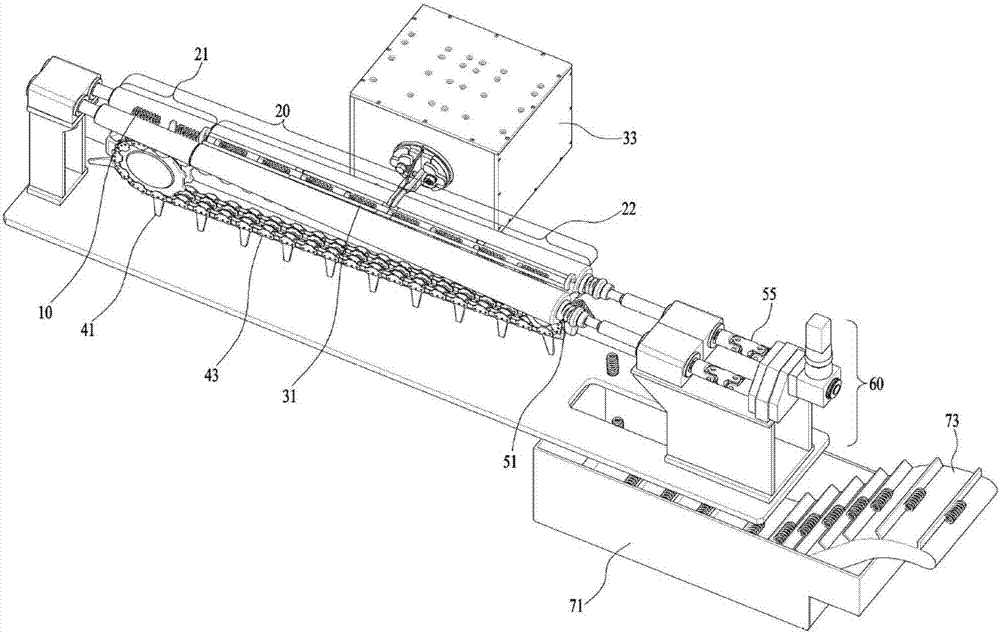

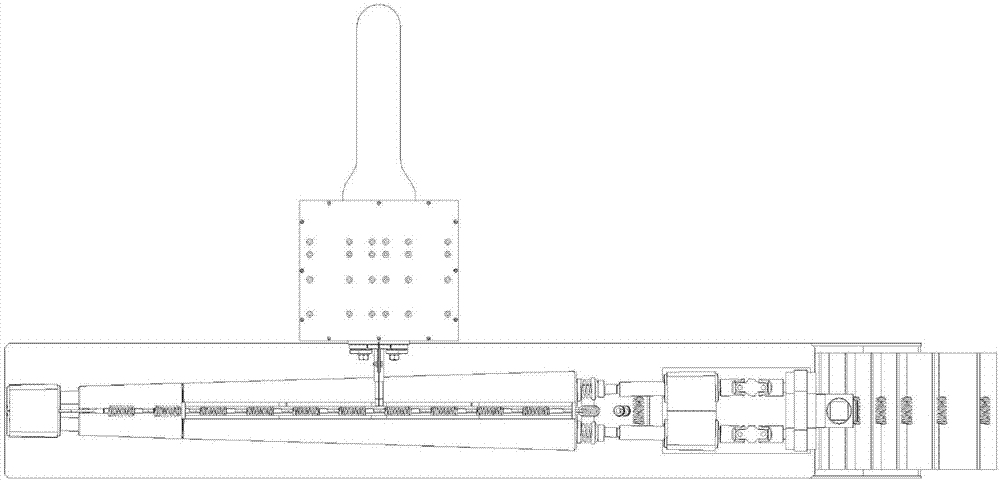

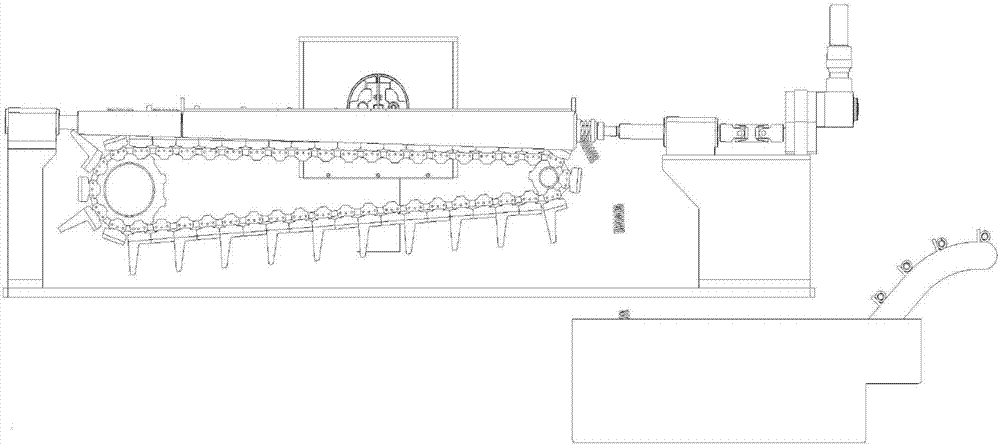

Continous Heating Device For Coil Springs And Heating Method For Coil Springs By Using This Device

A technology of coil springs and heating devices, applied in the direction of induction heating devices, springs, coil devices, etc., can solve the problems of unsuitable manufacturing of small coil springs, complex structure of continuous heating devices, complicated spring input process, etc., to improve quality and reliability The effect of high performance, simple structure and smooth power transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] It should be noted that the terms used in this specification are only used to describe specific embodiments, and are not used to limit the present invention.

[0048] Moreover, as long as there is no special definition in other meanings in this specification, the technical terms used in this specification should be understood as the meanings commonly understood by those of ordinary skill in the technical field to which the present invention belongs, and should not be interpreted in an overly broad sense. to be interpreted, or should not be interpreted in an overly narrowed sense.

[0049] In addition, as long as different meanings are not clearly indicated in the context, expressions of the singular number used in this specification include expressions of the plural number. In this application, terms such as "consisting" or "comprising" should not be interpreted as necessarily including various structural elements or multiple steps described in the specification, but sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com