torque converter continuously variable transmission

A technology of continuously variable transmission and speed change wheel, applied in the direction of belt/chain/gear, mechanical equipment, transmission device, etc., can solve the problems of power loss, slow response to acceleration, etc., and achieve small power loss, large transmission ratio, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

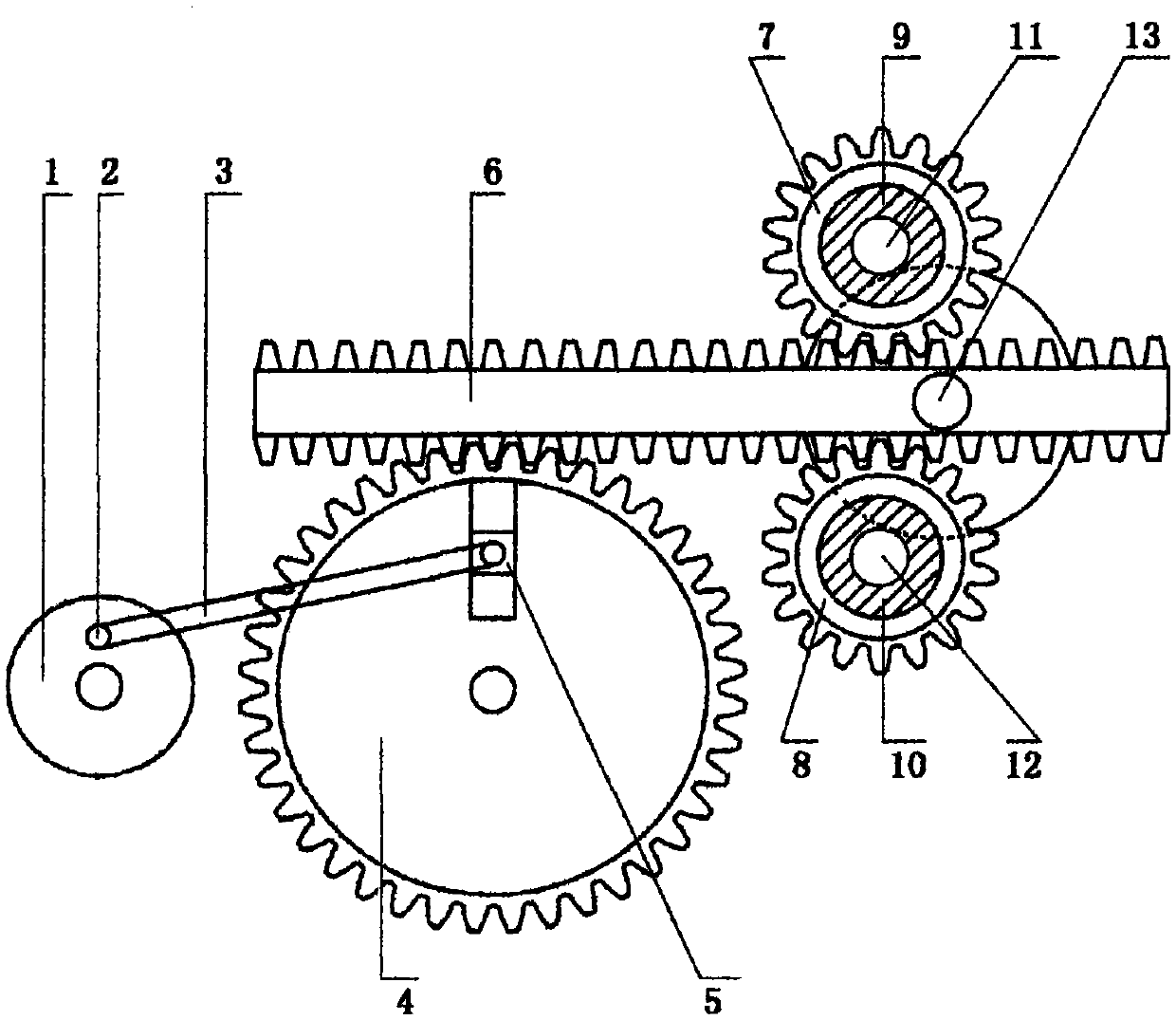

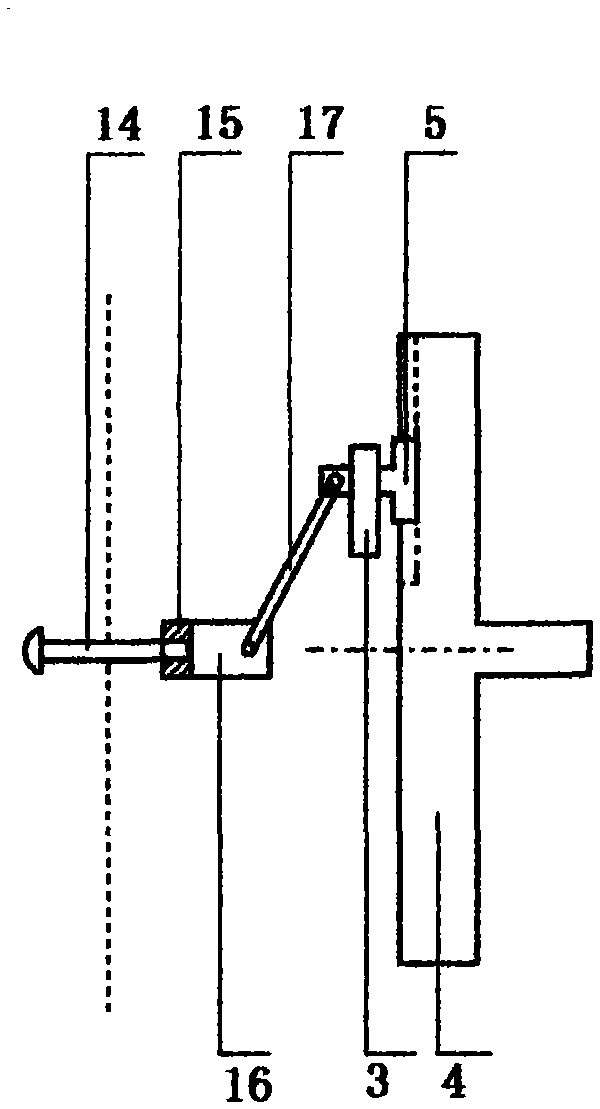

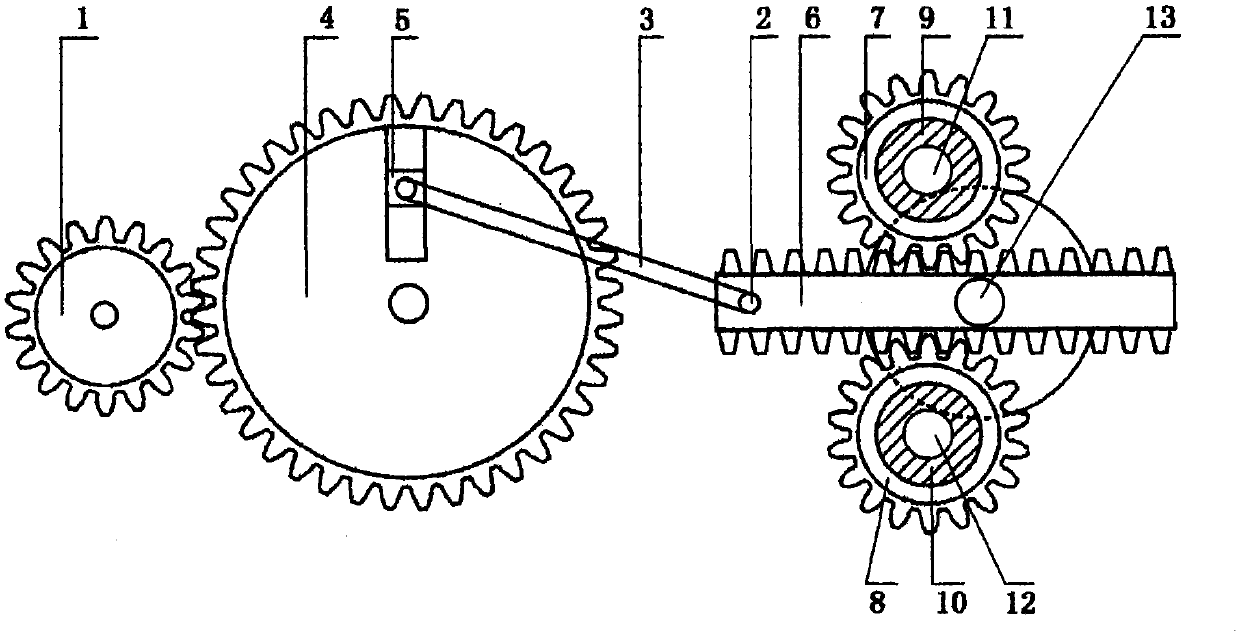

[0014] combine image 3 with figure 2 Describe this embodiment, this embodiment includes the power input wheel 1 that is contained in the casing, transmission link 3, speed change wheel 4, slide block 5, double-sided rack 6, reversing gear 7,8. Overrunning clutch 9,10. Reversing shafts 11, 12. Power take-off shaft 13, speed change control lever 14, bearing 15, sleeve 16, speed change connecting rod 17.

[0015] The slider 5 is installed in the radial groove of the speed change wheel 4. The speed change control rod is divided into two sections, the inner rod 14 and the outer sleeve 16. The middle part is connected by a bearing 15. The speed change control rod 14 and the speed change wheel 4 are respectively installed in the box. Both sides, and the speed change control lever 14 is on the coaxial line with the central axis of the speed change wheel 4, and one end of the speed change control lever 14 protrudes from the casing, and can slide axially on one side of the casing. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com