Rocker-type continuously variable transmission

A continuously variable transmission and rocker type technology, applied in the direction of belt/chain/gear, mechanical equipment, transmission device, etc., can solve the problems of engine and transmission system impact, discontinuous speed change process, discontinuous speed change, etc., to achieve power transmission Smooth, reliable power transmission, eliminating the effect of instantaneous impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

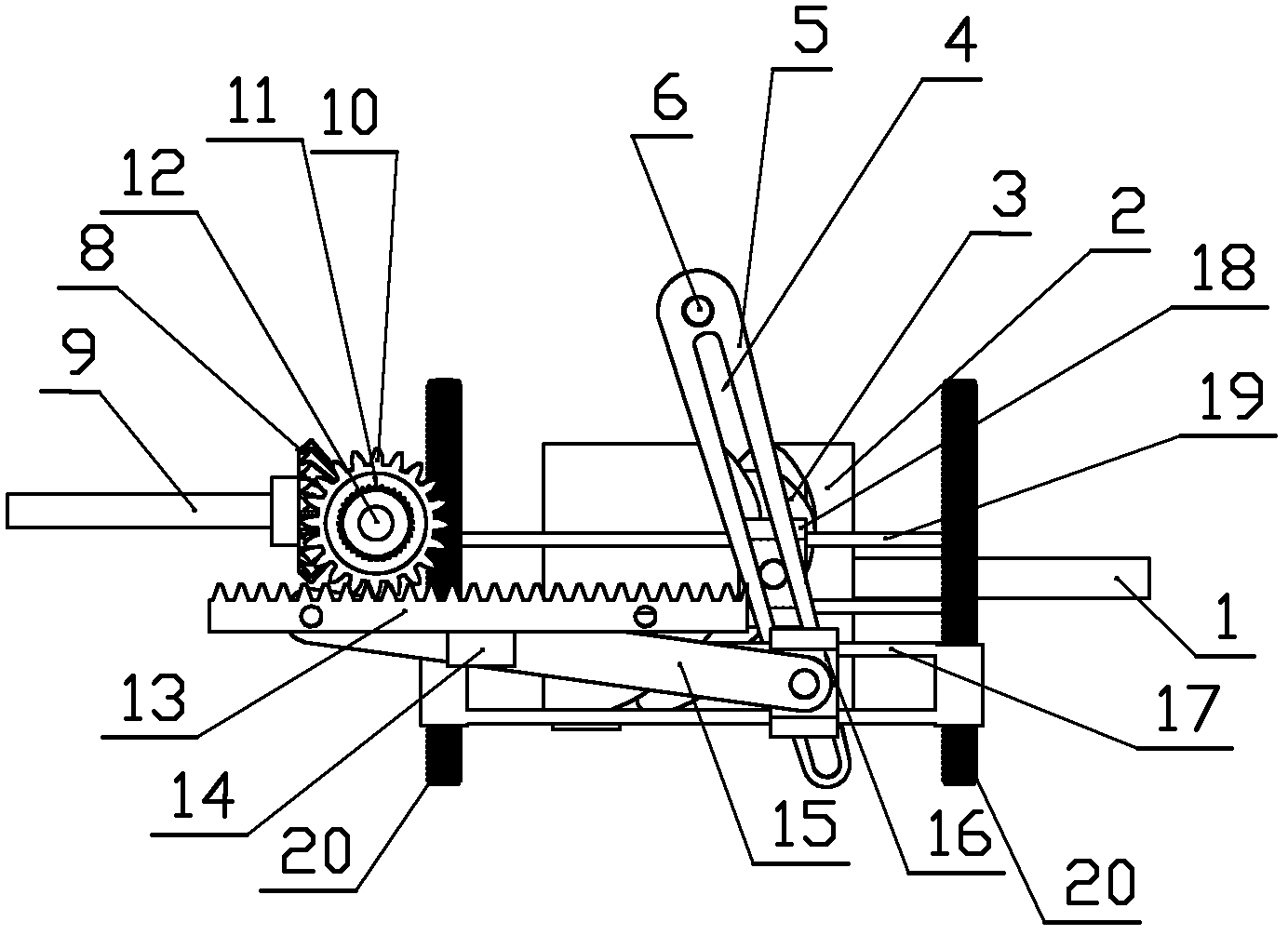

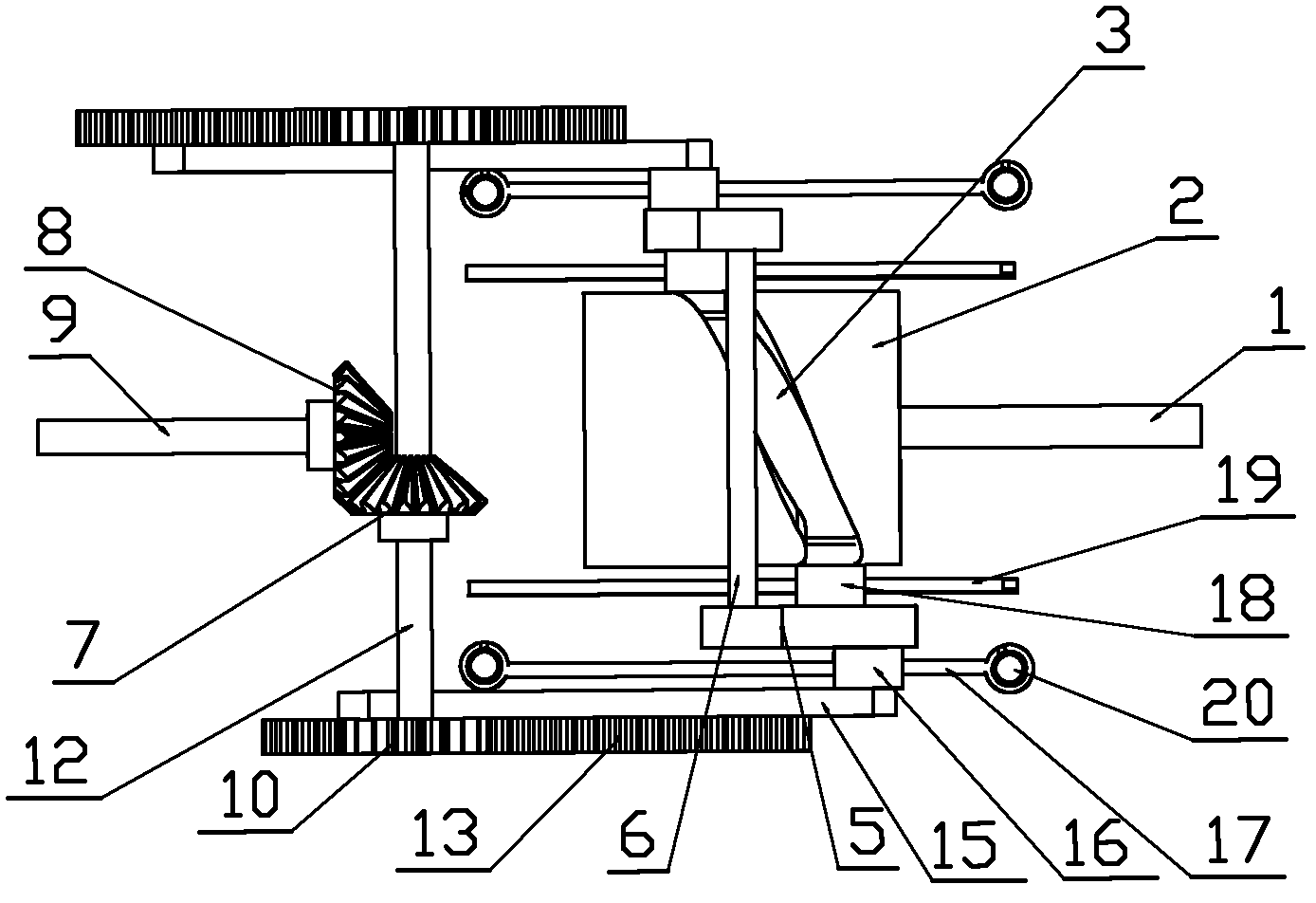

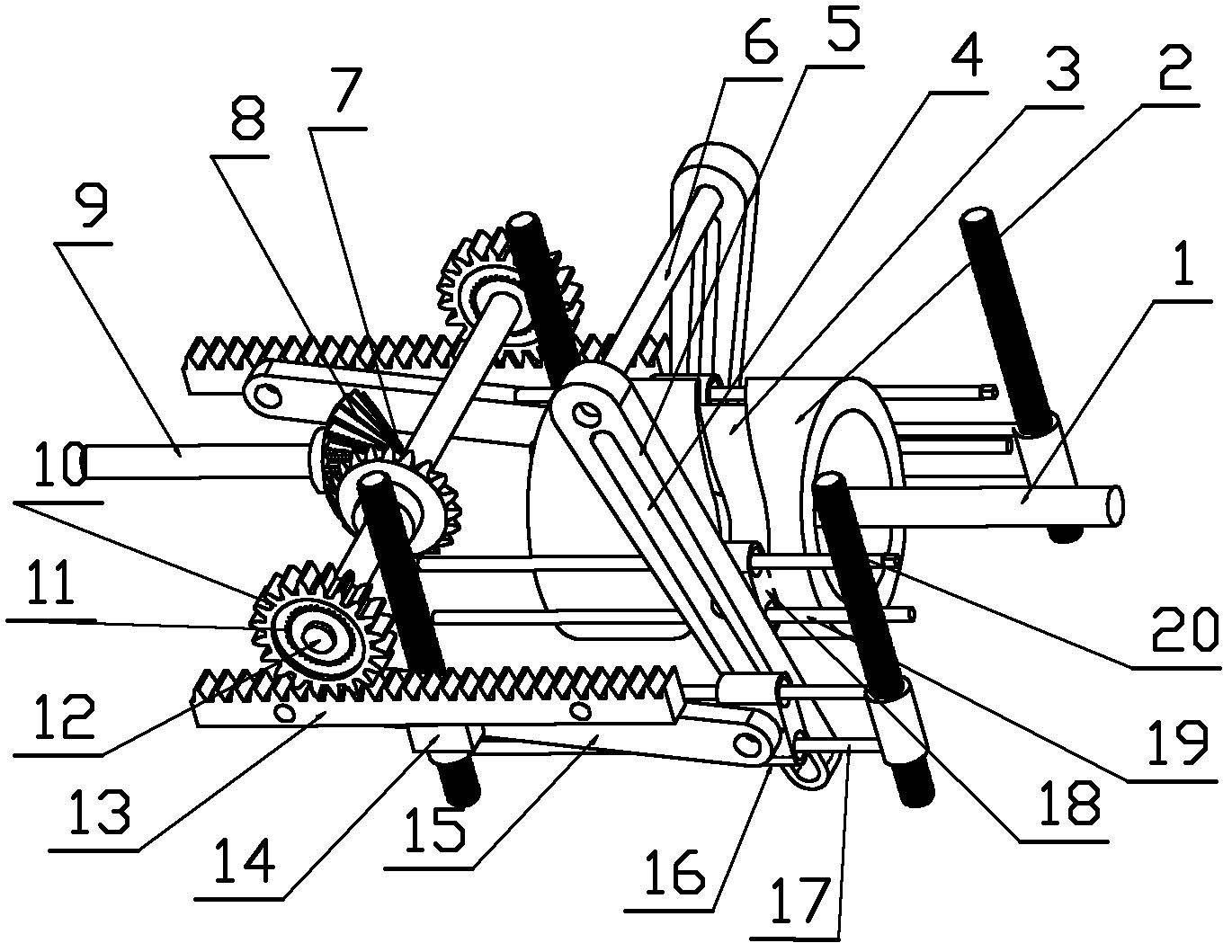

[0039] The specific embodiment of the present invention is shown in the attached drawings, and its structure is that a slider I18, a slide I19, a rocker 5, a slider II and a slider I18 are installed on the slide I19 symmetrically on both sides of the cylindrical cam 2. The roller on one side of the slider Ⅰ18 is installed in the slideway 3 of the cylindrical cam 2, and the roller on the other side is embedded in the slide groove 4 of the rocker 5; the slider Ⅱ16 is installed on the slideway Ⅱ17, and the slider Ⅱ16 is one The roller on one side is embedded in the sliding groove 4 of the rocker 5, and the other side is flexibly connected to the bottom of the connecting rod 15; the connecting rod 15 is connected with the rack 13 through the rack bracket 14, and the rack 13 meshes with the spur gear 10 The spur gear 10 is equipped with a one-way bearing 11; a gear shaft 12 is installed between the two one-way bearings 11, a bevel gear I7 is installed in the middle of the gear shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com