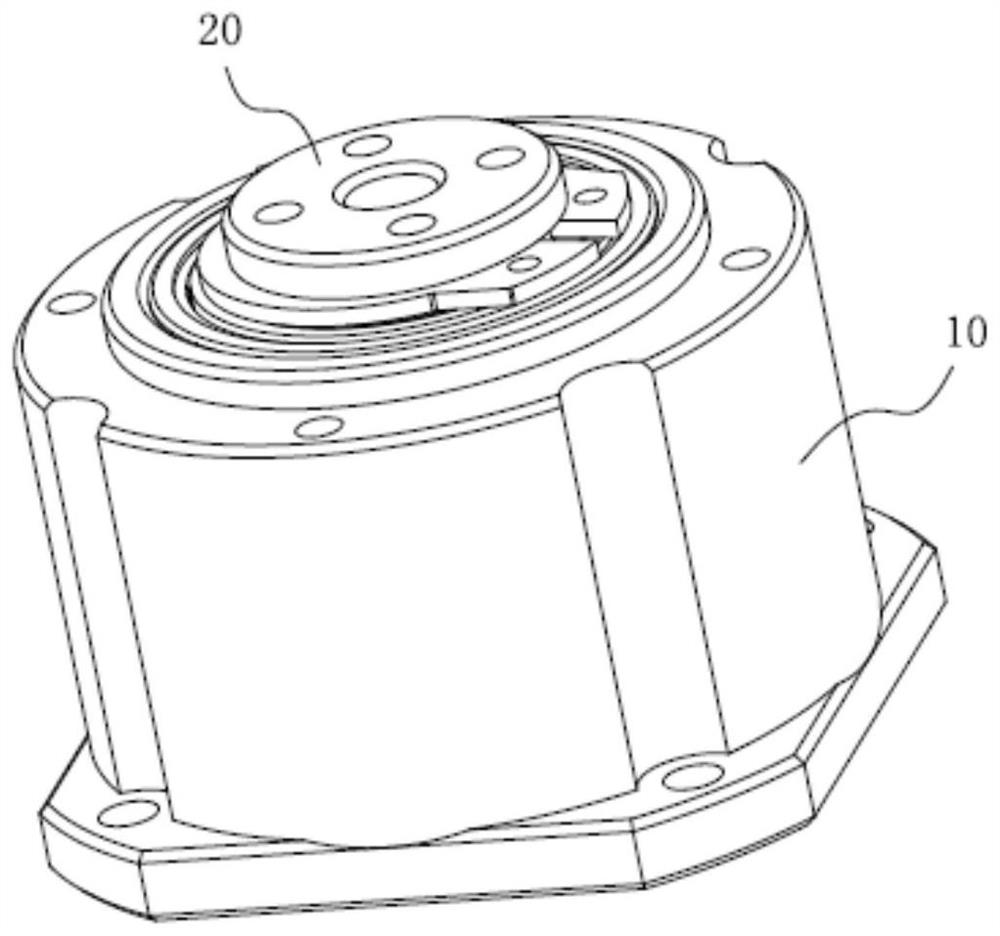

Coaxial servo drive device

PendingCN108199524AImprove stabilityCompact structureMagnetic circuit rotating partsMechanical energy handlingMechanical wearDrive motor

The invention provides a coaxial servo drive device. The coaxial servo drive device comprises a servo drive roller; the shaft end of the roller is provided with a drive motor; the drive motor comprises a stator and a rotor body arranged in the stator; the rotor body and one end of the roller are in concentric fixed connection; and an encoder is arranged on the roller. The structure is ingenious, the idea is novel; the working efficiency, the stability and the accuracy of high-speed servo drive can be greatly improved; the structure is compact; the occupied space is small; the drive torque is large; the transmission is stable; the working time is long; the maintenance cycle is long; consumption of the electric energy is small; the mechanical wear is little; and the service life is long.

Owner:河南凌翼智联装备有限公司

Clutch

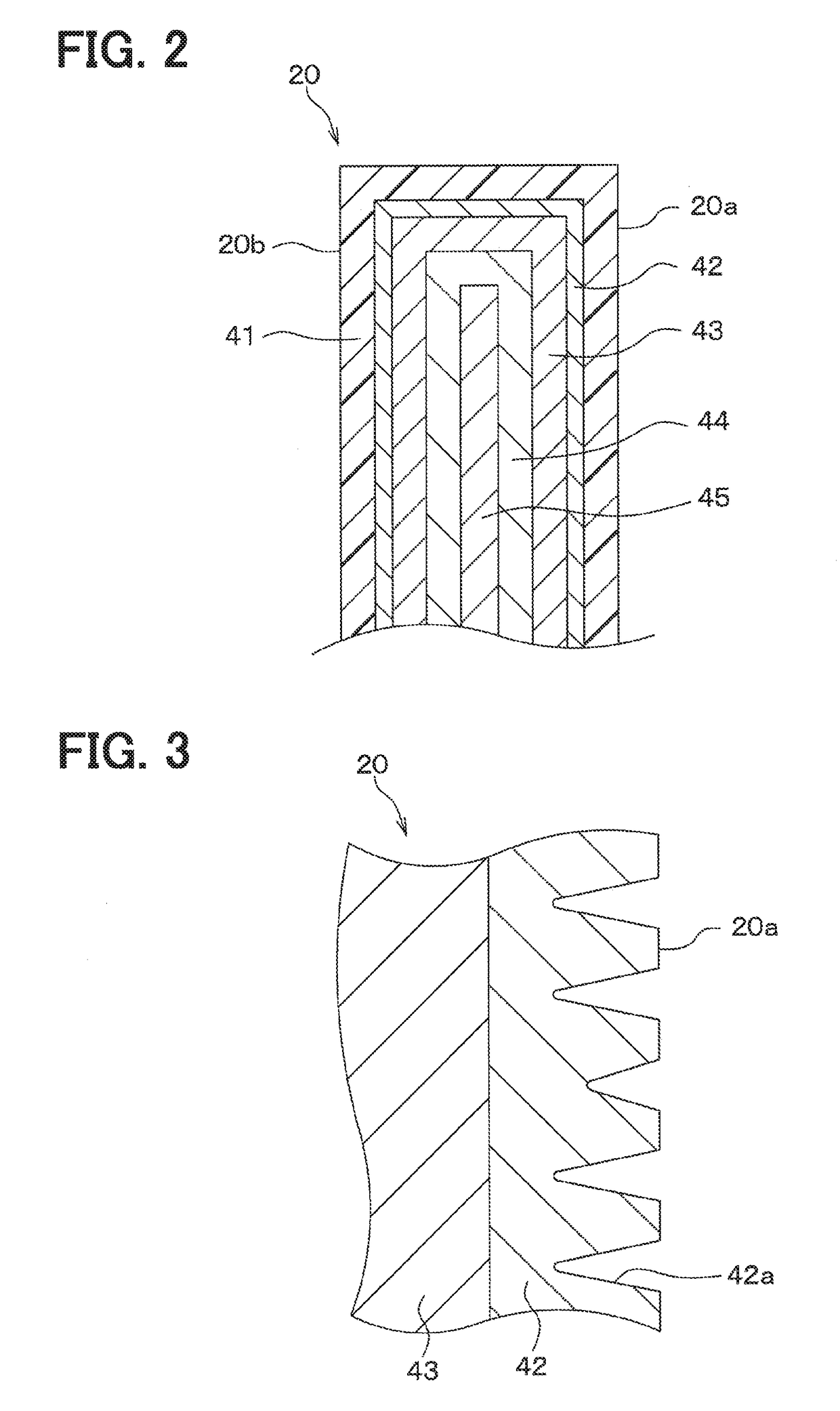

InactiveUS20180058516A1High transmission torqueIncrease transmission torqueYielding couplingMagnetically actuated clutchesClutch

A clutch includes: a rotor that has a steel material as a base material and is rotated upon receiving a rotational drive force from a drive source; and an armature that has a steel material as a base material and receives the rotational drive force from the rotor when the armature is attracted to the rotor by a magnetic force. The armature has a contact surface side region that includes a contact surface, which contacts a counterpart when the armature is attracted to the rotor. The contact surface side region has a plurality of pores opened at the contact surface and forms a nitride compound of an element of the base material through nitridization of a part of the base material while the contact surface side region is harder than an unreacted portion of the base material that is not reacted at the nitridization.

Owner:DENSO CORP

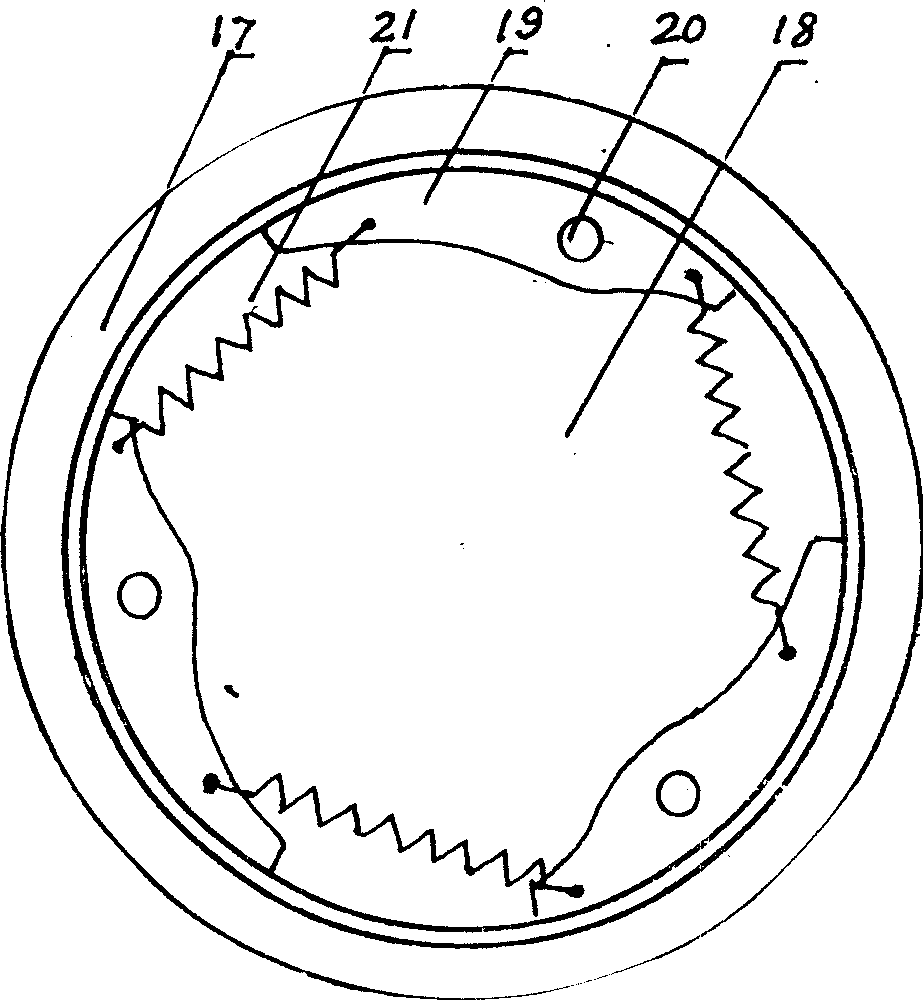

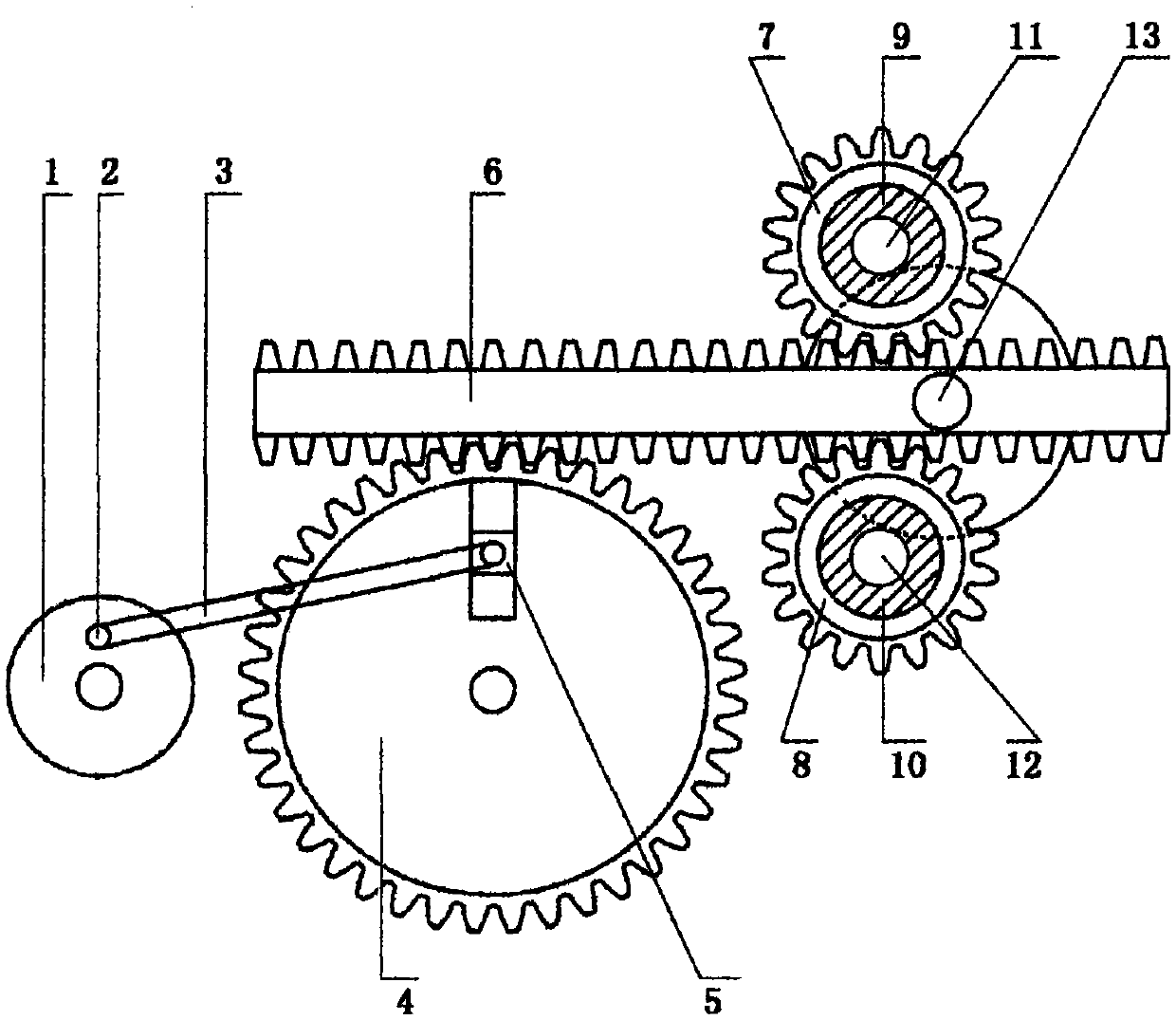

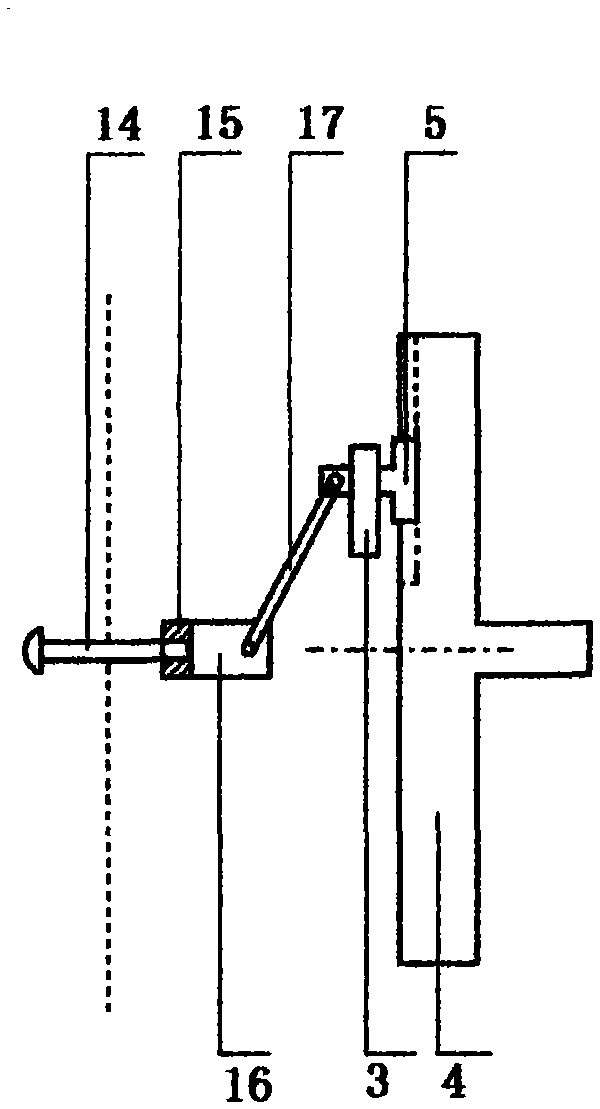

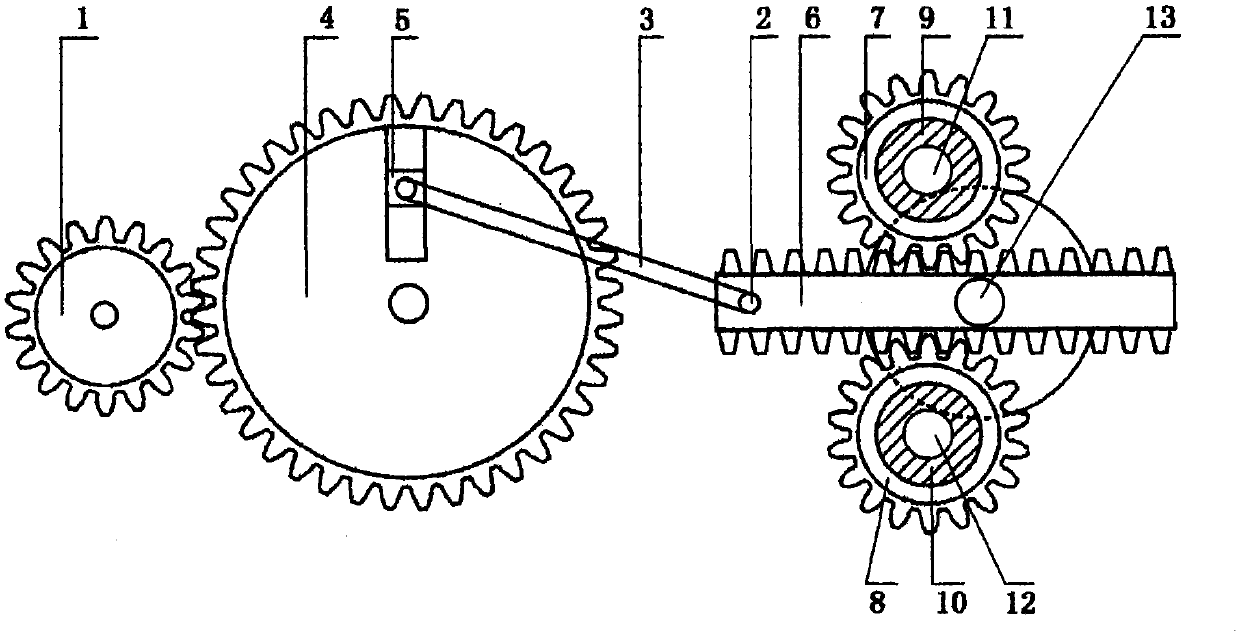

torque converter continuously variable transmission

The invention relates to a mechanical speed-changing device, in particular to a variable torque type continuously variable transmission. The variable torque type continuously variable transmission realizes infinitely variable speed by changing torque of a speed-changing wheel through a speed-changing control rod. The working principle of the variable torque type continuously variable transmission is that a sliding block with a short shaft is mounted in a groove, in the radial direction, of a speed-changing wheel in the box; an eccentric shaft of a power wheel is connected with the short shaft of the sliding block through a transmission rod; a speed-changing control rod can control movement of the sliding block; the torque of the speed-changing wheel is changed through movement of the sliding block, so that the amplitude of the reciprocating rotation of the speed-changing wheel is changed and the reciprocating stroke of a rack meshed with the speed-changing wheel is changed; the reciprocating motion of the rack is transformed into homodromous rotation by a reversing wheel internally provided with an overrunning clutch; power is output through an output shaft. The radial groove of the speed-changing wheel also can lock the sliding block through isometric pin holes to form speed change with gears. The variable torque type continuously variable transmission is stable in process, large in transmission and suitable for speed change of a main shaft of an engine.

Owner:武利民

Cylinder type permanent magnetic speed controller

InactiveCN104578629ALarge output torqueIncreased torque densityDynamo-electric machinesTorque densityMagnetic poles

A cylinder type permanent magnetic speed controller comprises an outer magnetic conductive cylinder, a thin-wall copper cylinder, permanent magnet blocks and an inner magnetic conductive cylinder, wherein the outer magnetic conductive cylinder, the thin-wall copper cylinder, the permanent magnet blocks and the inner magnetic conductive cylinder are arranged in sequence from outside to inside. The outer wall of the thin-wall copper cylinder is tightly attached and fixed to the inner surface of the outer magnetic conductive cylinder to form a first rotor assembly, and multiple permanent magnet blocks are attached and fixed to the outer surface of the inner magnetic conductive cylinder in the circumferential direction to form a second rotor assembly. The cross section of each permanent magnet block can be in a fan shape or other shapes, and the magnetizing direction of the permanent magnet blocks meets a given computational formula. The first rotor assembly and the second rotor assembly are mounted coaxially, and an air gap is formed between the outer surface of each permanent magnet block and the inner surface of the thin-wall copper cylinder. The cylinder type permanent magnetic speed controller has the advantages that most magnetic energy of a magnetic pole set is collected in the air gaps, the utilization rate of the magnetic energy is high, and the torque density is large. The permanent magnetic speed controller can transmit more torque or power, the structural size is small, the production cost is low, and needed mounting space is small.

Owner:HENAN POLYTECHNIC UNIV

High-power hybrid wind power gear box

PendingCN114123717AAchieve mechanical isolationSolving resonance problemsMagnetic circuit rotating partsPermanent-magnet clutches/brakesDrive shaftGear wheel

The invention relates to a high-power hybrid wind power gear box, and belongs to the field of wind power. The gearbox comprises a low-speed-level mechanical planetary gear, a medium-speed-level coaxial magnetic gear, a high-speed-level coaxial magnetic gear, a first coupler, a second coupler and the like. The mechanical planetary gear comprises a planet carrier, a planet wheel, a gear ring, a sun wheel and an output shaft; each coaxial magnetic gear comprises an outer rotor magnetic gear, an inner rotor magnetic gear, a magnetic adjusting ring, a driving shaft, a driven shaft and the like. A planet carrier of the low-speed-level mechanical planet gear is connected with a wind wheel main shaft through a shrinkage sleeve, and an output shaft of the low-speed-level mechanical planet gear is connected with a driving shaft of the medium-speed-level coaxial magnetic gear through a first coupler; the medium-speed driven shaft is connected with a driving shaft of the high-speed coaxial magnetic gear through a second coupler, and the high-speed driven shaft is fixed to a rotating shaft of the wind driven generator through a coupler. The device does not need a complex and heavy oil injection lubrication cooling system, is low in energy consumption, light in weight, simple and convenient to operate and maintain, can greatly reduce the operation and maintenance cost, and is particularly suitable for doubly-fed and semi-direct-driven wind driven generators.

Owner:QUFU NORMAL UNIV

A form design method of reducer

ActiveCN111895058BFlexible sizeReduce manufacturing costDesign optimisation/simulationCAD circuit designDrive shaftReduction drive

The invention belongs to the technical field of reducers, and in particular relates to a forming design method of a reducer, wherein the reducer designed by the forming design method includes an outer ring gear, a roller and a drive shaft, the outer ring gear is a stator, and the The drive shaft rotates and drives the roller to rotate, and the roller revolves around the drive shaft. The contour line of the cross-section of the drive shaft is a curve of equal width, and the above items are determined according to actual needs. Data: m, n, r, R and Q, and arrange multiple rollers on the grille, and then use the above parameters for design calculations, so as to obtain the tooth profile of the outer ring gear. A new planetary gear reducer can be designed and obtained by applying the technical solution of the present invention, thereby solving the problem that there is no reducer in the prior art that can not only meet the requirements of a simple design structure, a small size, but also a flexible matching design of the reduction ratio. question.

Owner:深圳市泉锲科技有限公司

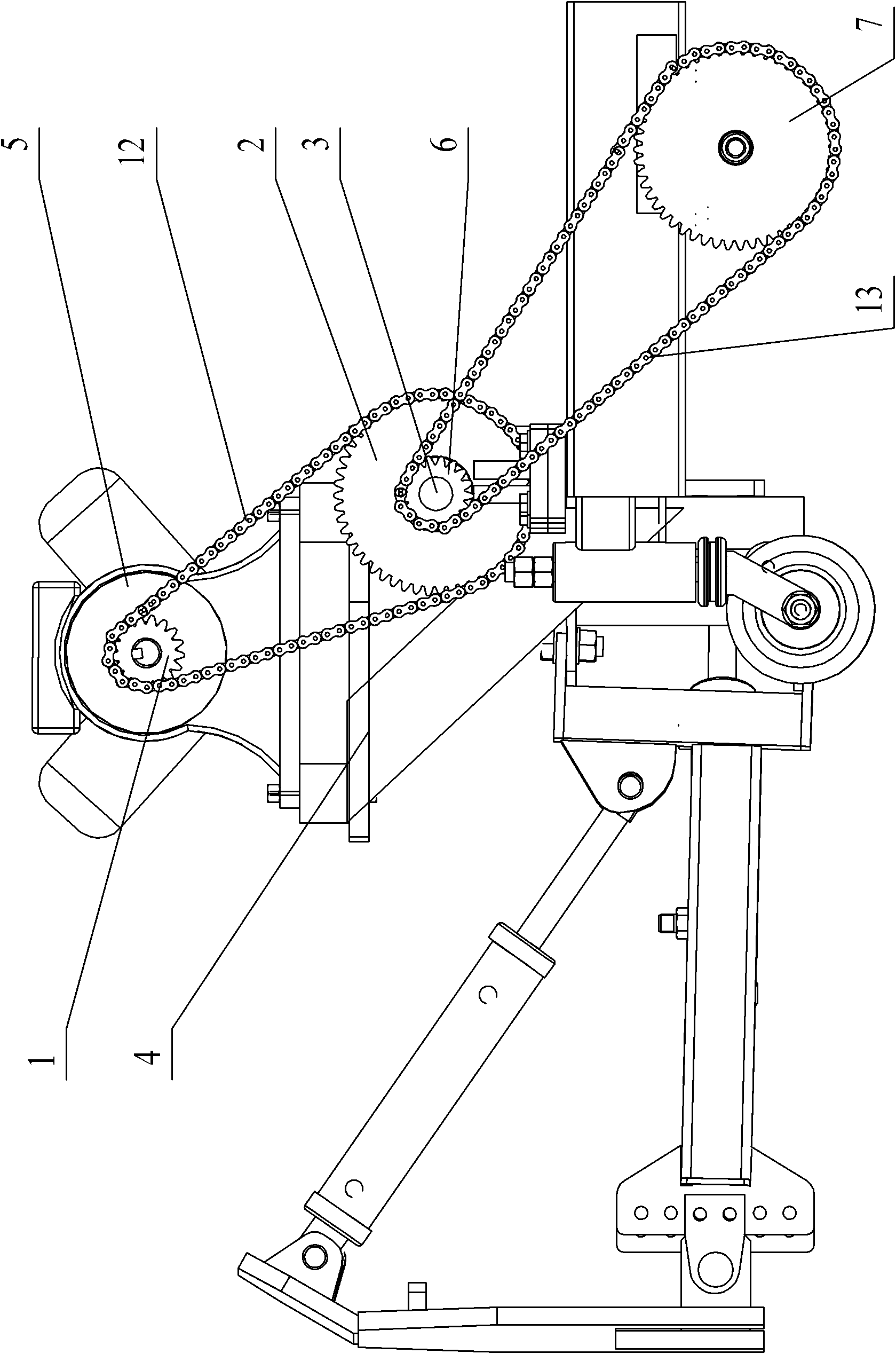

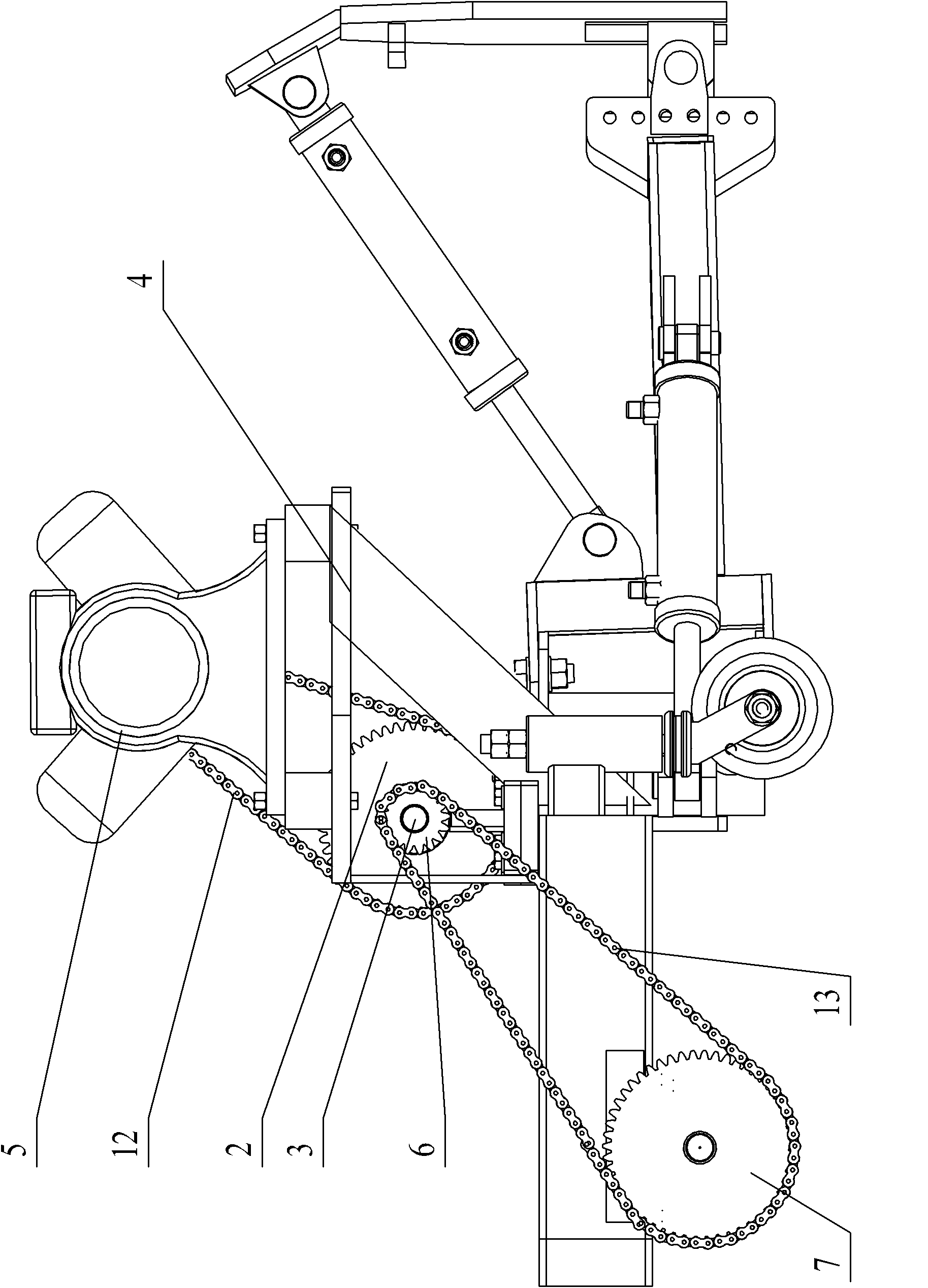

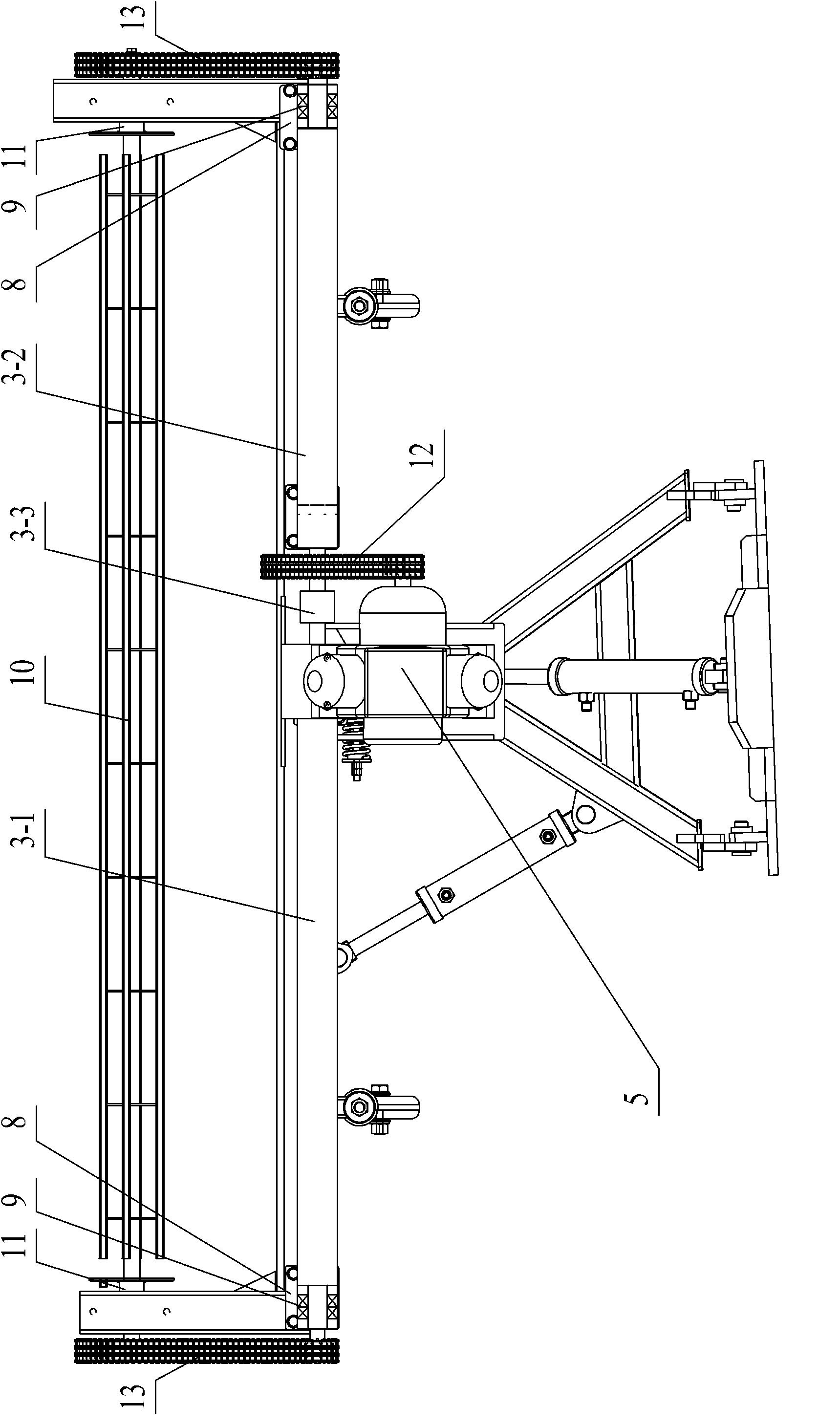

Inverted tooth chain output transmission device for snow caster

The invention discloses an inverted tooth chain output transmission device for a snow caster, relates to an output transmission device for the snow caster, and solves the problems of easy slipping, easy fatigue stretching, low transmission efficiency and small torque of transmission of a vee belt, and easy damage, short service life, low efficiency and high maintenance cost of transmission of a reduction box. An air-cooled two-cylinder diesel engine is arranged on a main framework, and an output shaft of the air-cooled two-cylinder diesel engine is provided with a driving toothlet chain wheel; two ends of a transmission shaft pass through a bearing seat and are fixedly connected with a drive small chain wheel; a driven sprocket canine tooth chain wheel is arranged on the transmission shaft, and the driving toothlet chain wheel is in transmission connection with the driven sprocket canine tooth chain wheel through an inverted tooth chain; and a roller shaft is fixedly connected to the main framework through two pillow block bearings, two ends of the roller shaft pass through the corresponding pillow block bearings and are fixedly connected with a drive big chain wheel, and each drive small chain wheel is in transmission connection with the corresponding drive big chain wheel through a transmission chain. The inverted tooth chain output transmission device is suitable for the snow caster.

Owner:哈尔滨市环隆卫生工具厂

Transmission for tractor

ActiveCN103161888BHigh transmission torqueImprove athletic abilityToothed gearingsGearing detailsGear wheelControl theory

The invention discloses a speed changer used for a tractor. The speed changer used for the tractor comprises a speed changer body, a cone gear I (8), a two-tap position installing-changing device and a cone gear II (9), wherein the speed changer body is provided with a tap position gear (25), the cone gear I (8) is connected with a speed-changing tap position gear shaft of the speed changer body, the two-tap position installing-changing device is connected with an range shift device and the cone gear II (9) is connected with an input shaft of the two-tap position installing-changing device in a meshed mode. The cone gear I (8) is installed to be connected with cone gear II (9) in a meshed mode. Deceleration is achieved on the speed-changing tap position gear shaft of the speed changer body. The cone gear I (8) and the cone gear II (9) can be used as intermediate gears so as to enlarge a transmitting torsion of the speed changer and improve a movement performance of the speed changer.

Owner:泰安泰山国泰拖拉机制造有限公司

A form design method of reducer

ActiveCN111895059BFlexible sizeReduce manufacturing costGeometric CADSpecial data processing applicationsDrive wheelReduction drive

The invention belongs to the technical field of reducers, and in particular relates to a forming design method of a reducer, comprising the following steps: determining the reduction ratio m, where m is an even number greater than or equal to 4; determining the radius Q of the roller; simulating a roller The movement track of the roller: the driving wheel rotates around the central axis of the driving wheel at an angular velocity ω, and the roller is driven by the driving wheel to rotate around the center of the cross-section of the roller, and the roller is in the same direction as the driving wheel. If the roller revolves around the driving wheel at an angular velocity for one revolution, the roller will form a circle of motion trajectory at the center of the cross section; the points on the motion trajectory line will expand radially by a distance Q with the central axis of the driving wheel as the central axis, The tooth profile of one revolution of the outer ring gear is then formed. The application of this technical solution solves the problem that there is no reducer in the prior art that can not only meet the requirements of simple design structure, miniaturization of volume, but also realize flexible matching design of reduction ratio.

Owner:深圳市泉锲科技有限公司

Underneath type multiple-input rotation rotating table device

InactiveCN110685595ASmall footprintEasy to installDrilling machines and methodsGear wheelEngineering

The invention relates to the technical field of engineering machinery, particularly to an underneath type multiple-input rotation rotating table device. According to the invention, a power system is meshed with a second shaft bevel gear wheel through a bevel gear wheel at the front end of a first shaft, so as to transmit power to the second shaft and realize reversing from the vertical rotation tohorizontal rotation; a spur gear on the second shaft is used for transmitting power to a slewing bearing spur gear, horizontal rotation of the slewing bearing spur gear is used for driving a force taking table fixed on the slewing bearing spur gear to rotate horizontally; the force taking table is hollow, and an inner octangle is arranged at the upper part of the force taking table; an outer octangle at the upper part of a core supplementing wheel carrier is embedded inside the force taking table; drill pipe core supplementing wheels are mounted at the inner upper part and the lower part of the core supplementing wheel carrier, so as to drive a drill pipe inserted therein to complete rotation of the drill pipe. The underneath type multiple-input rotation rotating table device has the characteristics of stable running, big driving torque, long service life, flexible operation and the like.

Owner:陈腊根

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com