Rotary force drive assembly and carbon powder box including same

A driving component and rotational force technology, applied in the field of rotational force driving components and toner cartridges, can solve the problem that the material elasticity of the sphere limiting part is high, affects the power transmission, and cannot be fixed on the power receiving part 105 and the sphere 103, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

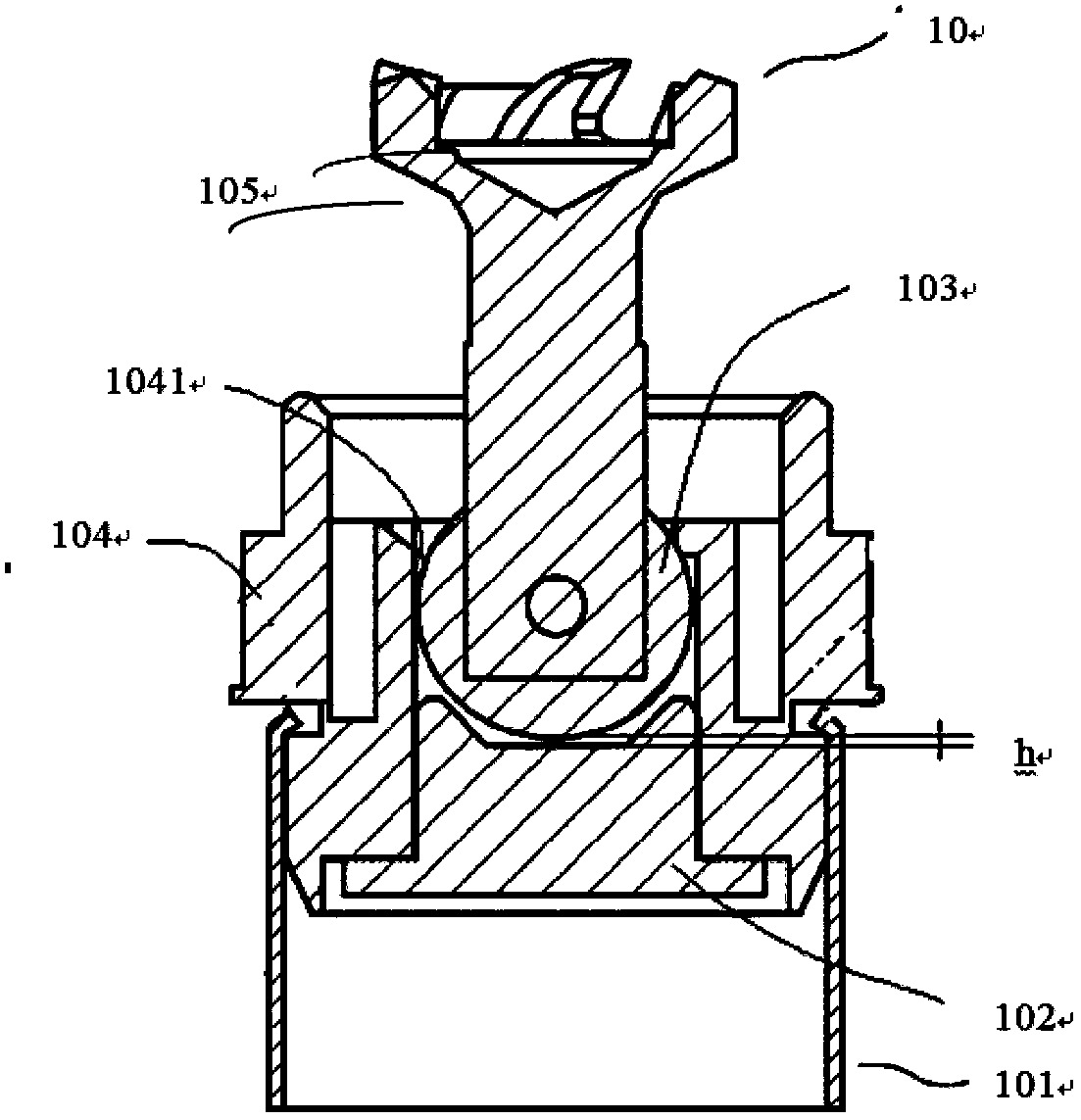

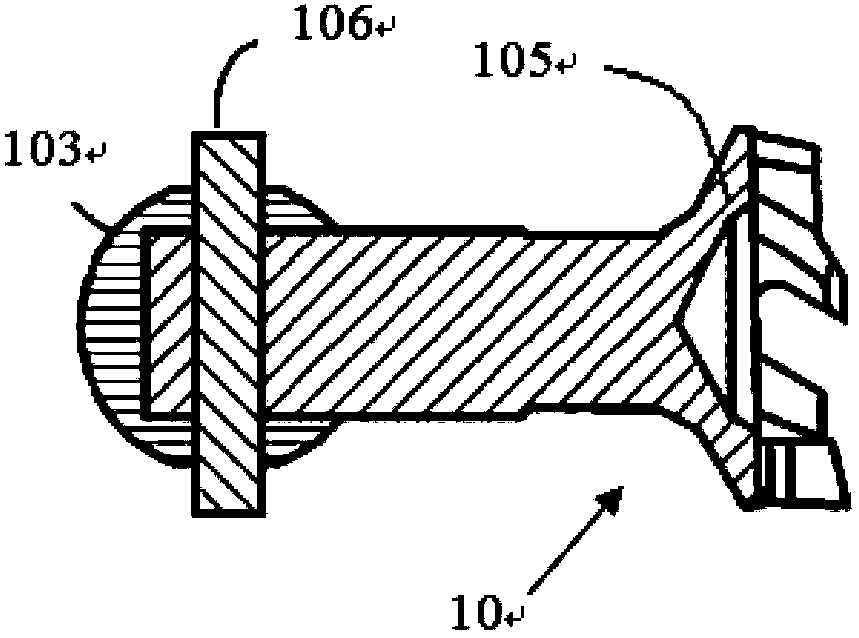

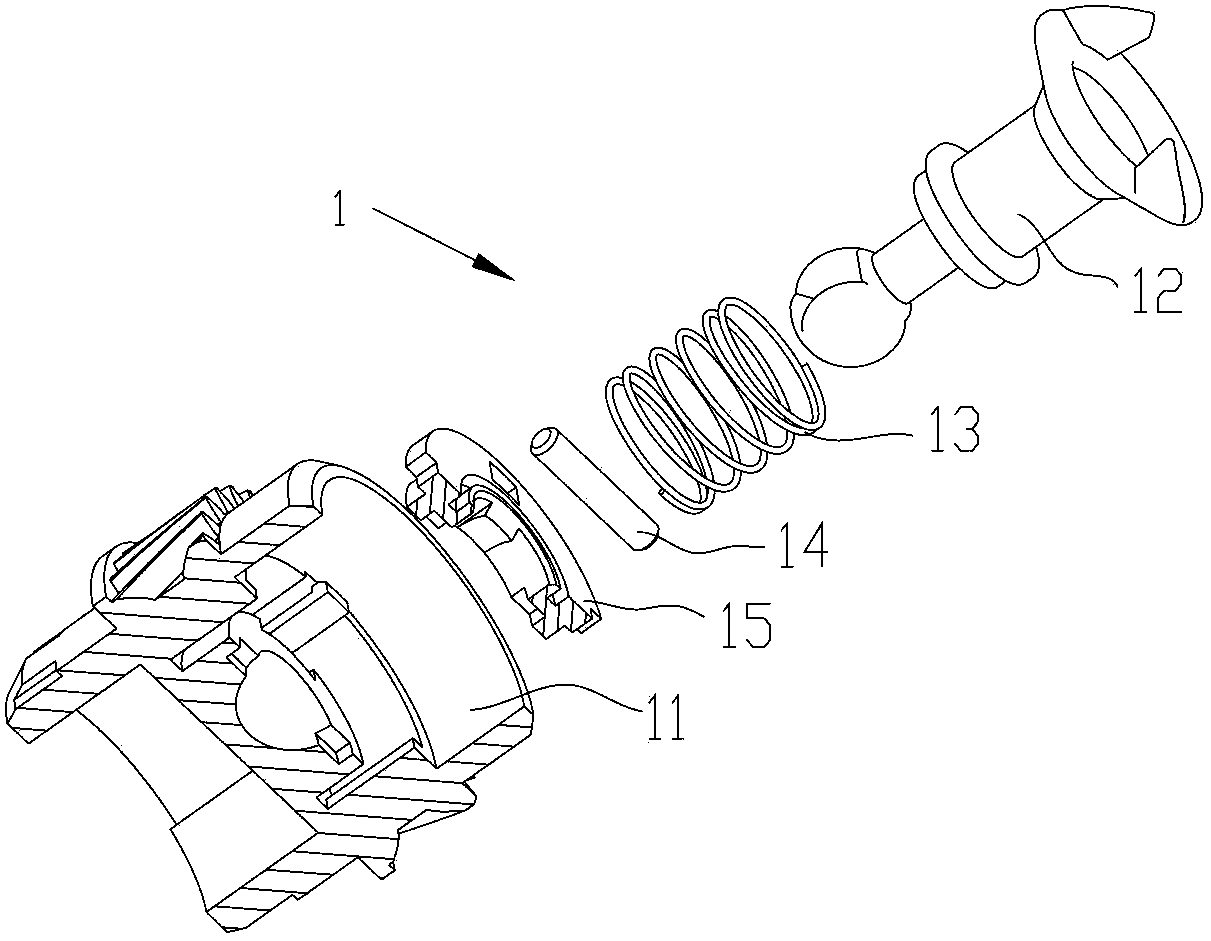

[0075] The exploded view of the technical solution adopted in embodiment one is as image 3 As shown, 1 is the driving force transmission assembly for driving the rotation of the photosensitive element, and the rotation driving force assembly is suitable for any type of photoelectric imaging device and is detachable from the photoelectric imaging device. installed toner cartridge. Wherein, 11 is the photosensitive element gear that is connected to one end of the photosensitive element; 12 is the rotational driving force receiving head that receives the rotational driving force from the electronic imaging device and transmits the driving force to the photosensitive element; Under the circumstances, make the rotating driving force receiving head 12 keep the vertical elastic element, adopt compression spring in the present embodiment, can also adopt the rubber sleeve with elastic force; 14 is the power transmission pin; 15 is the sphere limit baffle. Figure 4 It is a structural...

Embodiment 2

[0086] The exploded view of the technical solution of embodiment two is as Figure 26 As shown, 2 is a driving force transmission assembly, 21 is a photosensitive element gear, 22 is a rotating driving force receiving head, 23 is an elastic element, 24 is a power transmission pin, and 25 is a ball holding block; wherein, the rotating driving force receiving head 22 , the elastic element 23, and the power transmission pin 24 are all consistent with the structures of 12, 13, and 14 of Embodiment 1. The elastic element 23 may be a compression spring or an elastic rubber sleeve, and a compression spring is used in this embodiment.

[0087] The figure is a three-dimensional view of the photosensitive element gear 21, wherein 212 is a pair of sphere limiters, that is, the sphere limiter 152 on the sphere limiter baffle in Embodiment 1, and the sphere limiter in this embodiment The plate and the photosensitive element gear are designed as one. Figure 27 It is the bottom view of th...

Embodiment 3

[0094] The elastic elements in the first and second embodiments above are all cylindrical compression springs, or rubber sleeves with elastic force, and their function is mainly to make the rotating driving force receiving head 12 (22) Keep the vertical state, and absorb the axial movement caused by the gap between the sphere of the rotating driving force receiving head and the sphere holding surface. In the present invention, the shape of the elastic element is configured as a tower, which can also perform the same function. This embodiment is based on the structure of the driving force transmission assembly in Embodiment 1, and the cylindrical compression spring 13 is replaced by Figure 38 As shown in the tower spring 13A, the assembly drawing of its driving force transmission assembly is as follows Figure 39 shown. Meanwhile, the inner diameter of the narrowest end of the tower spring 13A is substantially equal to the outer diameter of the first stepped portion of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com