Method for operating a drive train for a motor vehicle and corresponding drive train

A technology for power trains and motor vehicles, applied in vehicle components, mechanical equipment, transportation and packaging, etc., and can solve problems such as intense load, multi-energy, noise generation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

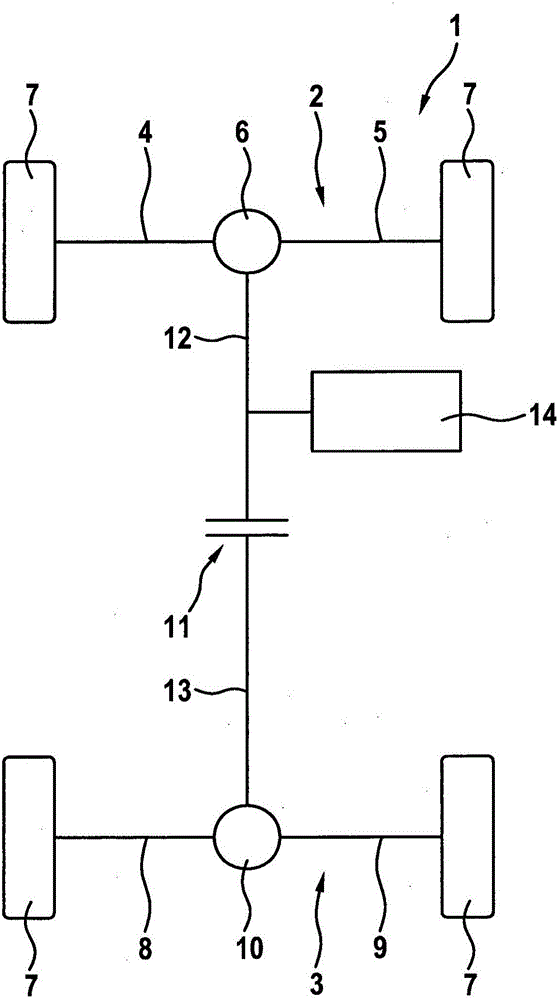

[0032] The drawing shows a schematic diagram of a drive train 1 , which is, for example, a component of a motor vehicle, not specifically shown. For example, drive train 1 has a primary transaxle 2 and a secondary transaxle 3 . The primary transaxle 2 has, for example, half shafts 4 and 5 , which are operatively connected to one another via an axle differential 6 . Wheels 7 are provided on each half axle 4 and 5 . Similarly, secondary drive axle 3 has half shafts 8 and 9 , which are operatively connected to one another via an axle differential 10 . Wheels 7 are likewise arranged on each axle shaft 8 and 9 .

[0033] The primary transaxle 2 and the secondary transaxle 3 are operatively connected to one another via a coupling device 11 with adjustable transmission torque. For example, the axle shafts 4 and 5 and 8 and 9 are here respectively present as output shafts of the corresponding axle differentials 6 and 10 , while the input shafts 12 and 13 of the axle differentials 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com