Patents

Literature

145results about How to "Smooth power delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

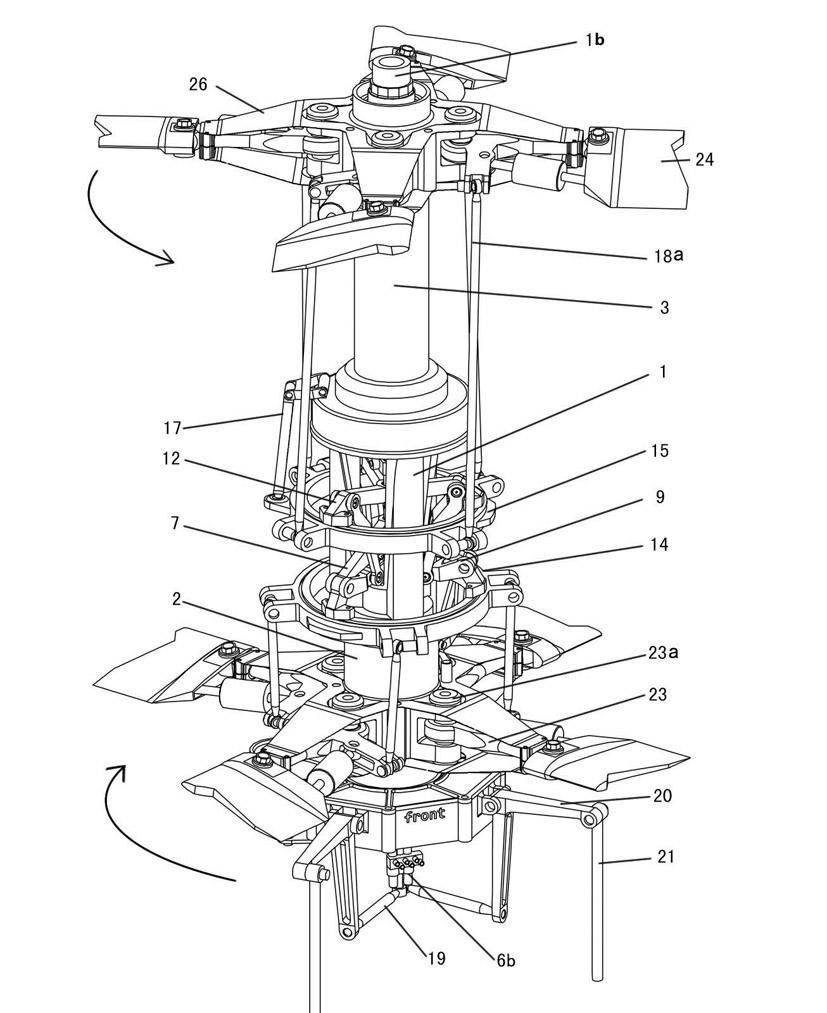

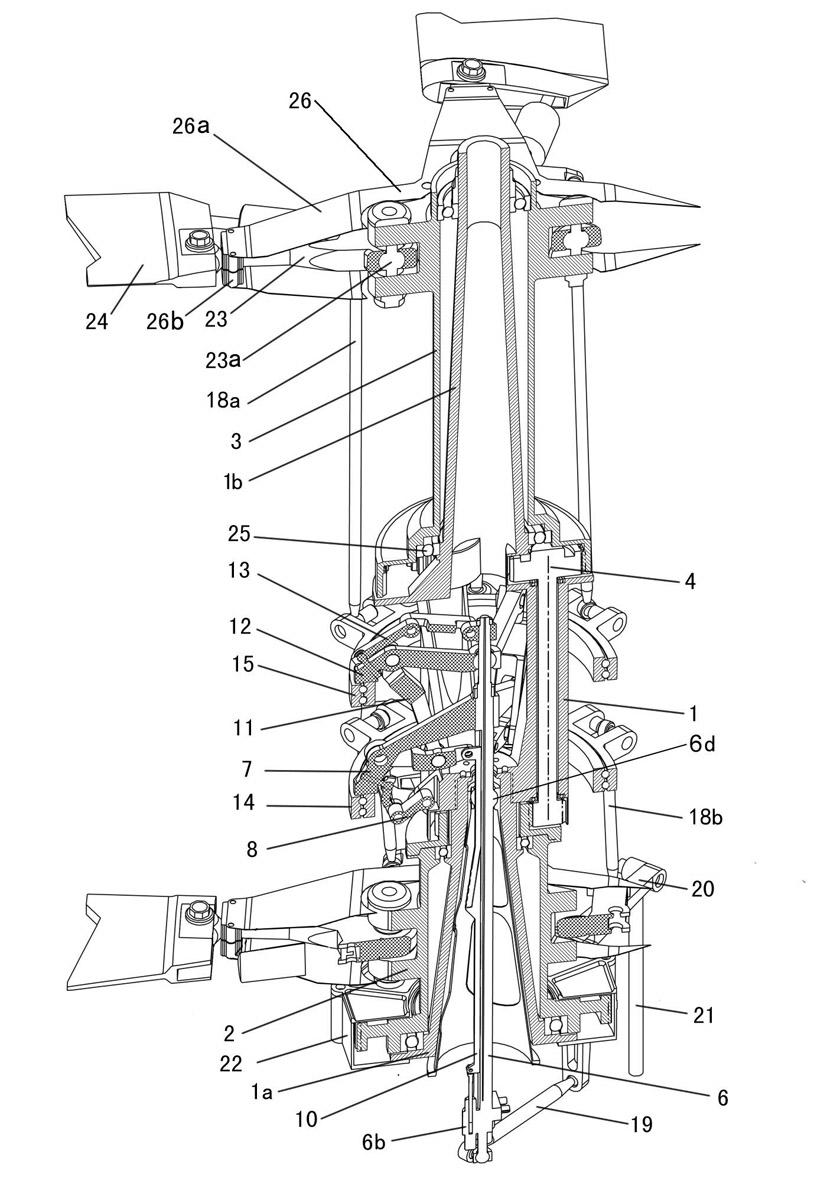

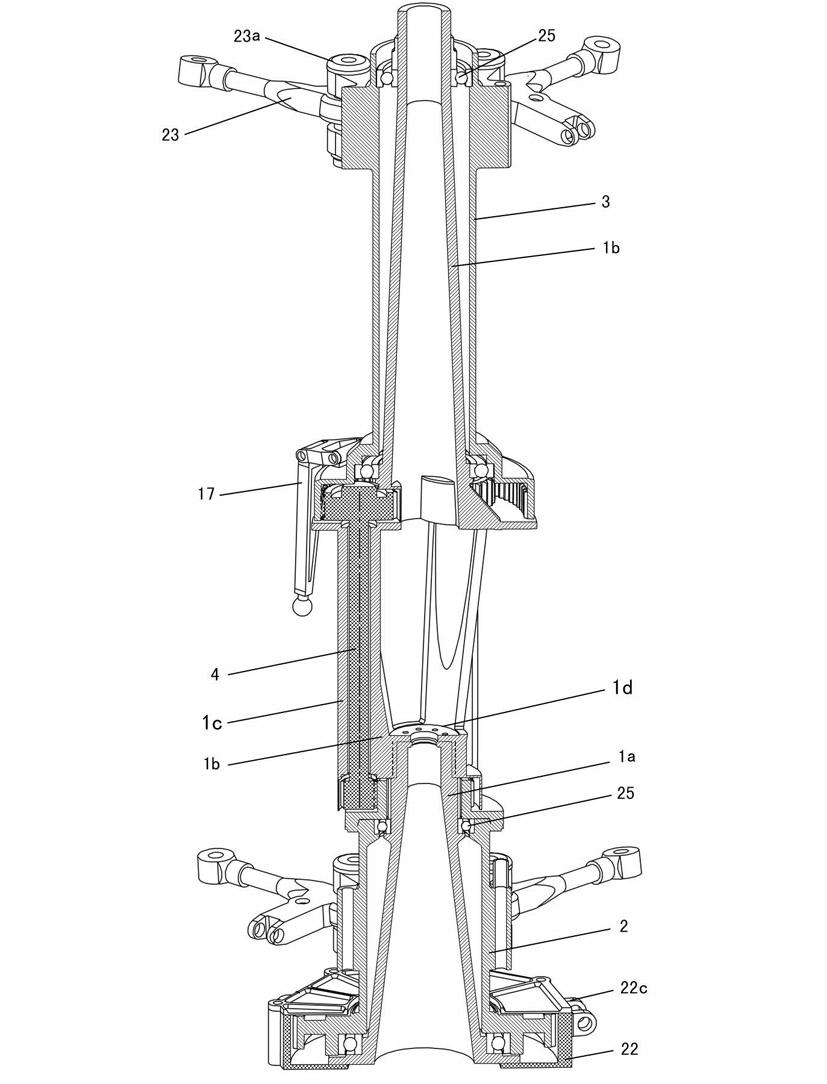

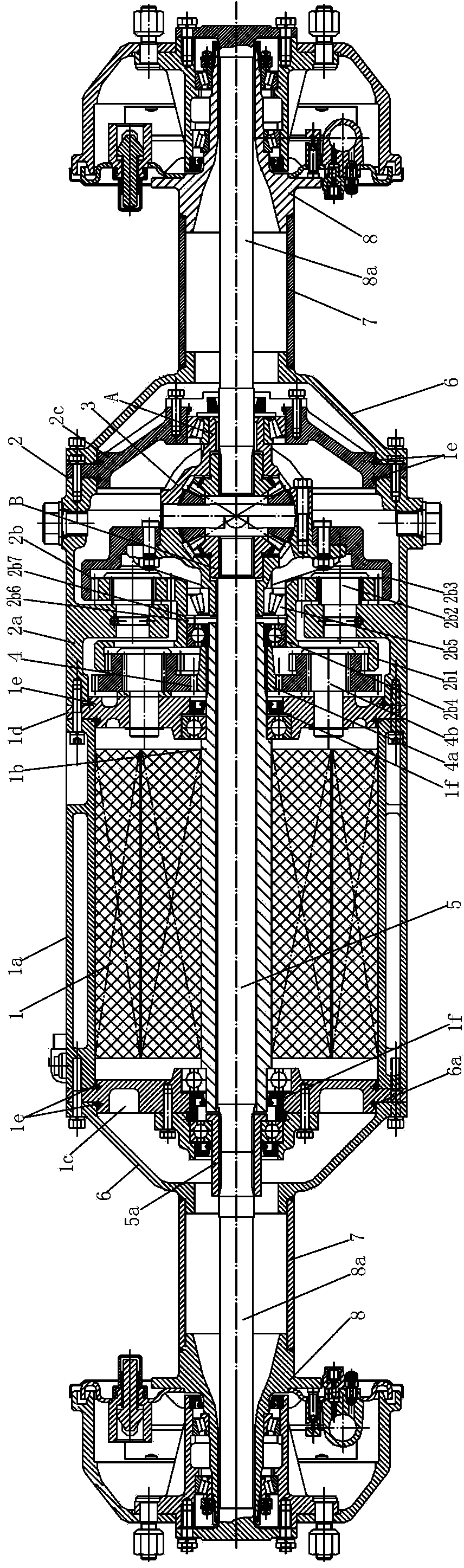

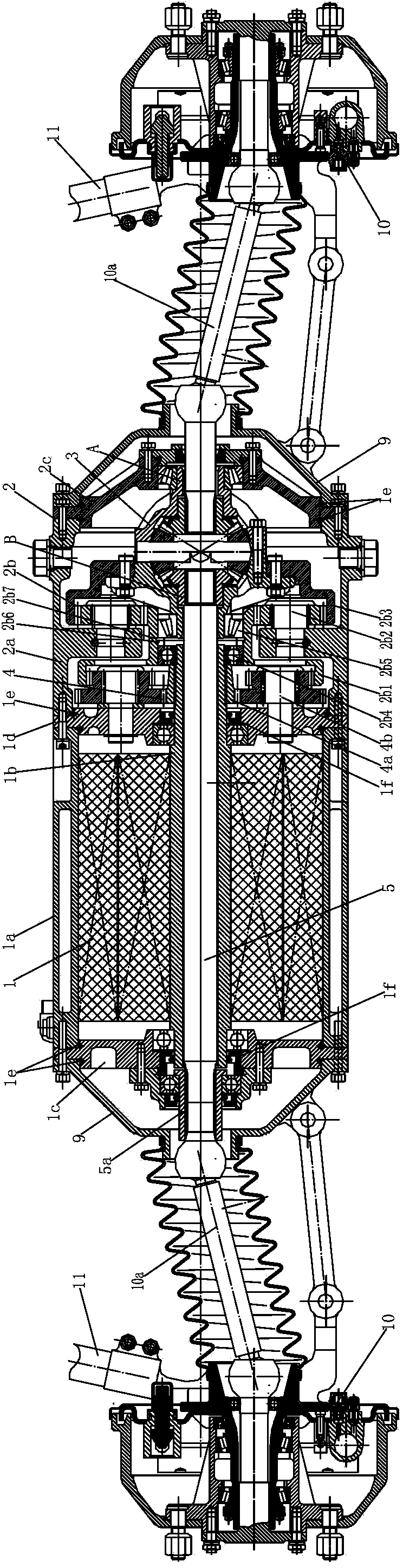

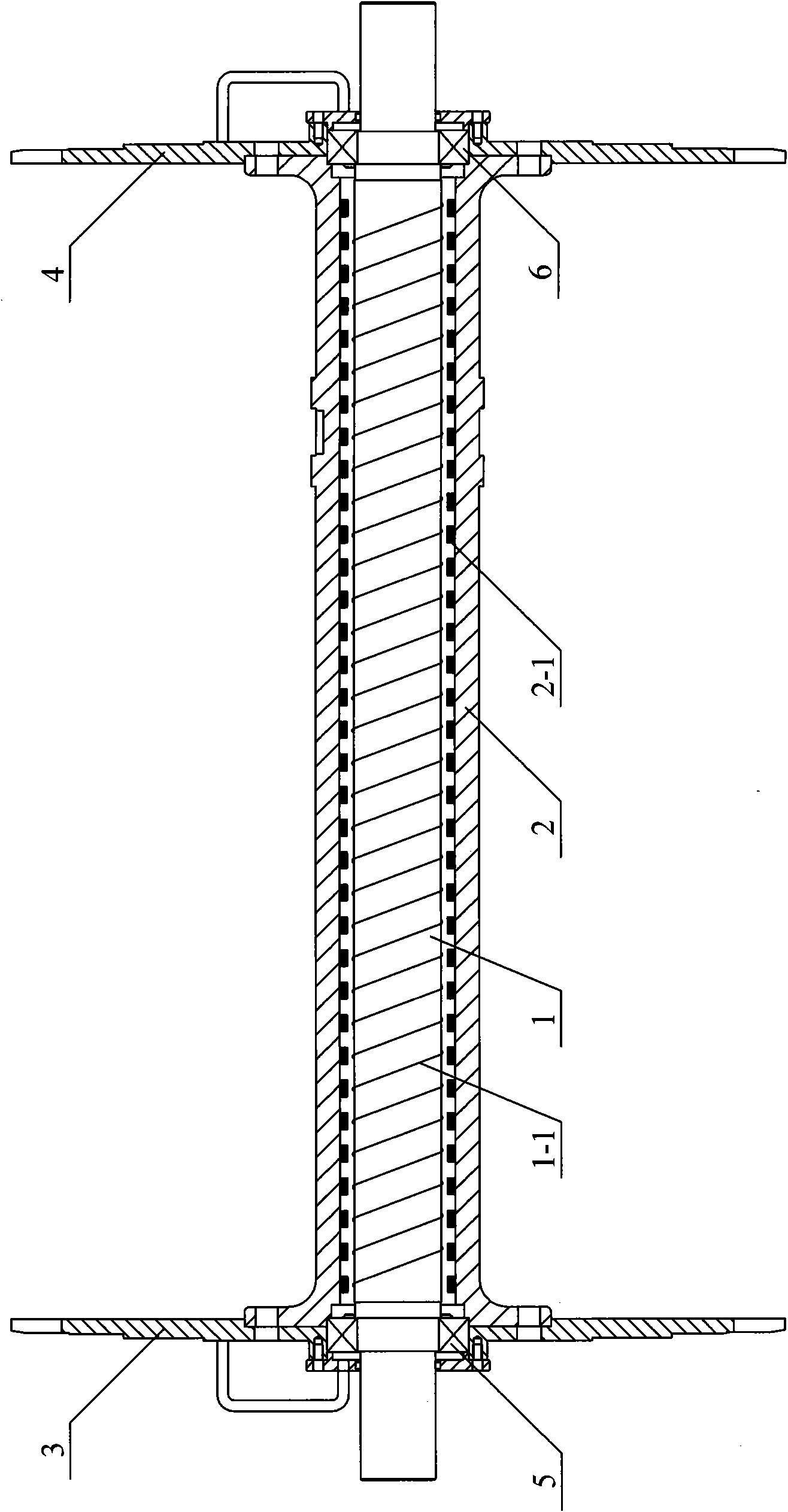

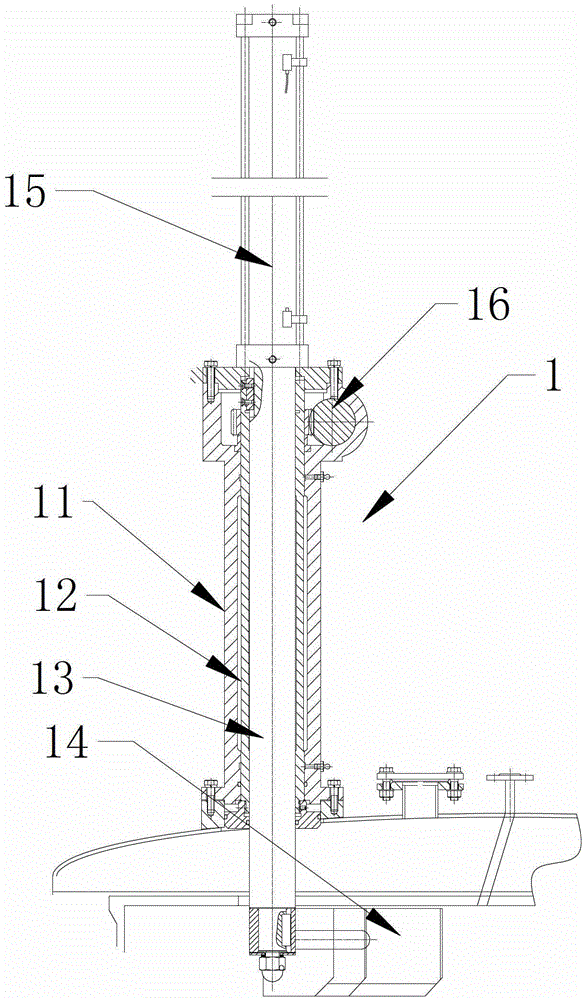

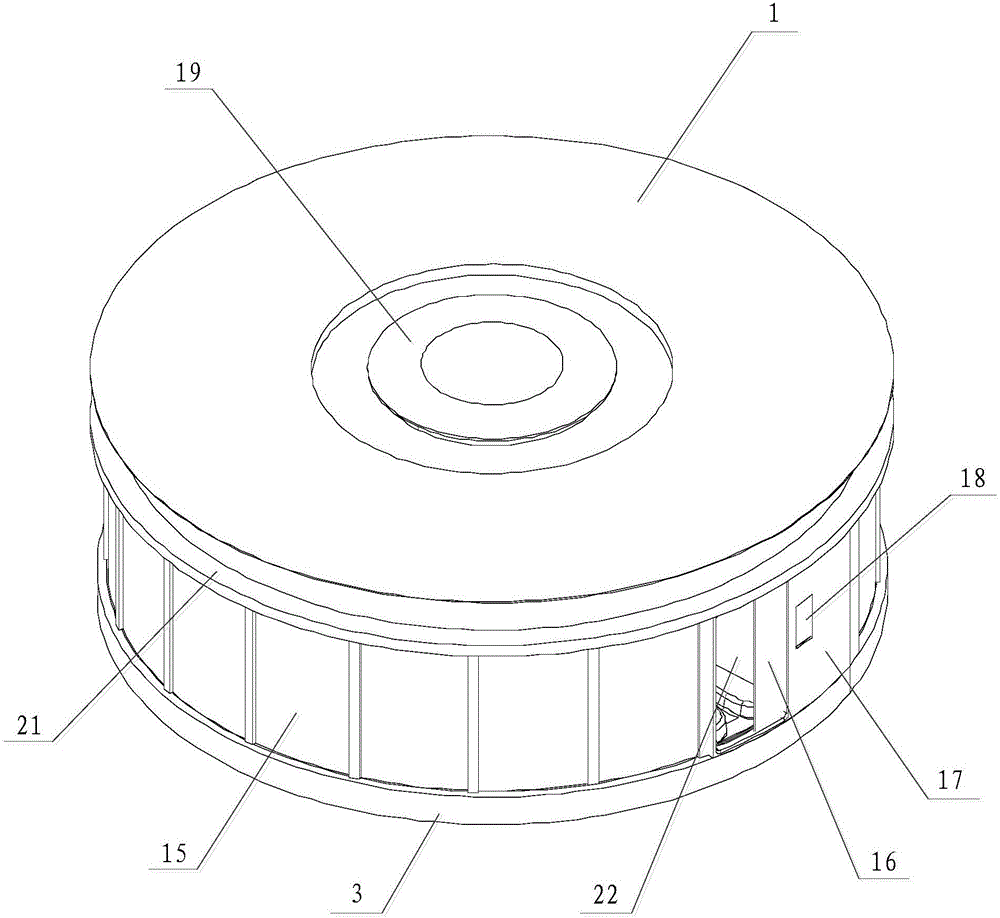

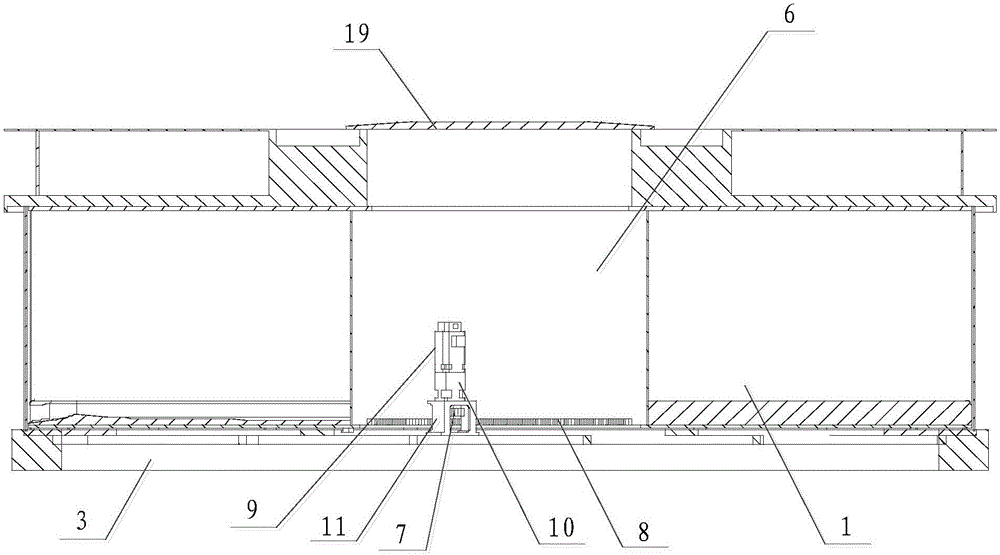

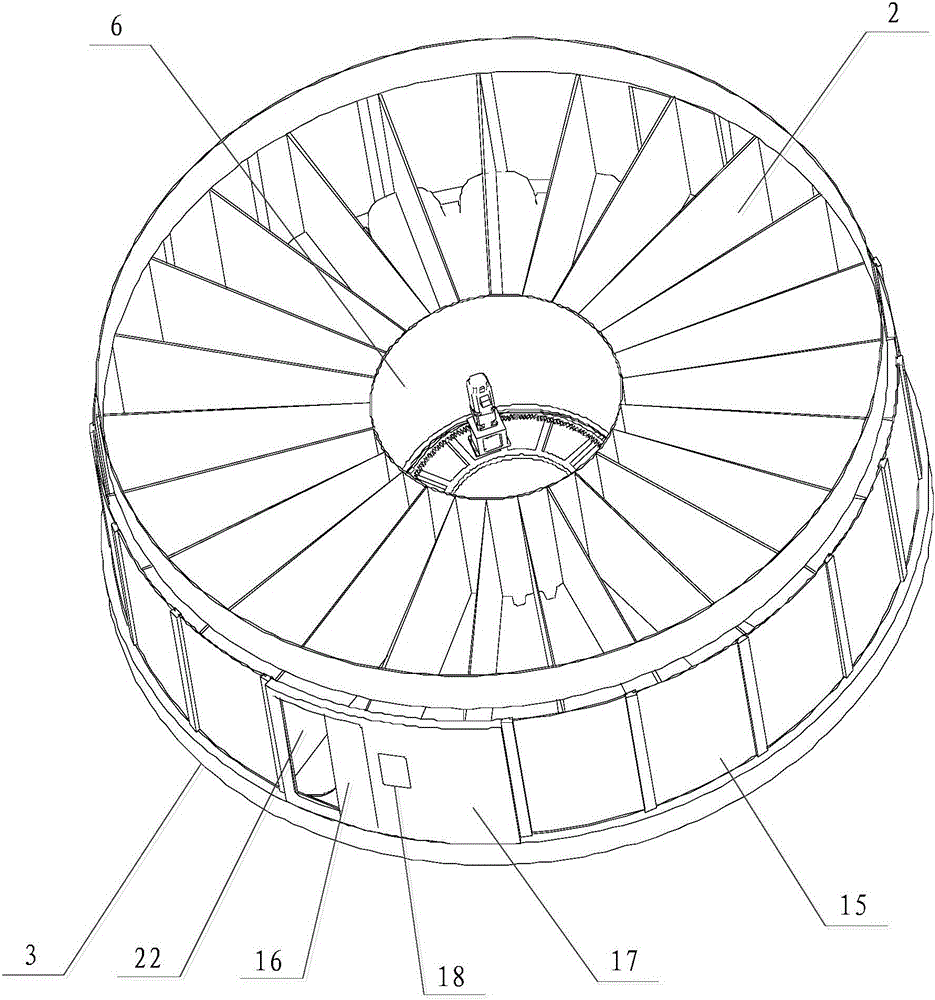

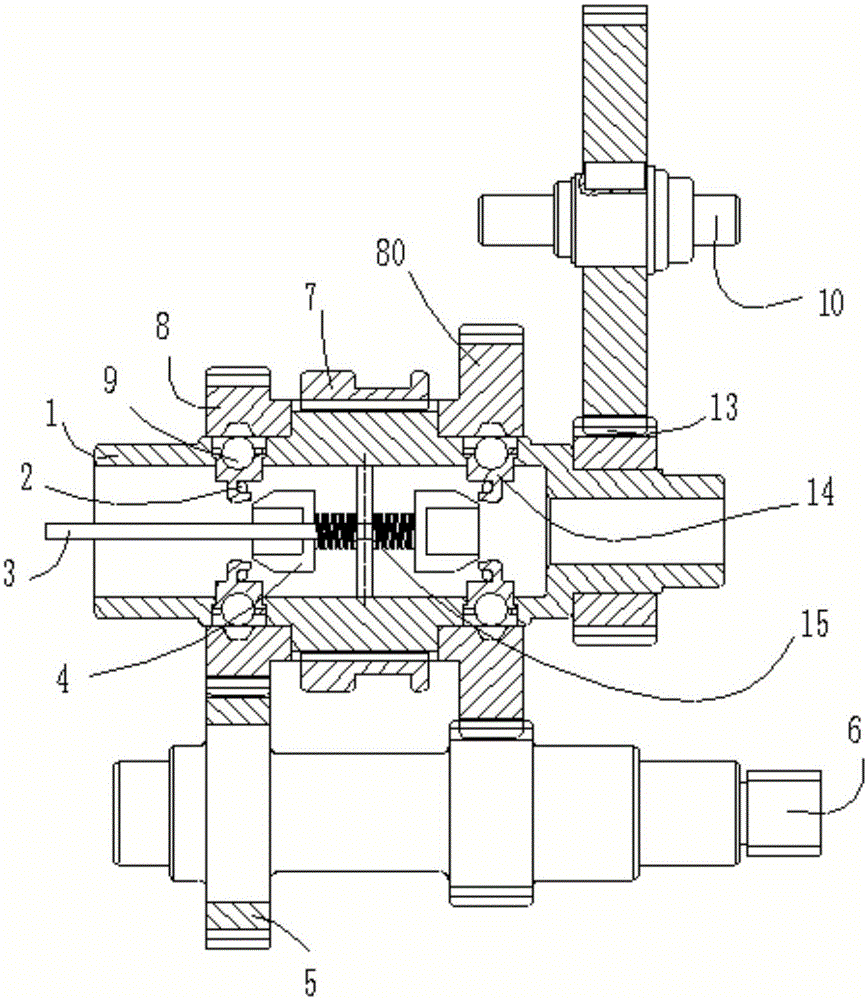

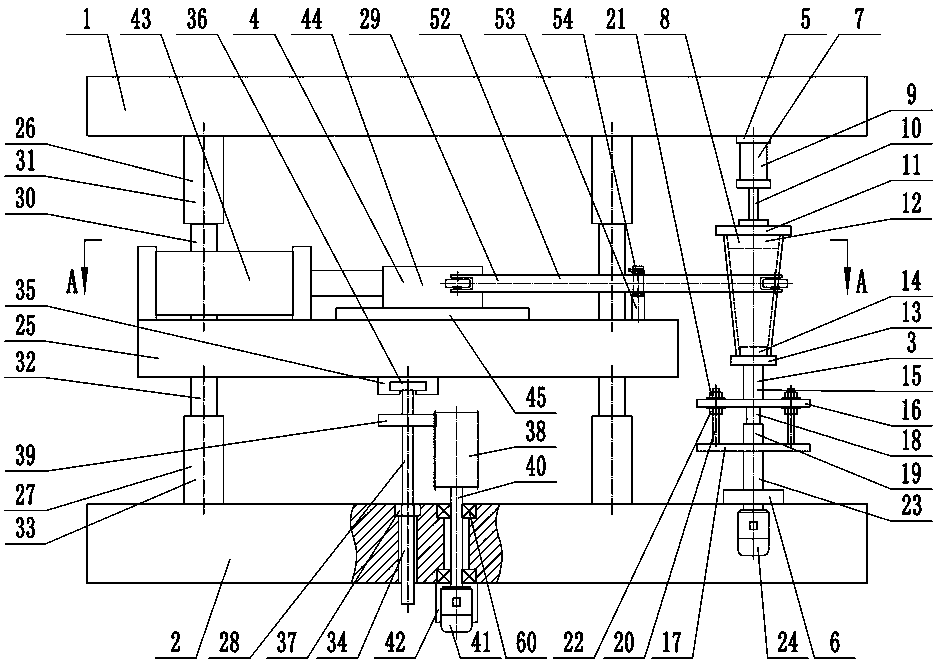

Coaxial drive and control structure for coaxial contrarotation rotor helicopter

The invention relates to a coaxial drive and control structure for a coaxial contrarotation rotor helicopter. A spindle is a hollow fixed shaft, the fixed shaft is provided with an upper rotor hub and a lower rotor hub, the upper rotor hub and the lower rotor hub are connected by virtue of a gearing shaft, the middle section of the fixed shaft comprises multiple support pillars which are uniformly distributed, an upper inclinator support and a lower inclinator support are arranged in spaces among the support pillars, a total propeller pitch sliding sleeve is arranged inside the lower section of the fixed shaft, a primary variable-pitch control rod is arranged in the total propeller pitch sliding sleeve and is located and hinged by virtue of a ball shaft, the upper part of the primary variable-pitch control rod is connected with the upper inclinator support and the lower inclinator support, and the lower end of the primary variable-pitch control rod is respectively hinged with a variable-pitch rocker arms by virtue of two variable-pitch connecting rods; and an upper inclinator and a lower inclinator are arranged between the upper rotor hub and the lower rotor hub and are hinged with an upper rotor control arm and a lower rotor control arm by virtue of an upper rotor control rod and a lower rotor control rod. By adopting the coaxial drive and control structure for the coaxial contrarotation rotor helicopter disclosed by the invention, the defect that a rotation control assembly penetrates a rotating surface is eliminated, thus the coaxial contrarotation rotor helicopter can be provided with more upper rotors and more lower rotors, lifting power of the helicopter is improved, full differentiating control can be realized, and manufacturing and processing costs of the spindle also can be reduced.

Owner:李游

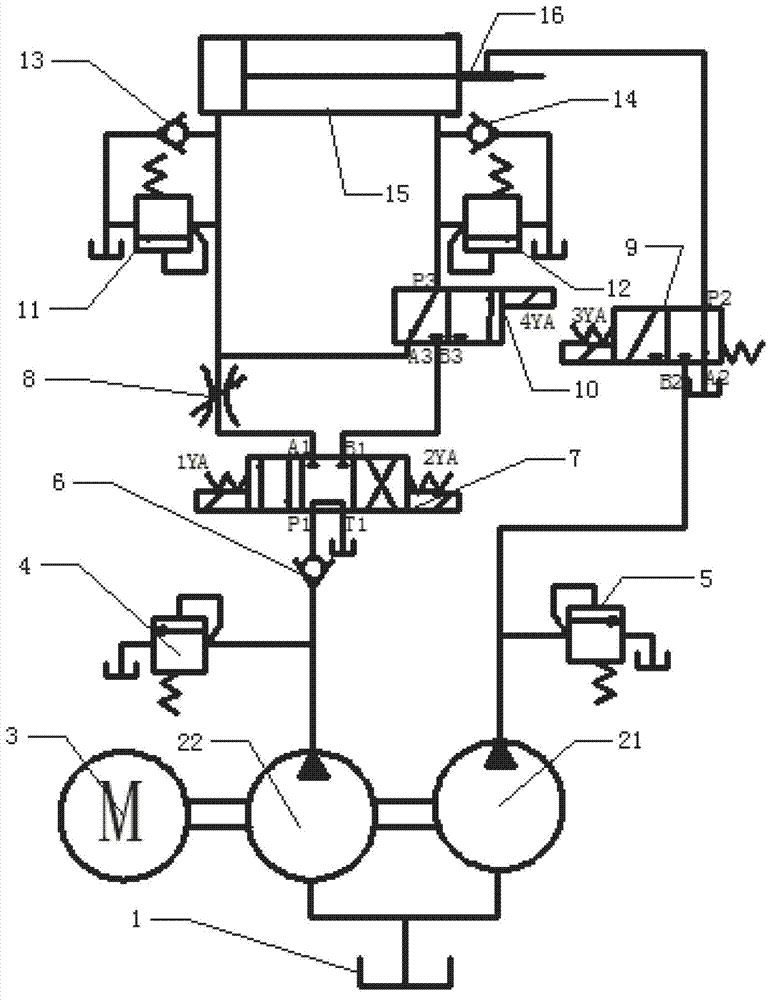

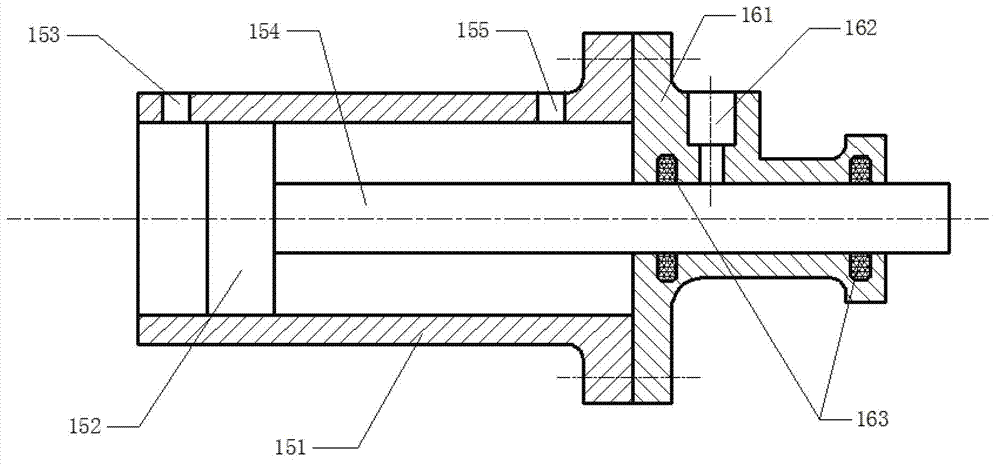

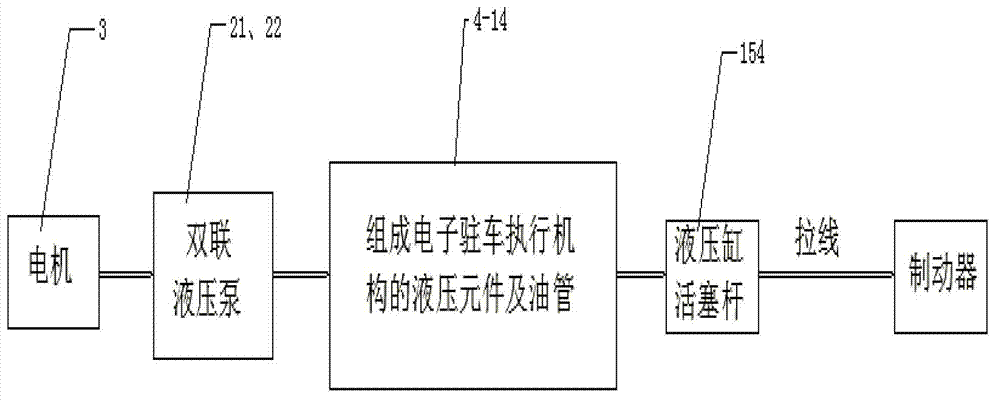

Hydraulically-controlled electronic parking executing mechanism

InactiveCN102729972AApplicable to a wide range of modelsPrevent jumpingBraking action transmissionLow noiseHydraulic cylinder

The invention discloses a hydraulically-controlled electronic parking executing mechanism, which comprises high-pressure and low-pressure pumps driven by using a motor in a duplex way, and a hydraulic cylinder, wherein the hydraulic cylinder comprises a cylinder body, a piston, a piston rod and a locking device; one end of the cylinder body is provided with an oil outlet, and the other end of the cylinder body is provided with an oil inlet; an unlocking oil port is formed at an elastic position on the locking device; the inlet of the high-pressure pump is connected with an oil tank; the port B2 of a first two-position three-way electromagnetic reversing valve is connected with the outlet of the high-pressure pump; the port P2 of the first two-position three-way electromagnetic reversing valve is connected with the unlocking oil port of the locking device; the inlet of the low-pressure pump is connected with the oil tank; the outlet of the low-pressure pump is connected with the port P1 of a three-position four-way electromagnetic reversing valve 7 through a first one-way valve; the inlet of a throttling valve is connected with the port A1 of the three-position four-way electromagnetic reversing valve, and the outlet of the throttling valve is connected with the oil inlet of the cylinder body, so that an oil inlet pipeline is formed; and the port B3 of a second two-position three-way electromagnetic reversing valve is connected with the port B1 of the three-position four-way electromagnetic reversing valve, and the port P3 of the second two-position three-way electromagnetic reversing valve is connected with the oil outlet of the cylinder body, so that an oil outlet pipeline is formed. A braking mechanism disclosed by the invention is suitable for wide vehicle types, and has continuous and stable power transmission, large and adjustable braking force, low wear and low noise.

Owner:NANJING UNIV OF SCI & TECH

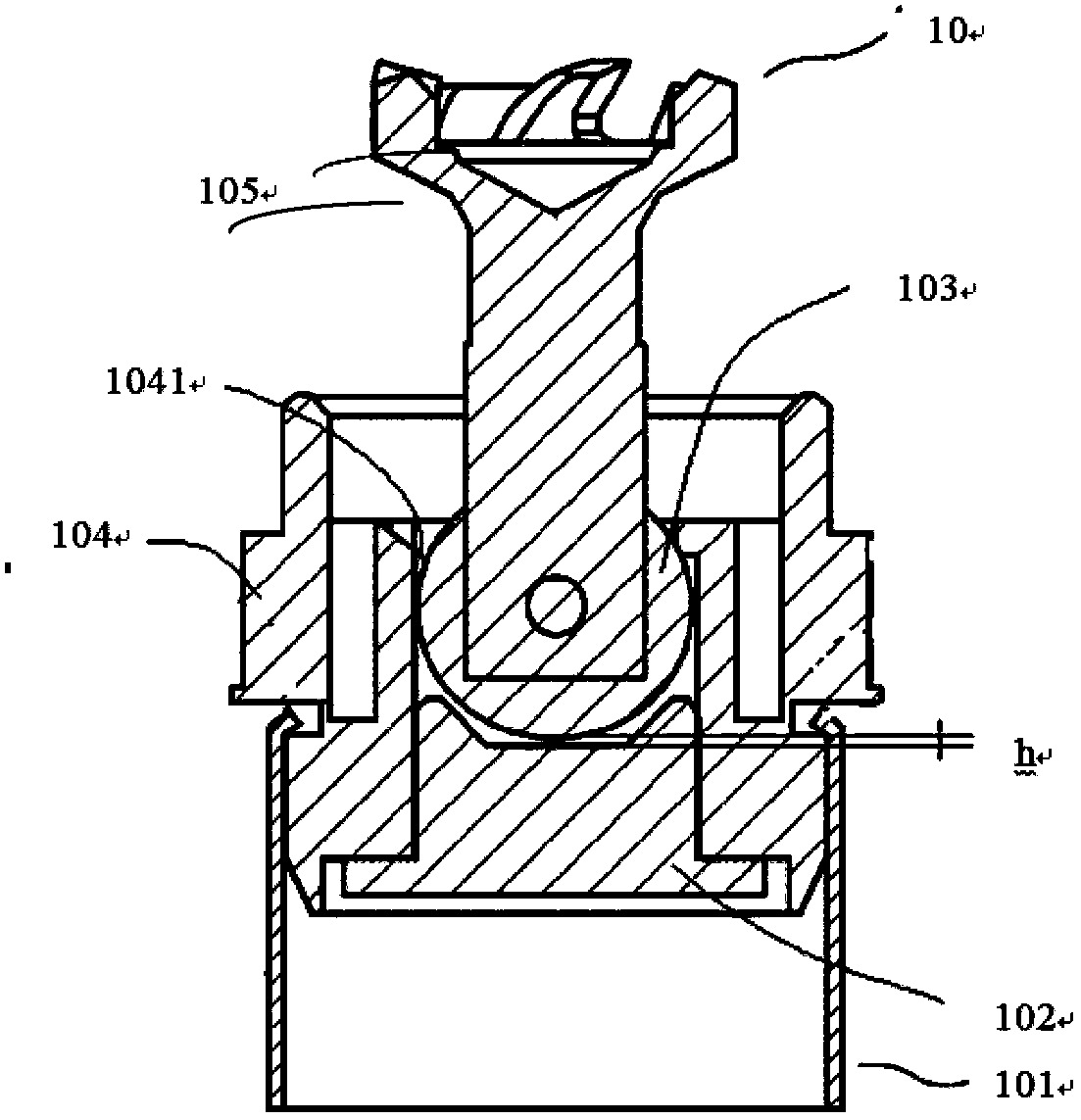

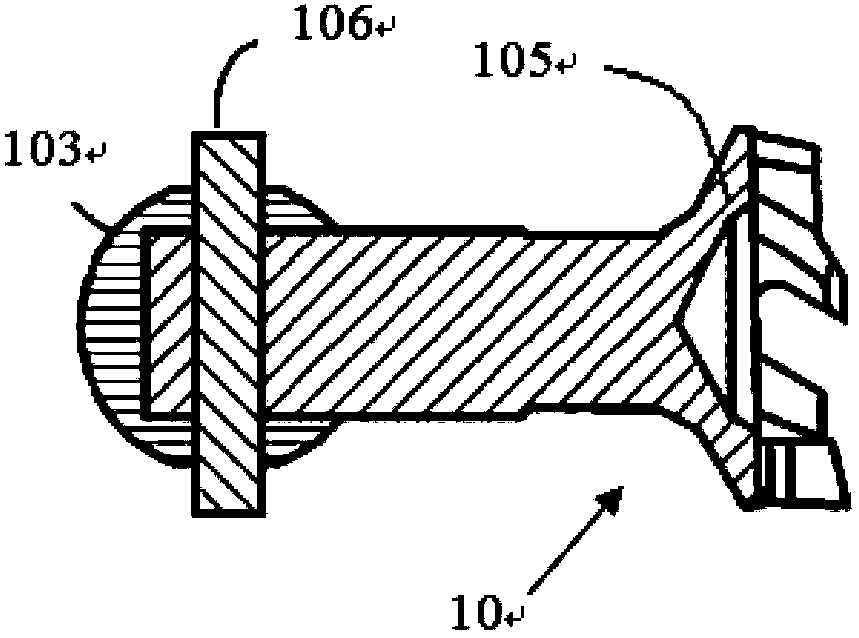

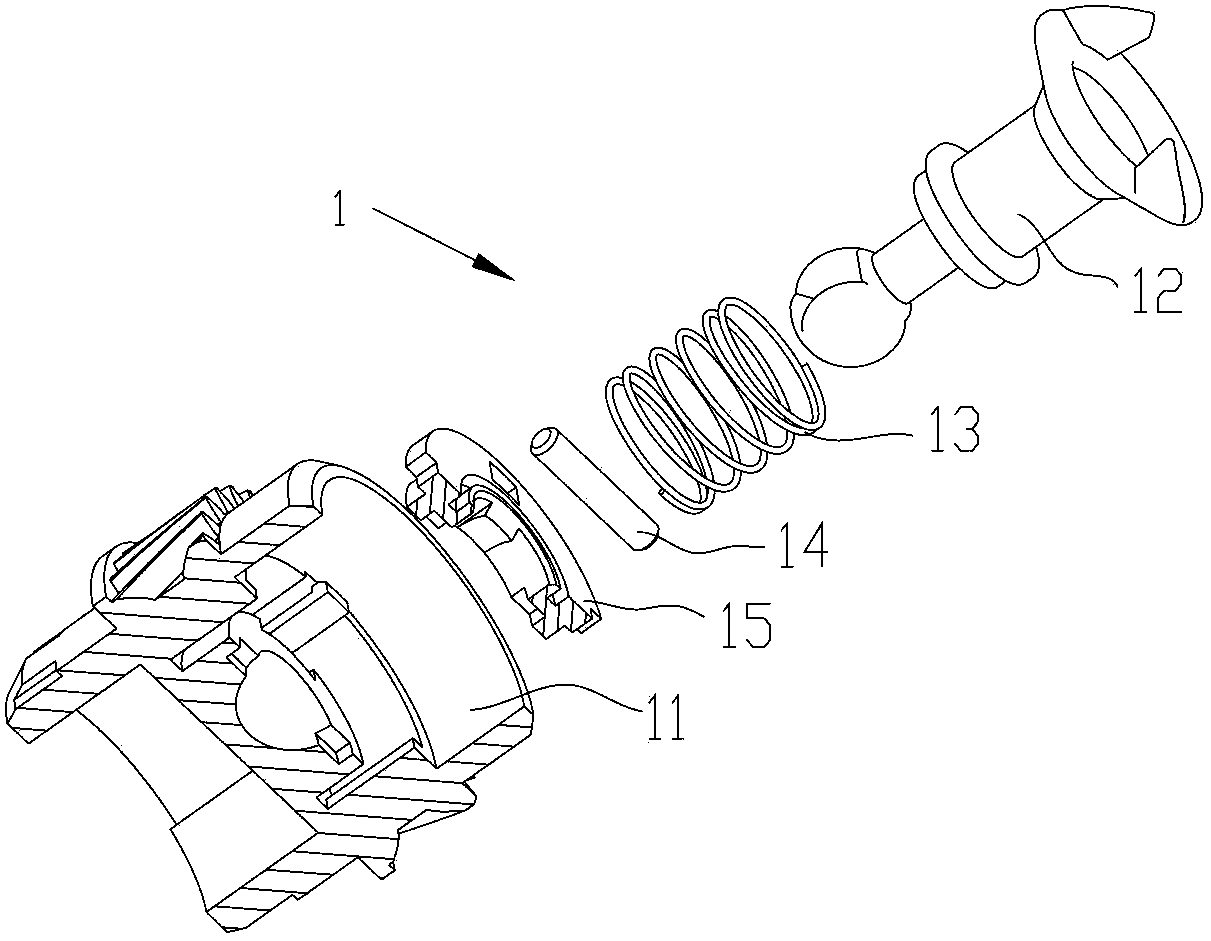

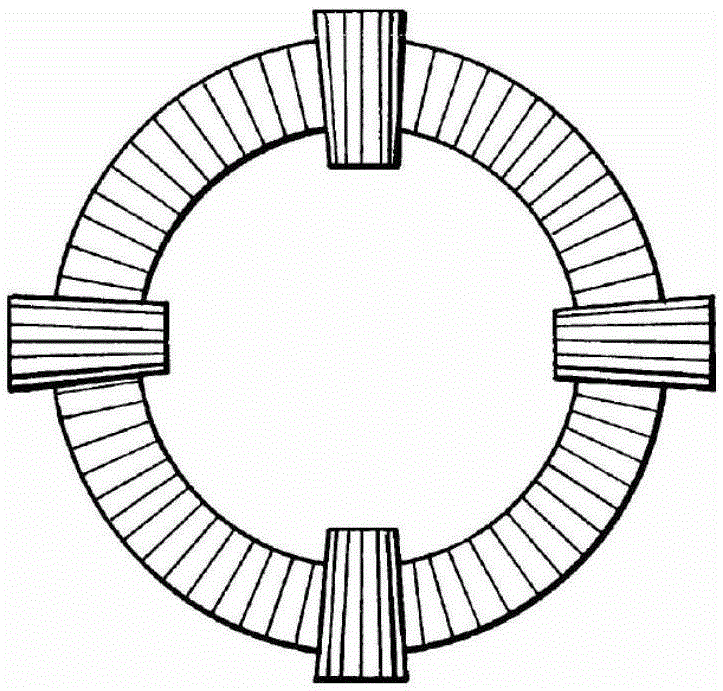

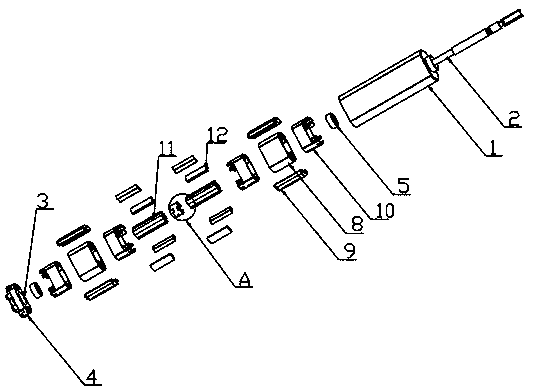

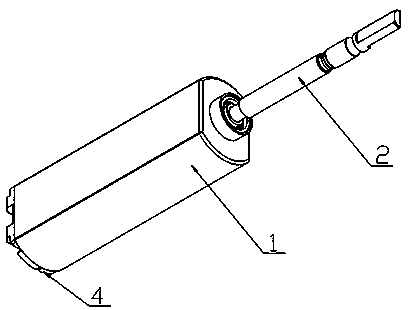

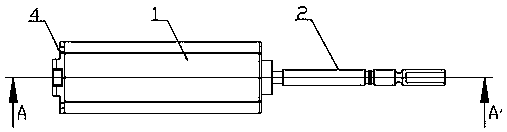

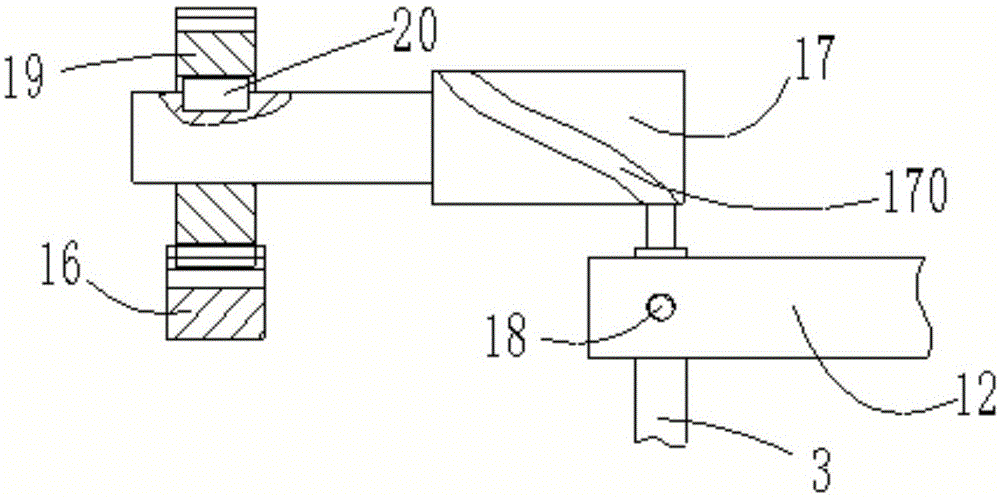

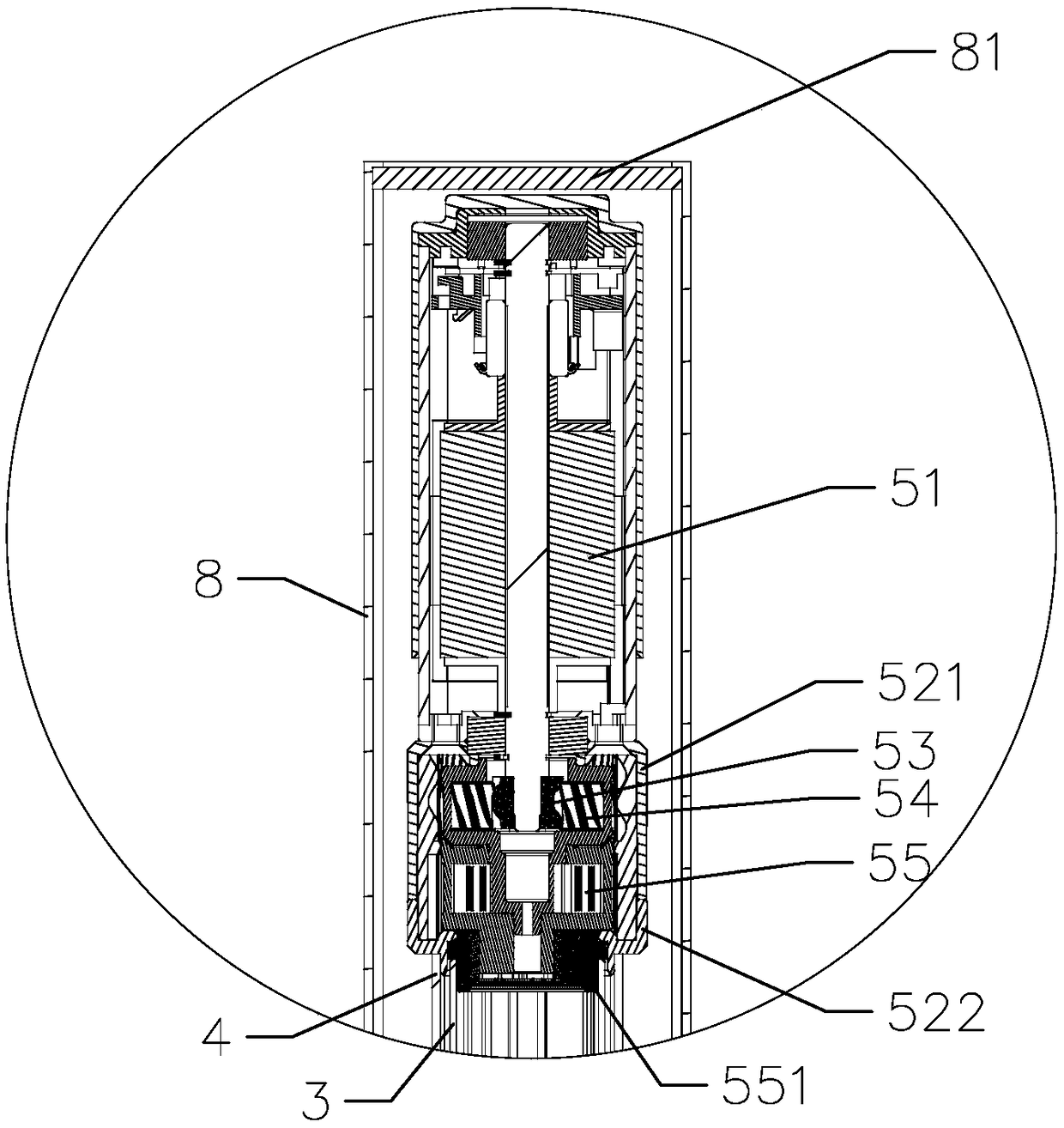

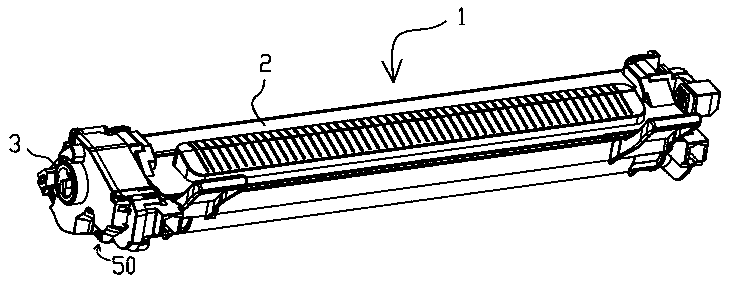

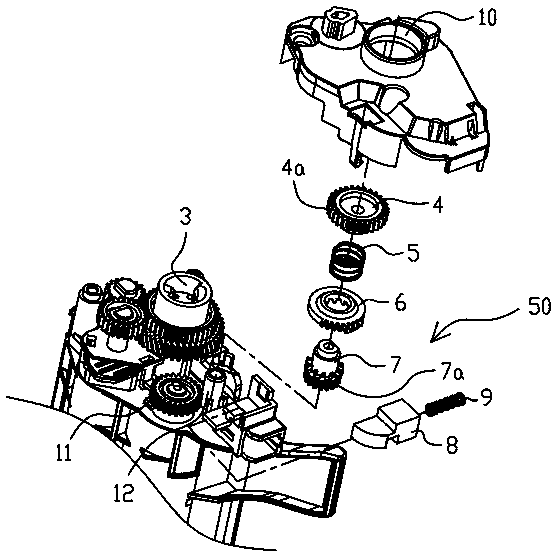

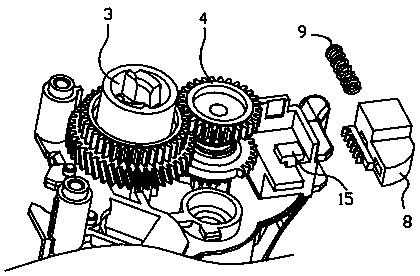

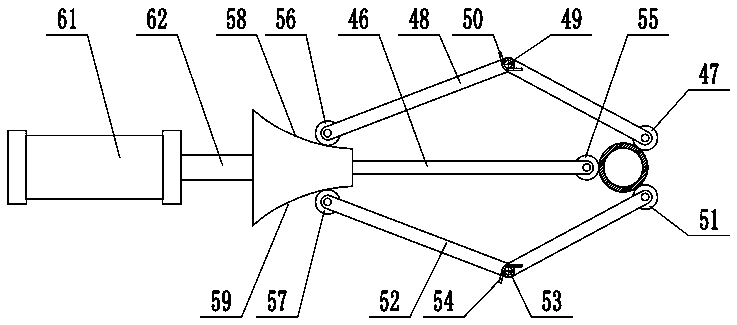

Rotary force drive assembly and carbon powder box including same

ActiveCN103513534AEasy to assembleSmooth power deliveryElectrographic process apparatusElectric power transmissionMechanical engineering

The invention relates to a rotary force drive assembly and a carbon powder box including the same. The rotary force drive assembly comprises a photosensitive element gear mounted at one end of a photosensitive element, a rotary driving force receiving head arranged on the photosensitive element gear, and a power transmission pin for transmitting a rotary driving force received by the rotary driving force receiving head to the photosensitive element gear; the end portion of the rotary driving force receiving head is provided with a sphere matched with the power transmission pin, and the sphere is provided with a through groove; the rotary force drive assembly comprises an upper positioning part and a lower positioning part, the power transmission pin passes through the through groove of the sphere, and the power transmission pin and the sphere are relatively fixedly arranged between the upper positioning part and the lower positioning part in the axial direction of the photosensitive element gear. The rotary force drive assembly has a function of arbitrary direction swing at a certain angle, at the same time, the assembly is simple, axial float quantity and radial float quantity of the rotary driving force receiving head can be effectively controlled, and stable and reliable power transmission can be achieved.

Owner:NINESTAR CORP

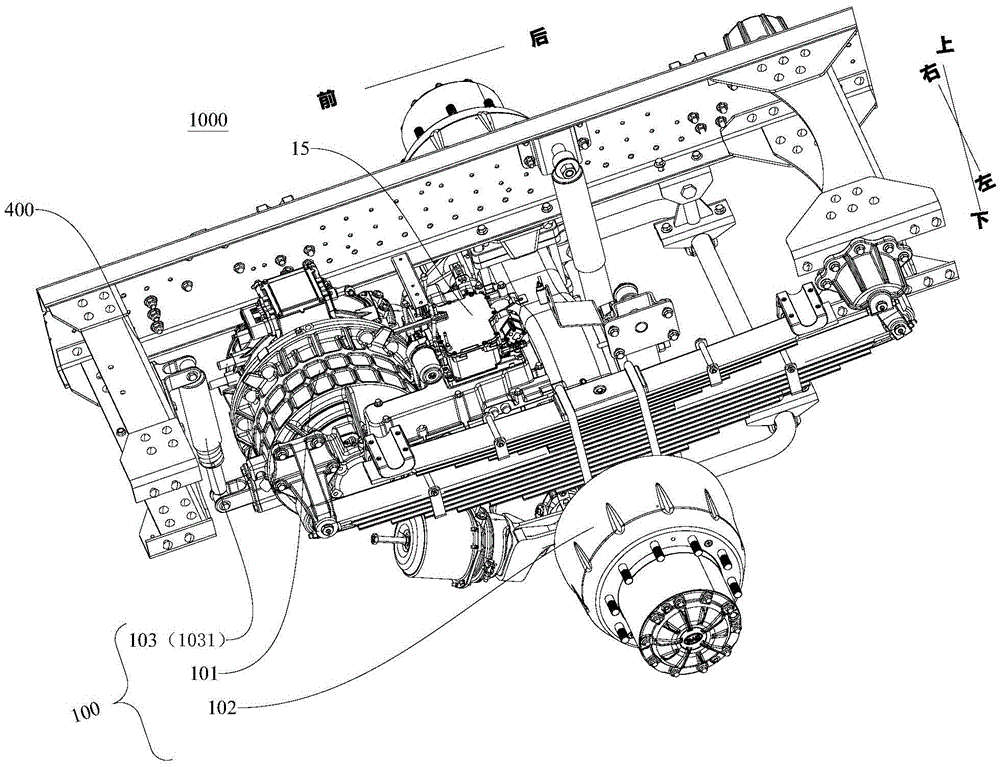

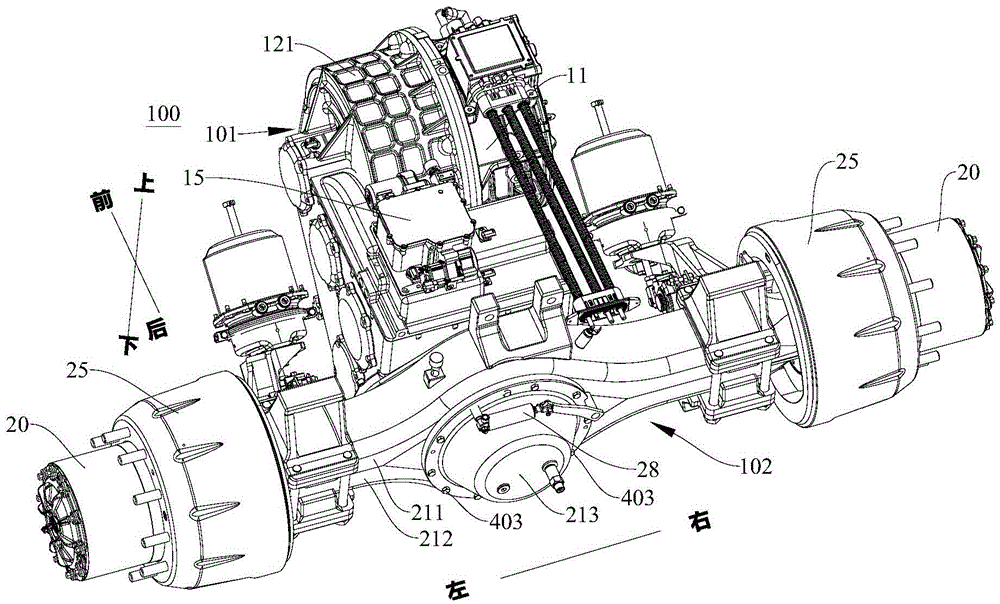

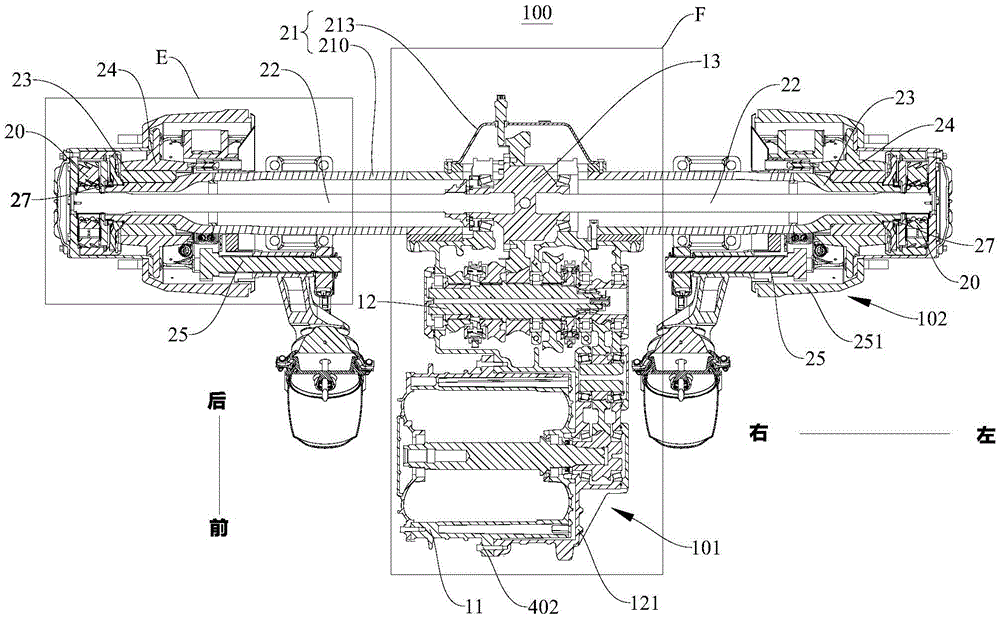

Vehicle and electric drive axle assembly used for vehicle

ActiveCN105966219ACompact structureHigh working reliabilityElectric propulsion mountingControl devicesVehicle frameEngineering

The invention discloses a vehicle and an electric drive axle assembly used for the vehicle. The electric drive axle assembly used for the vehicle comprises an electrodynamic assembly, an axle housing assembly and a suspension device, wherein the electrodynamic assembly comprises a power motor, a transmission and a differential mechanism, the transmission comprises a transmission shell body, the power motor is fixed on the transmission shell body, and the differential mechanism is supported on the transmission shell body; the axle housing assembly comprises an axle housing module and two semi-axles, the two semi-axles and the differential mechanism are located inside the axle housing assembly, and the transmission shell body is fixed on the axle housing assembly; and the suspension device is connected between the electrodynamic assembly and a frame of the vehicle. The electric drive axle assembly disclosed by the embodiment of the invention has the advantages of a compact structure, a small size, high reliability and high safety.

Owner:BYD CO LTD

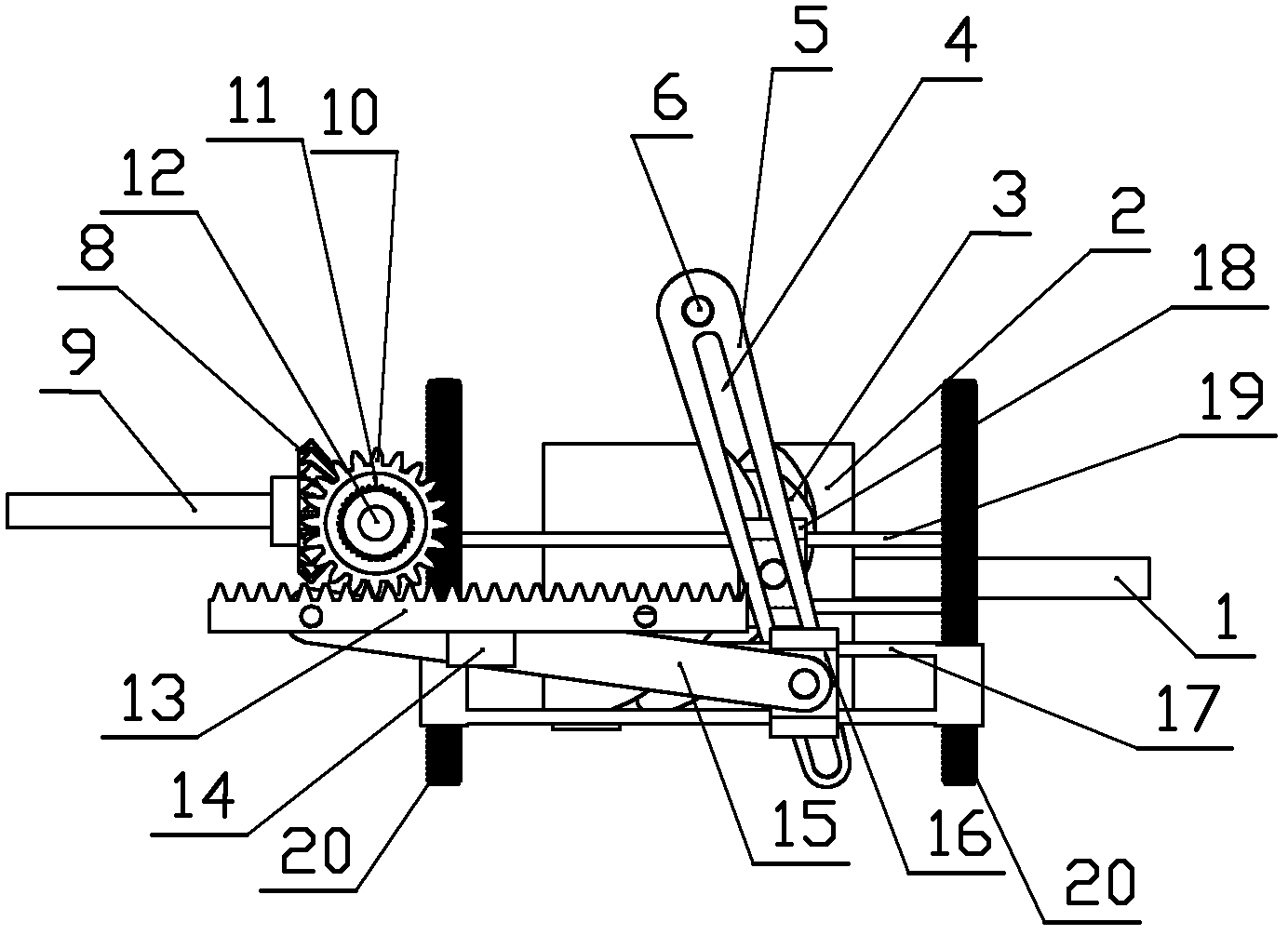

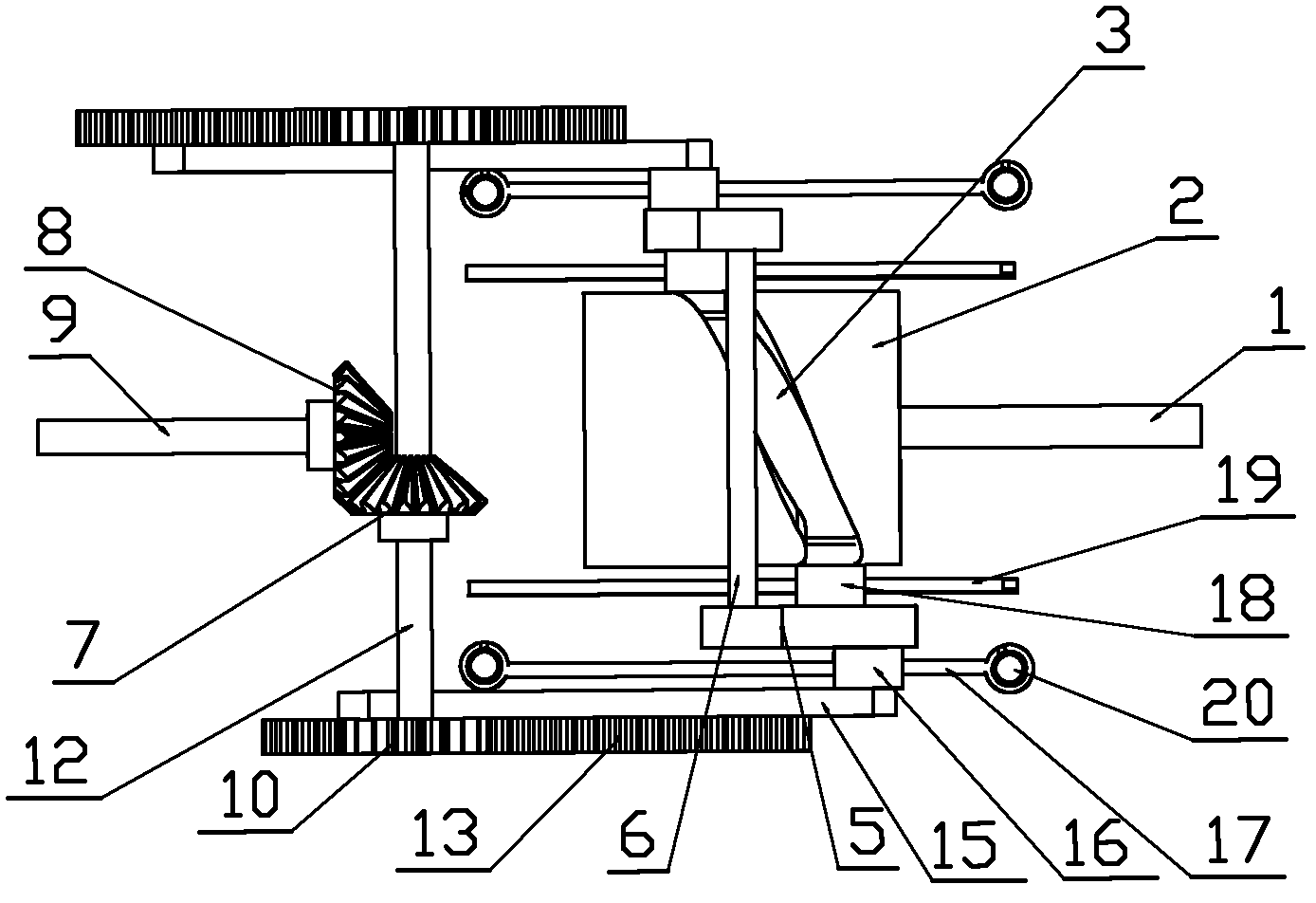

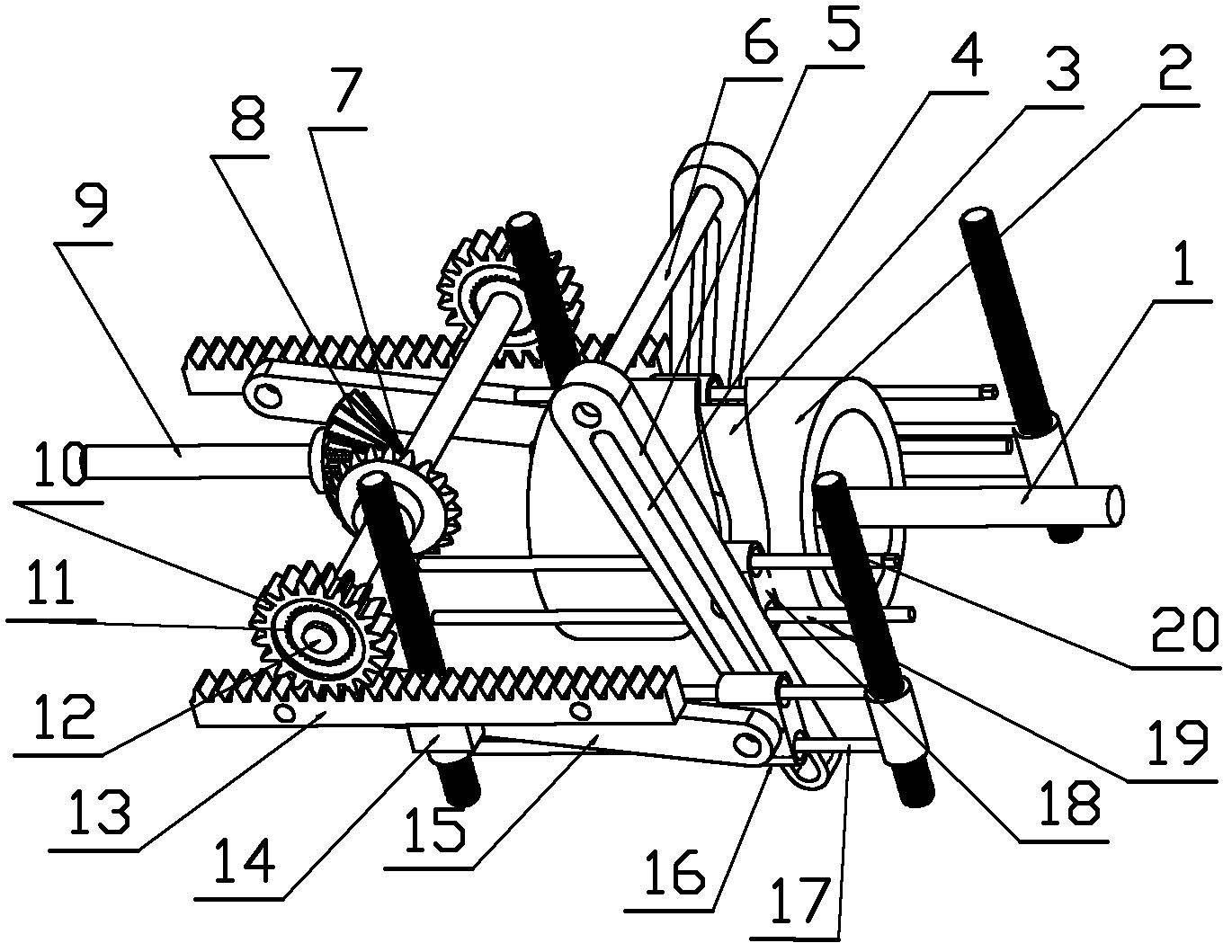

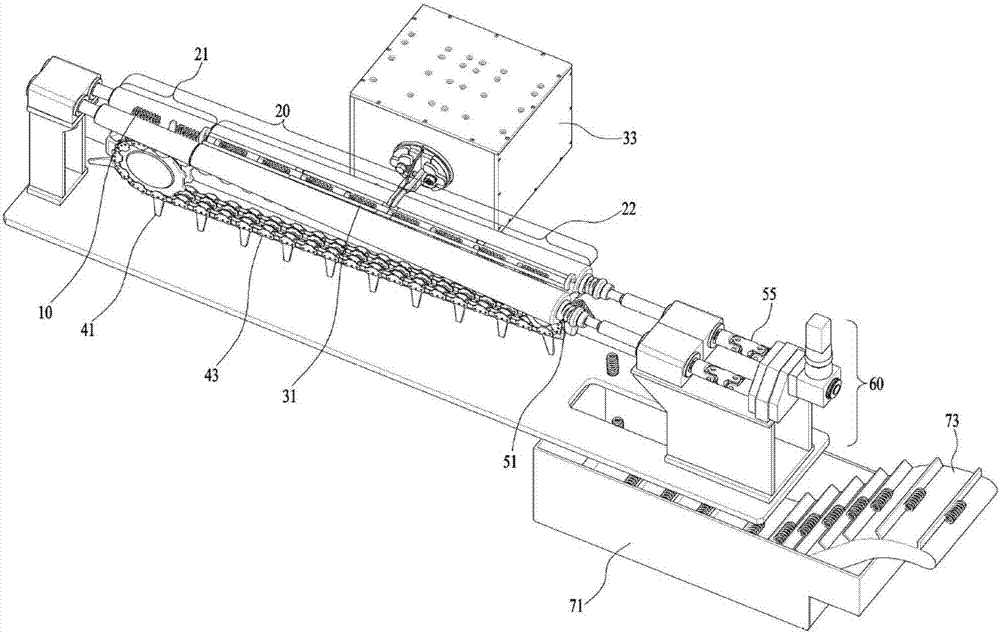

Rocker-type continuously variable transmission

The invention discloses a rocker-type continuously variable transmission, which relates to a mechanical continuously variable transmission for a vehicle. The rocker-type continuously variable transmission is structurally characterized in that sliders I, slide ways I, rockers, sliders II, slide ways II, connecting rods, racks, straight gears and one-way bearings are symmetrically and sequentially mounted on two sides of a cylindrical cam, the sliders I are mounted on the corresponding slide ways I, a roller on one side of each slider I is mounted in a slide way of the cylindrical cam, a roller on the other side of each slider I is embedded into a slide groove of one rocker, the sliders II are mounted on the corresponding slide ways II, a roller on one side of each slider II is embedded into a slide groove of the other rocker, the other side of each slider II is movably connected with the bottom of each connecting rod, the connecting rods are connected with the corresponding racks through rack supporting grooves, the racks are engaged with the straight gears, the one-way bearings are mounted in the straight gears, a gear shaft is mounted between the two one-way bearings, a bevel gear I is mounted in the middle of the gear shaft and engaged with a bevel gear II, a power output shaft is mounted on the bevel gear II, the front ends of the two opposite rockers are connected with each other by a rocker shaft, and a power input shaft is mounted at the bottom of the cylindrical cam.

Owner:DALIAN MARITIME UNIVERSITY

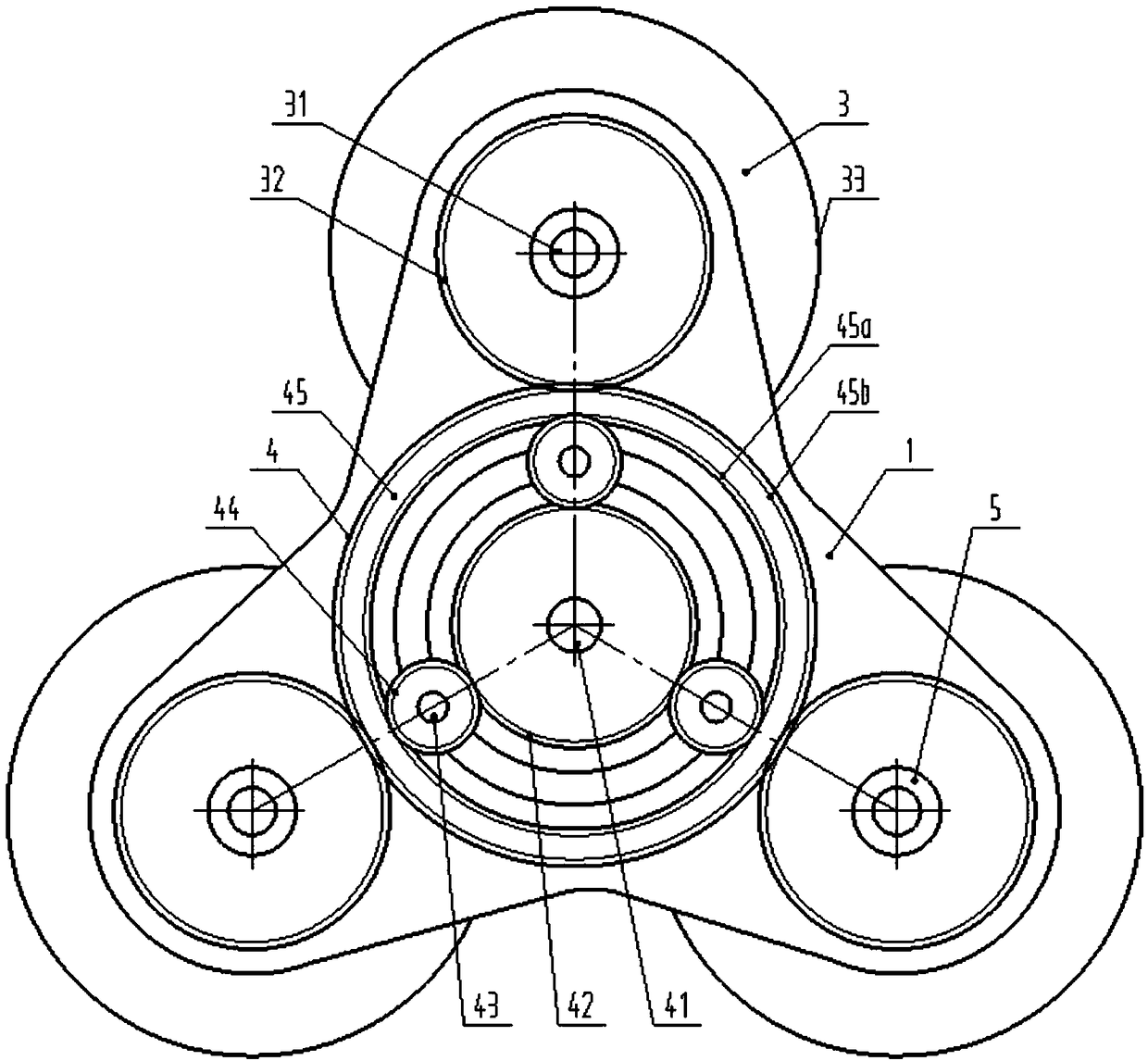

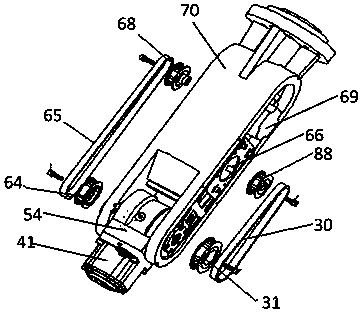

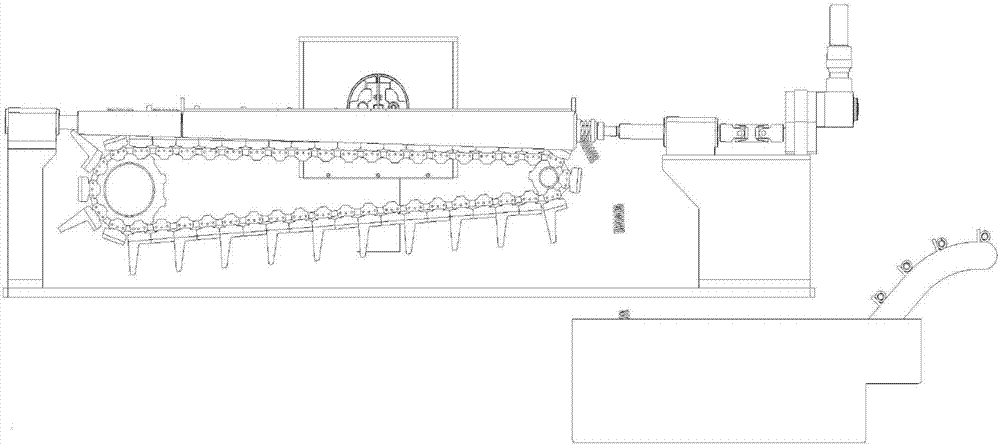

Driving device with power-assisted travelling and stairs climbing functions

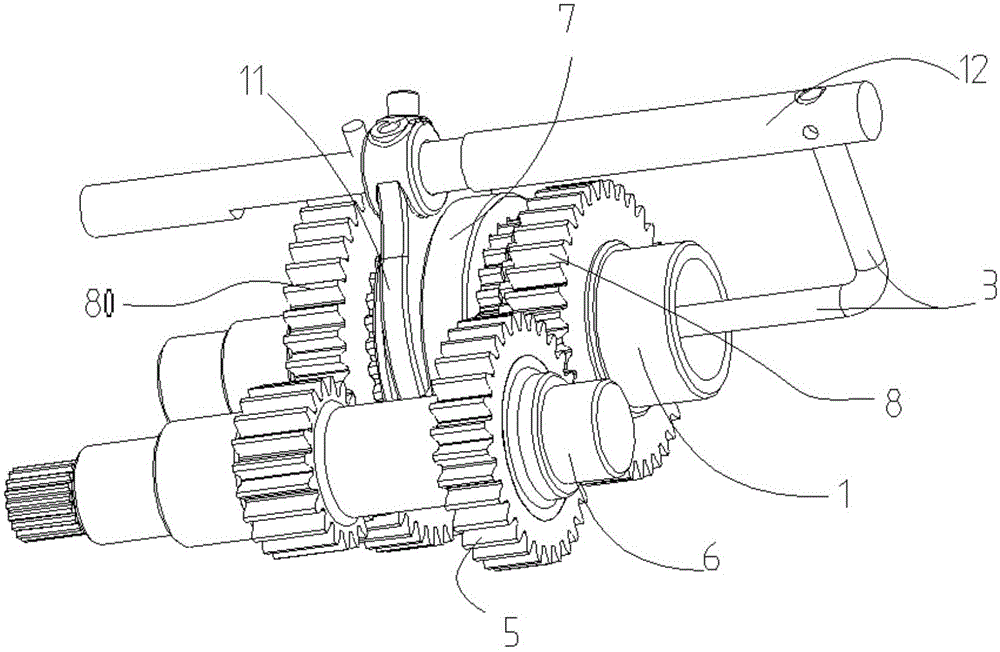

PendingCN108210189AAchieve obstacle crawlingRealize the need to use the functionWheelchairs/patient conveyanceToothed gearingsGear wheelClimbing stairs

The invention discloses a driving device with power-assisted travelling and stairs climbing functions. A travelling mechanism and a climbing frame are combined together to form a novel planet gear transmission principle; in travelling on a flat road, a driving portion drives a sun gear to positively rotate, two travelling wheels contact a ground at the same time, the sun gear drives a planet gearto reversely auto-rotate around a planet shaft, inner teeth and outer teeth of a tooth ring and the planet gear rotate reversely in sync, and a transmission gear drives the travelling wheels to positively rotate, thus achieving travelling rotation; in stairs climbing, the sun gear positively rotates, the travelling wheels counter stairs and are blocked, the transmission gear and the inner and outer teeth of the tooth ring stop rotating, the sun gear drives the planet gear to revolve positively along the inner teeth, and the planet shaft drives the climbing frame to positively rotate, thus achieving obstacle surmounting and climbing. The technical problem is solved that an existing star gear structure hardly climbs stairs since the climbing frame is powered to reversely operate when the travelling wheels are unable to operate; the driving device has the advantages of simple structure and good safety and reliability of use.

Owner:贾银霞

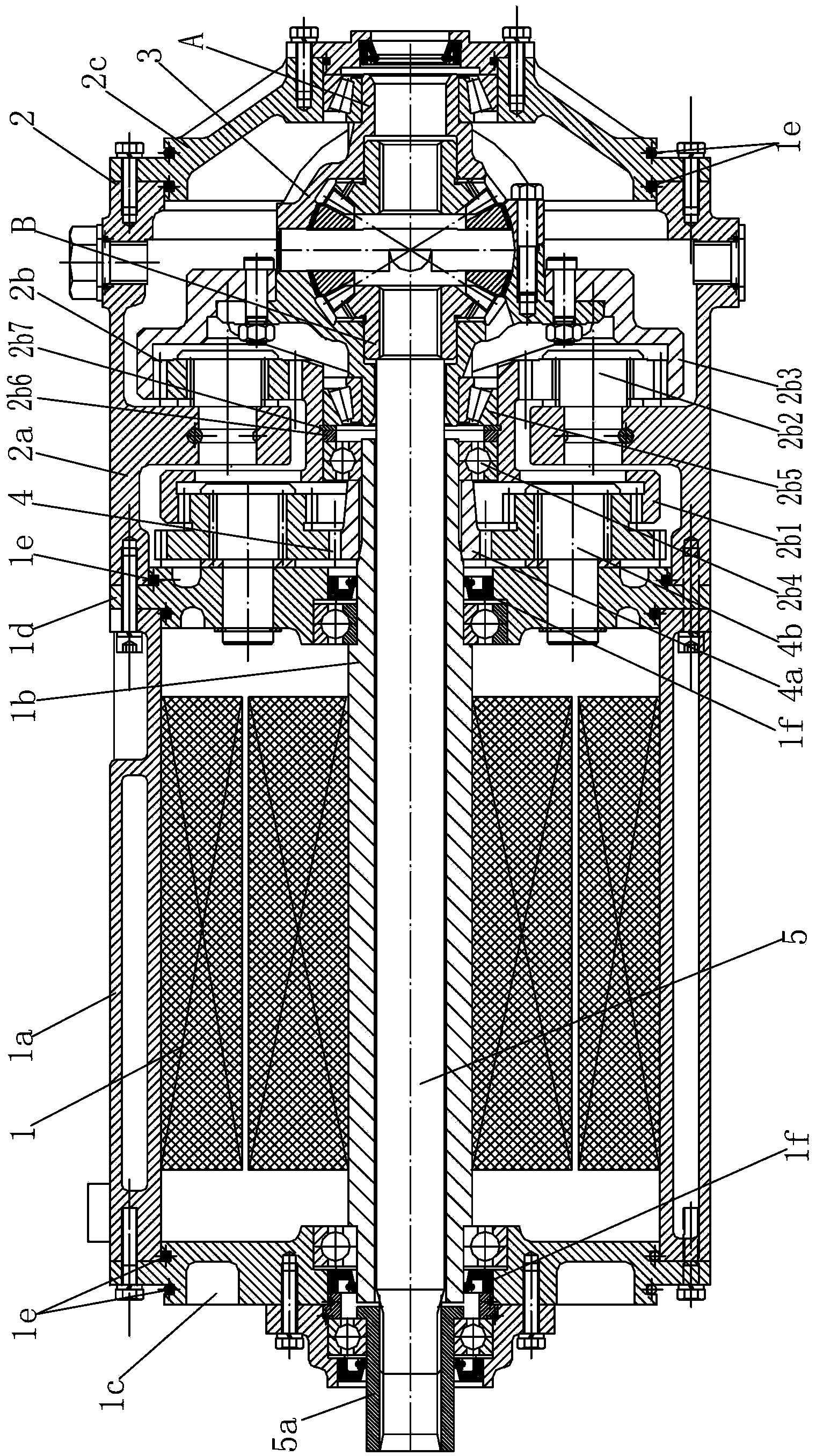

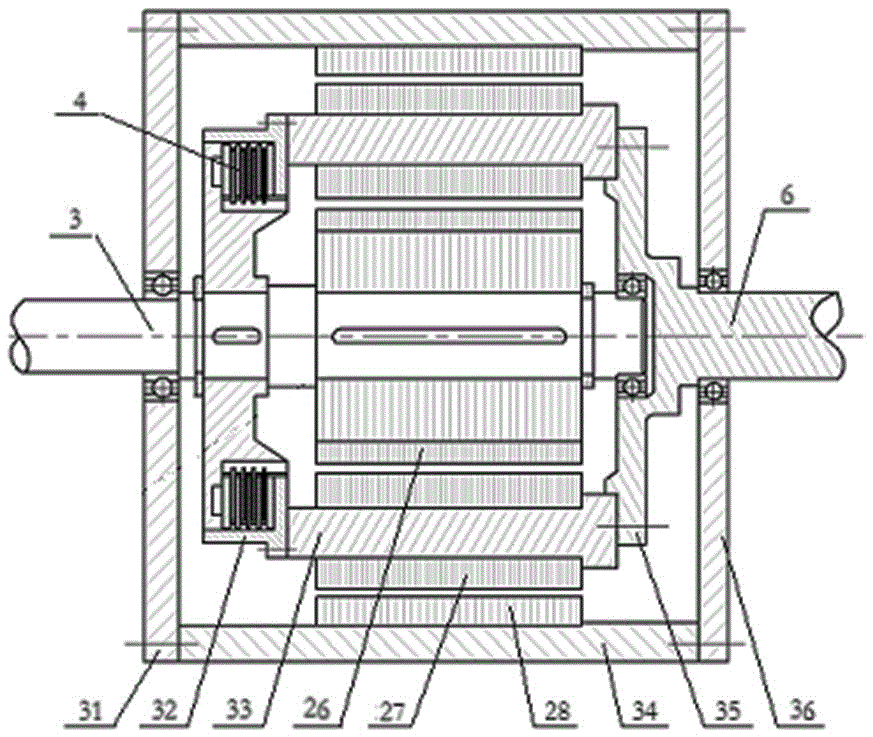

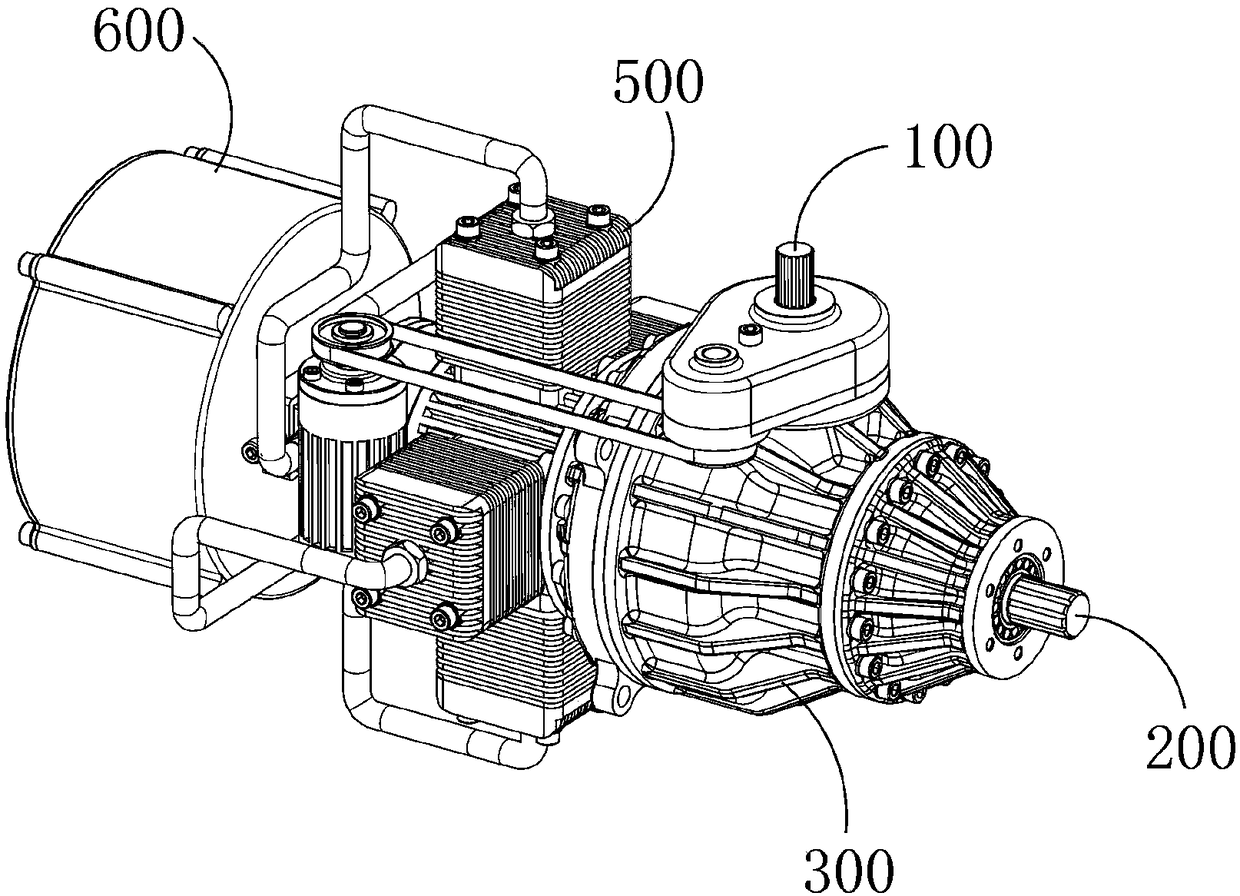

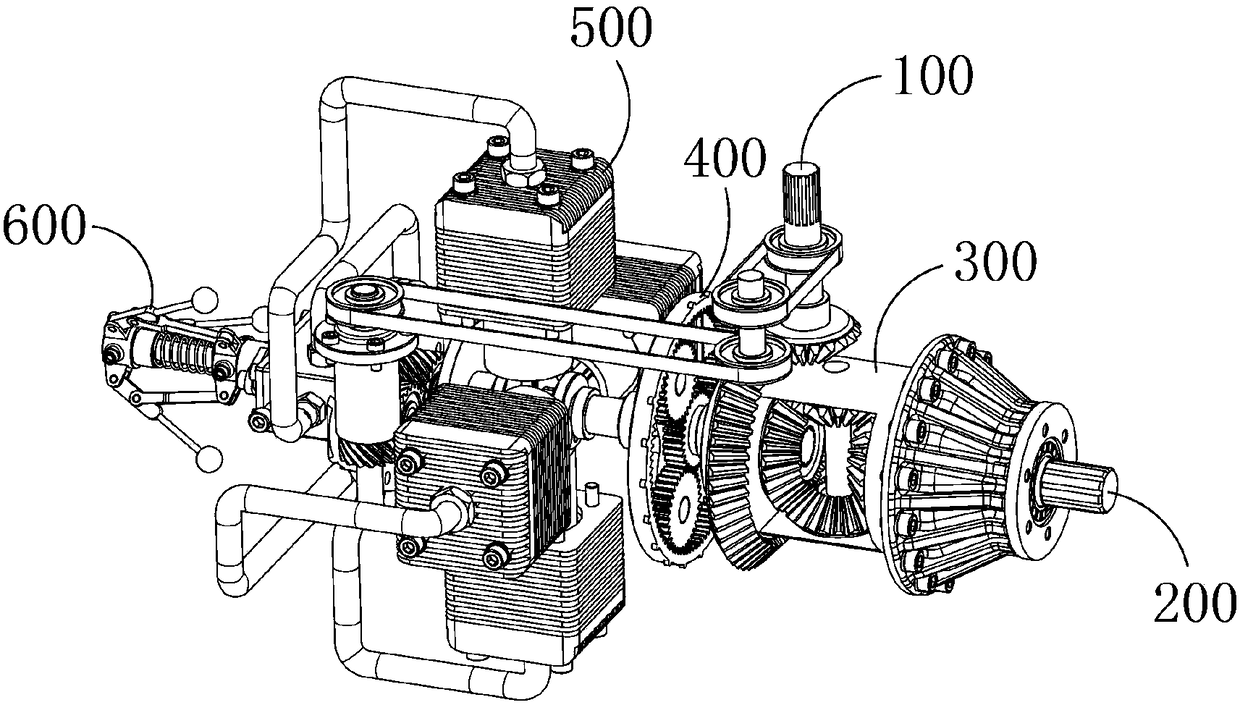

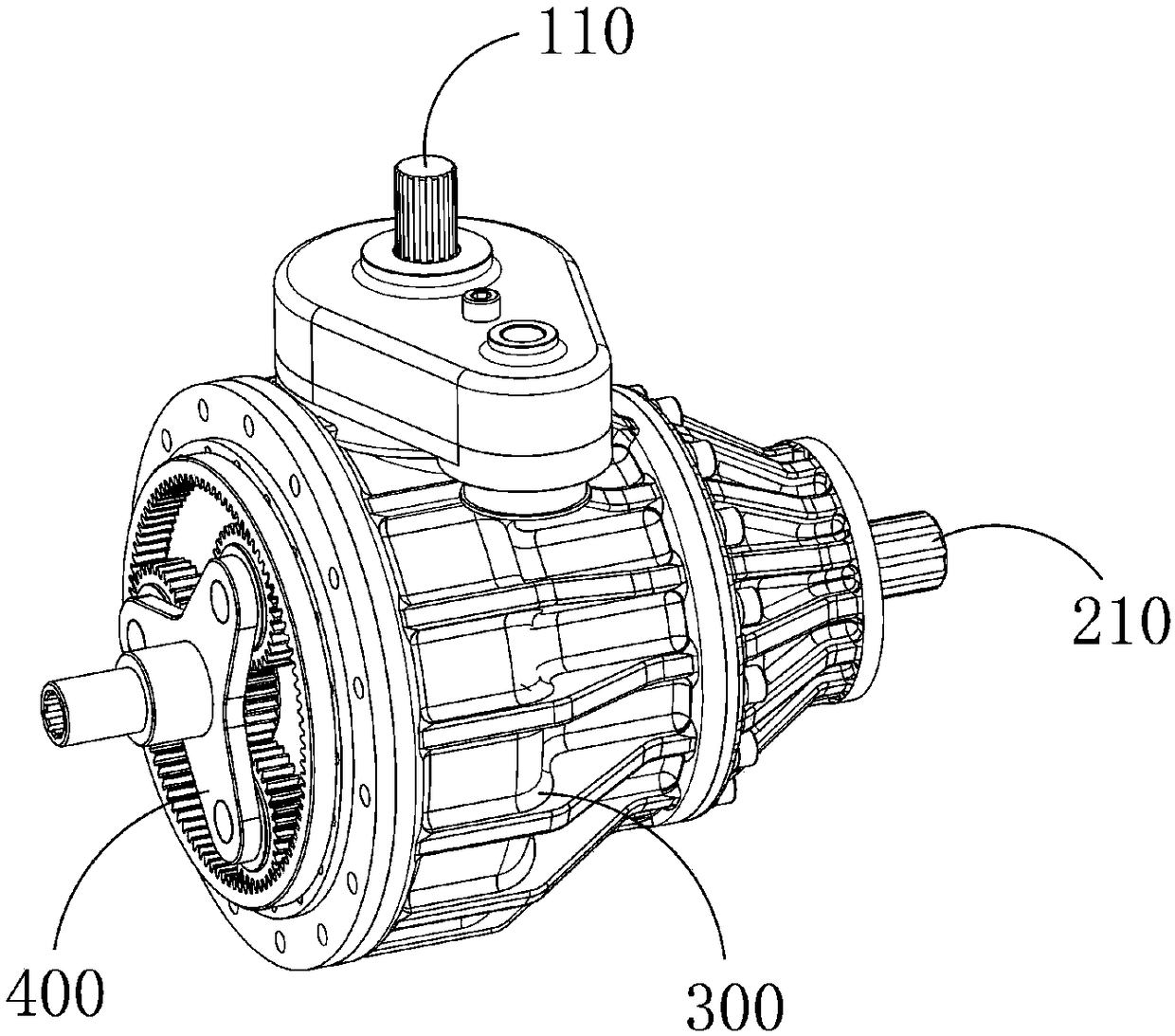

Torque conversion differential assembly of coaxial motor

ActiveCN103448540AGuaranteed coaxialityImprove balanceElectric propulsion mountingGearing detailsControl theoryTorque converter

The invention discloses a torque conversion differential assembly of a coaxial motor. The torque conversion differential assembly comprises a motor sub-assembly, a torque converter sub-assembly and a differential sub-assembly. The motor sub-assembly comprises a motor shell, a motor rear end cover, a motor front end cover and a rotor shaft, the motor rear end cover and the motor front end cover are respectively mounted at two ends of the motor shell, and the rotor shaft is movably mounted on the motor rear end cover and the motor front end cover and is of a hollow structure; the torque converter sub-assembly comprises a torque converter shell, a speed change mechanism and a torque converter end cover, the torque converter end cover is mounted at the front end of the torque converter shell, the rear end of the torque converter shell is mounted on the motor front end cover, the front end of the rotor shaft is in transmission connection with an input end of the speed change mechanism, an output end of the speed change mechanism is fixed onto a shell of the differential sub-assembly, an output end B of the differential sub-assembly is mounted on the torque converter end cover, and an output end A and the output end B of the differential sub-assembly are coaxial with the rotor shaft. The torque conversion differential assembly has the advantages of small occupied space, good balance and applicability to vehicles.

Owner:GEYUAN POWER

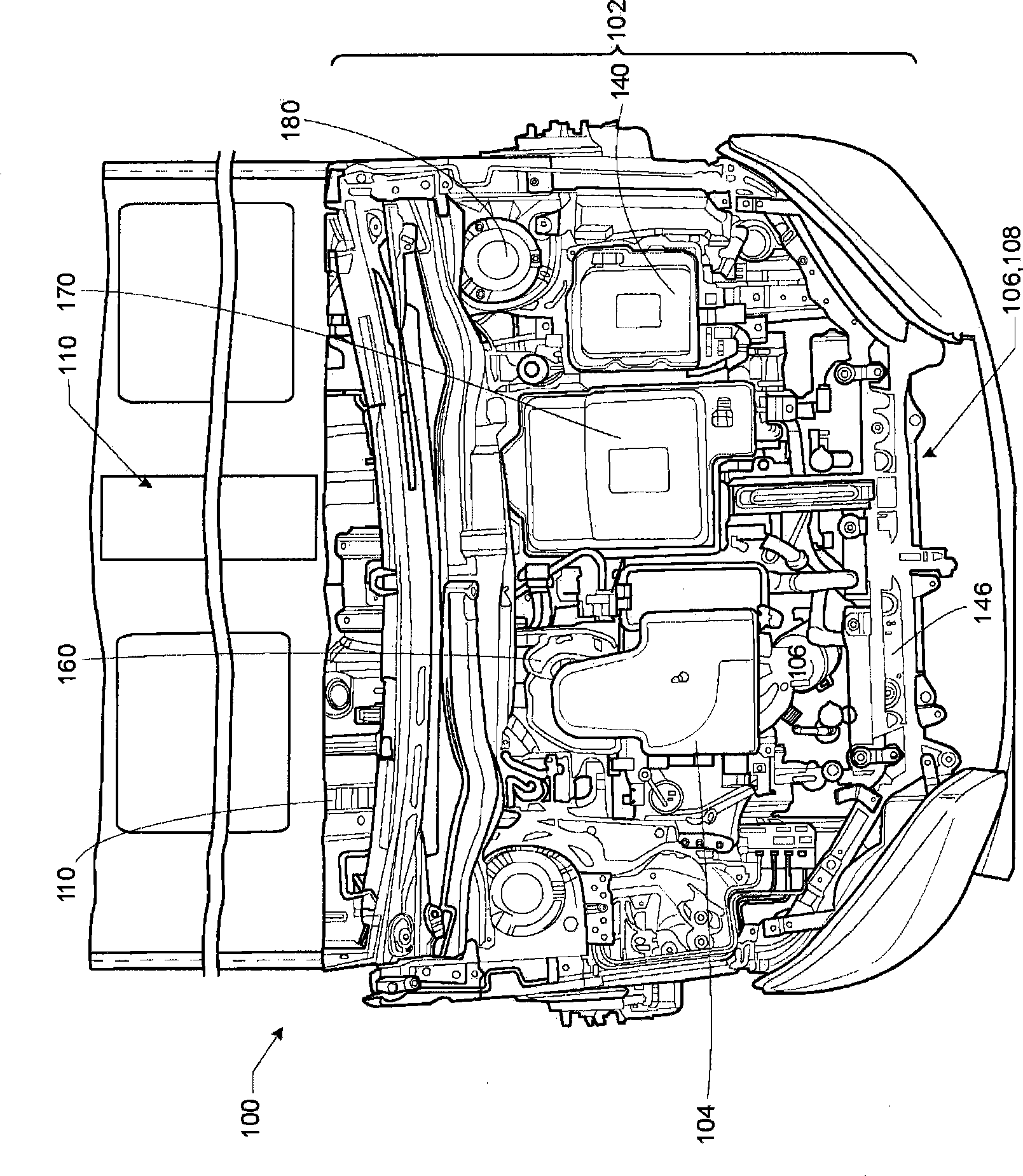

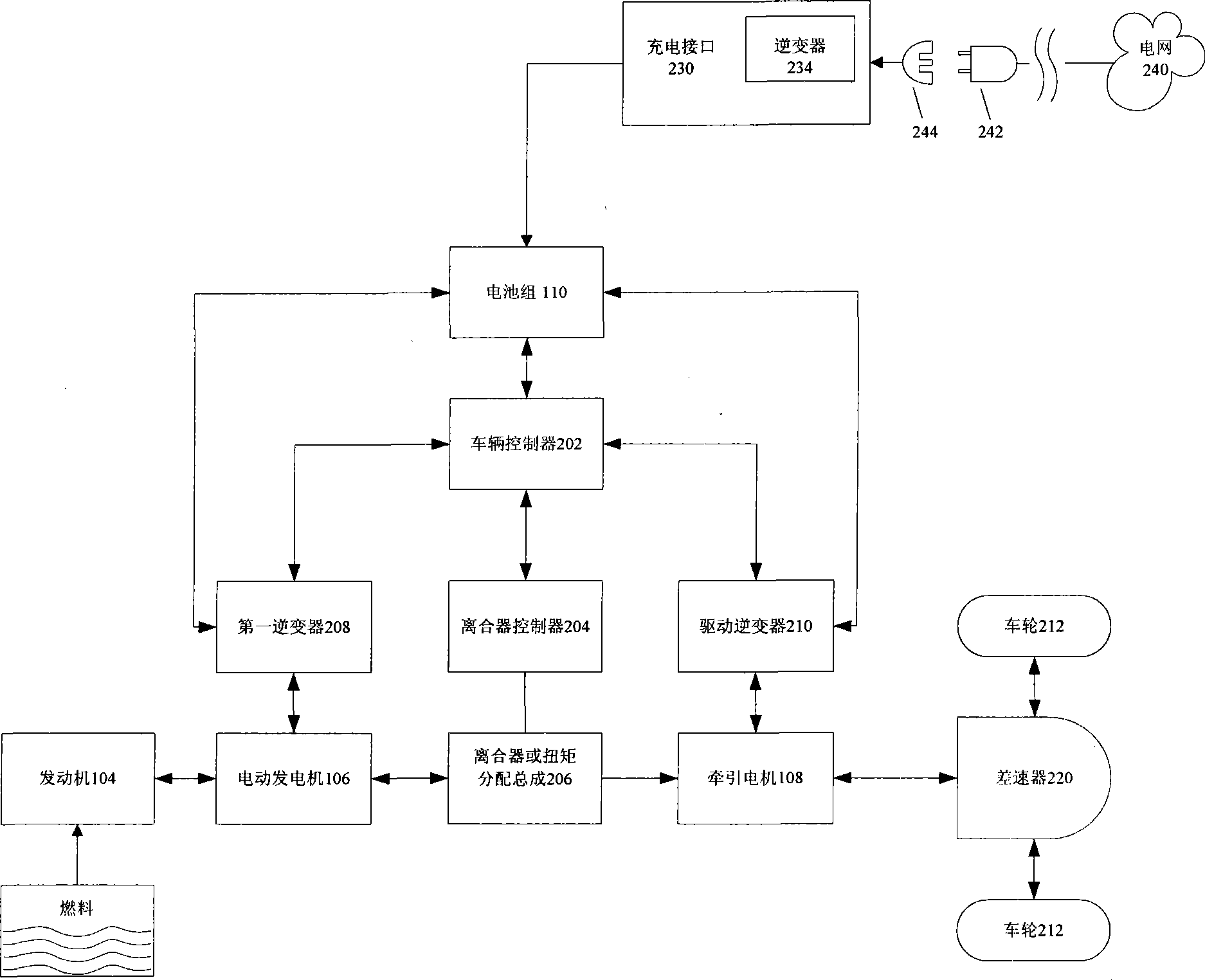

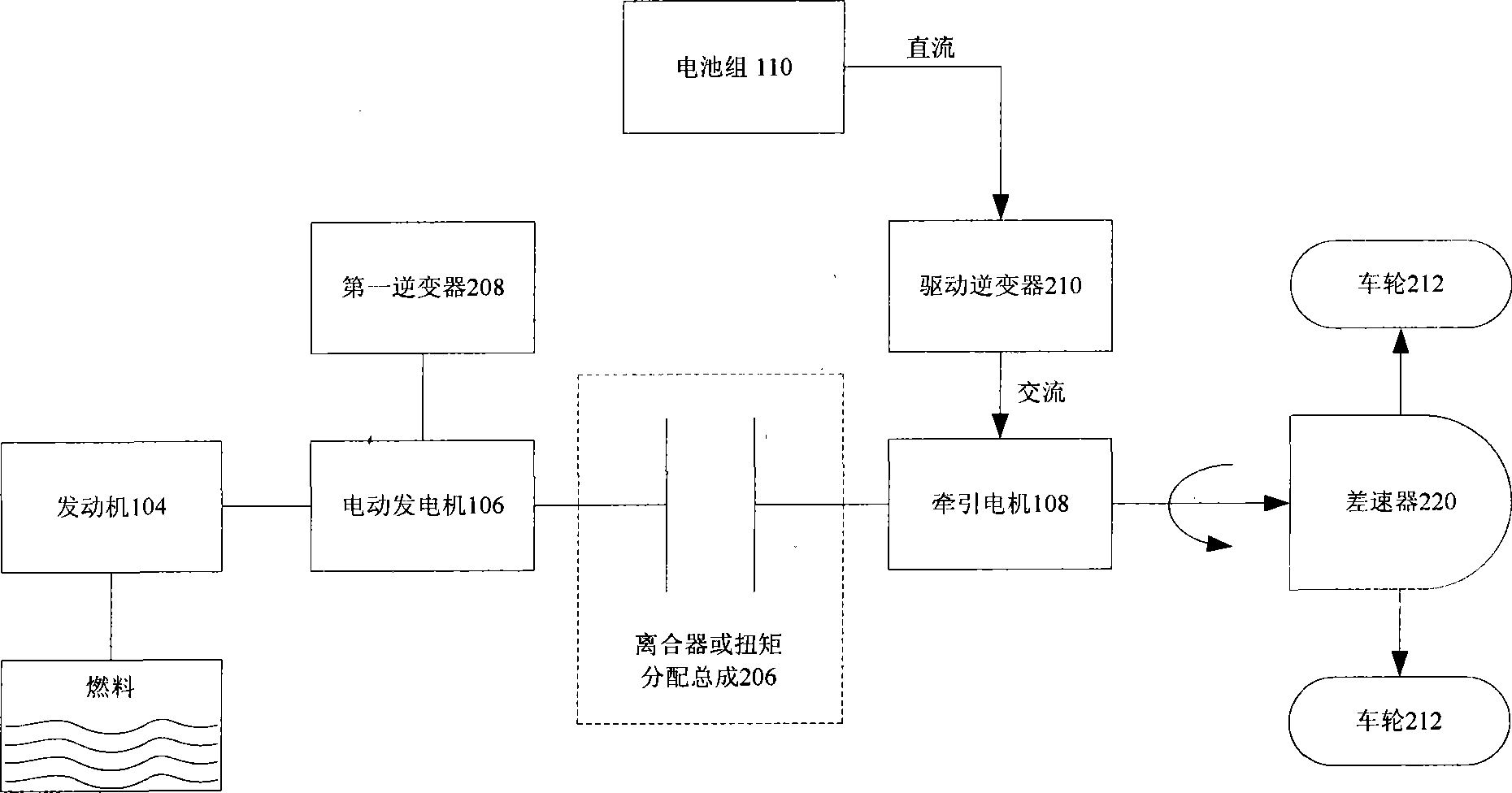

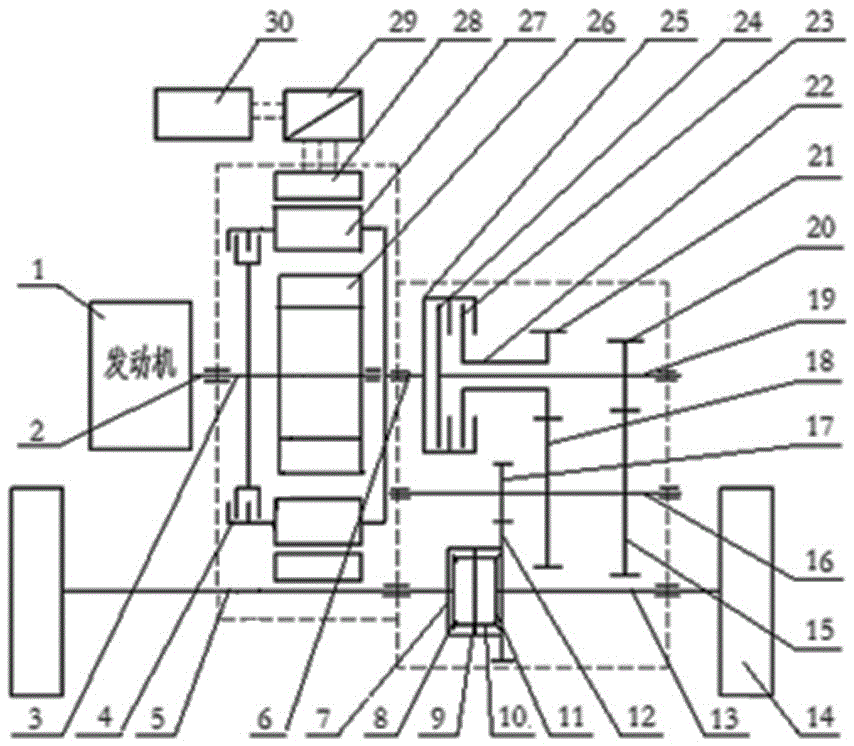

Hybrid vehicle with changeover panel assembly

ActiveCN101445040ARealize comprehensive utilizationIncrease profitHybrid vehiclesElectric propulsion mountingRotational axisElectrical battery

The invention relates to a hybrid vehicle with a changeover panel assembly, comprising a battery system, an engine, a first electric motor, a second electric motor and a clutch assembly, wherein, the battery system is used for receiving, storing and supplying electric energy, the engine is driven by a flywheel, the first electric motor is provided with a hollow rotating shaft, the hollow rotating shaft is rotatably connected with the flywheel of the first electric motor, and the clutch assembly arranged between the engine and the first electric motor. In the whole operation process of the hybrid vehicle provided in the invention, the second vehicle is used as the main power source for driving the vehicle, and the engine always operates with optimum efficiency, so that a hybrid power drive system can have excellent self-efficiency, and can meet required power and make maximum use of power, so as to improve fuel utilization rate and reduce discharge of tail gas, thus realizing low emission and low fuel consumption.

Owner:BYD CO LTD

Integrated two-gear hybrid electric vehicle driving system with double-rotor motor

InactiveCN105667295AHigh power transmission efficiencySmooth power deliveryGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingClutchVariator

The invention provides an integrated two-gear hybrid electric vehicle driving system with a double-rotor motor. The integrated two-gear hybrid electric vehicle driving system comprises an engine, a multi-disc wet type friction clutch, the double-rotor motor, a double-clutch two-gear speed changer, a differential mechanism, an inverter controller and a power battery. An electromagnetic type power coupling mechanism is composed of the multi-disc wet type friction clutch and the double-rotor motormulti-disc wet type friction clutch, and an engine starting mode, a parking and charging mode, a pure electric driving mode, an engine independent driving mode, a hybrid driving mode and a regeneration braking mode of a vehicle can be realized respectively; rapid and smooth switching of low-speed gears and high-speed gears of the vehicle can be realized through the double-clutch two-gear speed changer; the driving system integrates the multi-disc wet type friction clutch and the double-rotor motor, and the double-clutch two-gear speed changer and the differential mechanism, and has the advantages of high transmission efficiency, compact structure, high integration degree and convenience for arrangement and light weight of the whole vehicle; the dynamic property, economical efficiency, emission performance and comfort of the whole vehicle are improved.

Owner:HEFEI UNIV OF TECH

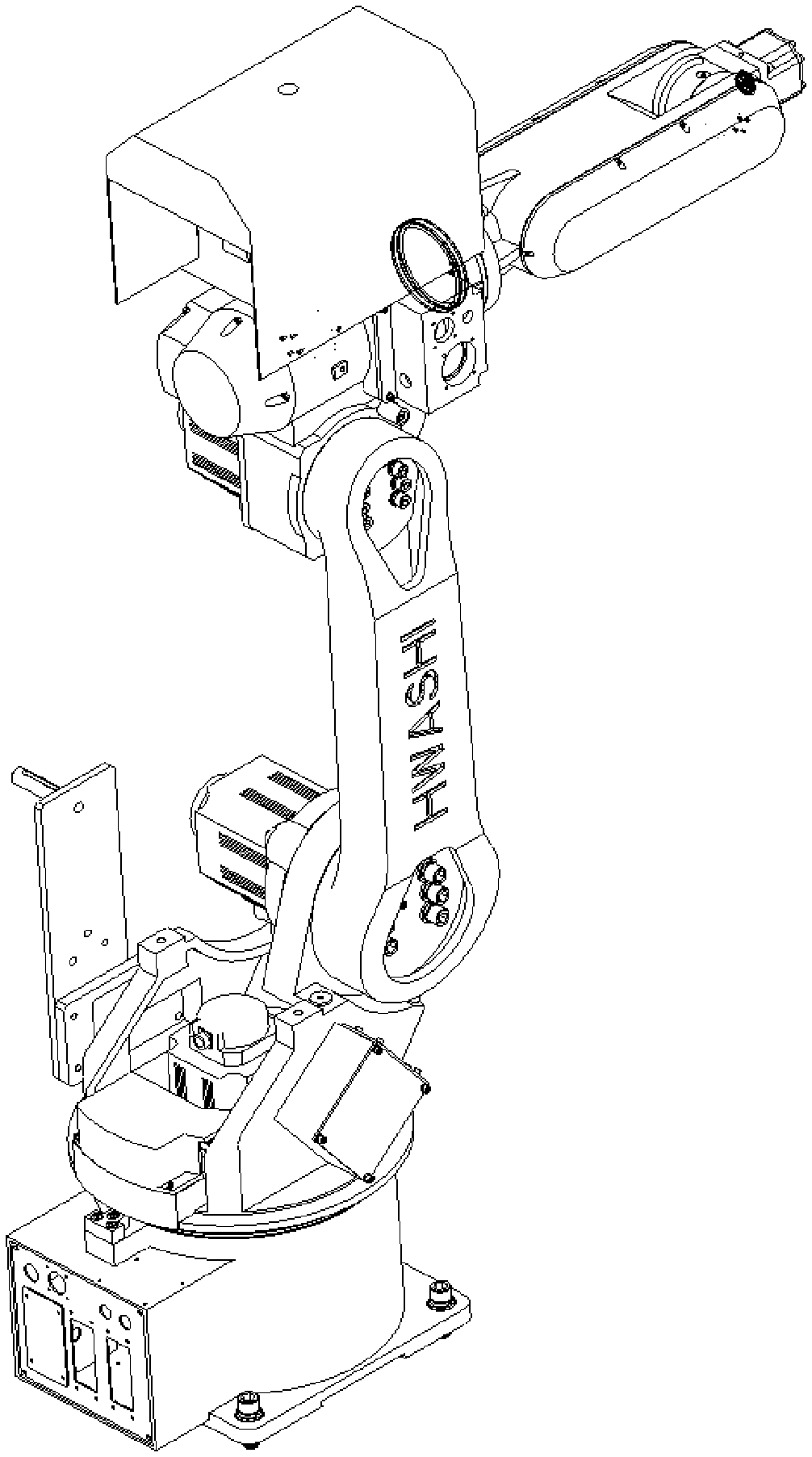

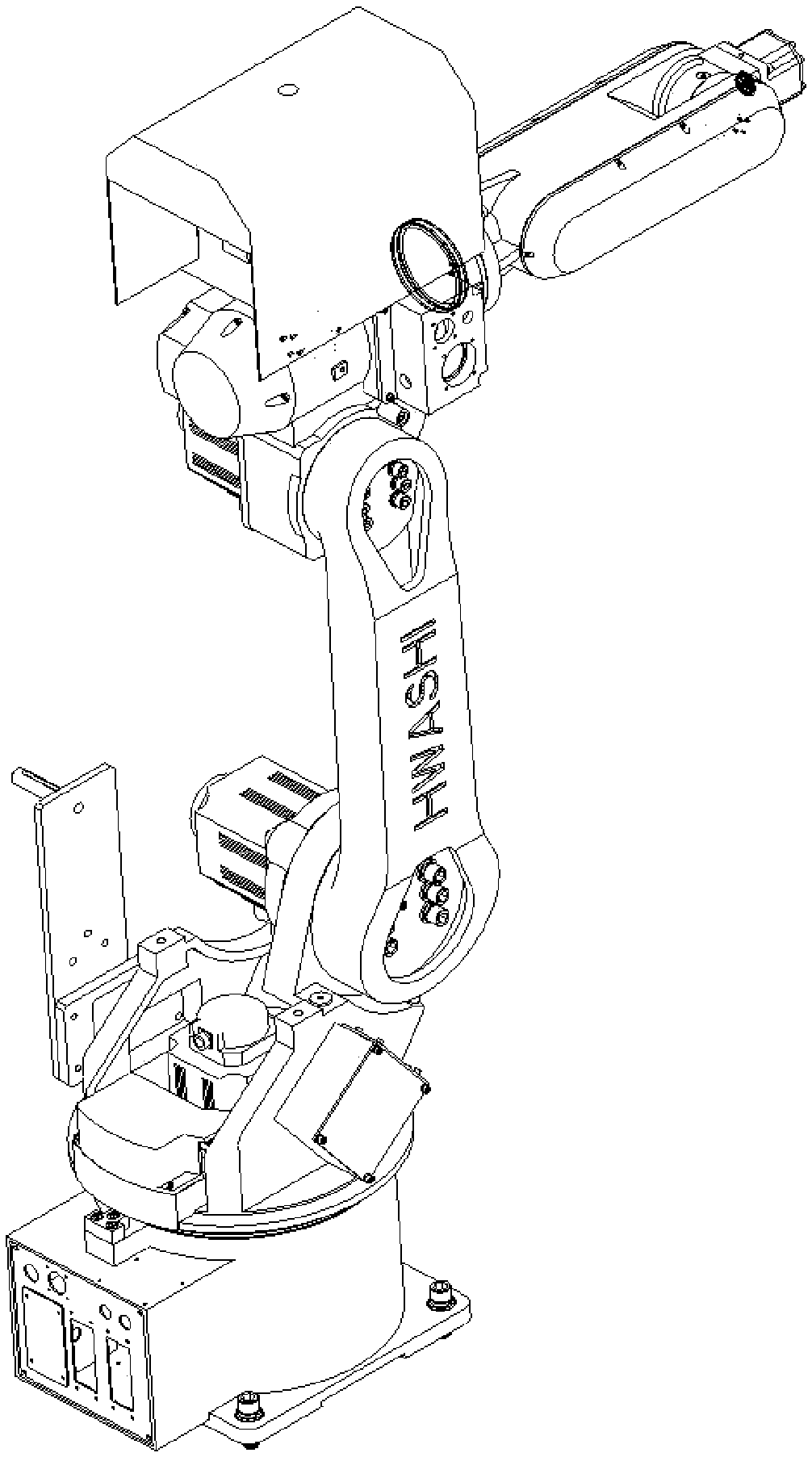

Six-axis robot

ActiveCN108312134ARealize no dead angle workRealize automatic and intelligent workProgramme-controlled manipulatorJointsAngular degreesReducer

The invention discloses a six-axis robot which comprises a first joint structure, a second joint structure, a third joint structure, a fourth joint structure, a fifth joint structure and a sixth jointstructure. When the six-axis robot is under operation, each of the joint structures can rotate around one axis direction; and the six joint structures can independently rotate in the six axis directions, so that a robot control terminal can reach any angle and position to realize working without the dead angle in industrial application; in addition, six servo motors are adopted as drive sources,and a plurality of reducers are also introduced to enable the operating motion of the robot to be smoother, steadier and more controllable; and precise control over the robot can be realized through setting the deceleration proportion of each reducer and the working procedure of each servo motor. Moreover, a plurality of bearing pedestals and the corresponding bearing structures are arranged, so that undamped transmission and stable power transmission of all joints of the robot are realized, and the robot has high operational stability and working continuity.

Owner:HUASHI POWER SUPPLY TECH JIANGXI CO LTD

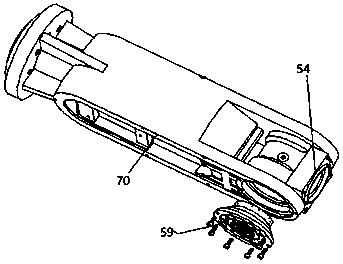

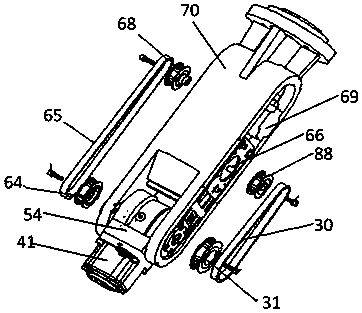

Robot

PendingCN110238834ARealize no dead angle workRealize automatic and intelligent workProgramme-controlled manipulatorElectric power transmissionReducer

The invention provides a robot. The robot comprises a first joint structure, a second joint structure, a third joint structure, a fourth joint structure, a fifth joint structure, a sixth joint structure and a manipulator, wherein each joint structure can rotate around an axis direction during operation of the robot, the six joint structures can independently rotate in six axis directions, the manipulator can perform telescopic movement along a straight line so that the robot can reach any angle and position, and dead-angle-free work in industrial application is realized; six servo motors are adopted as driving sources, and a plurality of speed reducers are introduced, so that the operation action of the robot is more stable and controllable; the automatic precise control of the robot can be achieved through setting the speed reduction ratios of all the speed reducers and setting the working procedures of all the servo motors and the oil cylinder air cylinders; and no damping transmission and stable power transmission are ensured through a plurality of bearing seats and a bearing structure, so that the robot has good operation stability and work automation.

Owner:贾培军

Driving device of escalator

The invention discloses a driving device of an escalator with stable power transmission, high working efficiency, low fault rate and long service life, belonging to the technical field of the escalator. The driving device comprises a stator shaft, a rotor sleeve, a first chain wheel, a second chain wheel, a first bearing and a second bearing, wherein, the outer surface of the stator shaft is distributed with coils, and the inner surface of the rotor sleeve is distributed with permanent magnets, and the rotor sleeve is sheathed outside of the stator shaft; one end of the stator shaft is interconnected with the first chain wheel by the first bearing, and the other end thereof is interconnected with the second chain wheel by the second bearing; and one end of the rotor sleeve is fixedly connected with the first chain wheel and the other end thereof is fixedly connected with the second chain wheel.

Owner:SUZHOU XINDA ESCALATOR ACCESSORIES

Scraper assembly for centrifugal machine

The invention discloses a scraper assembly for a centrifugal machine. The scraper assembly comprises an outer cylinder which is fixed at the top of a casing vertically, a shaft sleeve installed inside the outer cylinder in a rotating manner, a driving shaft arranged inside the shaft sleeve and a scraper installed at the lower end of the driving shaft, wherein the scraper sticks into a rotary drum of the centrifugal machine, the shaft sleeve and the driving shaft are connected through a sliding key, an axial power device provided with a driving shaft moving vertically is installed on the outer cylinder, and the shaft sleeve is driven by a rotary power device. According to the scraper assembly for the centrifugal machine, stable and quick power transmission and accurate scraper motion are achieved.

Owner:张家港市轻工设备厂有限公司

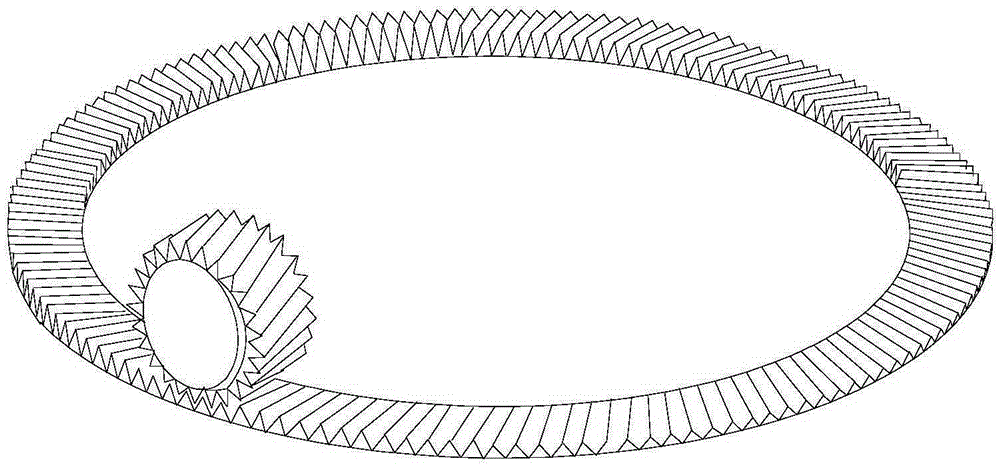

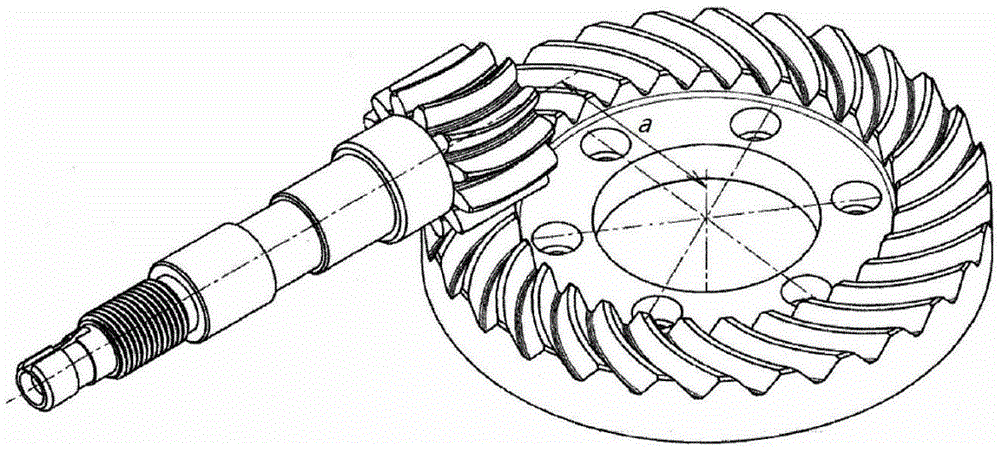

Herringbone tooth surface gear transmission mechanism and tooth milling method for herringbone tooth surface gear of herringbone tooth surface gear transmission mechanism

ActiveCN105333064ASimple structureNovel and reasonable designPortable liftingToothed gearingsButt jointEngineering

The invention discloses a herringbone tooth surface gear transmission mechanism. The herringbone tooth surface gear transmission mechanism comprises a herringbone tooth surface gear and a herringbone tooth cylindrical gear. The herringbone tooth surface gear comprises a disc gear body and a gear shaft. First herringbone teeth annually distributed are arranged on the surface of one side of the disc gear body. Second herringbone teeth are arranged on the periphery of a gear body of the herringbone tooth cylindrical gear. Each first herringbone tooth is composed of a first right-handed gear tooth and a first left-handed gear tooth which are connected to be herringbone in a butt joint manner. Each second herringbone tooth is composed of a second left-handed gear tooth and a second right-handed gear tooth which are connected to be herringbone in a butt joint manner. The second left-handed gear teeth are meshed with the first right-handed gear teeth. The second right-handed gear teeth are meshed with the first left-handed gear teeth. The invention further discloses a tooth milling method for the herringbone tooth surface gear in the herringbone tooth surface gear transmission mechanism. The herringbone tooth surface gear transmission mechanism is high in bearing capacity, good in meshing performance, stable in transmission, low in noise and high in practicability. By means of the tooth milling method for the herringbone tooth surface gear, the tooth width of the herringbone tooth surface gear can be utilized to the maximum extent.

Owner:宁波市吉尔传动部件有限公司

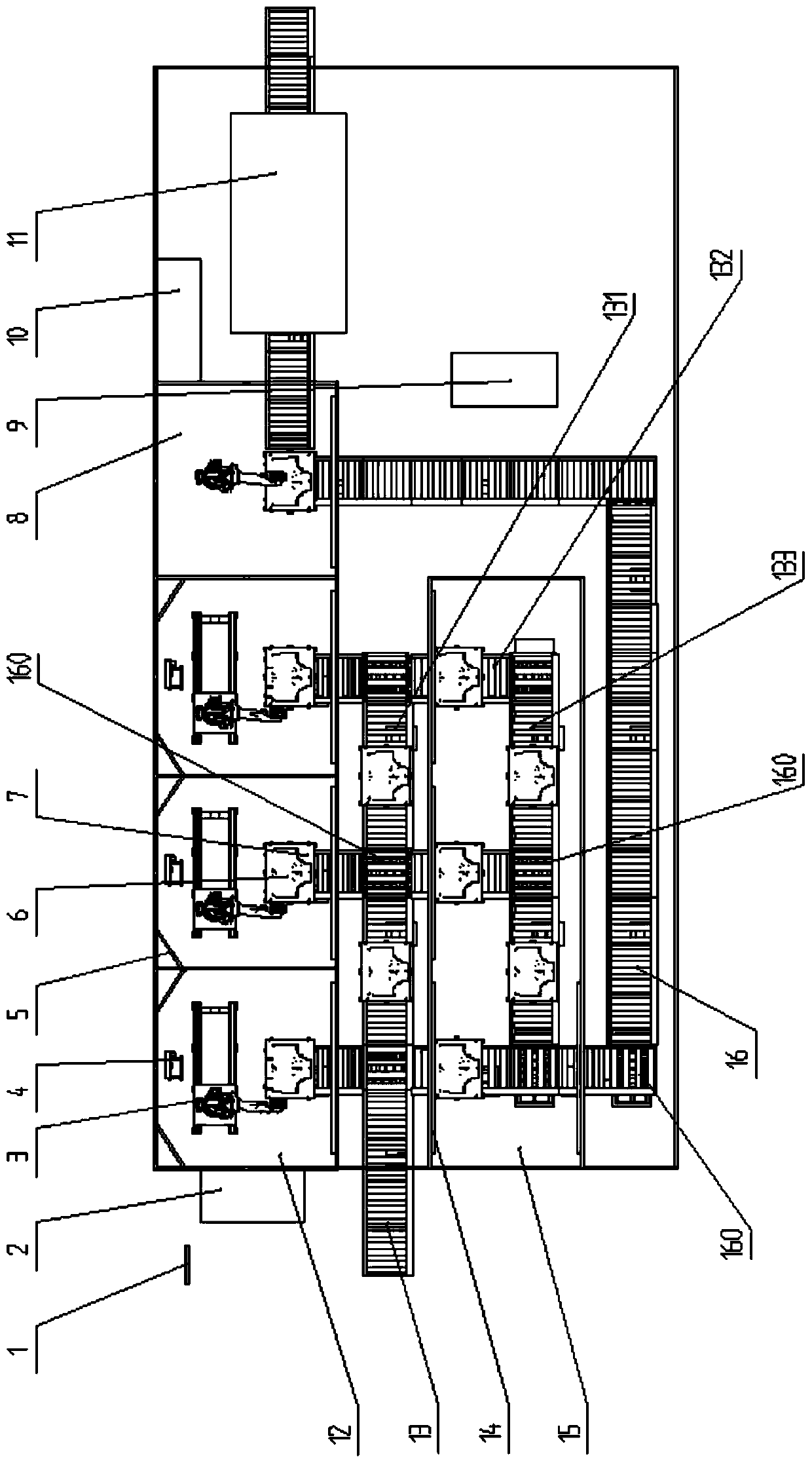

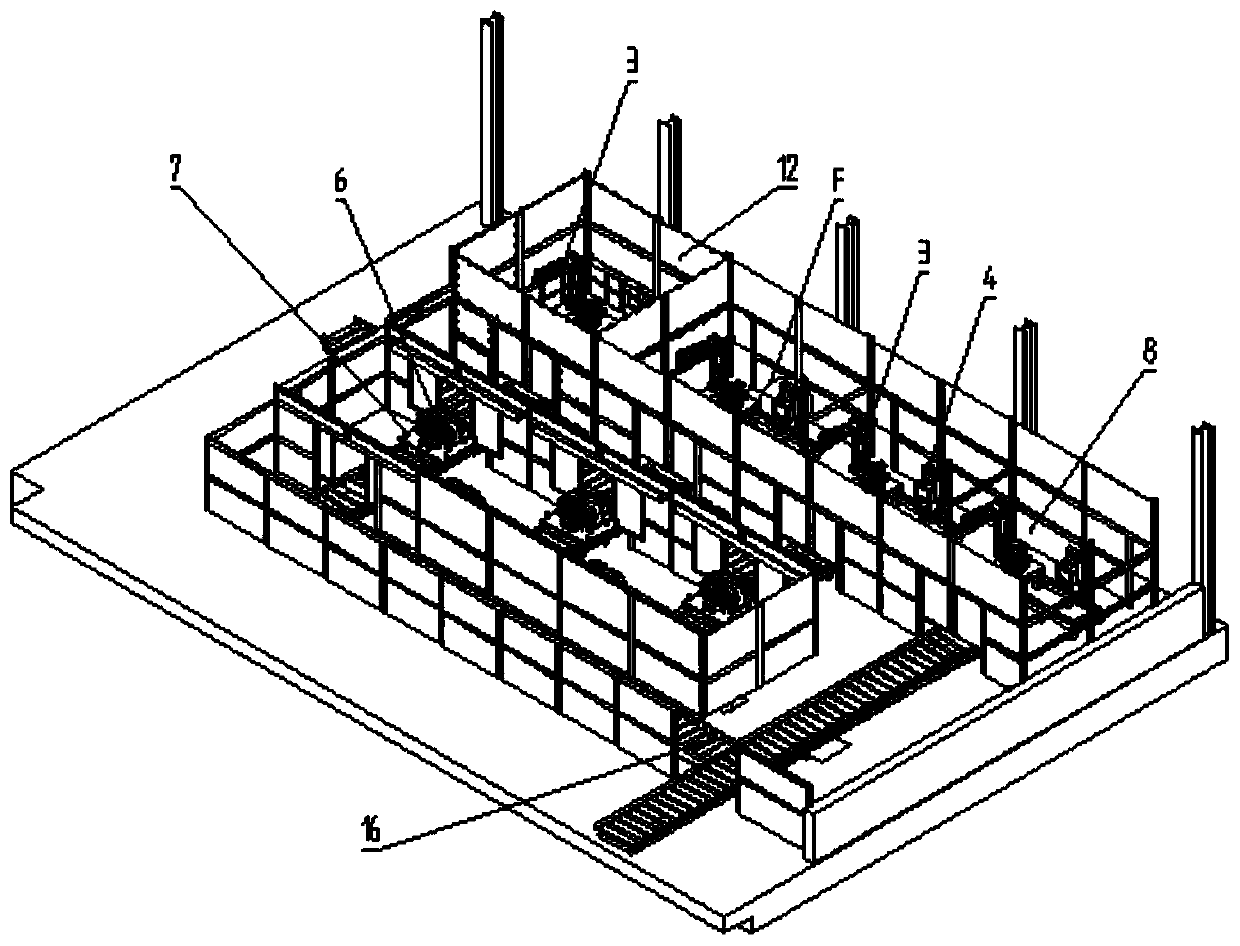

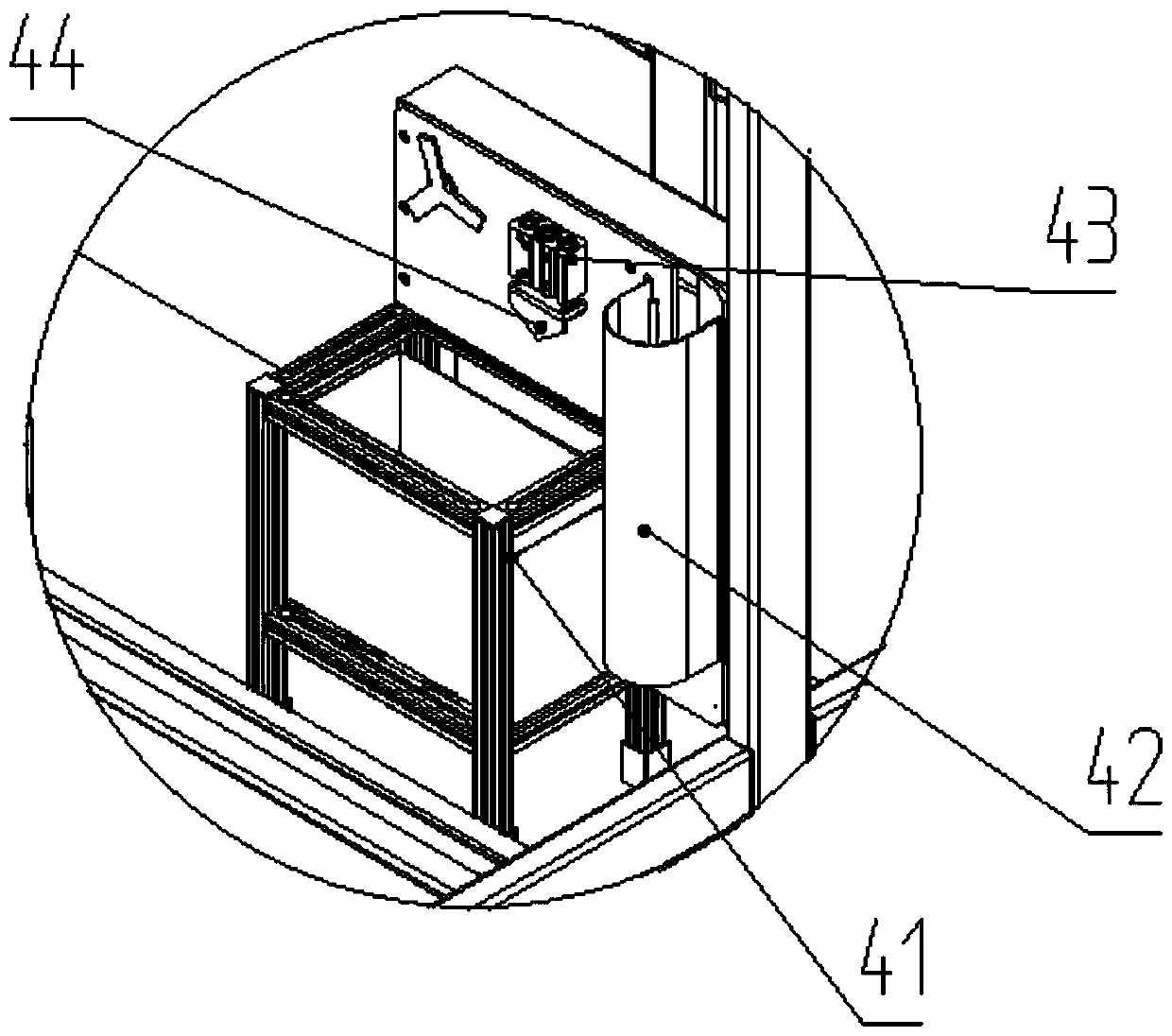

Intelligent polishing production line for putty on surface of casting

PendingCN111347316AImprove work efficiencyReduce labor intensityEdge grinding machinesGrinding wheel securing apparatusProduction lineGrating

The invention discloses an intelligent polishing production line for putty on the surface of a casting, and belongs to the field of machining. The intelligent polishing production line comprises a robot polishing chamber, a manual finishing chamber, a spraying chamber and a drying chamber which are sequentially arranged in an assembly line, the robot polishing chamber communicates with the manualfinishing chamber through a roller type conveying line to realize material transferring, the manual trimming chamber and the spraying chamber communicate with an accumulation line through the roller type conveying line and realize material transferring, the spraying chamber communicates with the drying chamber through the roller type conveying line, a polishing robot is arranged in the robot polishing chamber and used for performing polishing on a plurality of to-be-ground positions of a workpiece, a safety optical grating for monitoring the working range of the polishing robot is further arranged in the robot polishing chamber, and an abrasive paper replacing mechanism is arranged in the robot polishing chamber and used for replacing abrasive paper on the polishing robot. According to theintelligent polishing production line for the putty on the surface of the casting, the assembly line type automatic polishing is achieved, the manpower is saved, the working efficiency is improved and the intelligent polishing production line is more environmentally friendly.

Owner:天津三合智能装备制造有限公司

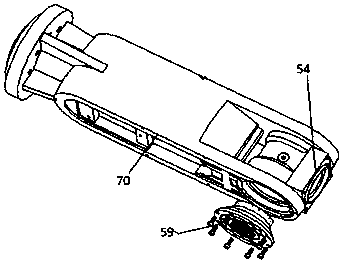

Bidirectional magnetic levitation sound wave motor device

PendingCN111541312AAvoid short service lifeReduce weightReciprocating/oscillating/vibrating magnetic circuit partsMagnetic circuit rotating partsElectric machineEngineering

The invention discloses a bidirectional magnetic levitation sound wave motor device which comprises a motor shell and a motor shaft branch, the motor shaft branch is arranged at the axis of the motorshell, an end cover is arranged at the bottom end of the motor shell, shaft holes are formed in the axis of the motor shell and the axis of the end cover, and the motor shaft branch penetrates throughthe two shaft holes. According to the invention, motion transmission is realized through an electromagnetic effect; a torsion bar and other elastic structures do not need to be installed; on one hand, the situation that the service life of the motor is short due to the fact that the elastic structure is easily damaged in use is avoided; on the other hand, the motor in unit volume can transmit torque with a larger numerical value; when the device is applied to an electric toothbrush, the weight of the electric toothbrush can be reduced, the up-and-down telescopic movement is closer to the tooth brushing feeling in daily life while left and right swinging is carried out, the cleaning effect is greatly improved, the user experience is improved, and the blank that no axial telescopic movementexists except radial left-and-right swinging in the market is filled up.

Owner:KERUI TECH (DONGGUAN) CO LTD

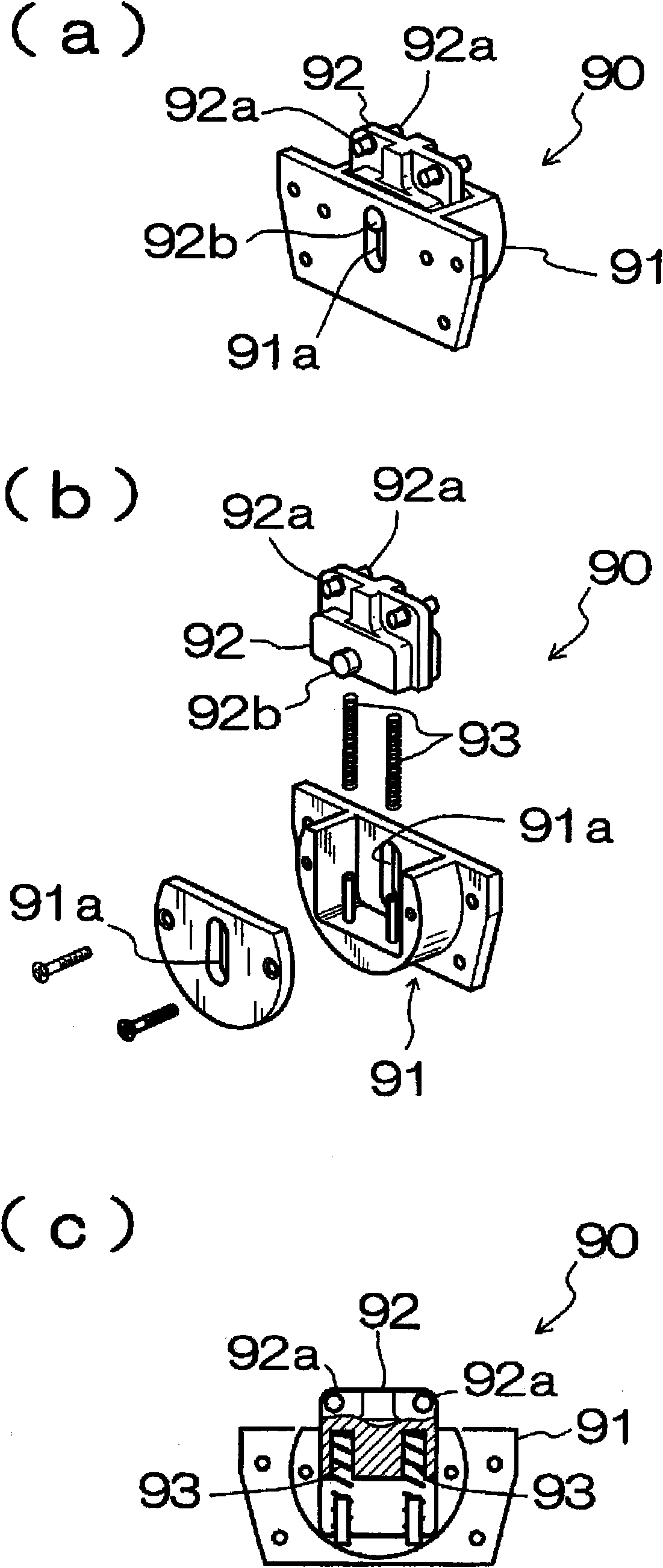

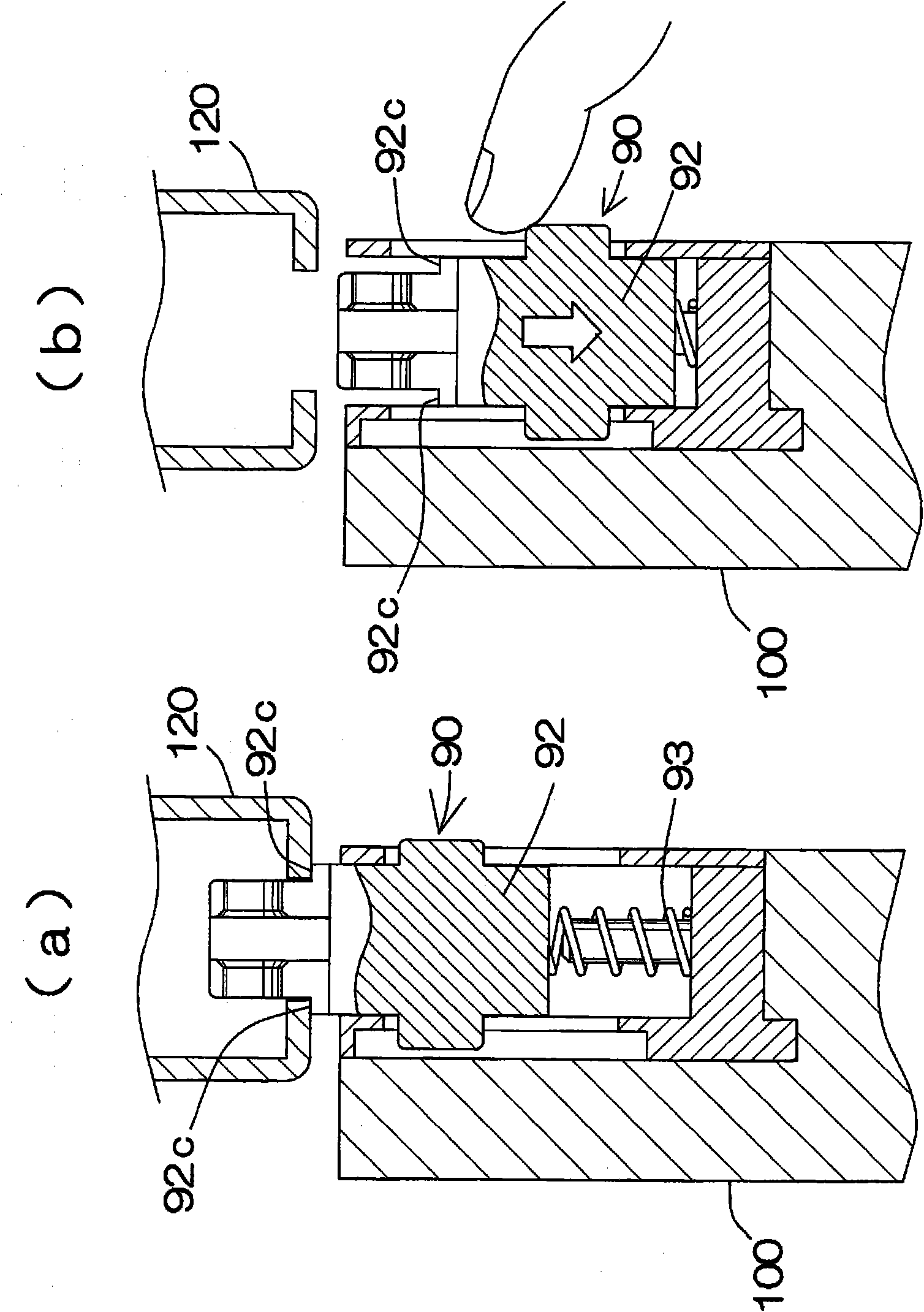

Shock absorbing mechanism of open/close moving element and drawing device employing it

InactiveCN101827992ASimple structureWon't fall offBuilding braking devicesWing openersCoil springEngineering

A shock absorber (1) includes, as main components, a spiral shaft (2) holding an abutting member (16) and a slider (30), a holder (5), an oil resistance type rotary damper (18), a damper spring (40) for urging the oil resistance type rotary damper (18) rearward, the abutting member (16) attached to the front end (3) of the spiral shaft (2), and a receiving member (17) on which the abutting member (16) can be made to abut. A drawing device (200) makes the shock absorber (1) fit a coil spring (29) for urging the slider (30) in the drawing direction to the spiral shaft (2), and makes the slider (30) support a hook member (34) rotatably such that sustention and switching can be made between the drawing posture and the drawing release posture.

Owner:KYOEI KANAMONO SEISAKUSHO +1

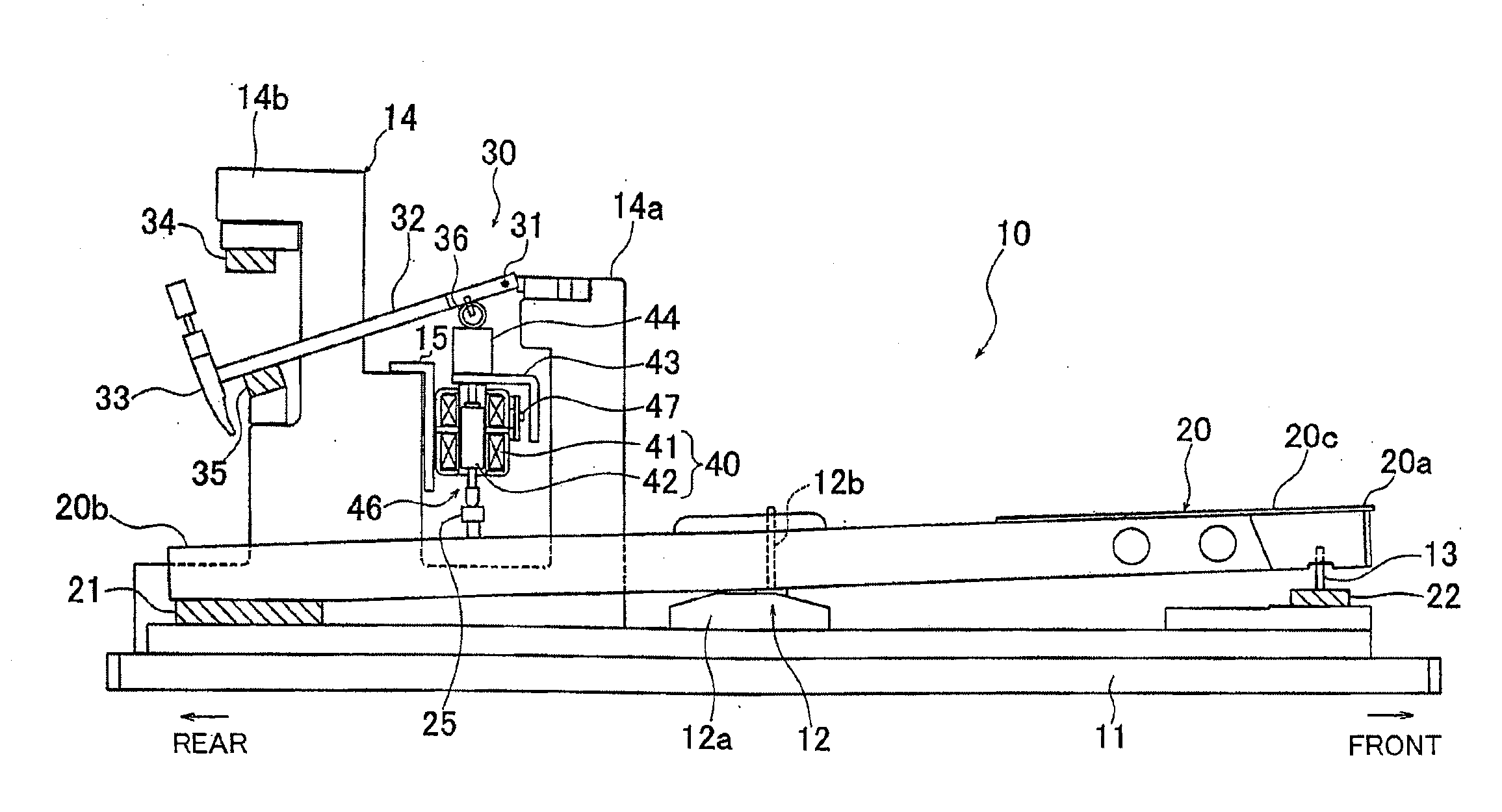

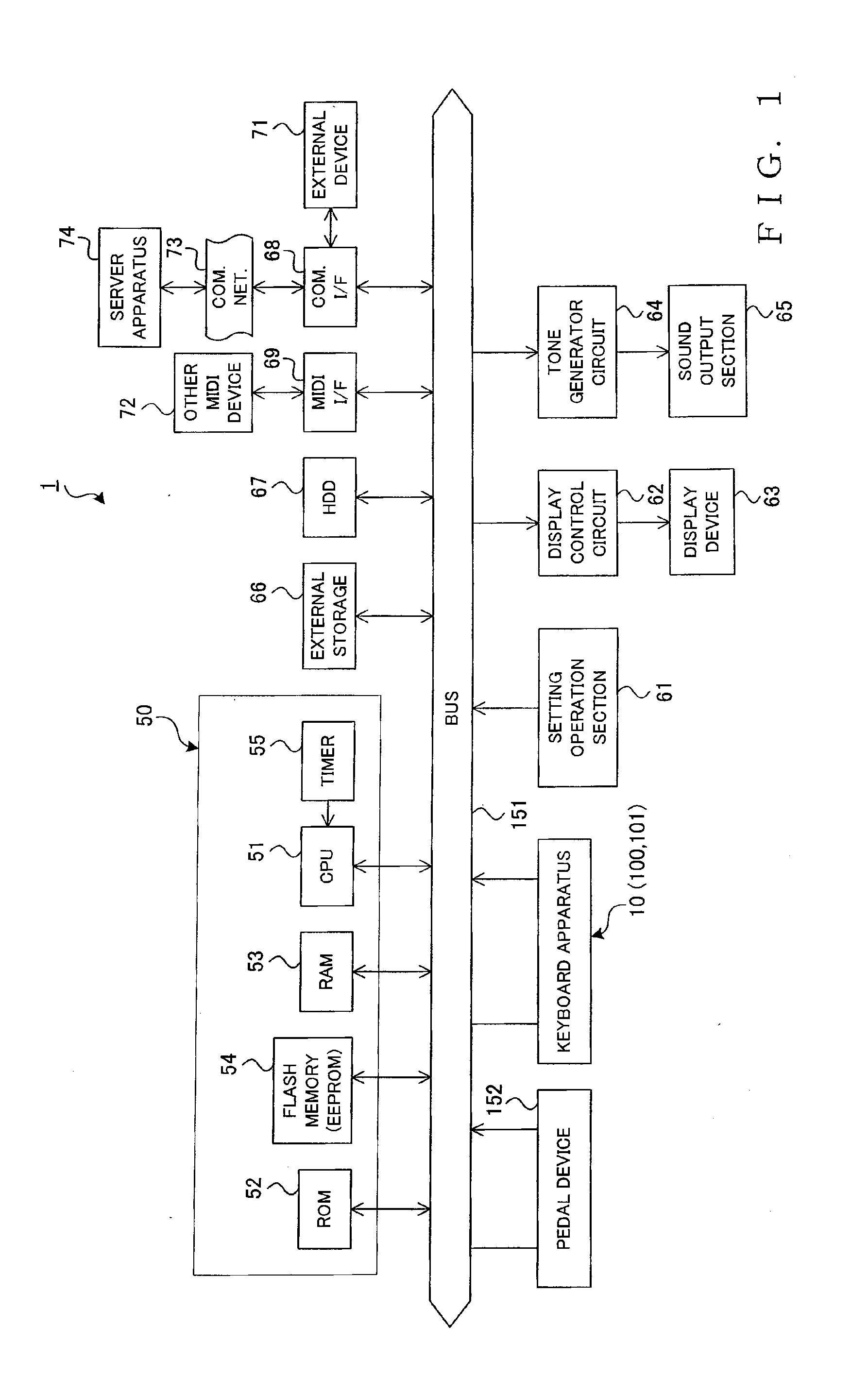

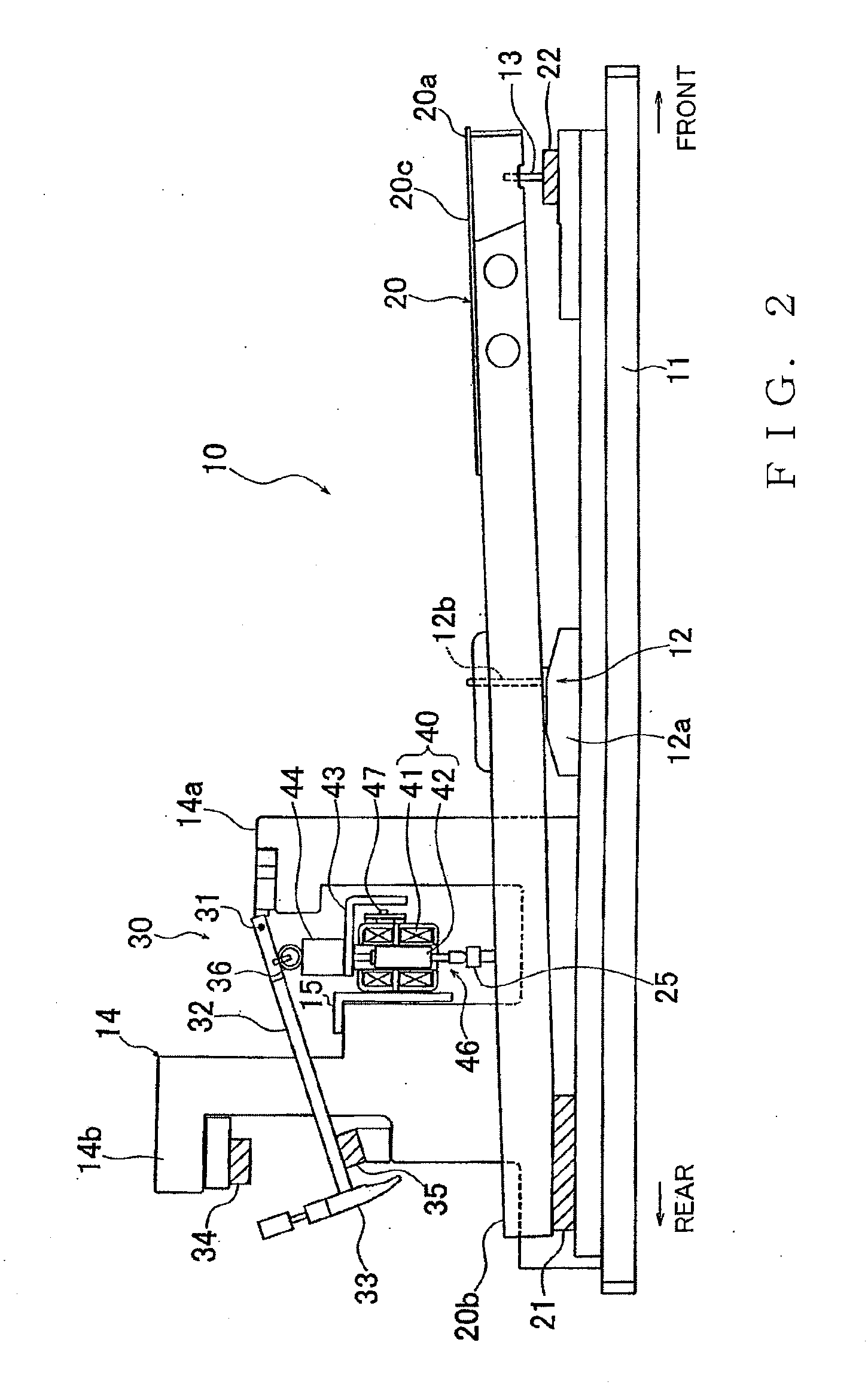

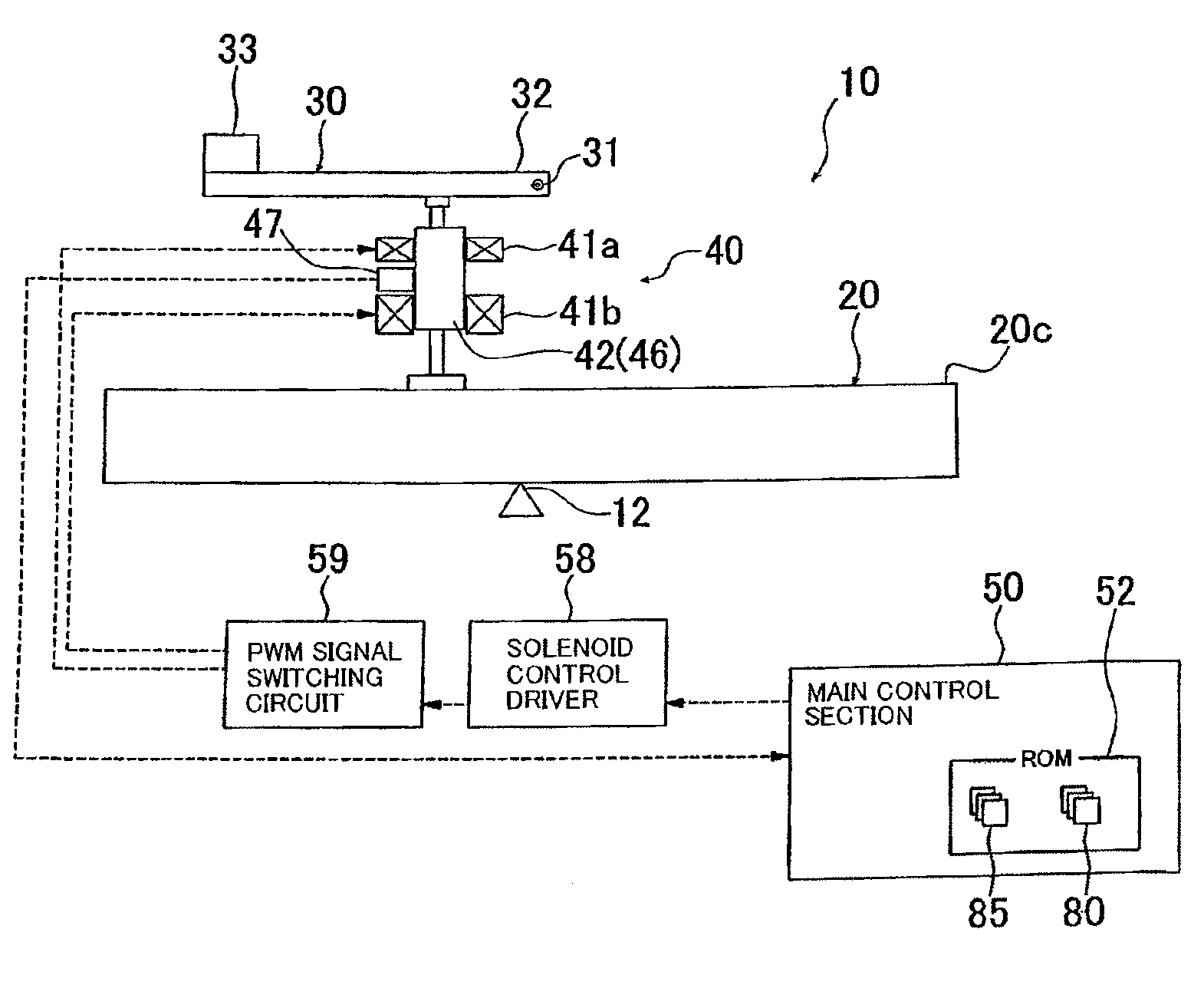

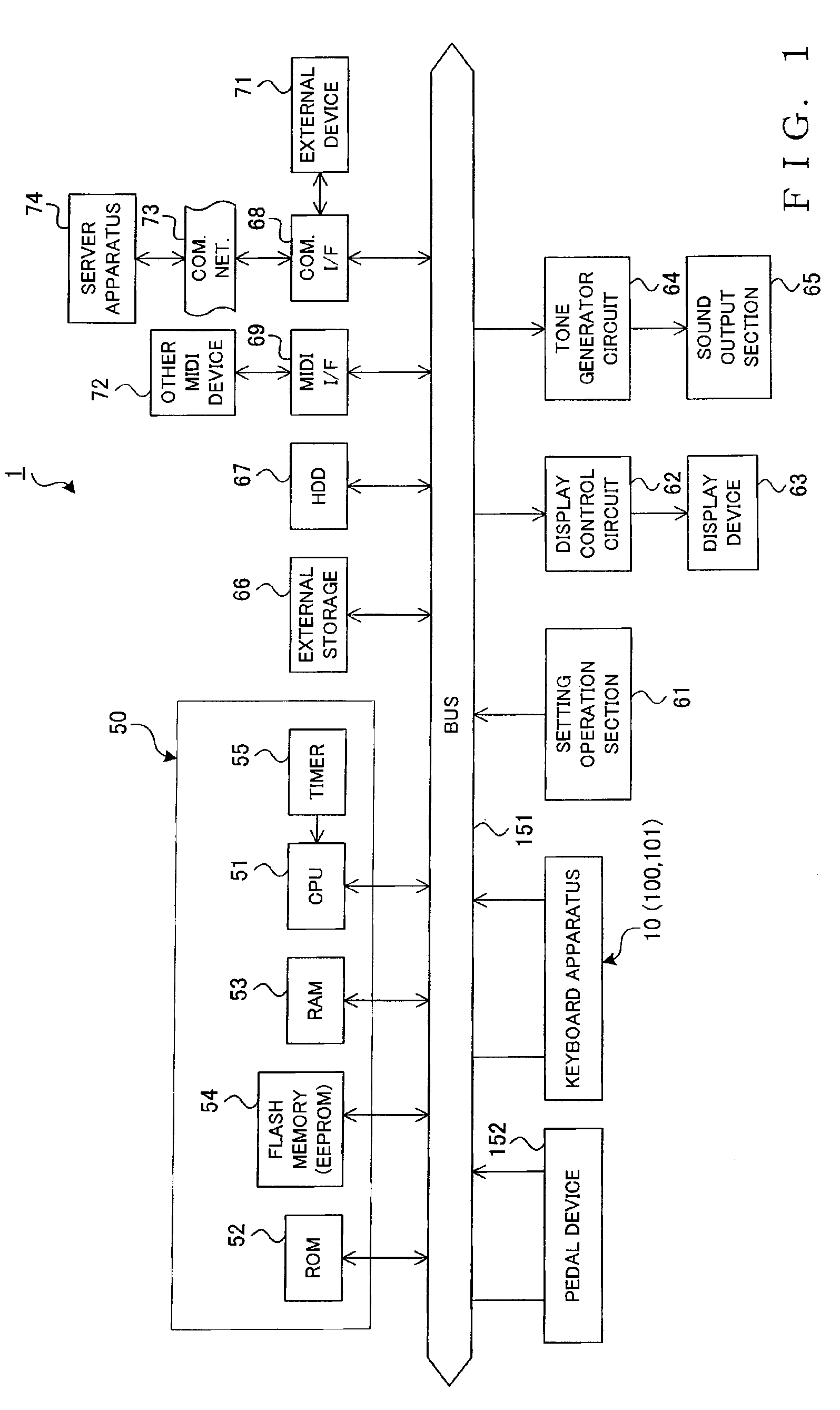

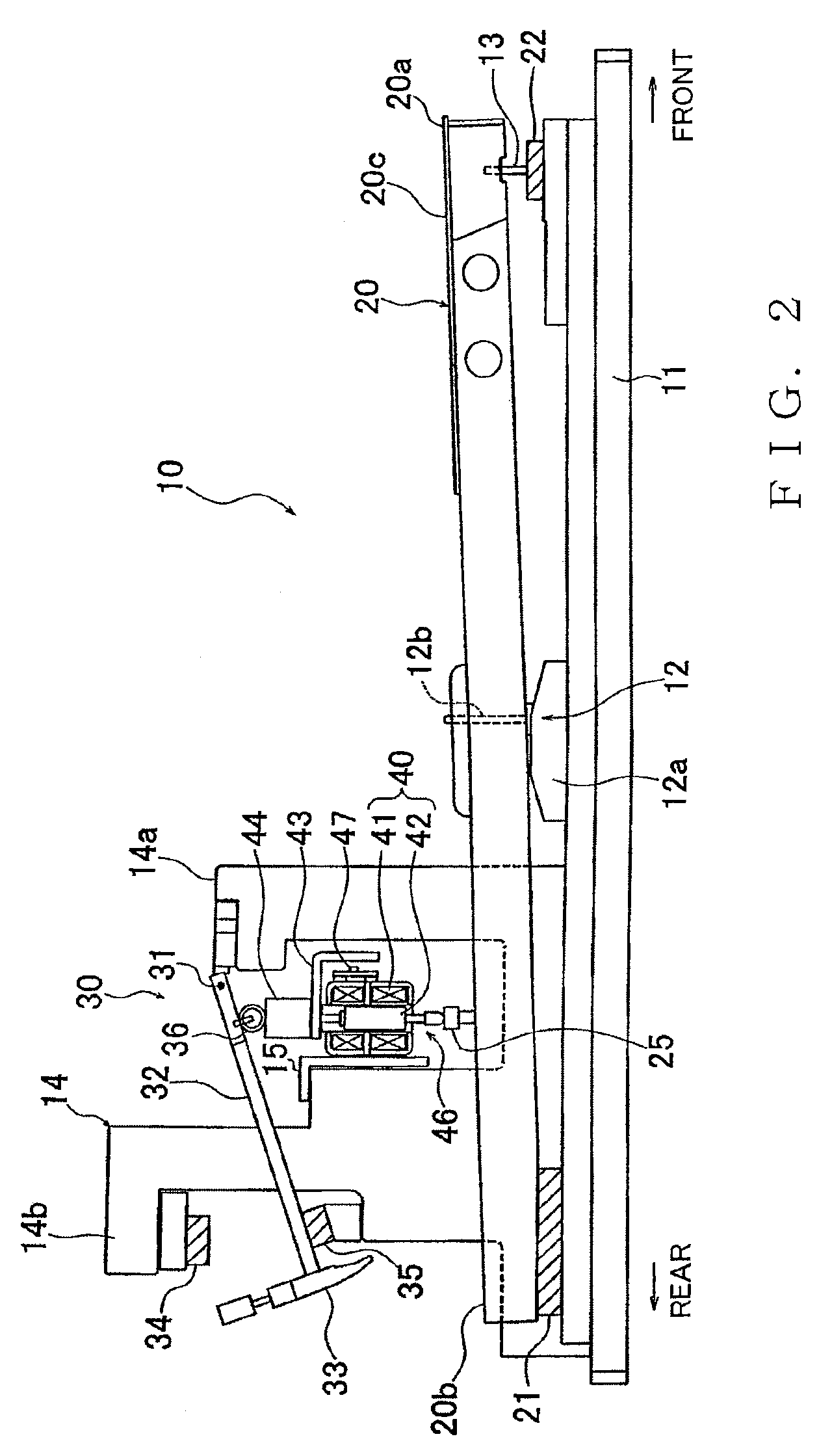

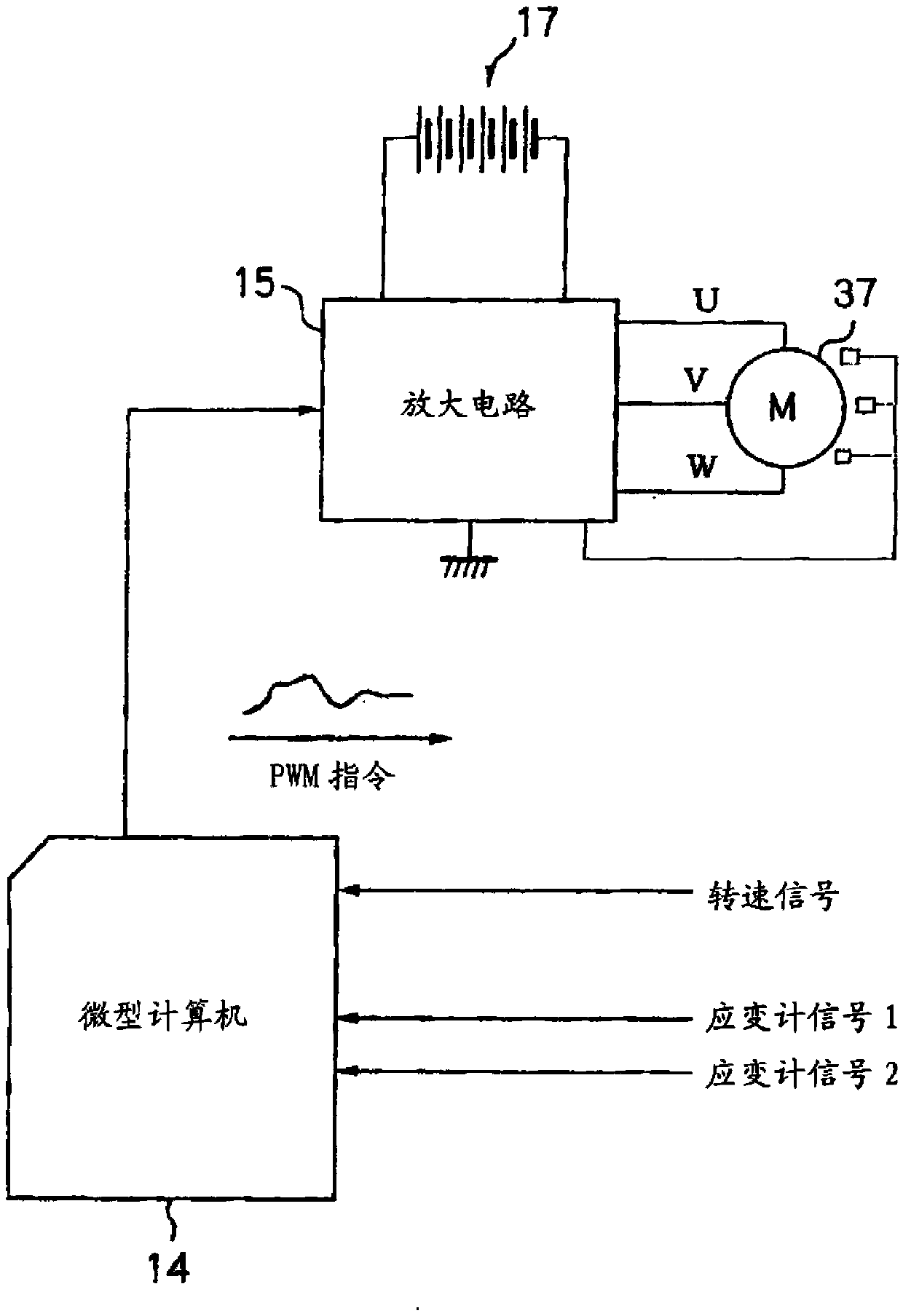

Keyboard apparatus

InactiveUS20100326257A1Easy constructionSmooth power deliveryElectrophonic musical instrumentsAutomatic musical instrumentsInertial massEngineering

In a keyboard apparatus including a key supported for pivoting movement about a pivot point, a mass member that imparts a reaction force to performance operation of the key in interlocked relation to the key, and an electromagnetic actuator provided between the key and the mass member for imparting a driving force to the key and mass member, a transmission member is provided in detachable abutment with the key and mass member. The transmission member can be disengaged from the key or the mass member depending on operating conditions of the key and the mass member. Thus, it is possible to not only prevent unnecessary binding forces from acting in areas where the transmission member and the key and the mass member abut against each other, but also achieve smooth movement of the key and the mass member and prevent increase of inertial mass of the transmission member. The smooth movement of the key and mass member can achieve force sense control with good responsiveness. Further, the key is pivotable in a key depressing direction as a reaction force imparted from the mass member is reduced by impartment, to the key, of a driving force by the actuator. Thus, the apparatus can perform both force sense control on depression operation of the key and an automatic performance involving automatic operation of the key, through cooperation between a reaction force imparted from the mass member to the key and the driving force imparted from the actuator to the key.

Owner:YAMAHA CORP

Keyboard apparatus

InactiveUS8288640B2Easy constructionSmooth power deliveryElectrophonic musical instrumentsAutomatic musical instrumentsInertial massEngineering

In a keyboard apparatus including a key supported for pivoting movement about a pivot point, a mass member that imparts a reaction force to performance operation of the key in interlocked relation to the key, and an electromagnetic actuator provided between the key and the mass member for imparting a driving force to the key and mass member, a transmission member is provided in detachable abutment with the key and mass member. The transmission member can be disengaged from the key or the mass member depending on operating conditions of the key and the mass member. Thus, it is possible to not only prevent unnecessary binding forces from acting in areas where the transmission member and the key and the mass member abut against each other, but also achieve smooth movement of the key and the mass member and prevent increase of inertial mass of the transmission member. The smooth movement of the key and mass member can achieve force sense control with good responsiveness. Further, the key is pivotable in a key depressing direction as a reaction force imparted from the mass member is reduced by impartment, to the key, of a driving force by the actuator. Thus, the apparatus can perform both force sense control on depression operation of the key and an automatic performance involving automatic operation of the key, through cooperation between a reaction force imparted from the mass member to the key and the driving force imparted from the actuator to the key.

Owner:YAMAHA CORP

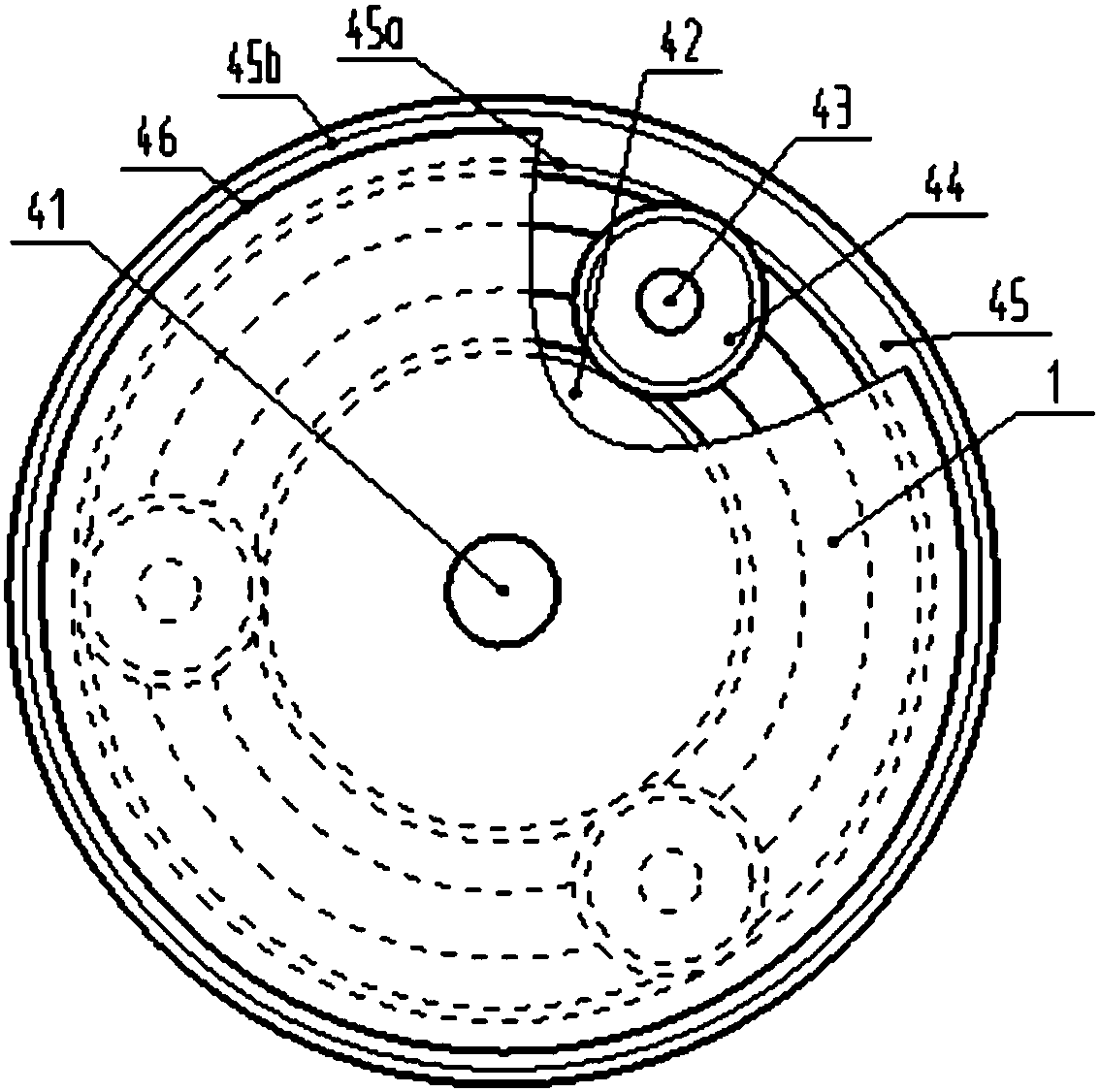

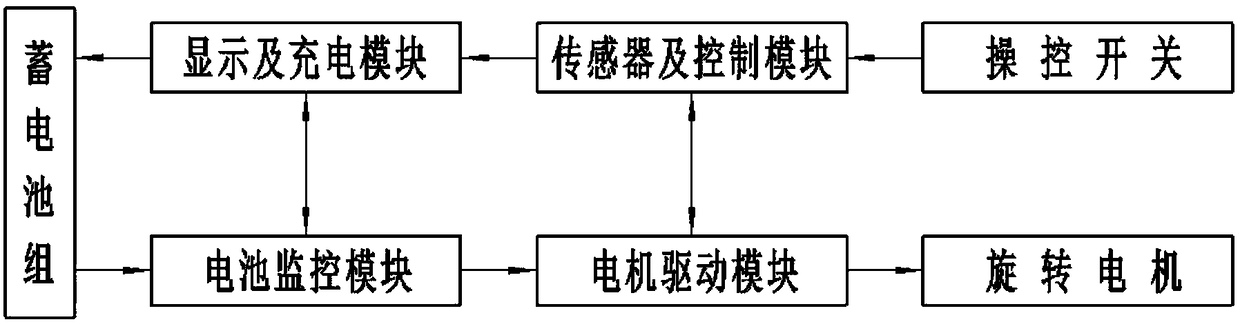

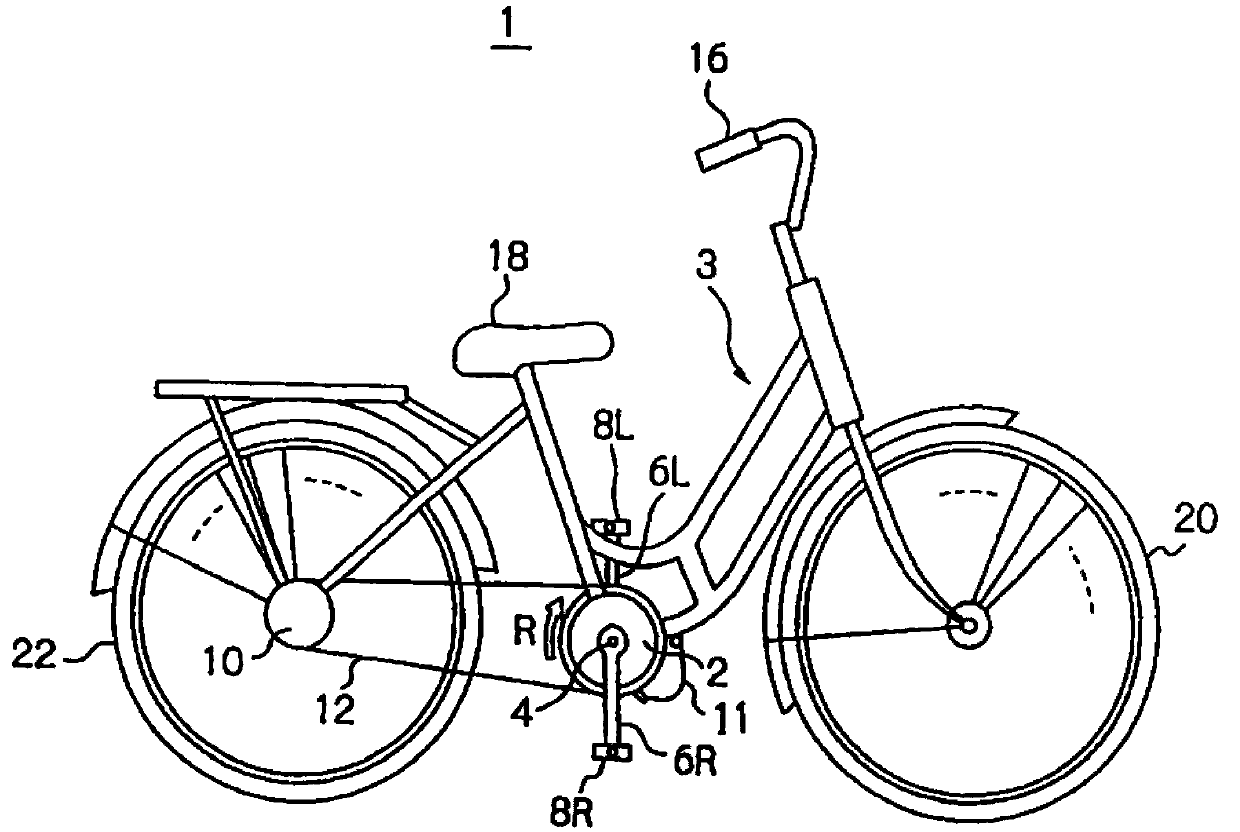

Bicycle depositing management device

The invention relates to a bicycle depositing management device. The bicycle depositing management device comprises a depositing device main body, an intelligent control device, and a rotation control device; the depositing device main body comprises at least one layer of a depositing database; the depositing compartments of different layers are stacked successively up and down; the depositing compartment of each layer consists of a plurality of rotatable depositing units; a rotary control device is arranged inside the depositing device main body for driving the depositing units to rotate; and an intelligent control device is arranged on the outer side wall of the depositing device main body and is in signal connection with the rotary control device. The technical scheme of the bicycle depositing management device provides a management device which can intelligently store bicycles and can realize intelligent bicycle storage and picking-up through intelligently controlling a rotary platform, which is simple, convenient and efficient.

Owner:许志雄

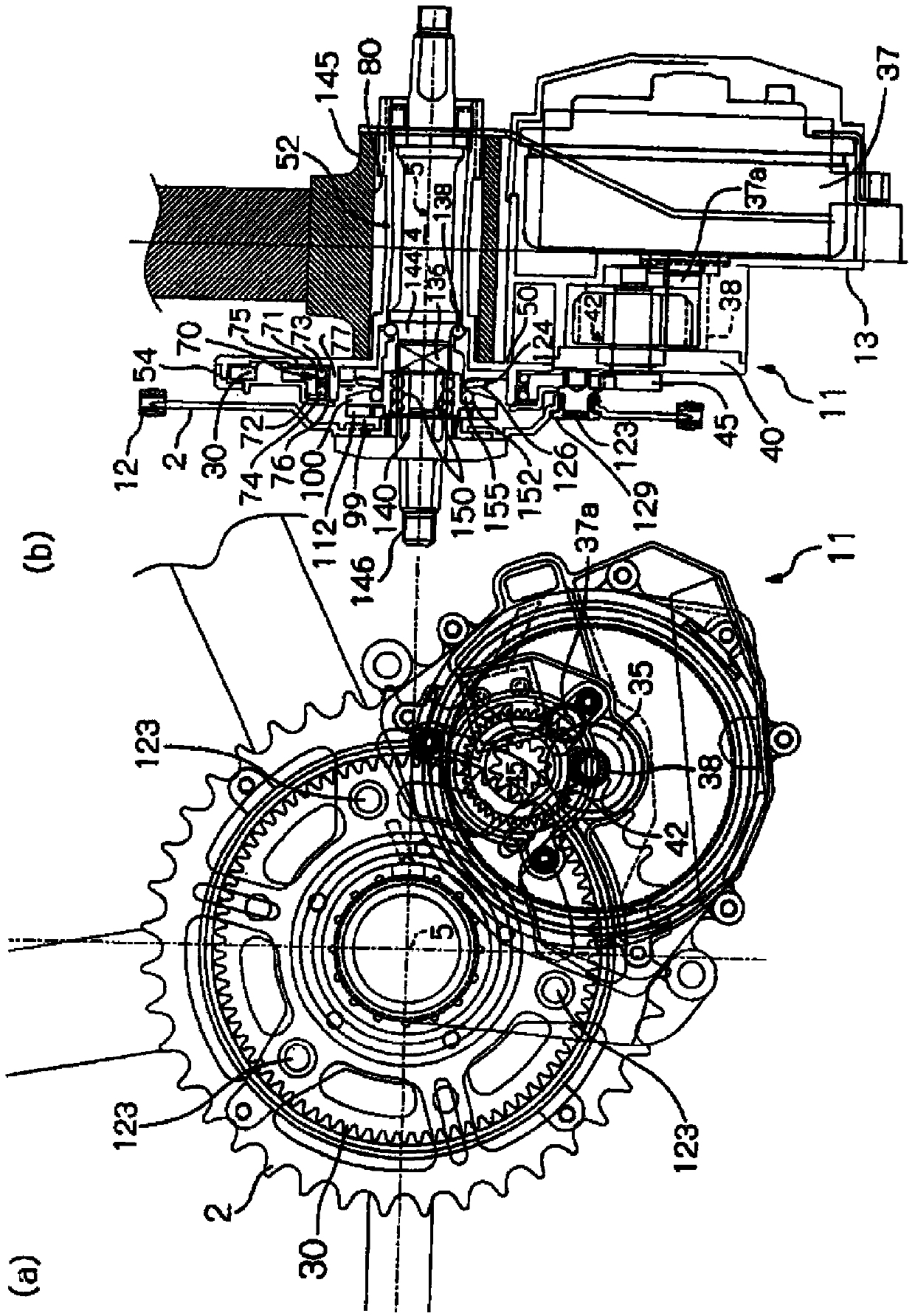

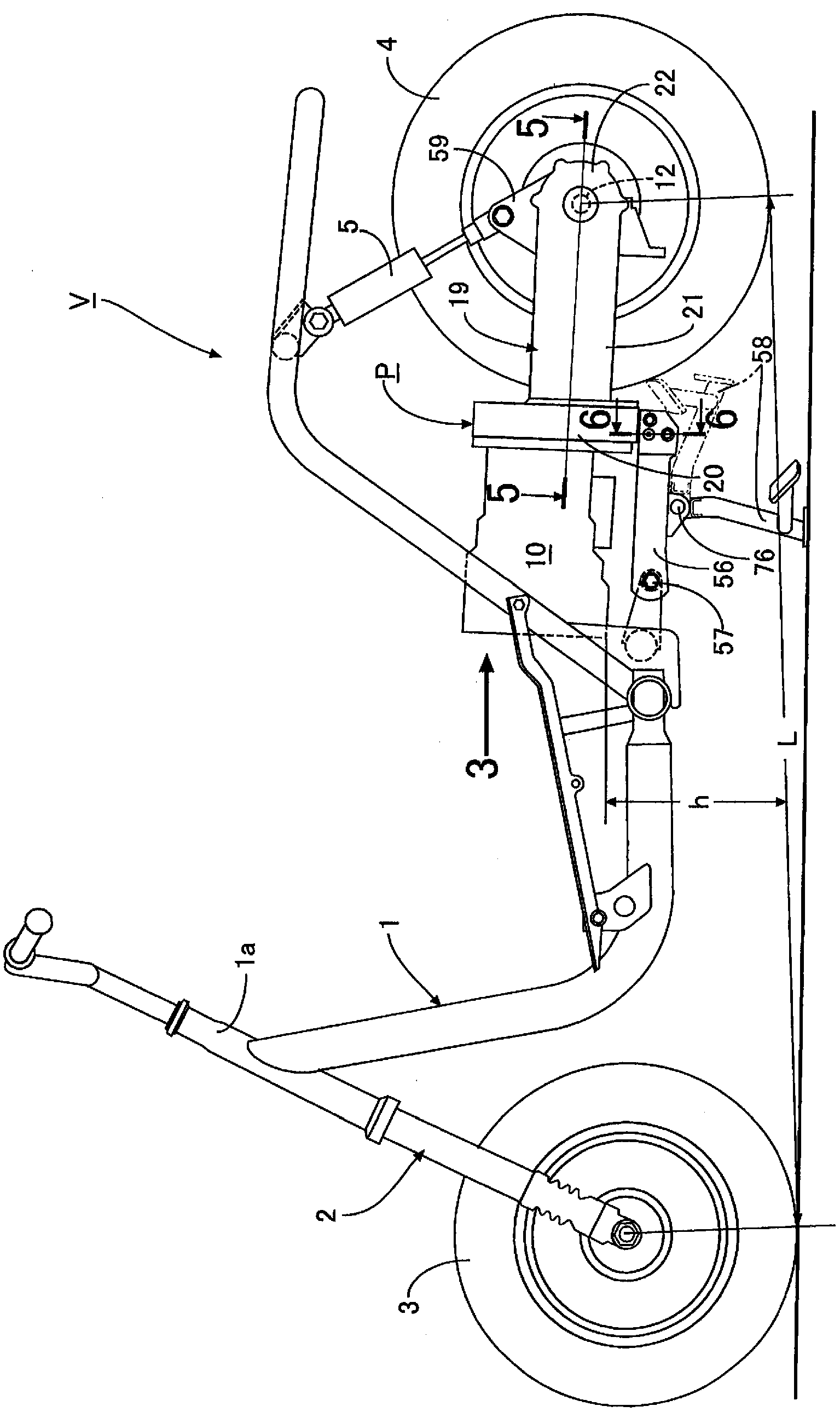

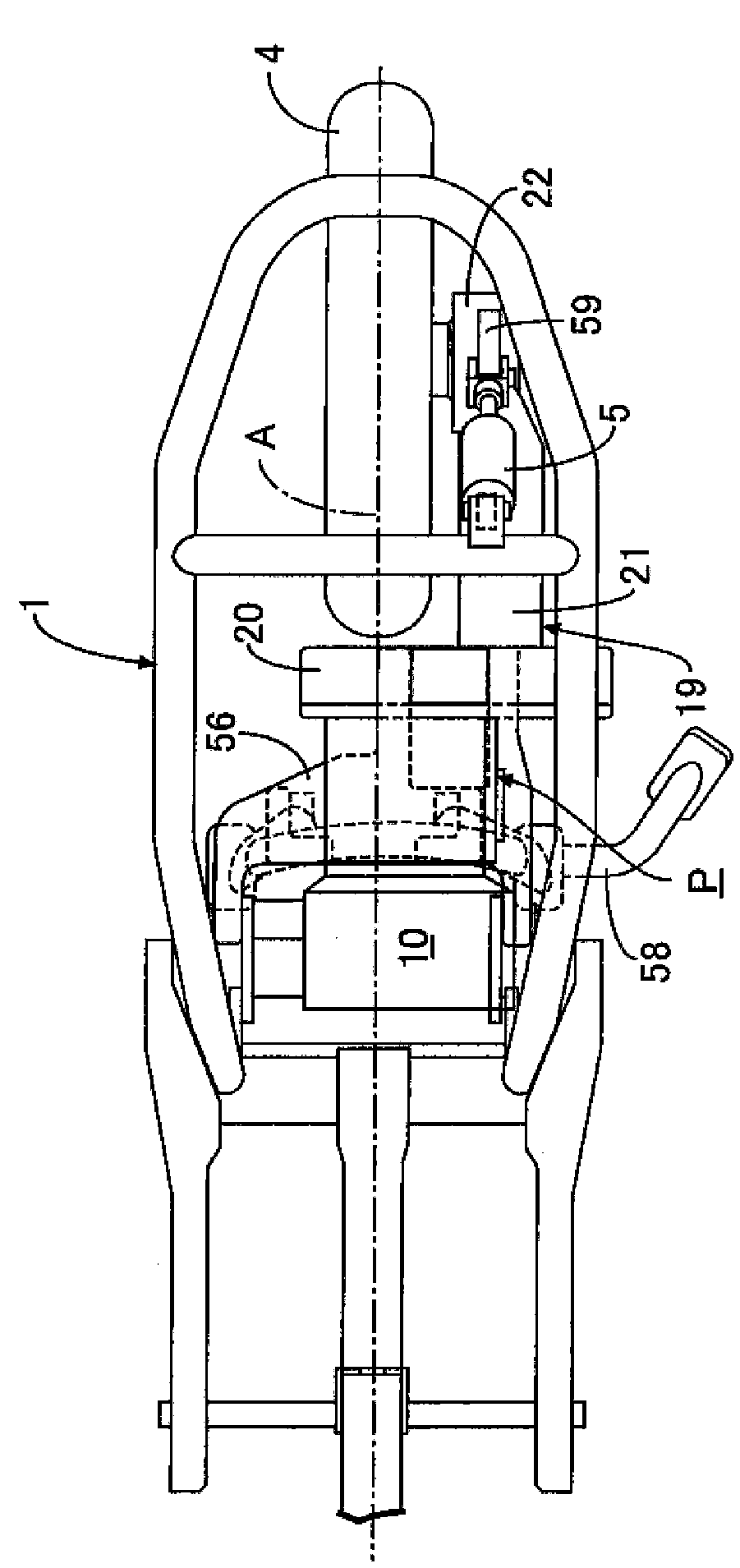

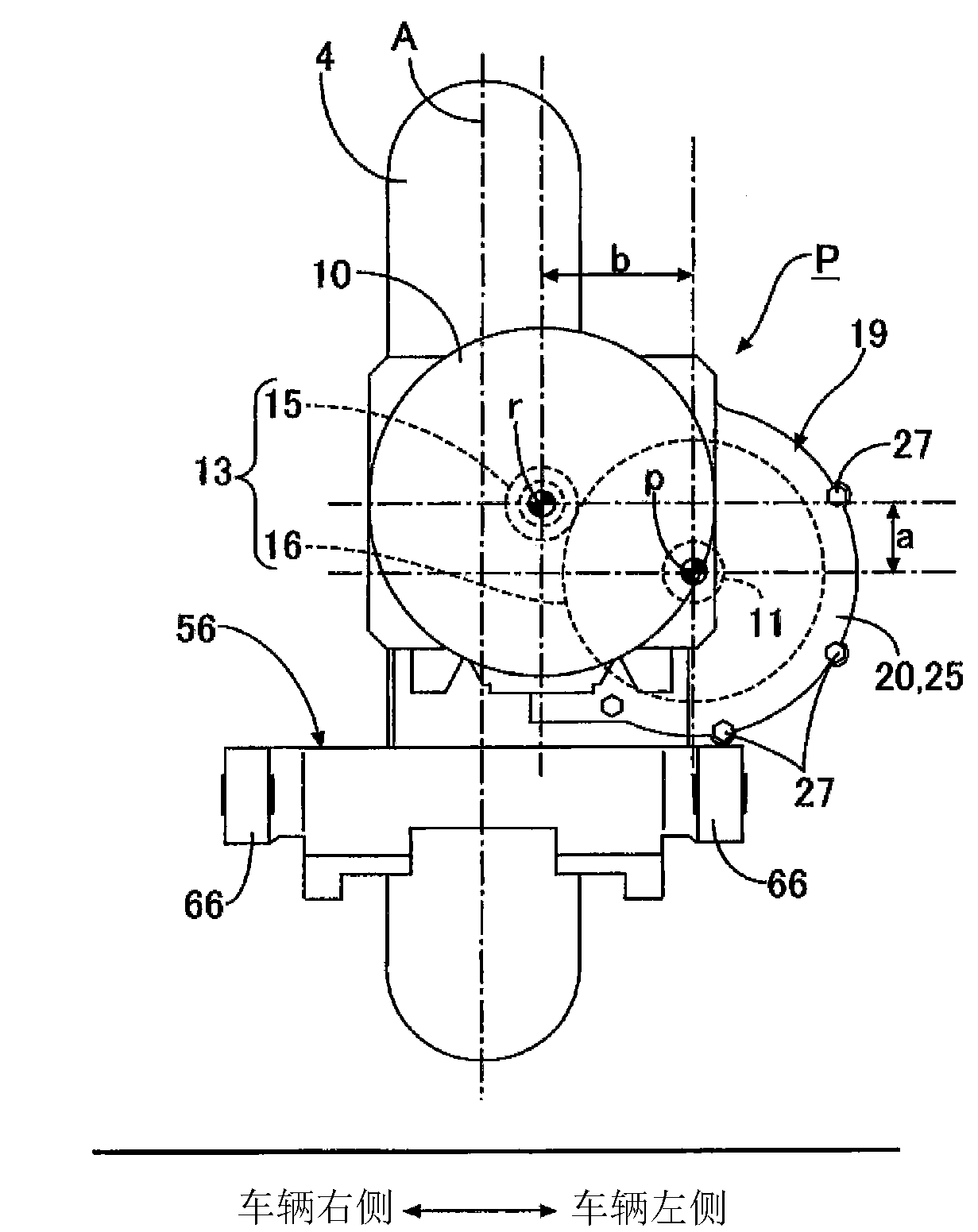

Assembly suitable for electric power assisted bicycle and capable of being mounted on bicycle frame

The invention provides an electric power assisted bicycle and an assembly suitable for the electric power assisted bicycle and capable of being mounted on a bicycle frame. The assembly not only can simplify an auxiliary power mechanism used for the electric power assisted bicycle but also can be easily mounted on the bicycle frame. The assembly is characterized in that at least the following components are arranged on a common base to form the assembly: a chain wheel, an electric power output mechanism, an auxiliary gear, a connecting mechanism and a drive shaft, wherein the chain wheel is used for transmitting pedaling force to a drive wheel and can rotate; the electric power output mechanism outputs electric power used for assisting the pedaling force through an output shaft; the auxiliary gear is connected with the output shaft of the electric power output mechanism through a gear mechanism; the connecting mechanism connects the auxiliary gear with the chain wheel coaxially; the drive shaft is stored in a shaft sleeve in a rotating mode by utilizing the pedaling force; the shaft sleeve is connected with the common base, or the shaft sleeve and the common base are formed integrally.

Owner:BAFANG ELECTRIC (SUZHOU) CO LTD

Automatic double-gear transmission

ActiveCN105114621ASimple and fast operationReduce frustrationControlled membersToothed gearingsAutomatic transmissionSteel ball

The invention discloses an automatic double-gear transmission and provides a power-failure-free mechanical transmission integrating flexible transmission with rigid transmission. The automatic double-gear transmission comprises a hollow shaft, spring rings, a boss push rod, a movable boss, a driving gear, an input shaft, an engagement sleeve, a driven gear I, a driven gear II, steel balls, an output shaft, a shifting fork, a shifting fork shaft, a transmission gear set and steel ball racks; the boss push rod is installed in the center of the hollow shaft; the boss push rod is connected with the shifting fork shaft through a bolt so that the linkage between the boss push rod and the shifting fork shaft can be achieved, and therefore the movable boss and the engagement sleeve are driven to move in the axial direction. According to the transmission, the gear shifting process is simple to operate, the ectrosis sense is not obvious, and impact, collision and friction in the connection process can be reduced effectively.

Owner:CHONGQING UNIV

Multi-way torque balance control automobile stable and soft start method

InactiveCN108556623AReduce shock loadExtended service lifeControl devicesDrive shaftEquilibrium control

The invention discloses a multi-way torque balance control automobile stable and soft start method. The method includes the steps that a brake is stepped, an engine is in an idling state, an inductiondevice is in a non-trigger state, the load borne by a transmission shaft b is larger than the load borne by a transmission shaft a, power of the engine is transmitted towards the transmission shaft a, and an automobile is static; the brake is released, the engine is in the idling state, the induction device is in the non-trigger state, the load borne by the transmission shaft b is smaller than the load borne by the transmission shaft a, the power of the engine is transmitted towards the transmission shaft a and the transmission shaft b, the power transmitted towards the transmission shaft b is gradually increased, and the automobile slowly advances; an accelerator is stepped, the engine is in a high-speed state, the induction device is in a trigger state, the load borne by the transmission shaft b is far smaller than the load borne by the transmission shaft a, the power of the engine is transmitted to the transmission shaft a and the transmission shaft b, the power transmitted towardsthe transmission shaft b is gradually increased, and the advancing speed of the automobile is gradually increased to the maximum value.

Owner:芜湖七创工业设计有限公司

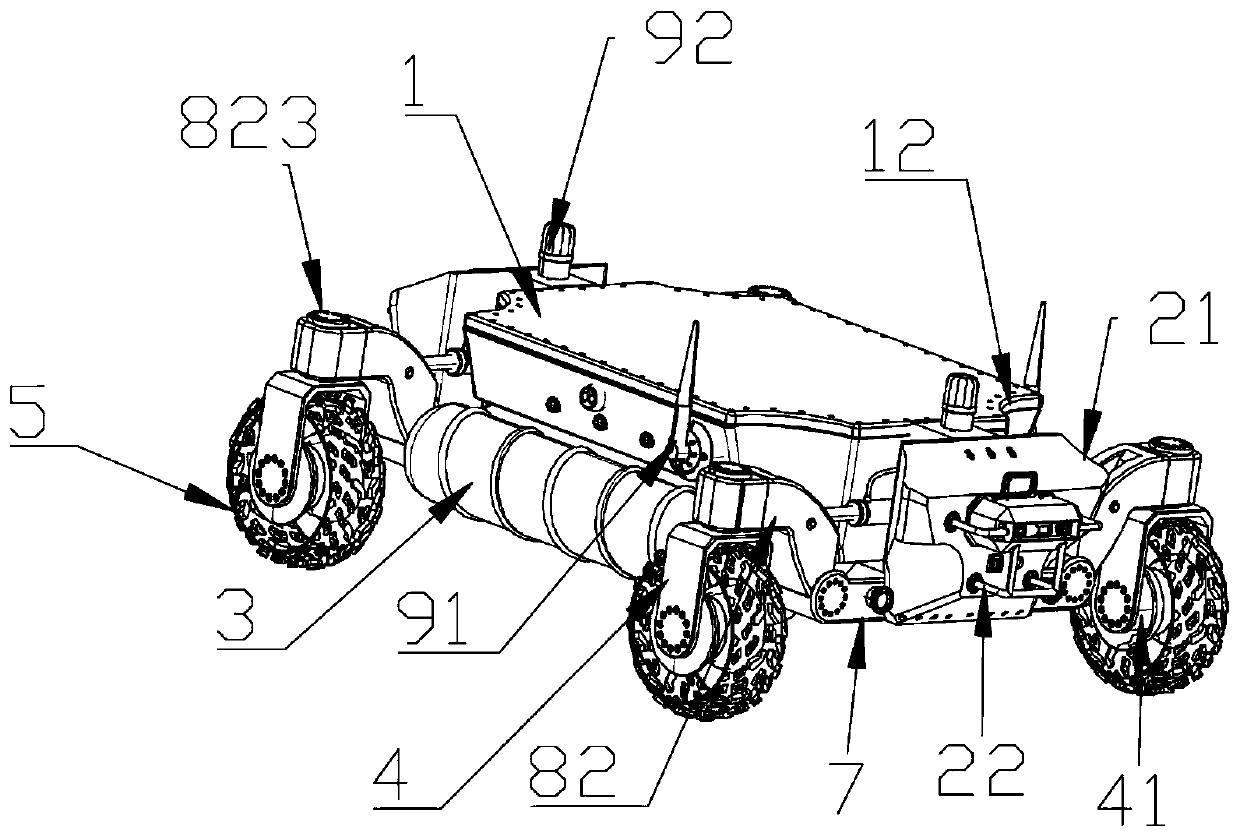

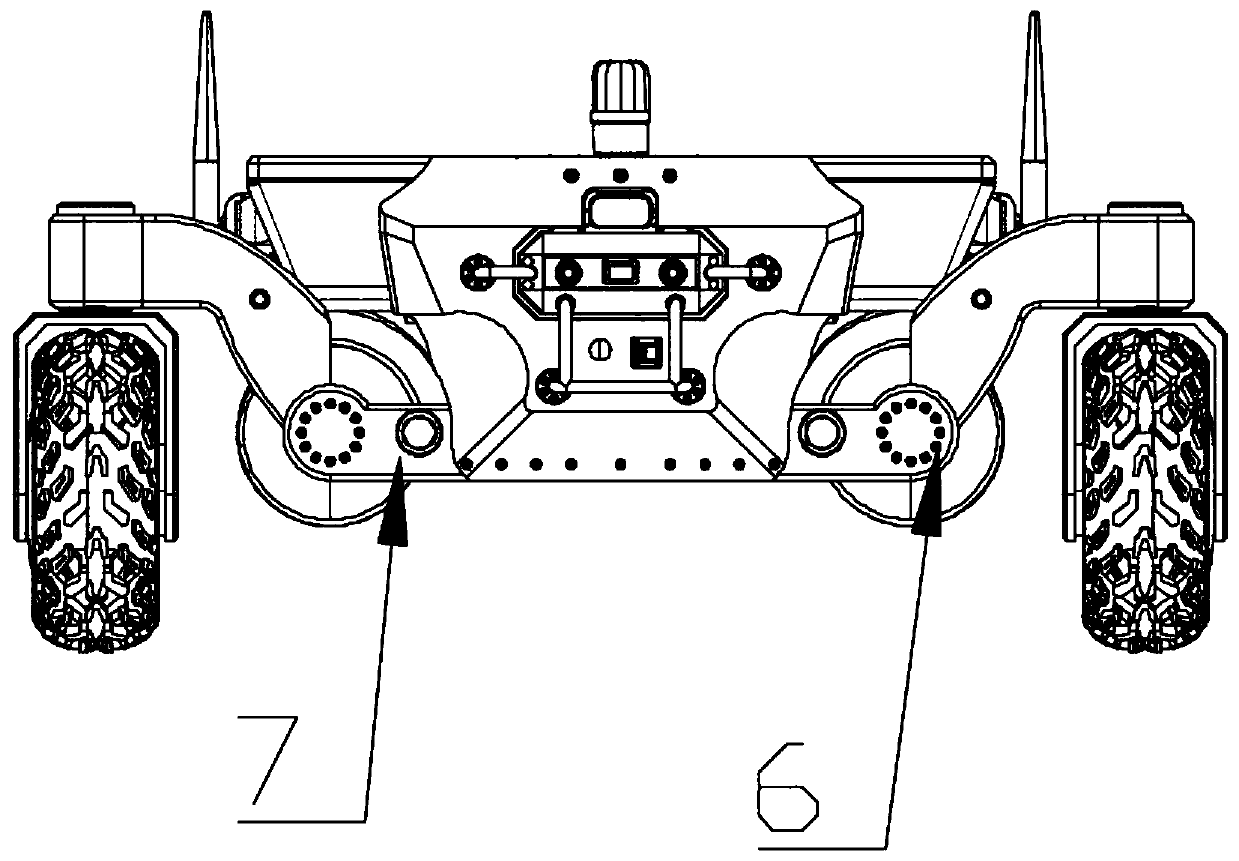

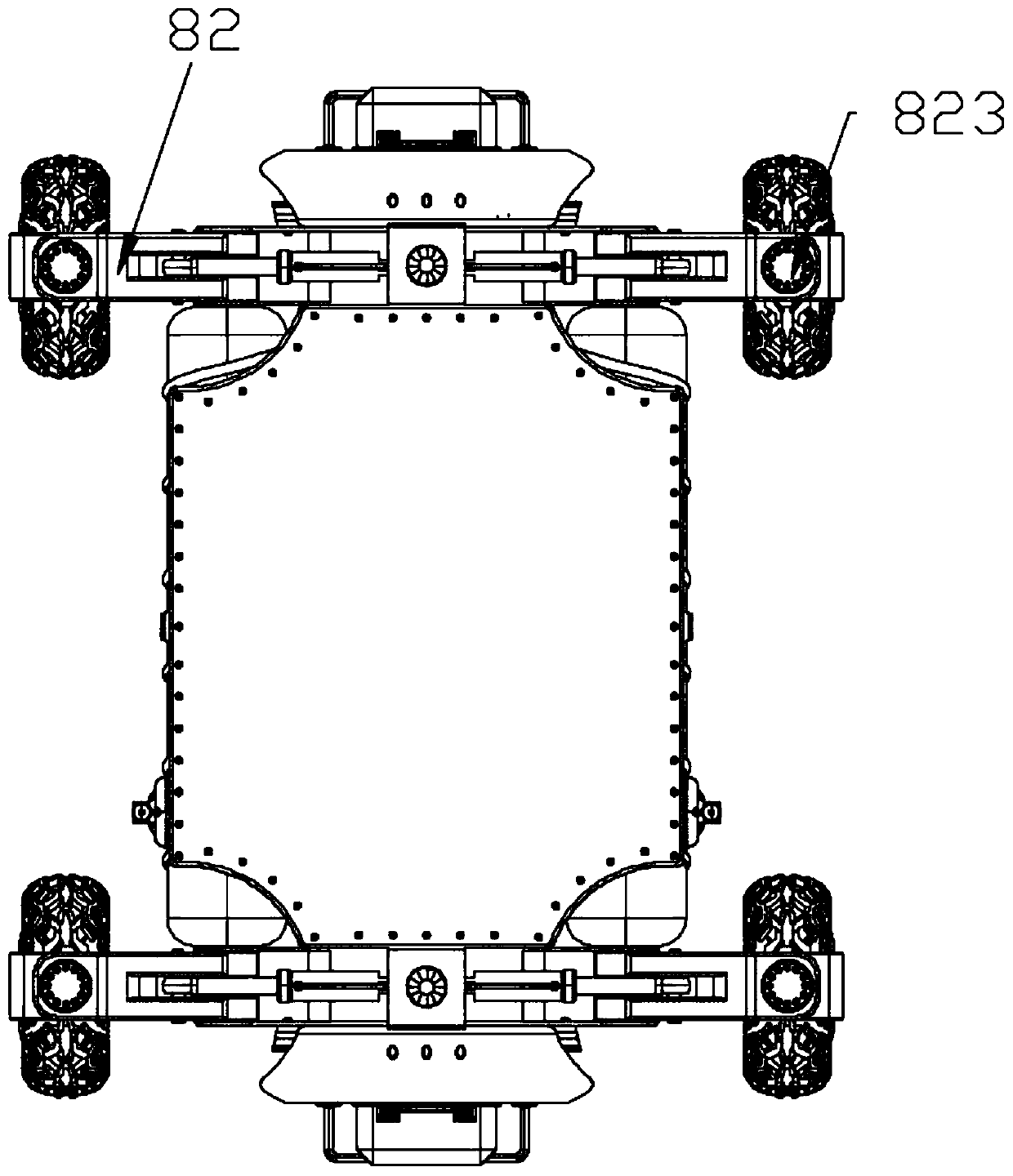

All-terrain vehicle

PendingCN111086569ASolve the problem of driving on complex roads that cannot beSolve the problem of not being able to flipInterconnection systemsVehiclesMechanical equipmentControl theory

The invention relates to the field of mechanical equipment, particularly to an all-terrain vehicle, which comprises a vehicle body, a first power generation device, a propelling device connected withthe vehicle body, and a second power generation device connected with the propelling device, wherein the position of the bottom side of the propelling device is lower than the position of the chassisof the vehicle body, the all-terrain vehicle further comprises transmission mechanisms, tire fixing devices, tires connected with the tire fixing devices, and first folding shafts arranged at the twoends of the vehicle body, the first end of the transmission mechanism is connected with the first power generation device, the second end of the transmission mechanism is connected with the tire fixing device, the third end of the transmission mechanism is connected with the first folding shaft, and the transmission mechanism can drive the tire to turn over by using the first folding shaft as theaxis. According to the invention, the wheel type running state or the propelling device working state is switched by turning over the tires so as to run on different running surfaces.

Owner:九立(北京)机器人科技有限公司

Continous Heating Device For Coil Springs And Heating Method For Coil Springs By Using This Device

Owner:DAEWON APPLIED ENG CO

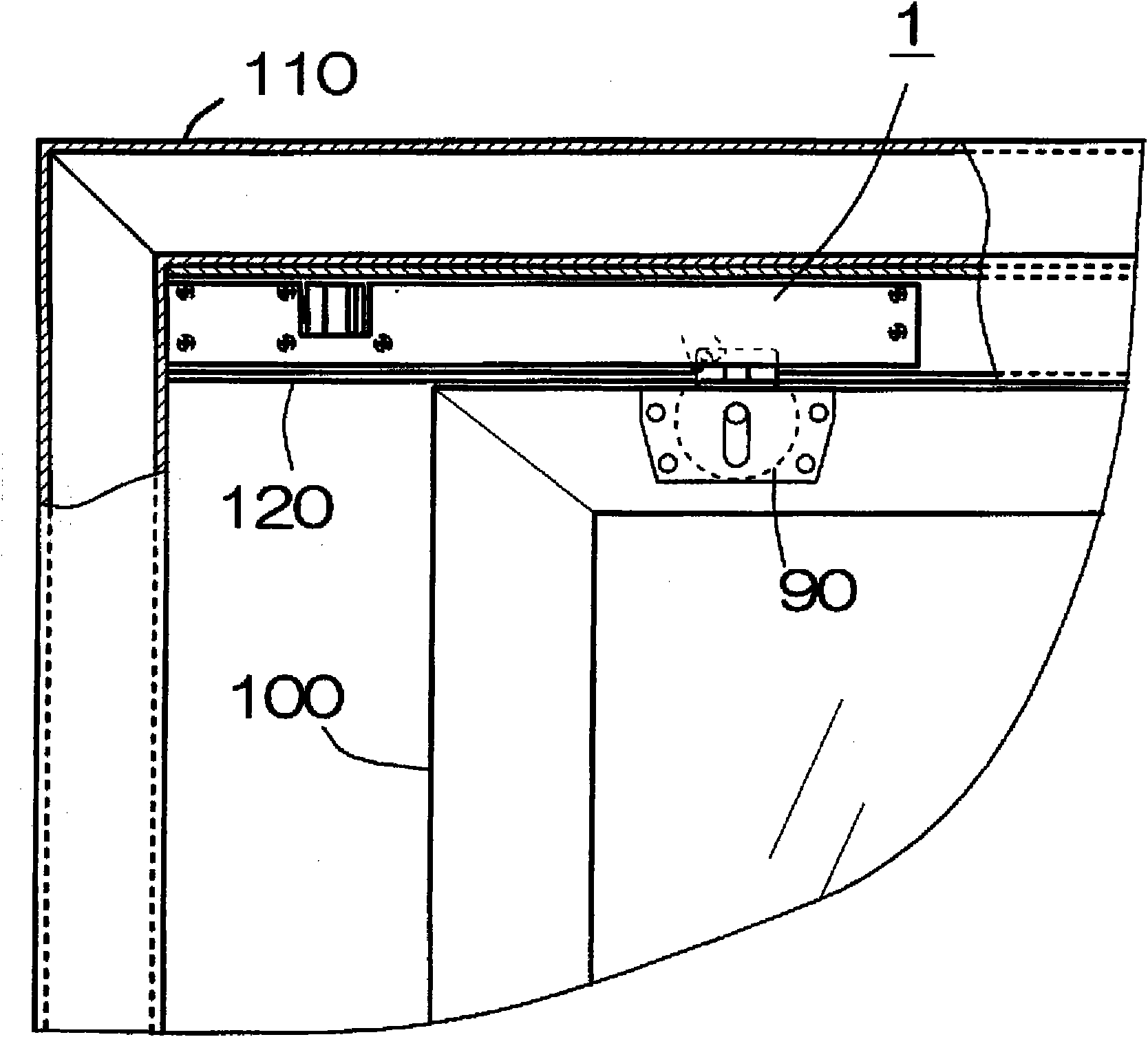

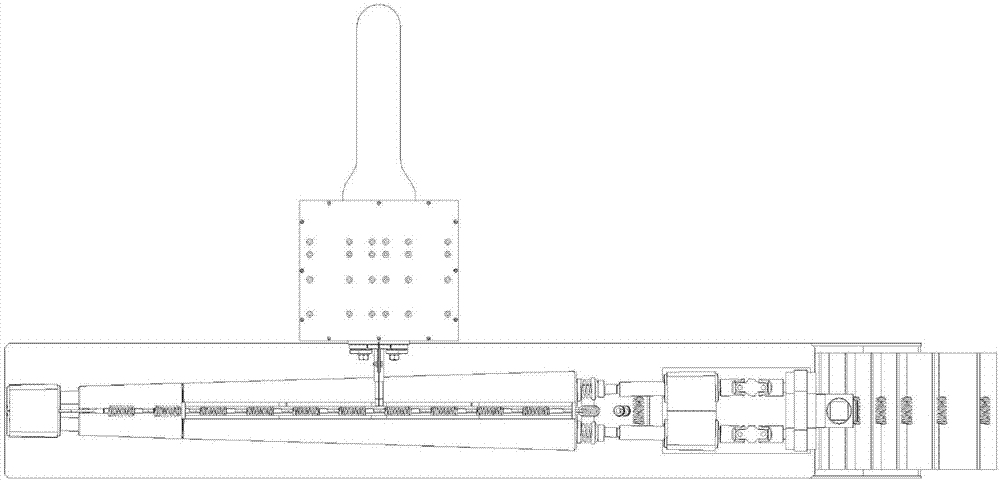

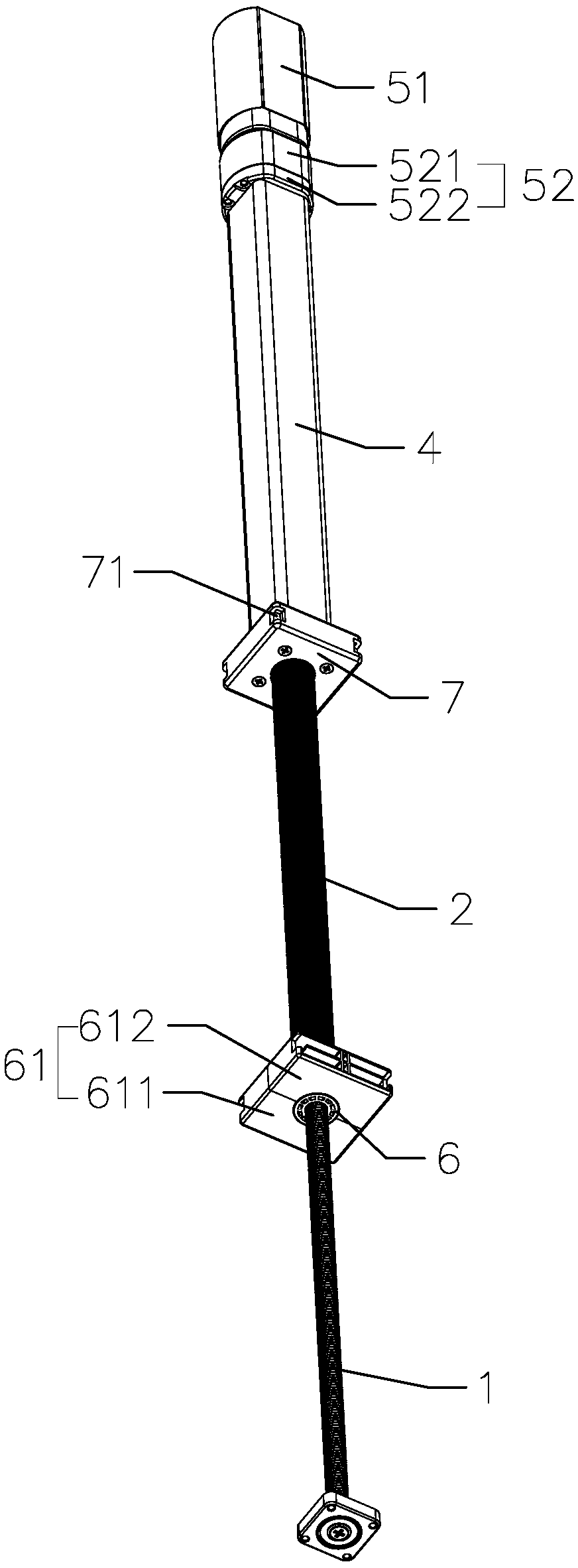

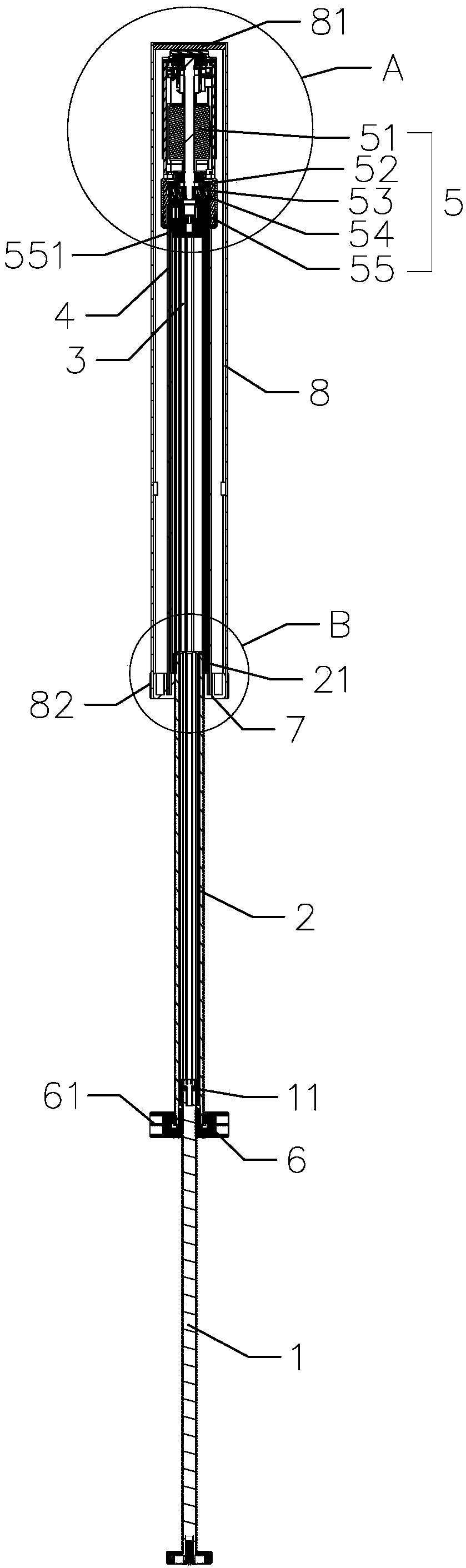

Transmission assembly for lifting stand column and lifting stand column

ActiveCN109399502AReduce stressExtended service lifeLifting framesArchitectural engineeringScrew thread

The invention provides a transmission assembly for a lifting stand column and the lifting stand column. The lifting stand column comprises an inner pipe. The transmission assembly comprises a hollow core shaft, a transmission threaded rod, a sleeving arranged on the exterior of the hollow core shaft, a guide pipe limited into the sleeving and a drive device used for driving the guide pipe to rotate. The guide pipe and the hollow core shaft can synchronously rotate, and the guide pipe and the hollow core shaft can relatively extend and retract in the axial direction. The transmission threaded rod and the hollow core shaft can synchronously rotate, and the transmission threaded rod and the hollow core shaft can relatively extend and retract in the axial direction. The drive device is locatedin the inner pipe and fixedly installed at the upper end of the sleeving. The lower end of the sleeving is fixedly connected with a first transmission nut which is in screw-thread fit with the hollowcore shaft. The first transmission nut is fixedly connected with the inner pipe. The upper end of the sleeving is freely arranged. Shake caused by the drive device is transmitted to the first transmission nut through the sleeving and cannot be directly transmitted to a lifting platform above the inner pipe, the shaking feeling is reduced, the transmission assembly is more stable in transmission,and the lifting shake of the lifting stand column is relatively small.

Owner:ZHEJIANG JIECHANG LINEAR MOTION TECH

Box having counting mechanism

Owner:JIANGXI YIBO E TECH CO LTD

Electric power unit for vehicle

InactiveCN103287536AEasy to assembleGuaranteed coaxial accuracyWheel based transmissionMotorised scootersElectric power systemDrive shaft

The invention provides an electric power unit for a vehicle, which requires small numbers of parts and assembly processes and which is also capable of reducing the weight and securing the stiffness of a transmission case. A second gear case portion (22) housing a secondary reduction gear train (14) is provided integrally continuous to a rear end of a shaft case portion (21) housing a propeller shaft (11). A first opening portion (23) for inserting the propeller shaft (11) and a drive gear (17) of the secondary reduction gear train (14) and for attaching a first bearing (33) supporting a rear portion of the propeller shaft (11) is provided in a front end of the shaft case portion (21). In addition, a second opening portion (24) for inserting a driven gear (18) of the secondary reduction gear train (14) and a rear axle holder (48) holding a bearing (47) supporting a rear axle (12) is provided in one side portion of the second gear case portion (22).

Owner:MUSA PRECISION IND CO LTD

Centering accurate-grinding device for metal bobbin

ActiveCN108637810AAchieve compactionContinuous and fast rotationGrinding carriagesRevolution surface grinding machinesBobbinEngineering

The invention provides a centering accurate-grinding device for a metal bobbin, belonging to the technical field of textile machinery. The centering accurate-grinding device comprises a centering clamping rotary mechanism and an accurate grinding mechanism. The lower end of an upper clamping piston rod of an upper clamping component of the centering clamping rotary mechanism is connected with an upper clamping centering block, and a lower centering cylinder block of a lower clamping component is concreted above a lower pressing plate. A lifting lead screw of a lifting component of the accurategrinding mechanism is in threaded connection with a lifting lead screw nut, and a first curved surface and a second curved surface are symmetrically arranged at the two ends of an accurate grinding sliding block of an accurate grinding component. A third accurate grinding wheel is rotationally arranged at the other end of a carrier rod. A first transfer roller is rotationally arranged at one endof a first swing arm, and a first accurate grinding wheel is rotationally arranged at the other end of the first swing arm. A second transfer roller is rotationally arranged at one end of a second swing arm, and a second accurate grinding wheel is rotationally arranged at the other end of the second swing arm. The centering accurate-grinding device can realize accurate grinding for a taper-pipe-shaped metal bobbin and has strong applicability to the metal bobbin.

Owner:嘉兴市恒泰化工科技有限公司

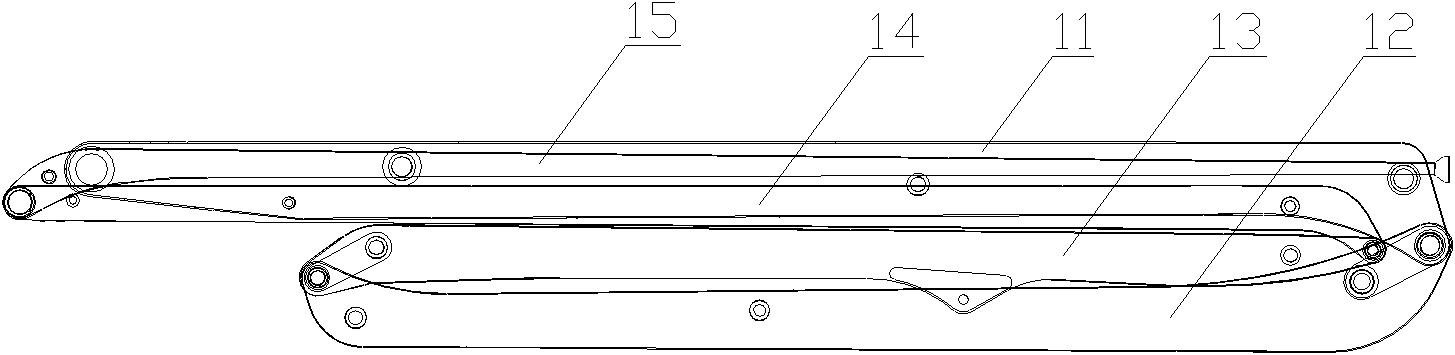

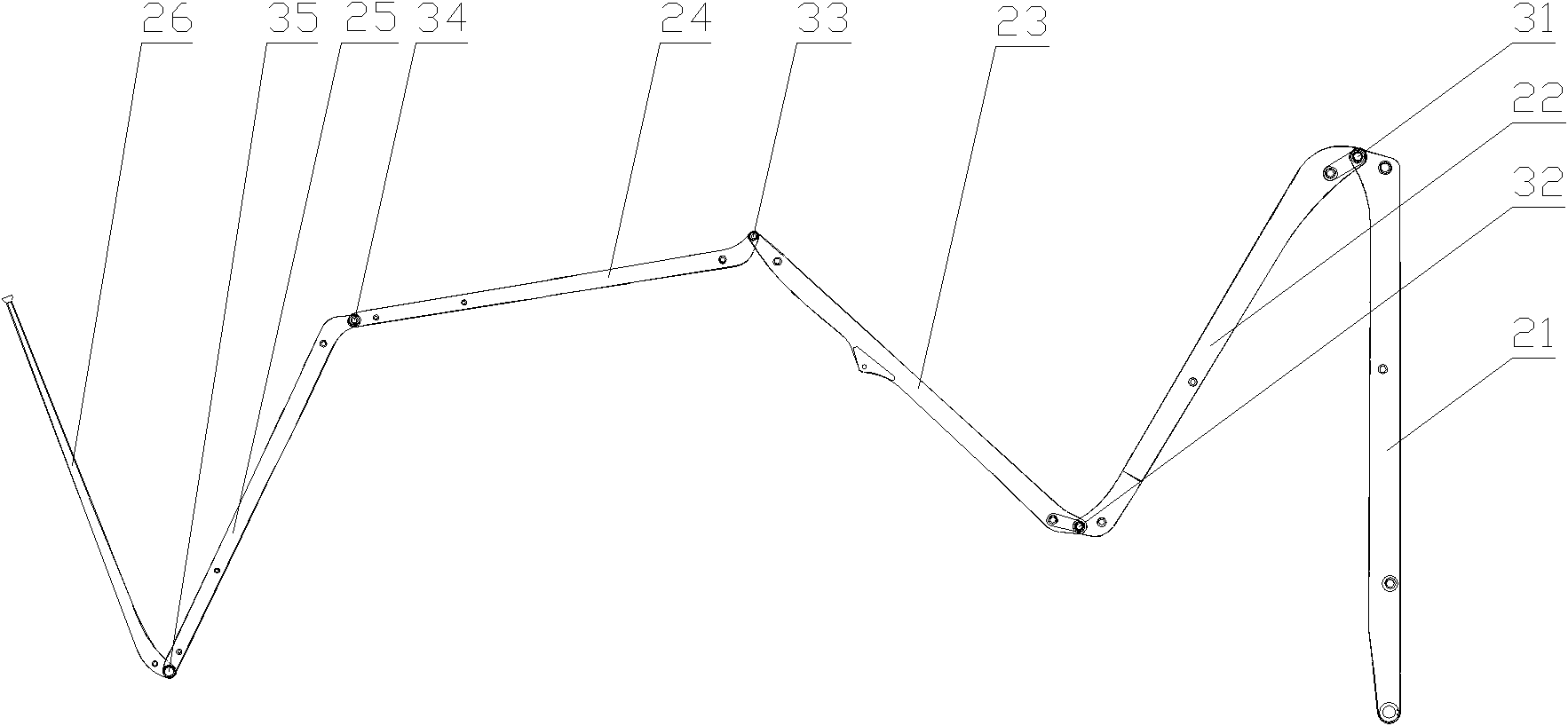

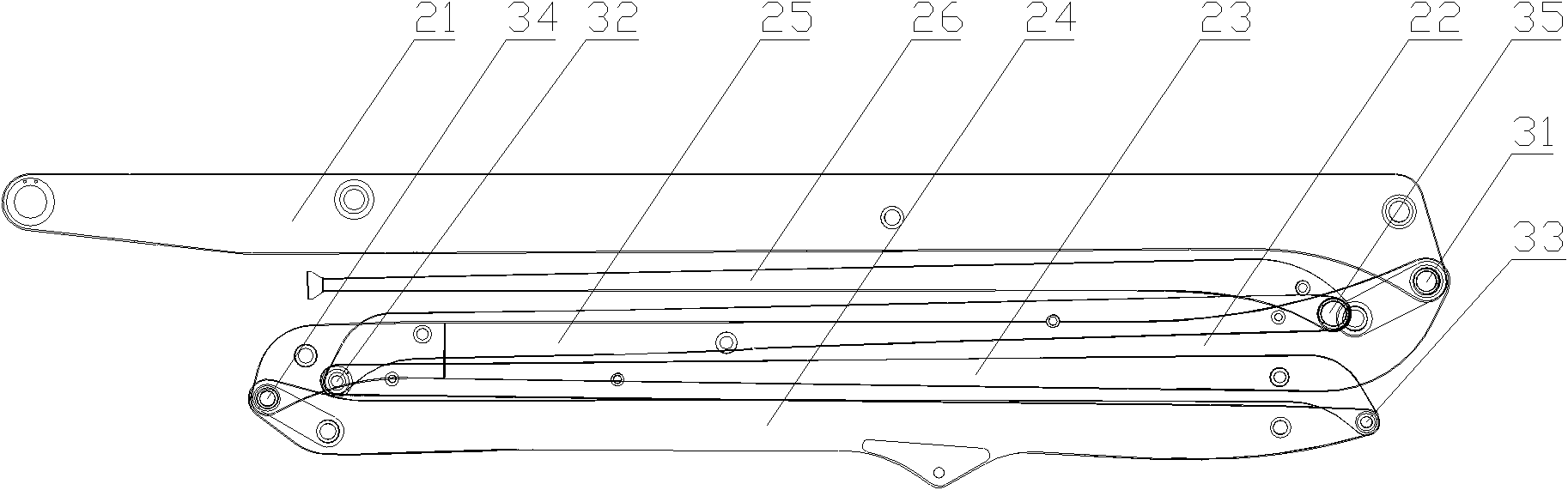

A boom type construction machine and its boom device

InactiveCN102296822AIncrease motivationSmooth power deliveryBuilding material handlingEngineeringConcrete pump

The invention discloses a boom device of a boom-type engineering machine, which comprises a first boom, a second boom, a third boom and a fourth boom which are movably connected respectively, and the third boom is a curved boom frame, power components are installed between each adjacent boom frame to drive any boom frame to rotate relative to its adjacent boom frame, and the folding direction of the second boom frame relative to the first boom frame is the same as that of the first boom frame The folding direction of the third arm frame relative to the second arm frame is opposite, and the folding direction of the fourth arm frame relative to the third arm frame is the same as that of the third arm frame relative to the first arm frame. The folding directions of the two booms are the same. In this way, the folding space of the fourth boom is large, so that the boom device is not easy to be super-high when the boom device is in the folded state, the number of booms of the boom device can be further increased, and the transition performance of the concrete pump truck is improved. The invention also discloses a boom-type construction machine comprising the above-mentioned boom device.

Owner:SANY HEAVY IND CO LTD (CN)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com