Bidirectional magnetic levitation sound wave motor device

A magnetic levitation and sound wave technology, applied in electromechanical devices, holding devices using magnetic attraction or thrust, magnetic circuits, etc., can solve problems such as no axial telescopic function, large changes in motor shaft swing, and difficulty in repair, avoiding the need for Short service life, stable power transmission process, improved cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

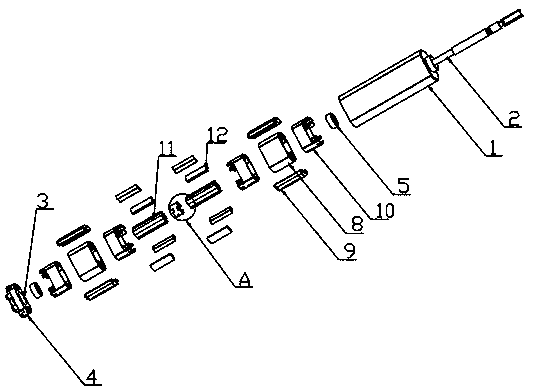

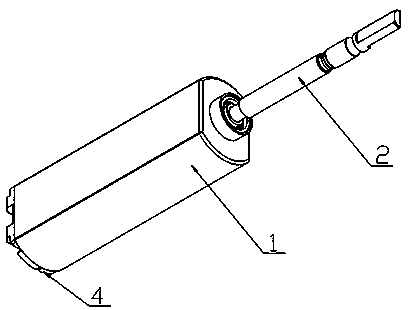

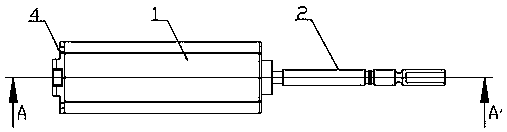

[0035] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0036] The present invention provides such Figure 1-14 A two-way magnetic levitation acoustic wave motor device shown includes a motor housing 1 and a motor shaft 2, the motor shaft 2 is arranged at the axis of the motor housing 1, and the bottom end of the motor housing 1 is provided with an end cover 4, so that The shaft centers of the motor casing 1 and the end cover 4 are provided with shaft holes 3, the motor shaft branch 2 runs through the two shaft holes 3, and the connection between the motor shaft branch 2 and the shaft hole 3 is provided with a bearing 5, so The inside of the motor housing 1 is provided with a transmission unit, the transmission unit is composed of a stator assembly 6 and a rotor assembly 7, and the rotor assembly 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com