Integrated two-gear hybrid electric vehicle driving system with double-rotor motor

A technology of hybrid electric vehicles and dual-rotor motors, which is applied to the arrangement of multiple different prime movers of power plants, pneumatic power plants, and general power plants, and can solve the problem of complex structure manufacturing and control of hybrid power systems, and it is difficult to take into account the overall situation. Vehicle dynamics and economy, complex transmission system structure and other issues, to achieve the effect of prolonging the mileage of the vehicle, compact structure and flexible control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

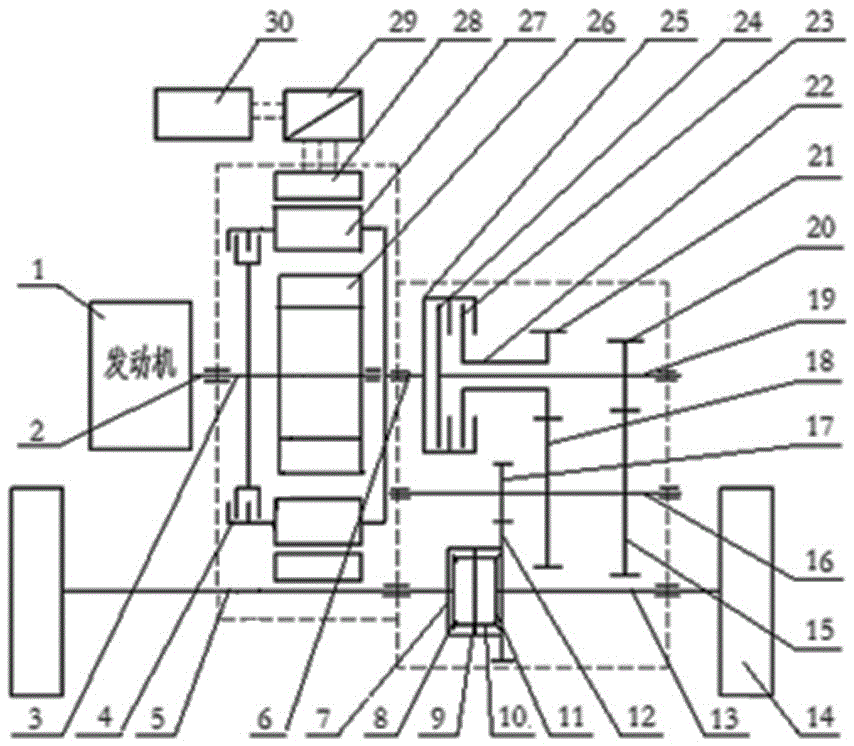

[0029] see figure 1 , the drive system of a two-speed hybrid electric vehicle with an integrated dual-rotor motor includes an engine 1, a dual-clutch two-speed transmission, a differential 7, a power battery 30, an inverter controller 29 and a power coupling mechanism; wherein the power battery 30 adopts a three-way Polymer lithium battery or lithium iron phosphate battery, power battery 30 and inverter controller 29 are electrically connected.

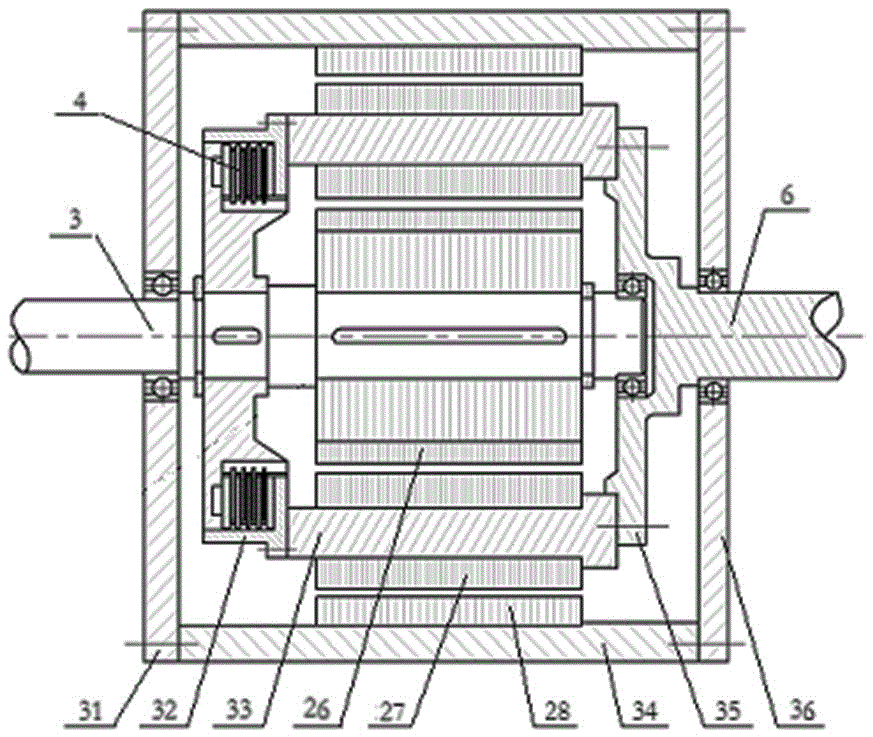

[0030] The power coupling mechanism includes a coupling motor and a coupling clutch 4 .

[0031] see figure 2 , the coupled motor is a permanent magnet brushless dual-rotor motor, including a stator 28, an outer rotor 27 and an inner rotor 26; wherein the inner rotor 26 and the outer rotor 27 form an inner motor, and the outer rotor 27 and the stator 28 form an outer motor. The inner rotor 26 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com