Synchronous power takeoff

A technology for synchronizing ring gears and gears, applied in transmissions, gear transmissions, belts/chains/gears, etc., can solve the problems of inconvenient use, small transmission torque, poor workmanship, etc., and achieve convenient shifting operation and reliability High, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

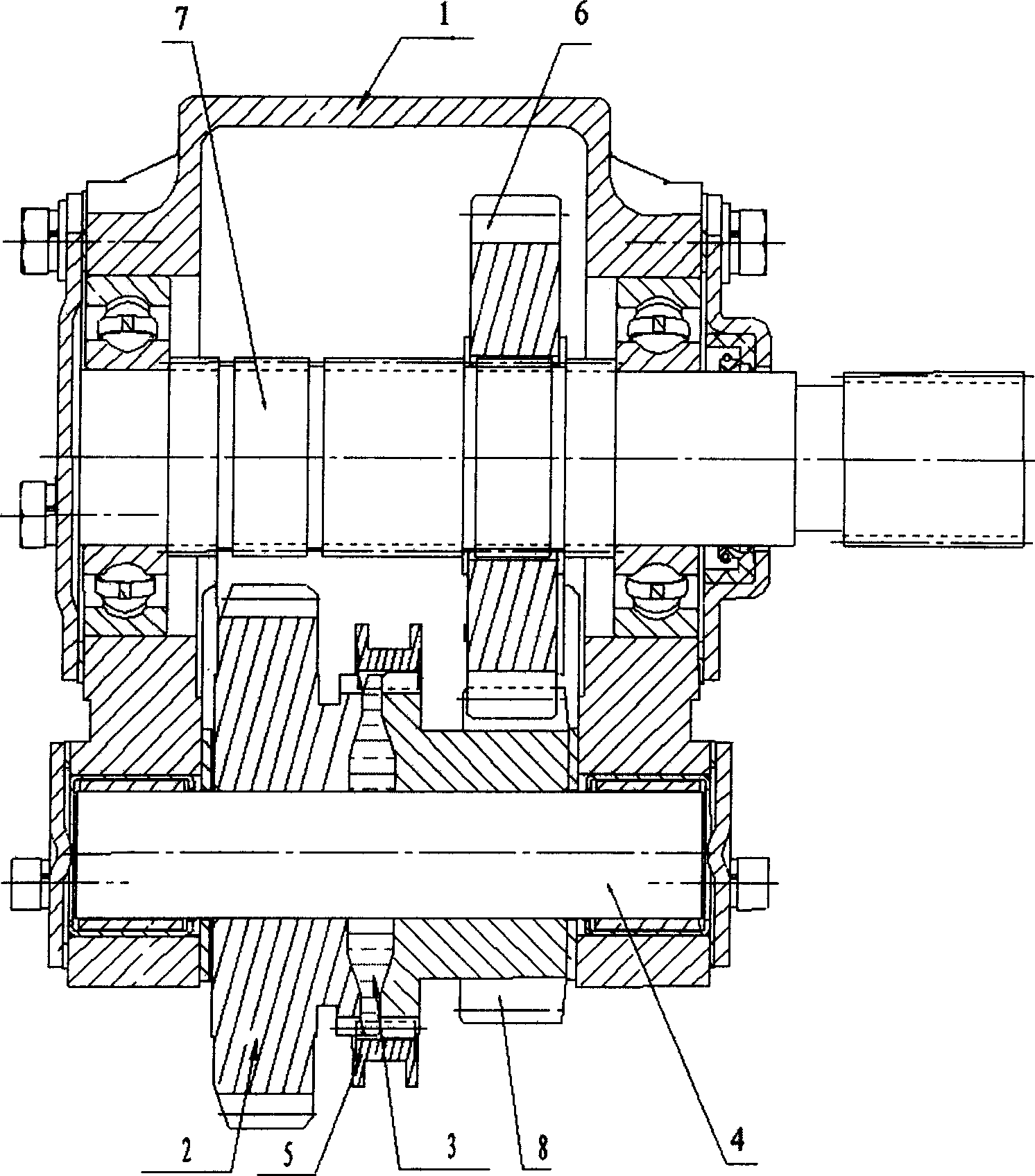

[0012] As shown in the drawings, a synchronous power take-off device is composed of two parts: gear transmission and gear shifting operation. The gear transmission part mainly includes: a housing 1 formed by one-time casting of aluminum alloy material. Inside the housing 1 is a Case (or transfer case) transmission gear, constant meshing power take-off gear 2, synchronous ring gear 3, intermediate shaft 4, combined ring gear (joint sleeve) with internal spline structure 5, a pair of constant meshing driven gears (intermediate shaft Gear 8 and output shaft gear 6) and the output shaft 7 with external splines, two pairs of symmetrical installation holes are processed on the housing 1, wherein, an intermediate shaft 4 is installed on a pair of installation holes, and an intermediate shaft 4 is installed on the intermediate shaft 4. Power gear 2, synchronous ring gear 3, interme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com