Check valve and rotor type compressor

A check valve and spool technology, applied in the field of compressors, can solve the problems of easily damaged springs and low reliability of check valves, and achieve the effects of improving reliability, increasing service life, and reducing lateral friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

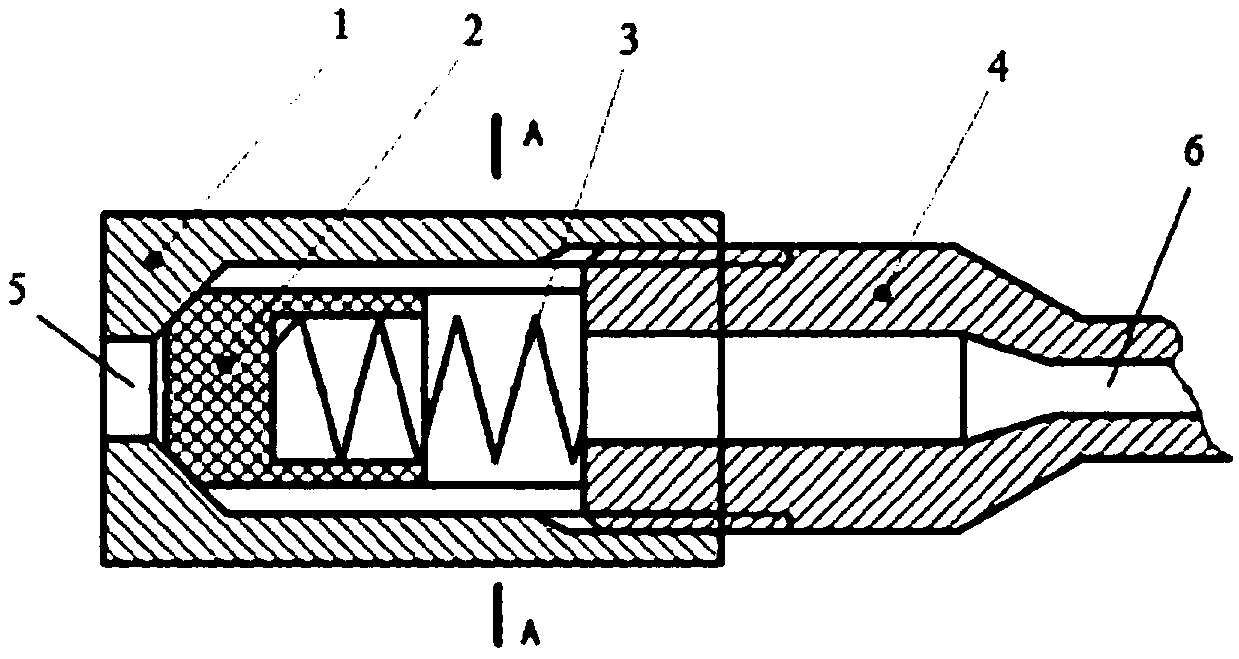

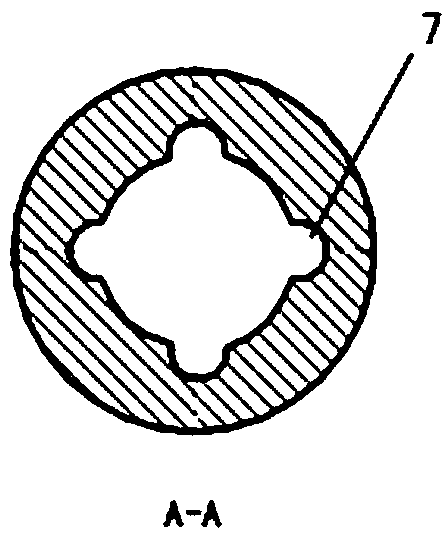

[0041] In order to make the purpose, advantages and characteristics of the present invention clearer, the following in conjunction with the attached Figure 1~4 A check valve and a rotary compressor proposed by the present invention are further described in detail. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

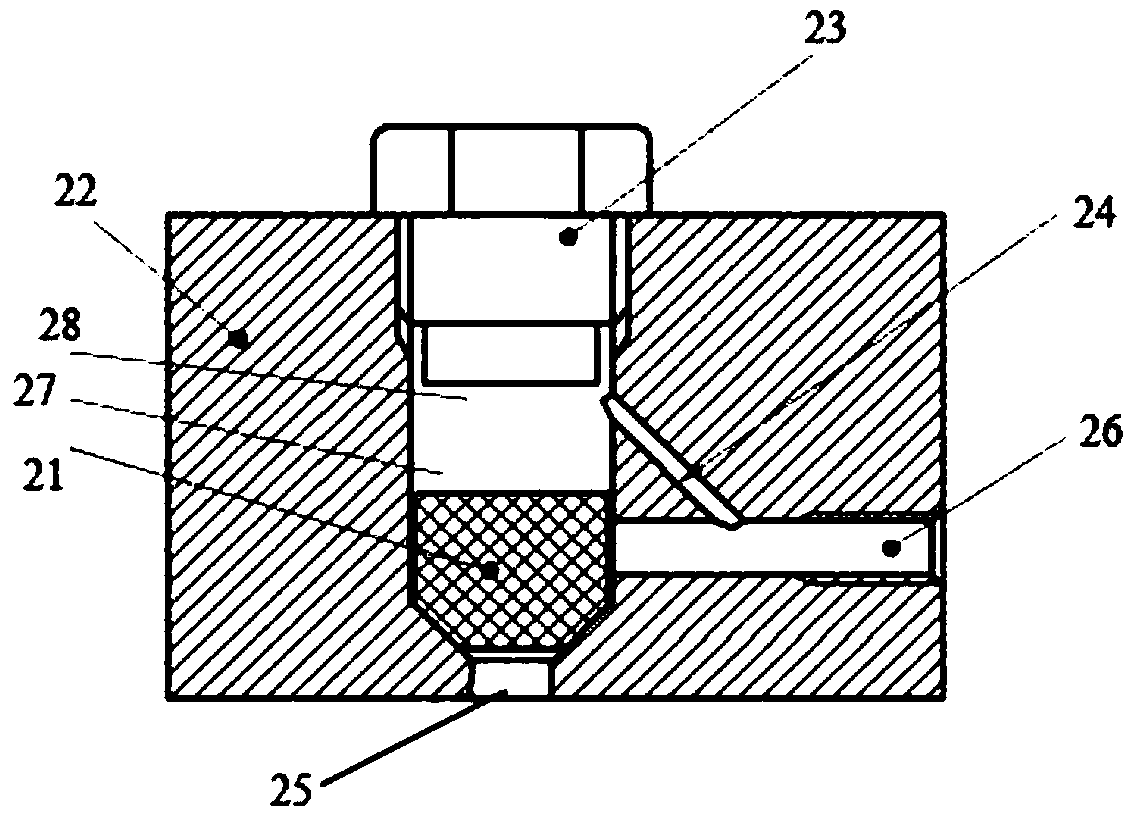

[0042] The embodiment of the present invention provides a check valve, refer to image 3 As shown, the check valve includes a valve core 21 and a valve seat 22;

[0043] The valve seat 22 is provided with an inner cavity along the first direction, and the angle θ between the first direction and the horizontal plane satisfies 0° image 3 The angle θ between the first direction and the horizontal plane in is 90°;

[0044] The valve core 21 is slidably arranged in the inner cavity, and divides the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com