Patents

Literature

32results about How to "Reduce lateral friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

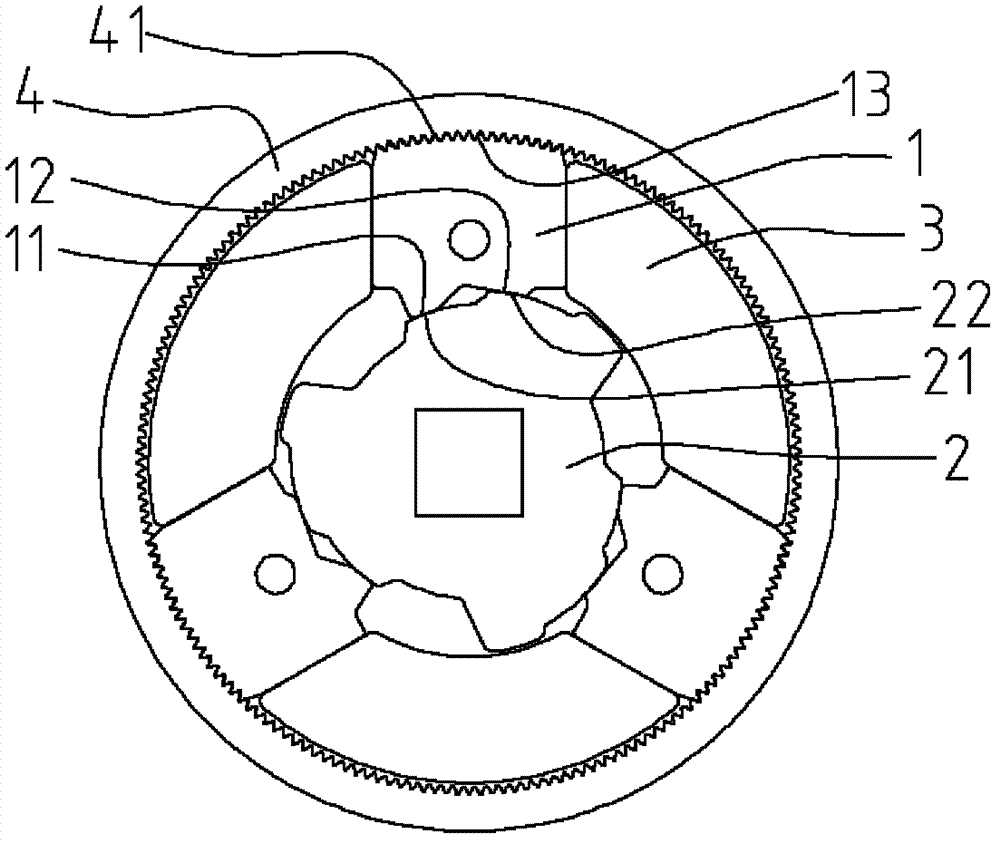

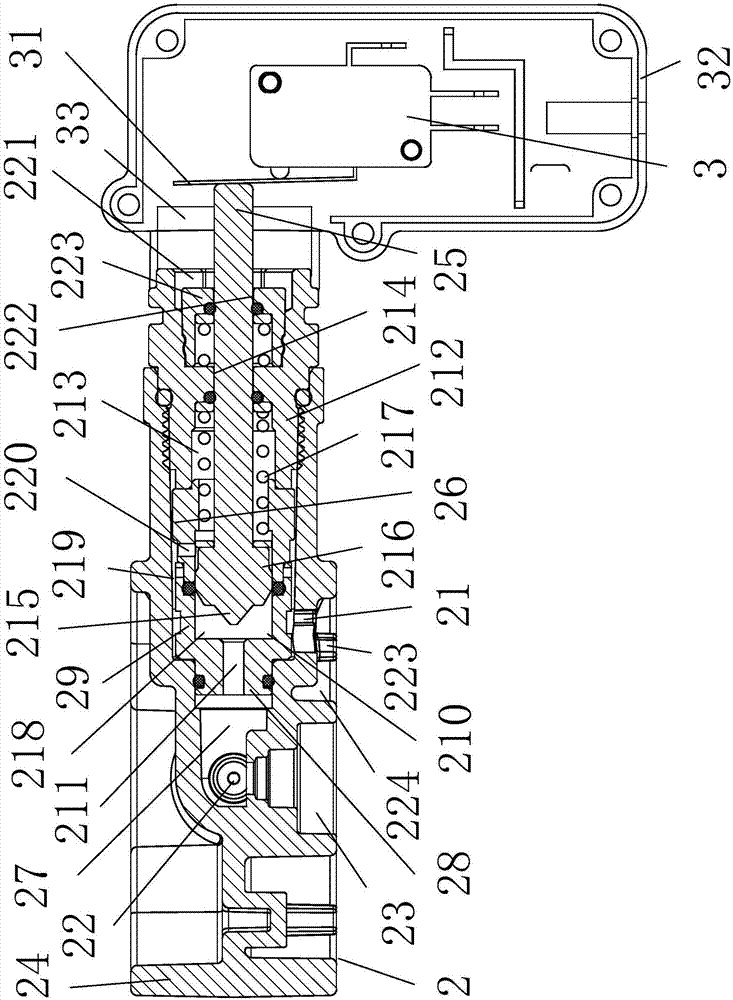

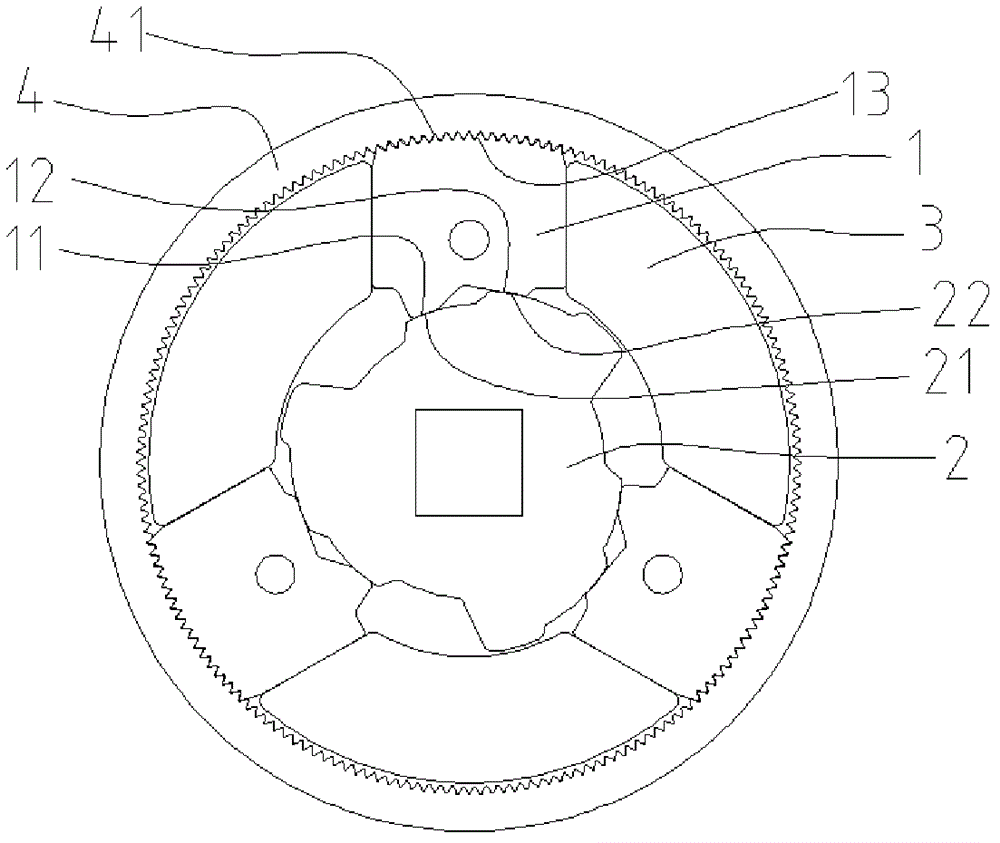

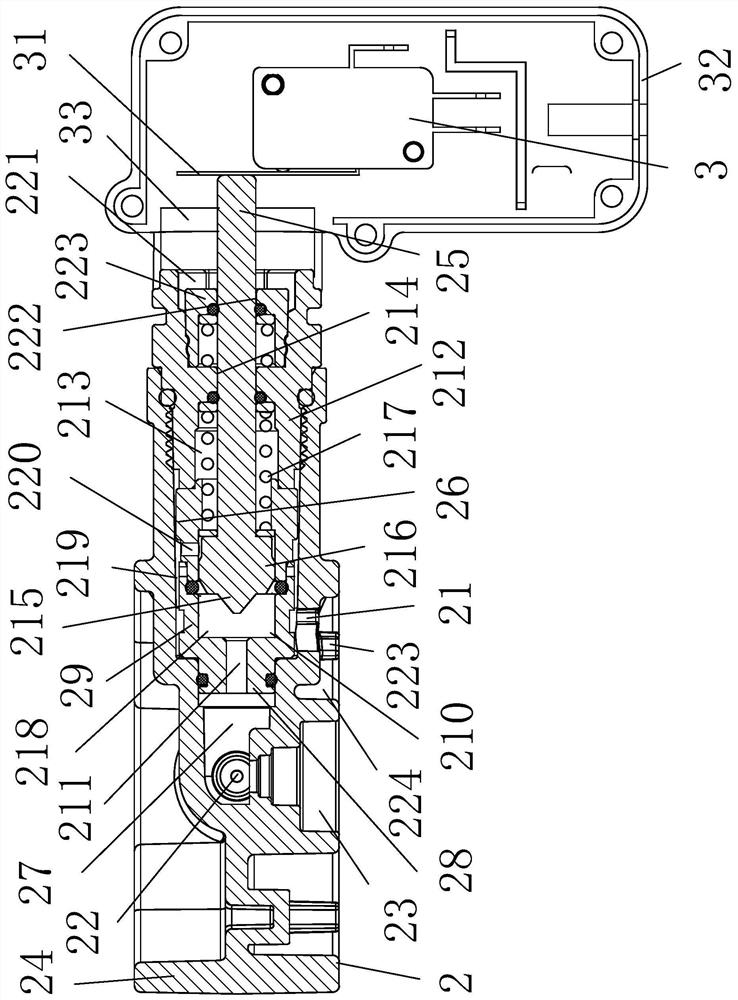

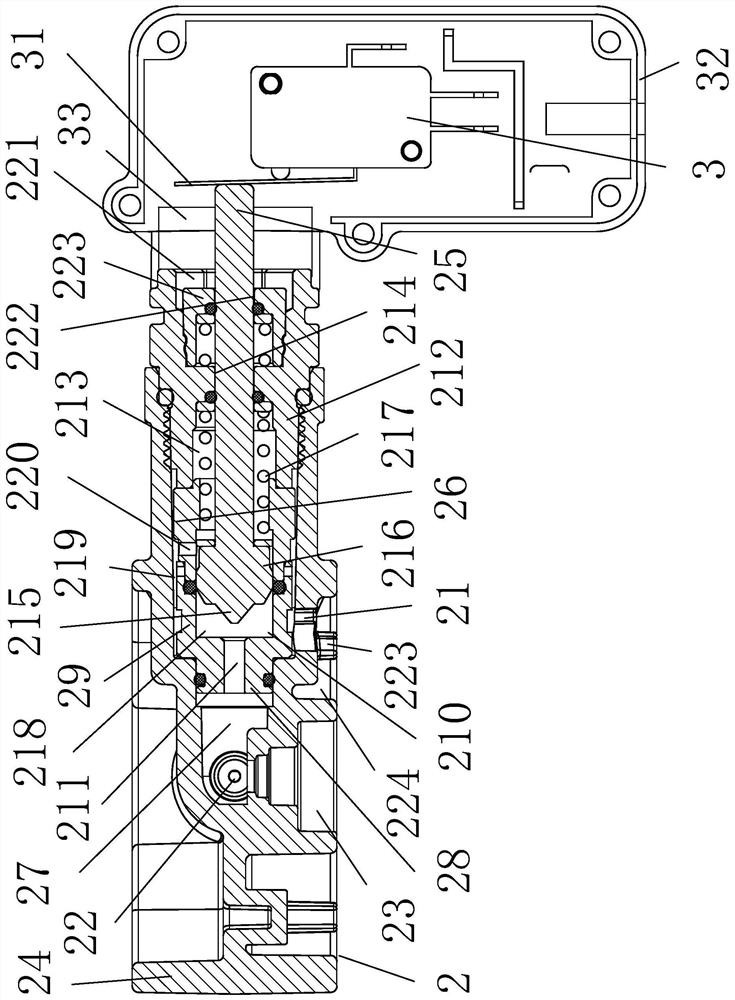

Seat angle adjusting device and seat with same

The invention discloses a seat angle adjusting device comprising a ratchet wheel, a stop plate, a locking slider and a pawl. A driving device can optionally drive the locking slider to a locking position or a retracting position and drive the pawl to a stretching position or a retracting position. The stop plate is provided with a first stop limit portion and a second stop limit portion. When the first stop limit portion is stressed by rotation torque in rotation direction, the locking slider at the locking position is abutted against the circumference of the first stop limit portion. When the rotation torque is larger than a first preset torque value, the first stop limit portion can deform circumferentially under the action of the locking slider, and the pawl at the extending position can be driven to rotate by the ratchet wheel to a toothed portion on one side of the pawl to mesh with the ratchet wheel completely. When the rotation torque is larger than a second preset torque value, the second stop limit portion can be abutted against the pawl, and the second preset torque value is larger than the first preset torque value. The invention further provides a seat utilizing the seat angle adjusting device on the basis of the above structure.

Owner:HUBEI AVIATION PRECISION MASCH TECH CO LTD

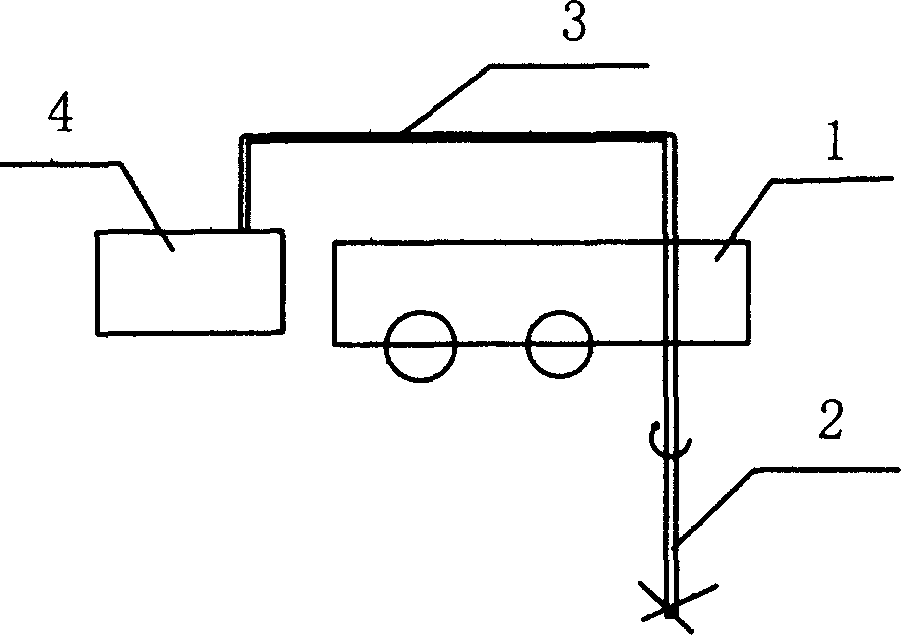

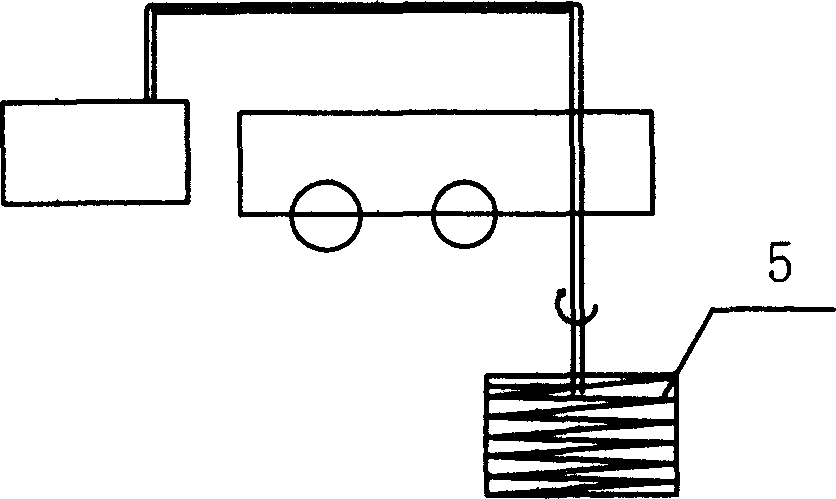

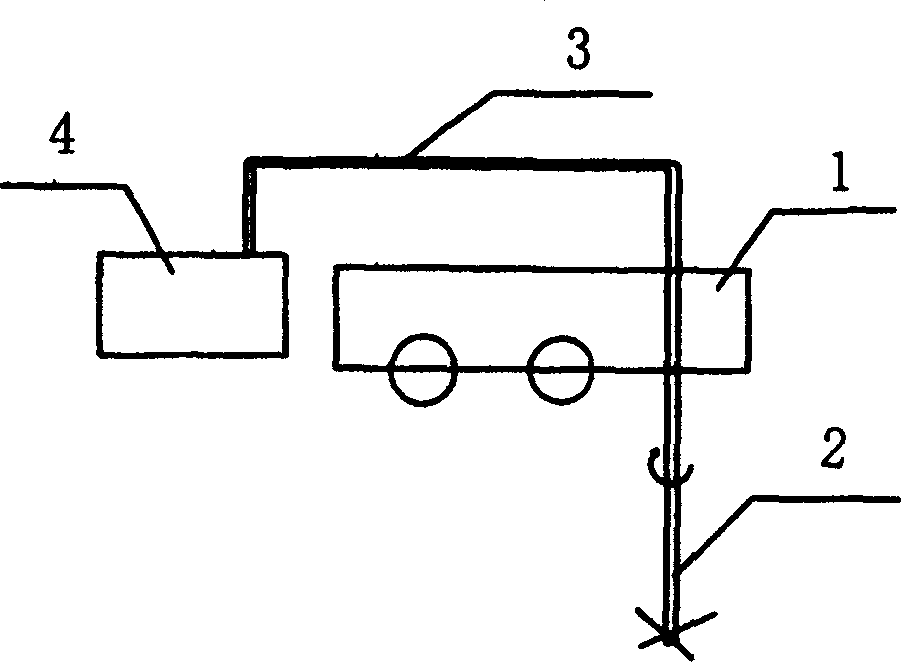

Prewhirl spray auxiliary pile sinking construction method

This invention discloses a method of assistant stake sinking by revolving spray, in this method we ensure the thickness of underground revolving spray before stake sinking, and use revolving spray to drill to move to the resistance layer of stake sinking in stake sinking point, then pass syrup liquid to the drill pole to carry the head of spray using the high pressure pump, with the high pressure level shoot to flow to spray to go in to resistance layer with jet pressure above 30 Mpas, at the same time the drill pole revolving at 15-30 r / min, promoting with 15-30 cm / min speed, to the resistance layer of underground sinking stake to harass revolving spray, then using the sinking stake equipments. The method of the invention avoided taking the soil from top to bottom in the beginning from the natural horizon, lowering resistance of sinking, raised sinking speed and protected stake body, increased the side rub resistance of the stake after the formation of stake. The invention is applicable to the processing of preparing stake used in underground stake sinking resistance layer in engineering construction.

Owner:MCC TIANGONG GROUP

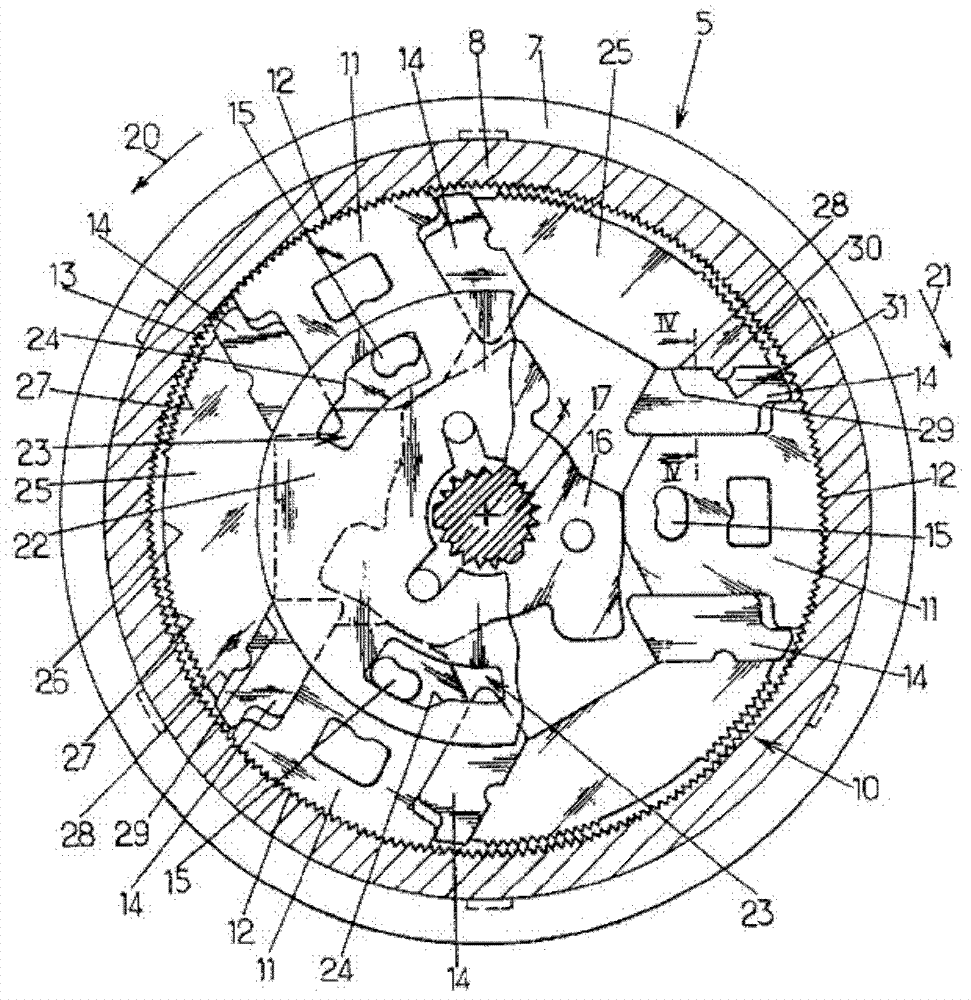

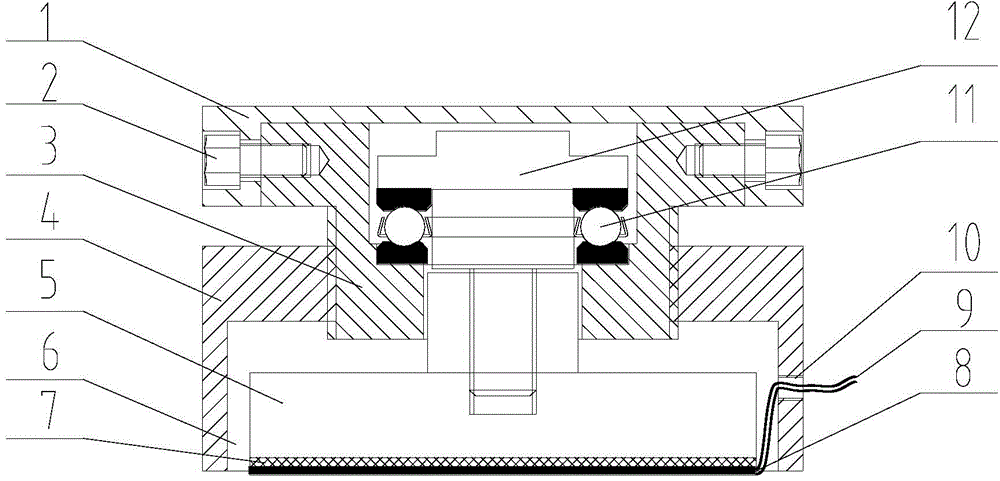

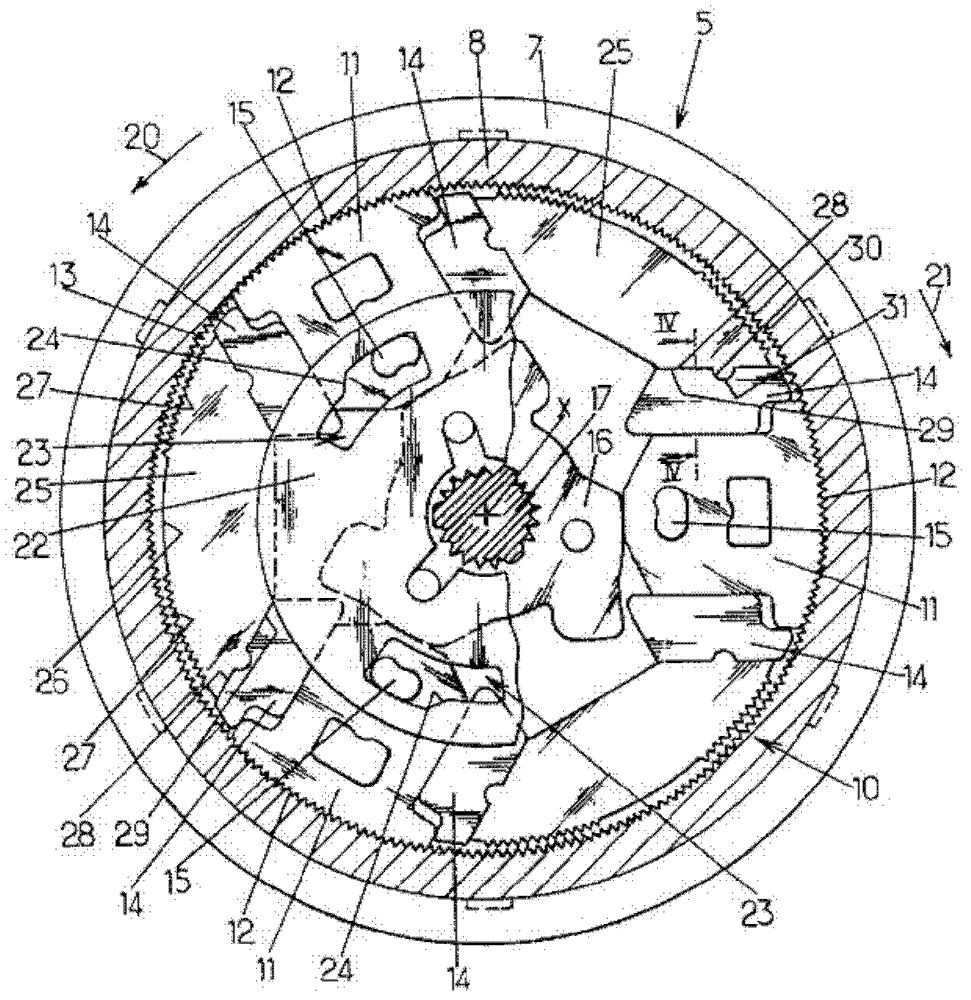

Damping device with two-rider for lubricating for automobile

InactiveCN1560489AShutoff speed sensitiveImprove vibration damping effectSpringsResilient suspensionsGuide tubeLubrication

The invention is a car damper with two guides and lubrication which can reduce the wear and enhance the damping effect. It includes an oil storing cylinder, a working oil cylinder is arranged in the oil storing cylinder, the bottom of the oil storing cylinder and the working oil cylinder are connected with bottom valve, a piston device is arranged in the working oil cylinder, the top of the working oil cylinder is arranged with a guiding cover and the second guiding cover, the two covers are covered out of the guiding bearing, a oil seal is arranged at top of the covers. The character is that tubes are arranged on the link shaft at two ends of the piston, interrupting spring bracket is arranged at two ends of the tube, interrupting spring is arranged on the interrupting bracket reversely, a oil storing slot is arranged on top of a guiding cover, a oil returning aperture penetrating the guide cover subjacent part on the cover, a ring slot is arranged on top of the second guide cover, a oil returning aperture is arranged on the inner wall of the ring slot, the guide cover oil returning aperture is connected to the second cover oil returning aperture.

Owner:范勇

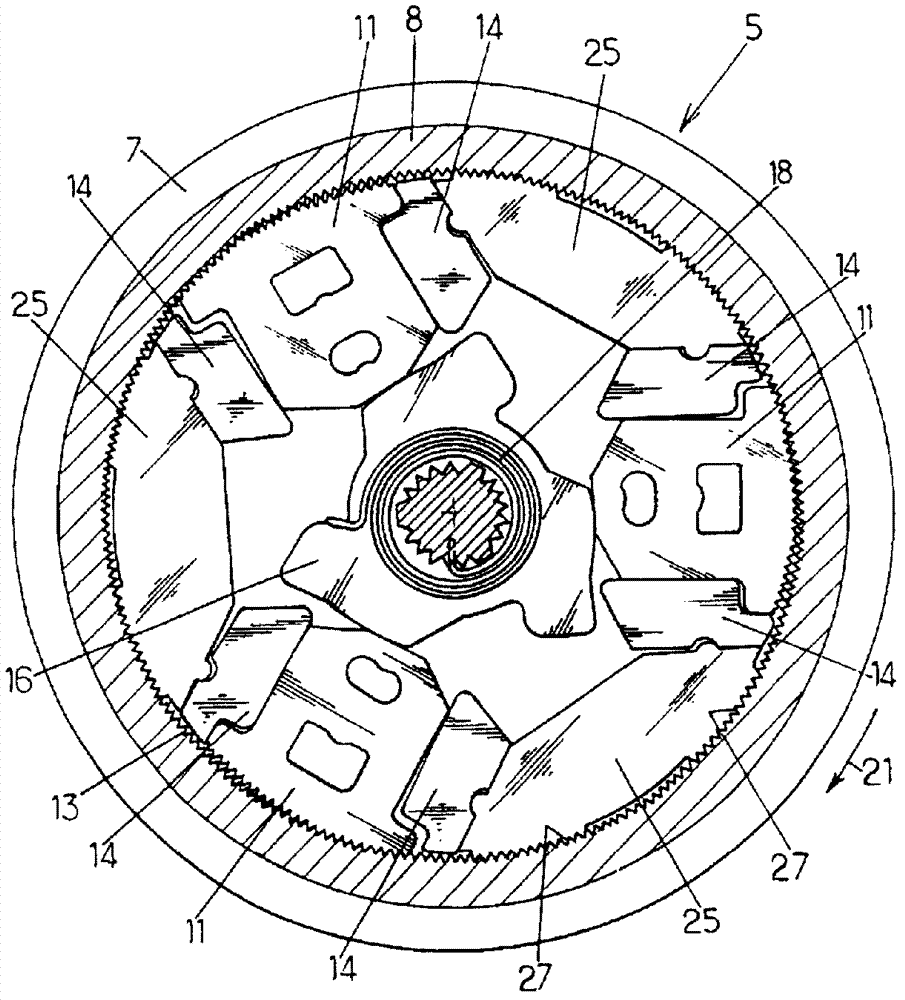

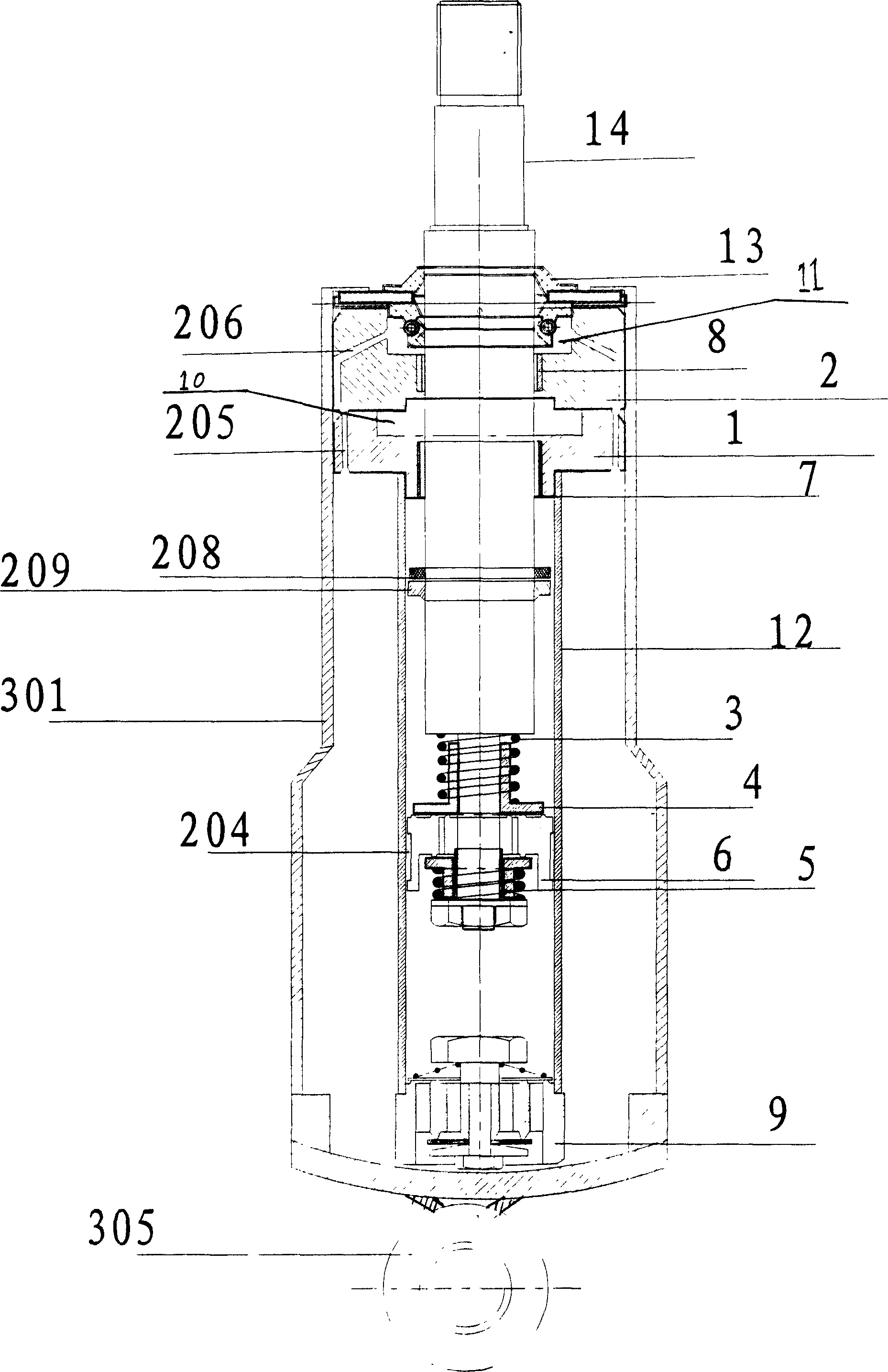

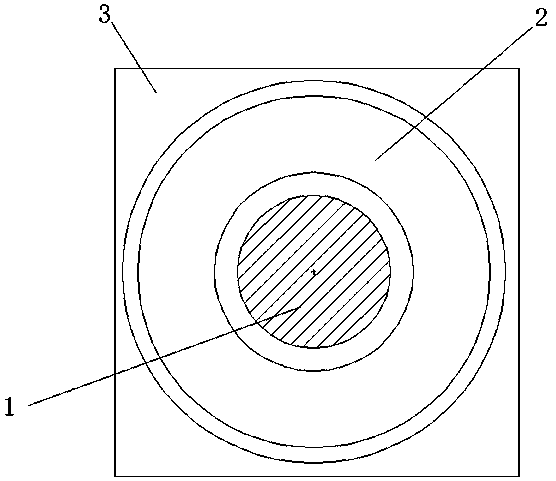

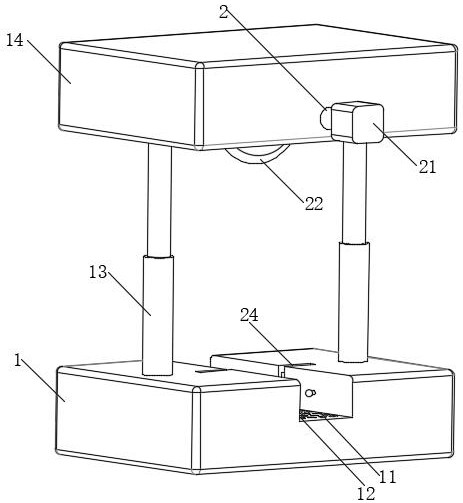

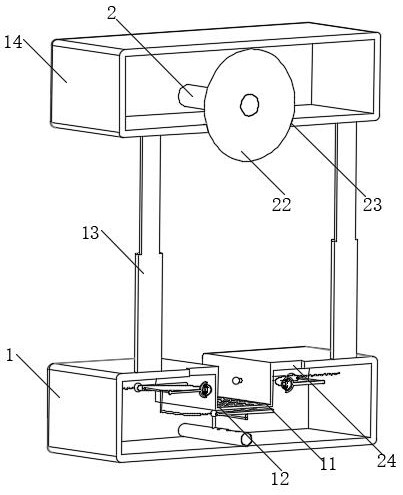

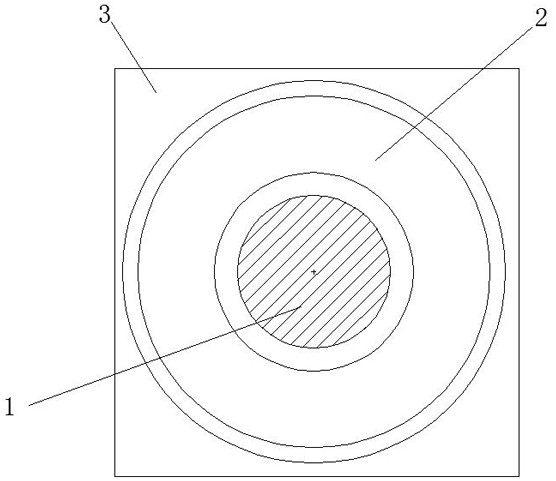

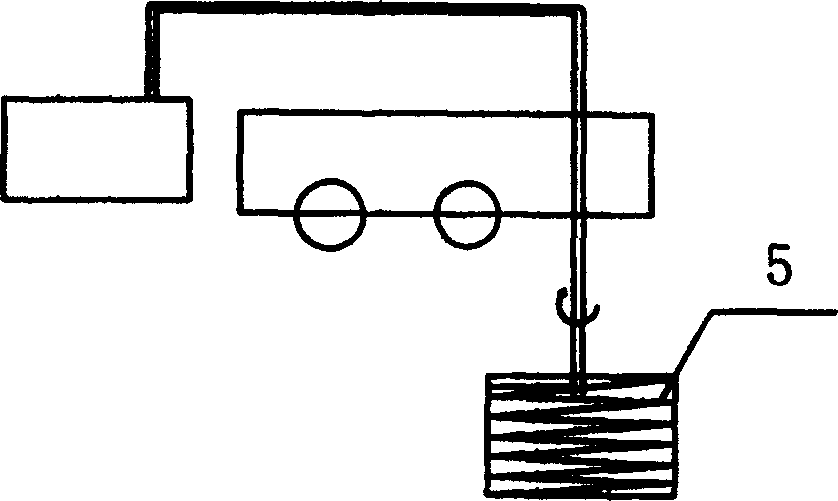

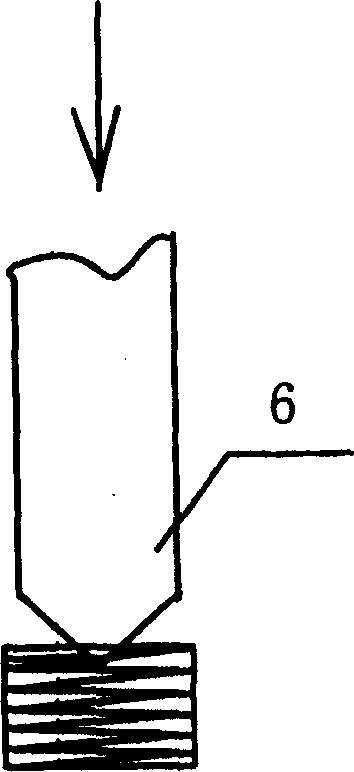

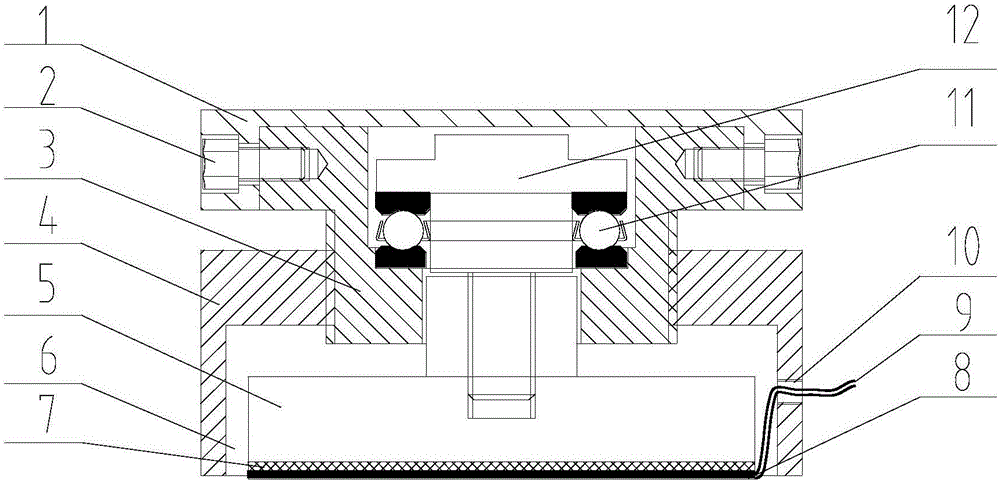

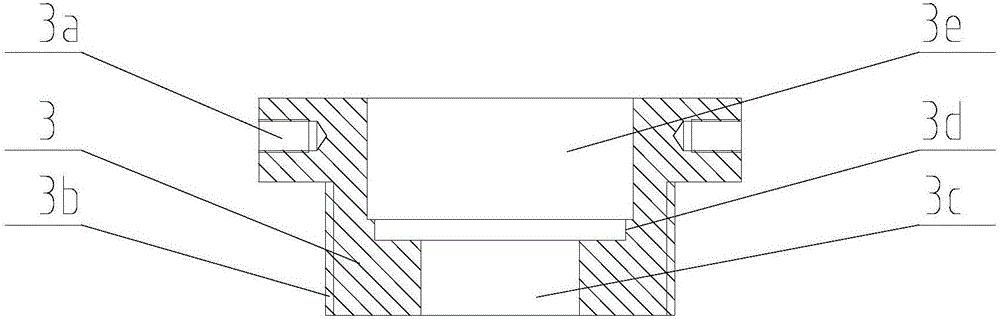

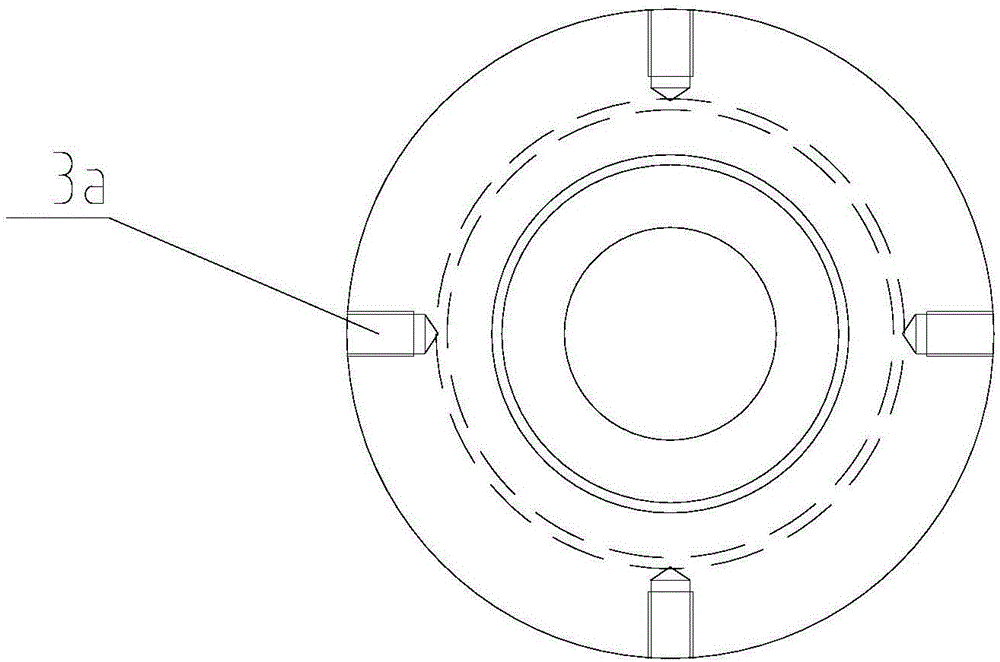

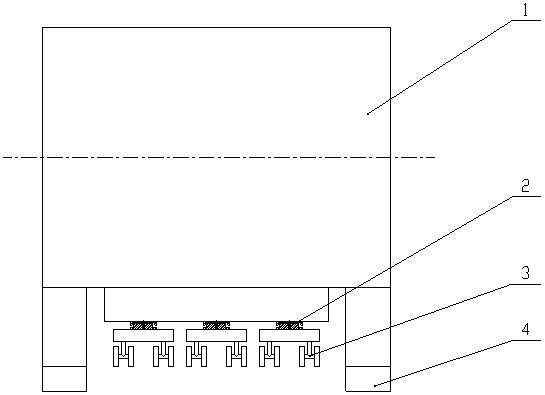

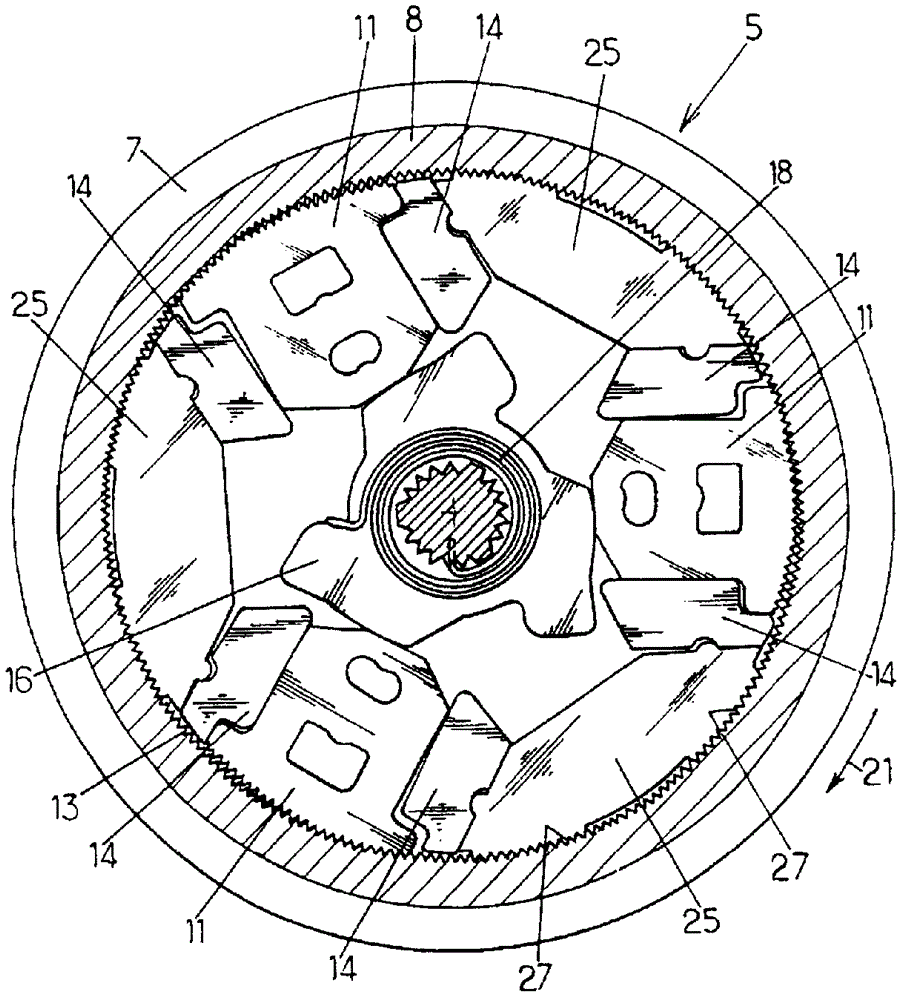

A hot press device for high temperature adhesive curing

ActiveCN105365251AMeet the conditions for multiple curingRotation will notMeasurement devicesPressesAdhesiveEngineering

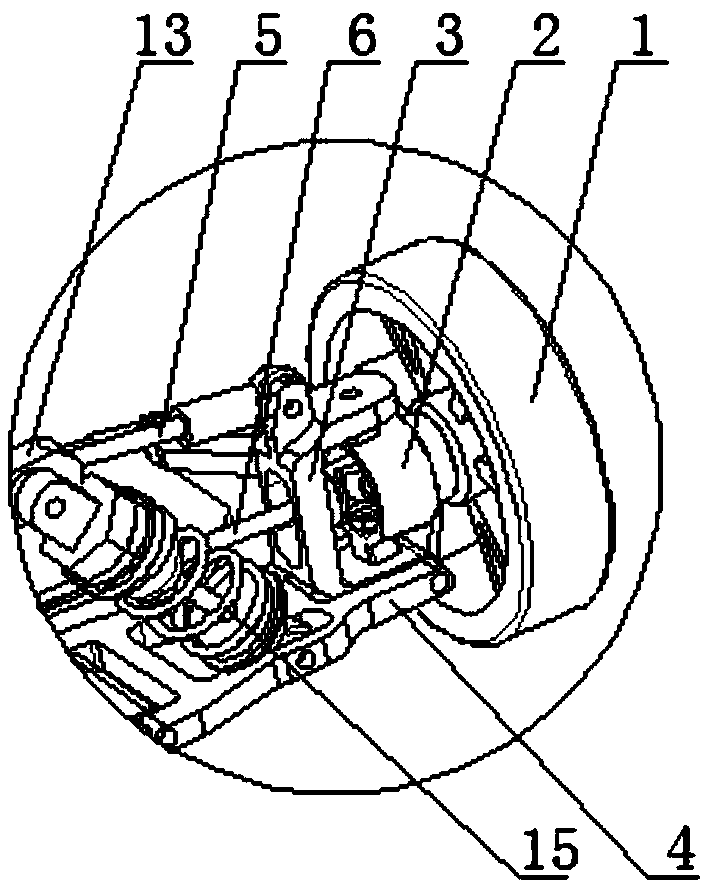

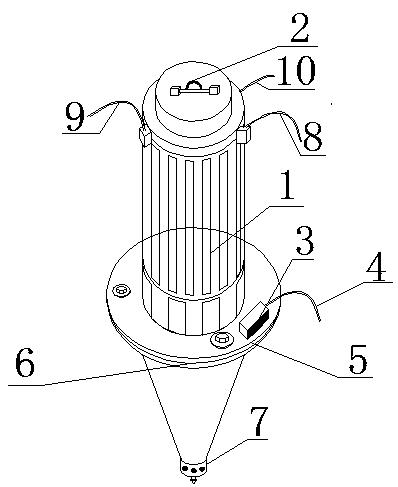

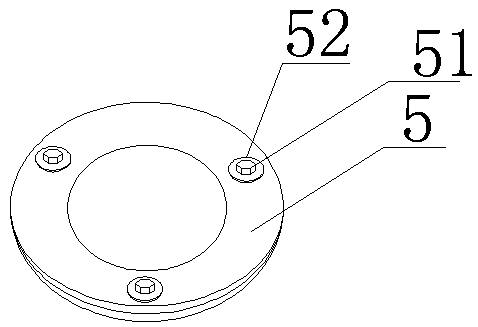

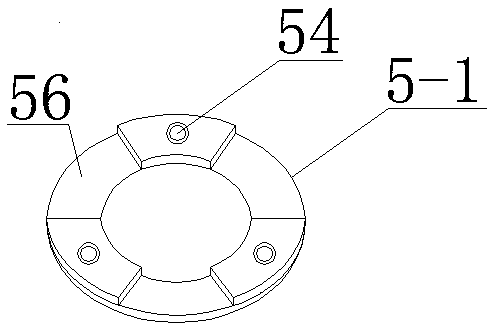

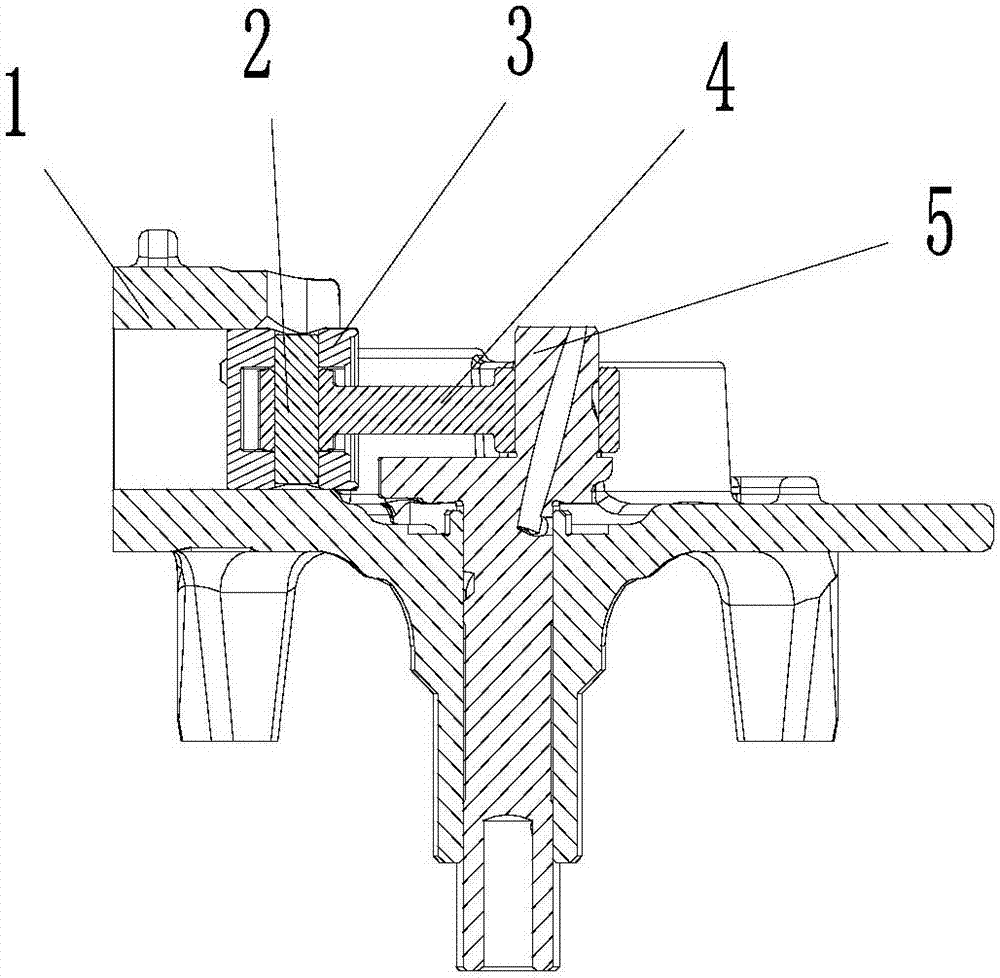

The invention provides a hot press device for high temperature adhesive curing. The hot press device comprises an end cover (1), bolts (2), a force rod (3), a base (4), a magnet (5), a high temperature rubber pad (7), an electric heating sheet (8), an electrode (9), a lead hole (10), a bearing (11), and a core shaft (12). The base (4) is of a cylindrical structure with an inverted U-shaped cross section; the upper bottom surface is provided with a through hole and the inner wall of the through hole is provided with a thread. The base (4) provides support, and the magnet (5), the high temperature rubber pad (7) and the electric heating sheet (8) are arranged in the base (4). The magnet (5) provides attracting force; the upper end of the magnet (5) is provided with an internal thread which is directly connected with a core shaft thread (12c) of the core shaft (12). The hot pressure device allows the temperature and the applied force to be adjusted, thereby meeting the conditions of multiple times of curing of a high temperature adhesive, and is simple in design, accurate in control and easy to operate.

Owner:TIANJIN AEROSPACE RELIA TECH +3

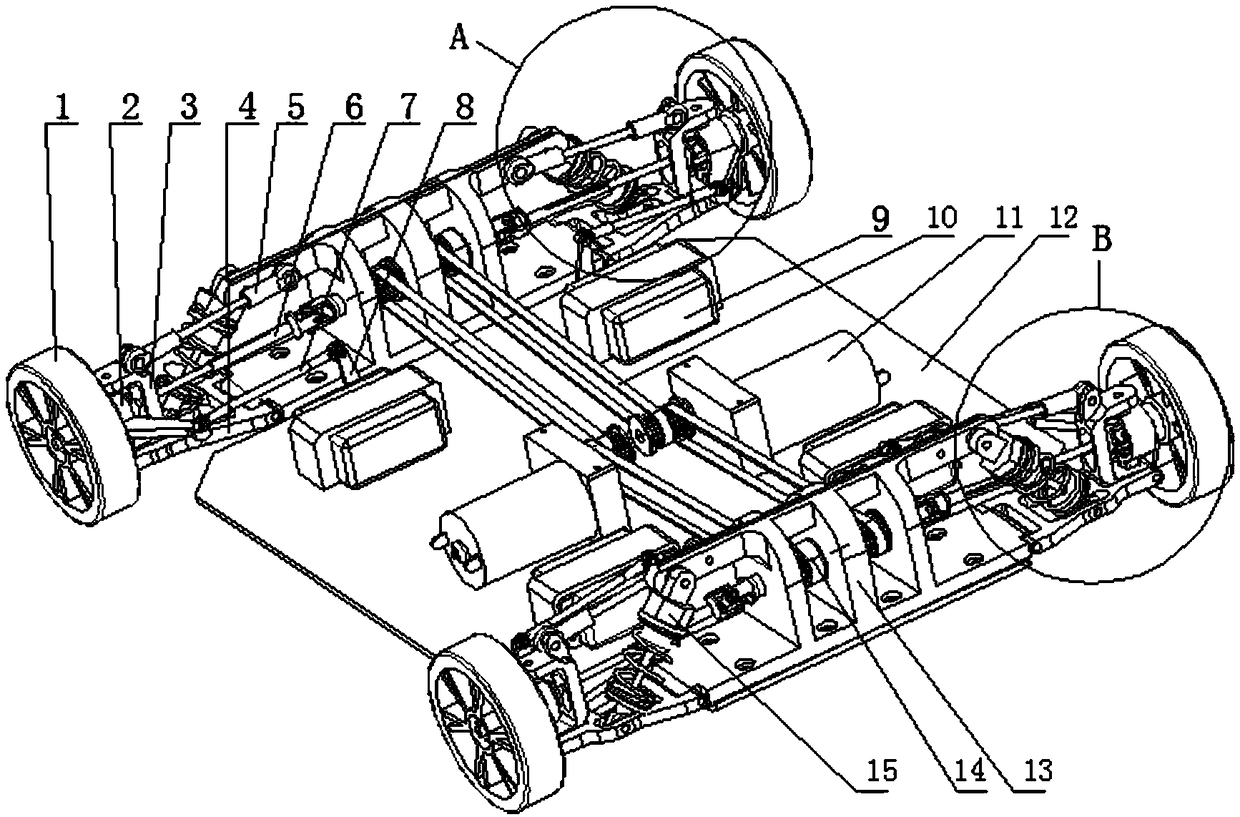

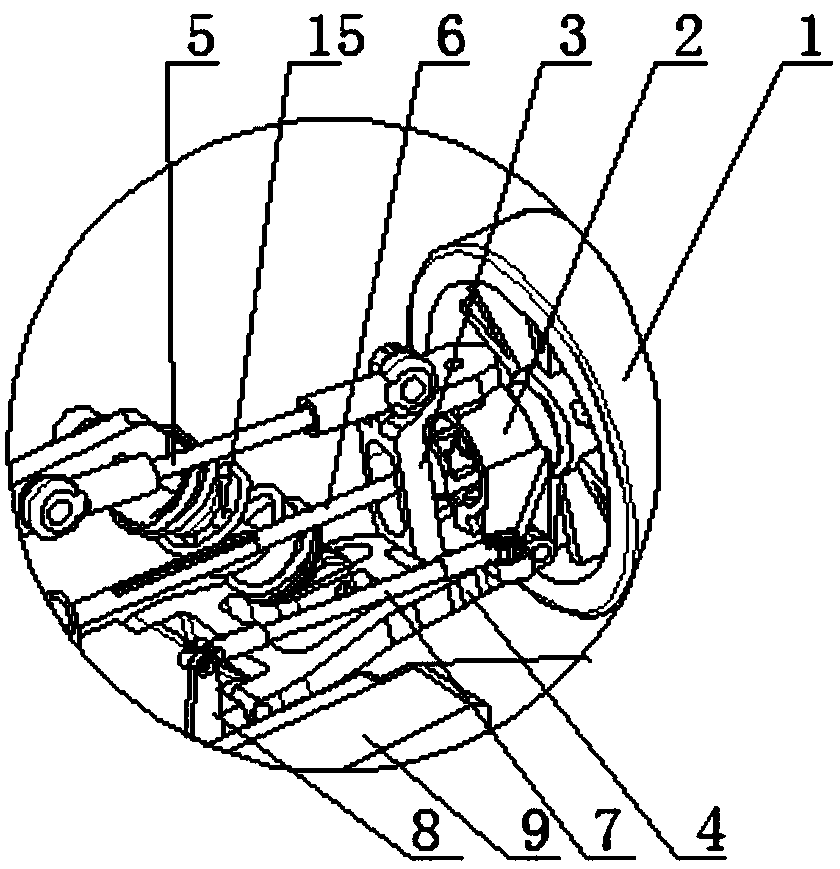

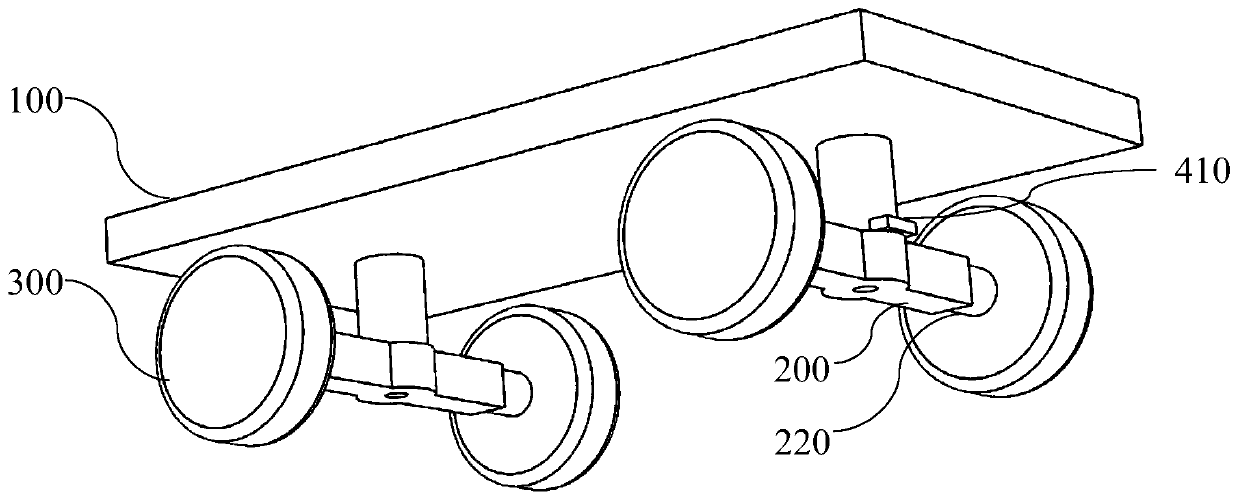

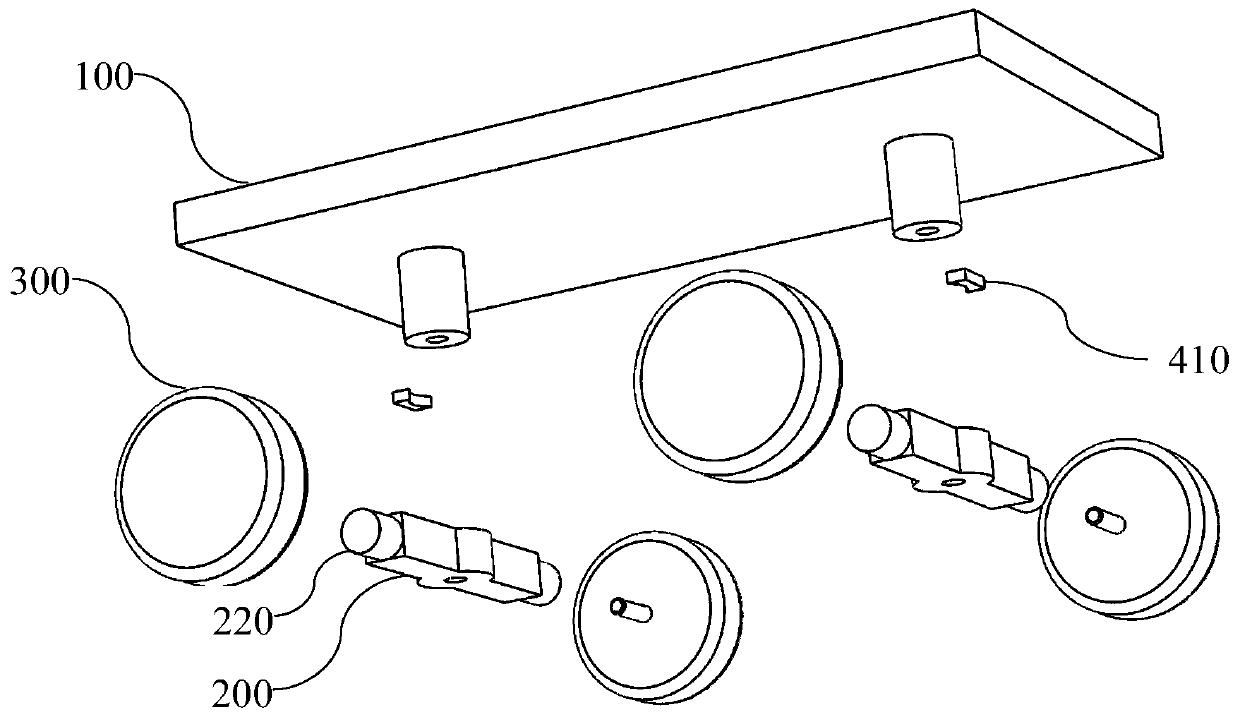

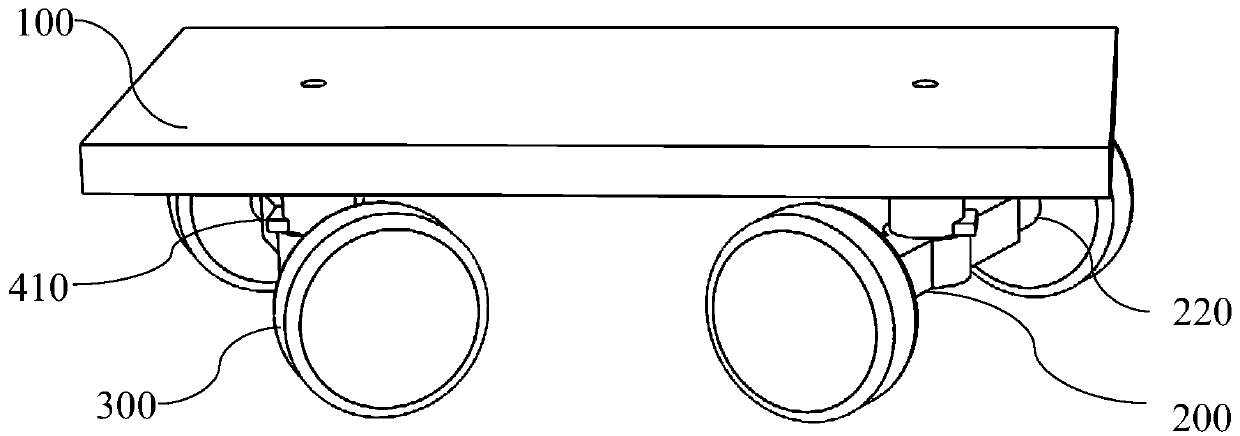

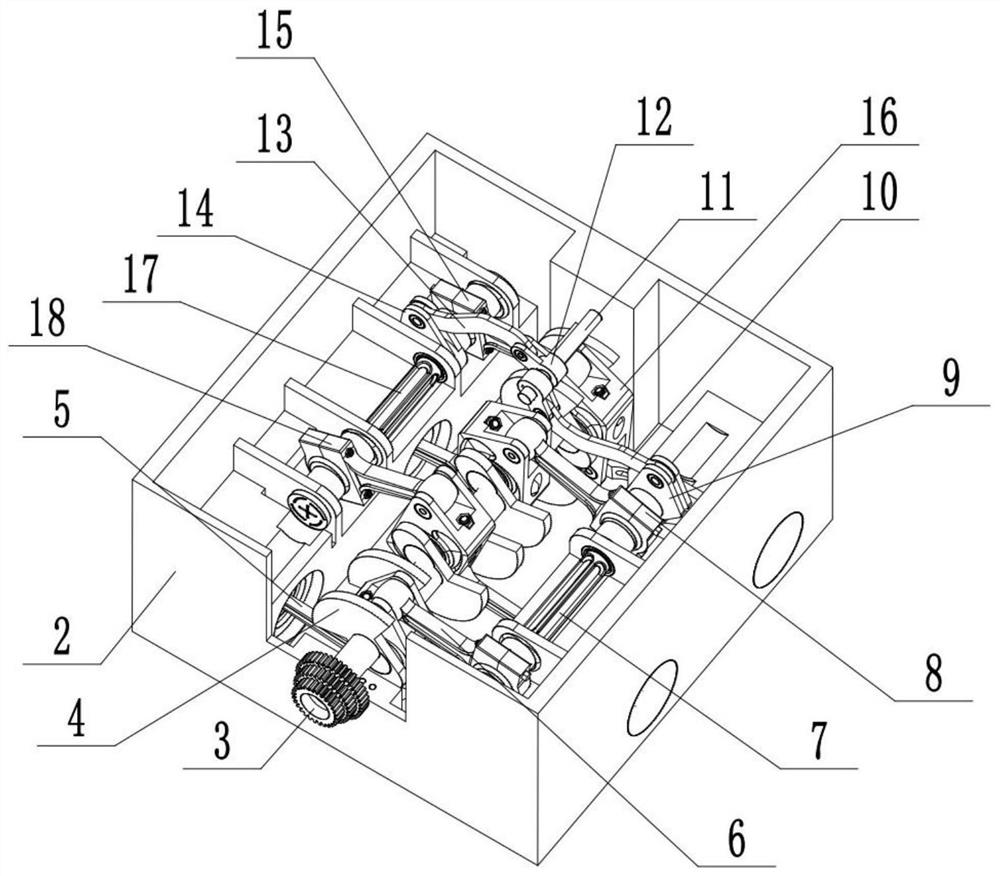

AGV four-wheel independent steering and differential combination control mechanism

PendingCN109398476AStrong limitationsWear fastElectrical steeringResilient suspensionsControl theory

The invention relates to an AGV four-wheel independent steering and differential combination control mechanism. A four-wheel independent steering and differential combination mode is adopted, throughmutual cooperation of two devices, the rotation angles of four wheels and the rotation speeds of the wheels on the two sides can be controlled at the same time, the 360-degree in-situ any-radius rotation turn-around action and slant motion are finished, an AGV can achieve in-situ 360-degree rotation, horizontal motion at each angle and steering at any radius, and compared with front wheel steeringand differential steering, the mechanism can finish the 360-degree in-situ any-radius rotation turn-around action and slant motion. Compared with an AGV using special tires (Mecanum wheels and universal wheels) for steering, the four-wheel independent steering and differential combination control mechanism can adopt common tires, the rotation directions of the four wheels and the differential quantity of the tires on the two sides are controlled so as to stably control the steering mode of a mobile platform, and abrasion of the tires can be reduced to the maximum limit. The AGV can be suitable for the complex ground under the condition that the flexible state is kept.

Owner:TIANJIN UNIV OF SCI & TECH

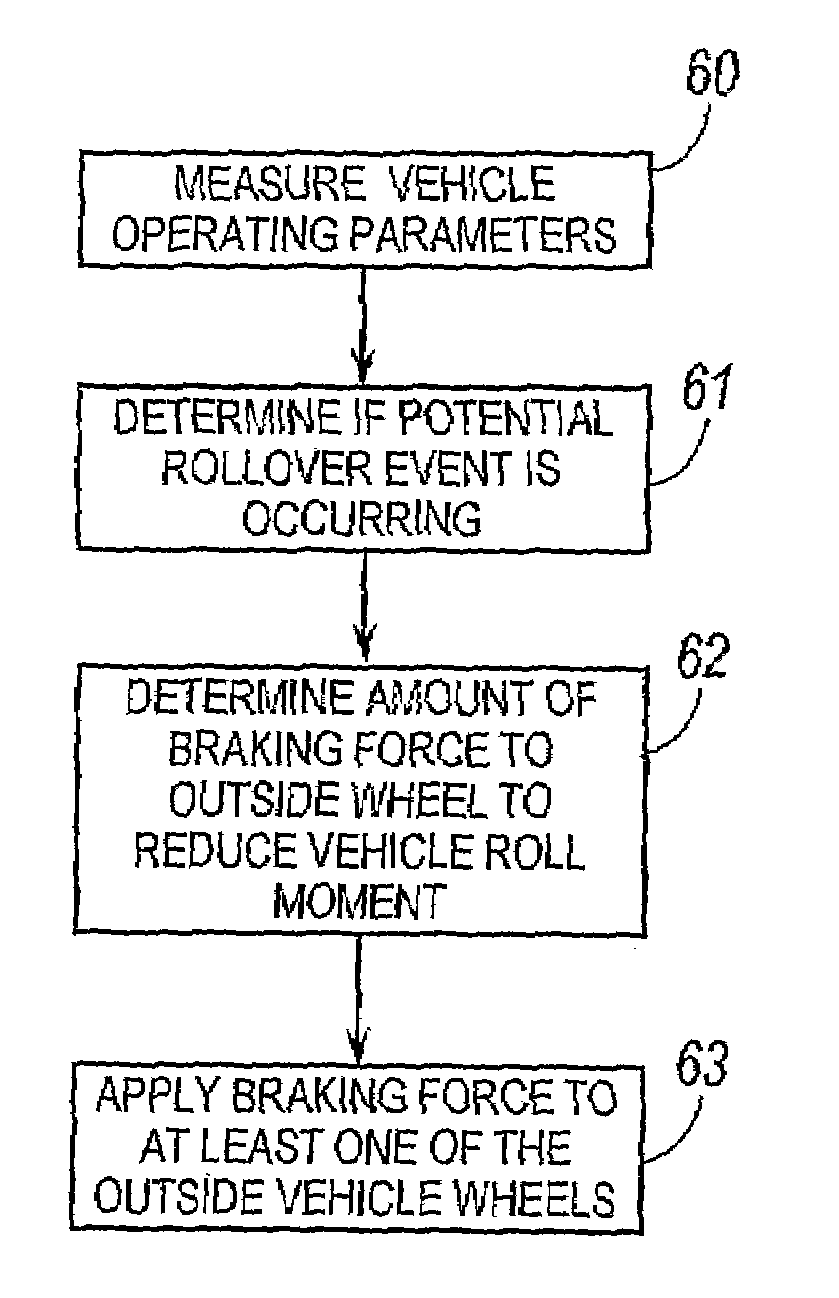

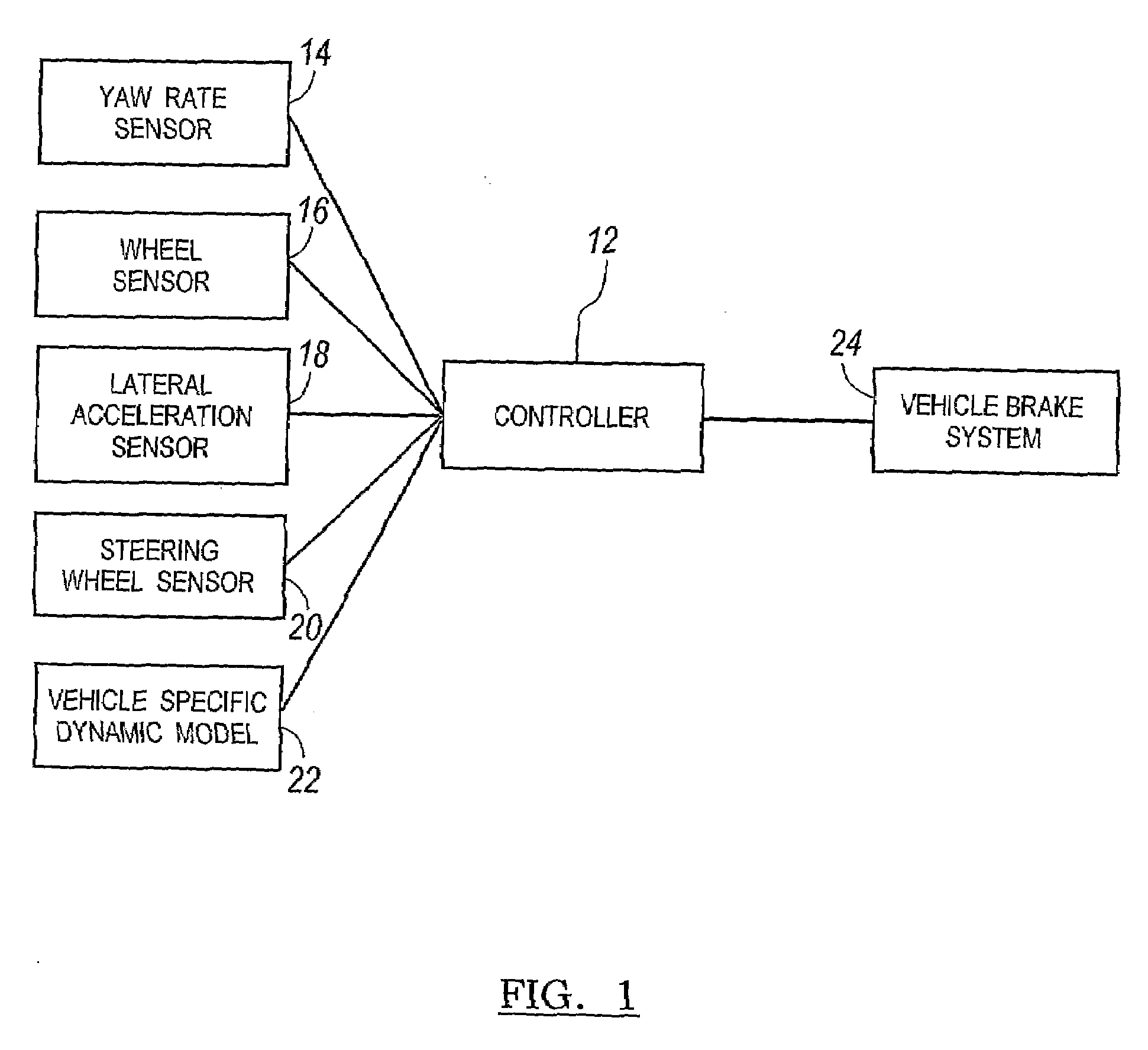

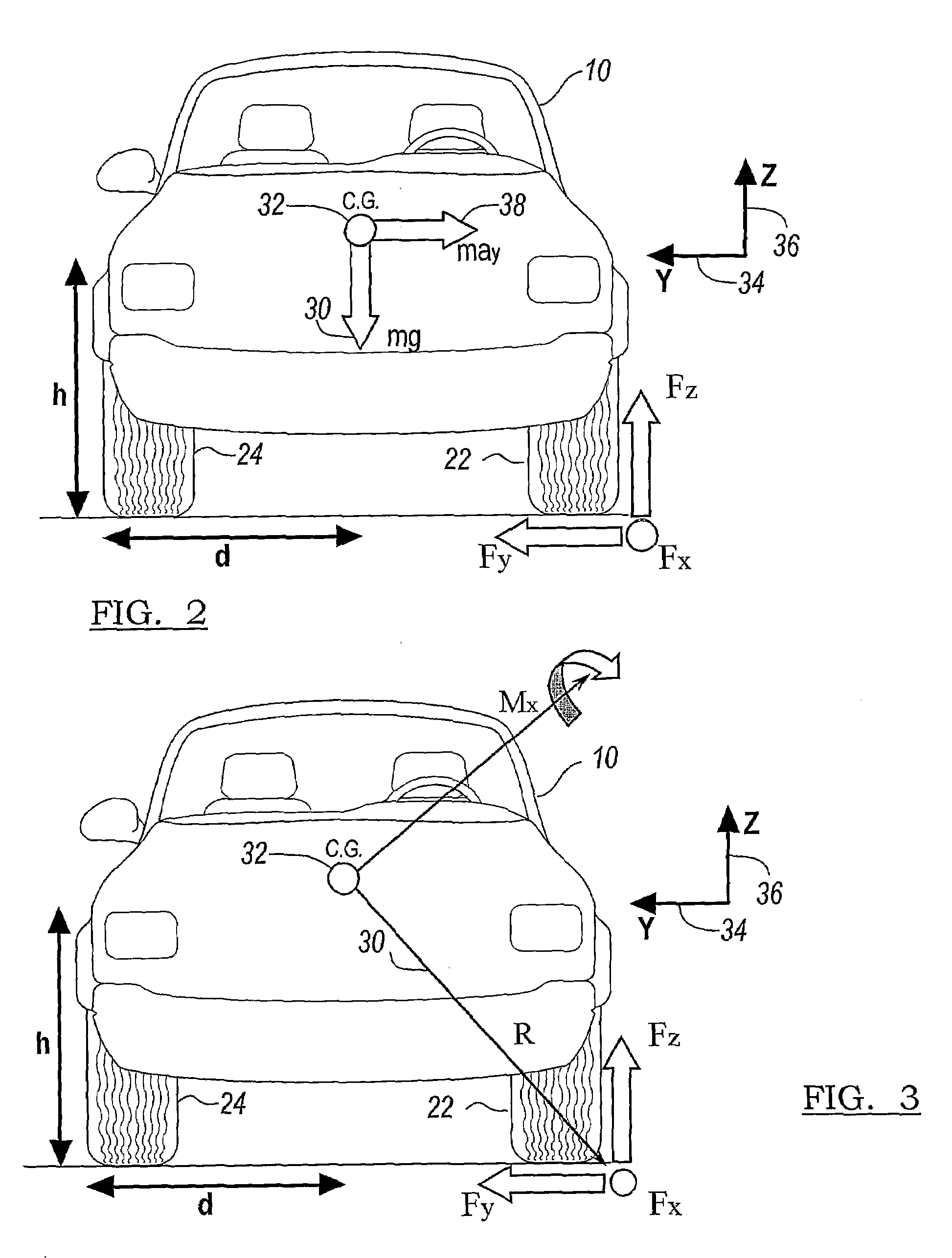

Vehicle Roll Mitigation Through Wheel Slip Controls

InactiveUS20080234912A1Reduce roll momentPeak lateral friction be reduceDigital data processing detailsAutomatic initiationsBrake torqueRoll moment

A method is provided for counteracting a roll moment in a vehicle rollover event. A potential occurrence of the rollover event is detected over an outside wheel. The potential rollover occurrence event is detected when a tire lateral force is greater than a lateral acceleration force. A braking torque is applied to at least one outside wheel (rear outside, front outside or both outside wheels) for producing a longitudinal wheel slip on the at least one outside wheel wherein the longitudinal wheel slip increases a longitudinal force acting on the at least one outside wheel, cooperatively producing a vehicle yaw for off setting an oversteering condition. The peak lateral friction is reduced between a tire coupled to the at least one outside wheel and an underlying road surface in order to reduce the peak lateral friction and the roll moment.

Owner:CHOI S BEN

Vehicle chassis, vehicle and control method of vehicle chassis

PendingCN110155171AReduce weightEasy loadingAxle unitsRolling resistance optimizationCarrying capacityControl system

The invention provides a vehicle chassis and a control method thereof. The vehicle chassis comprises a vehicle body, a control system, steering axles and at least three power wheels, the control system is in signal connection with all the power wheels and is used for monitoring and controlling the rotating speed of all the power wheels, each steering axle comprises a steering axle body and two hubbearings which are separately positioned at the two ends of the steering axle body, the steering axles are rotationally connected to the vehicle body and can freely rotate at any angle relative to the vehicle body in the horizontal direction, the power wheels are connected to the vehicle body or the hub bearings, at least two power wheels are connected with the hub bearings of the steering axlesin a one-to-one correspondence mode, and the power wheels connected to the hub bearings are used for providing the steering force for the rotation of the steering axles relative to the vehicle body. According to the vehicle chassis, the power wheels are used for providing the steering force of the vehicle chassis, so that the occupied vehicle inner space and the weight are greatly reduced, the dead weight of the vehicle body caused by the vehicle chassis in the straight running process is avoided, and the carrying capacity and the safety of the vehicle are improved.

Owner:KEENON ROBOTICS CO LTD

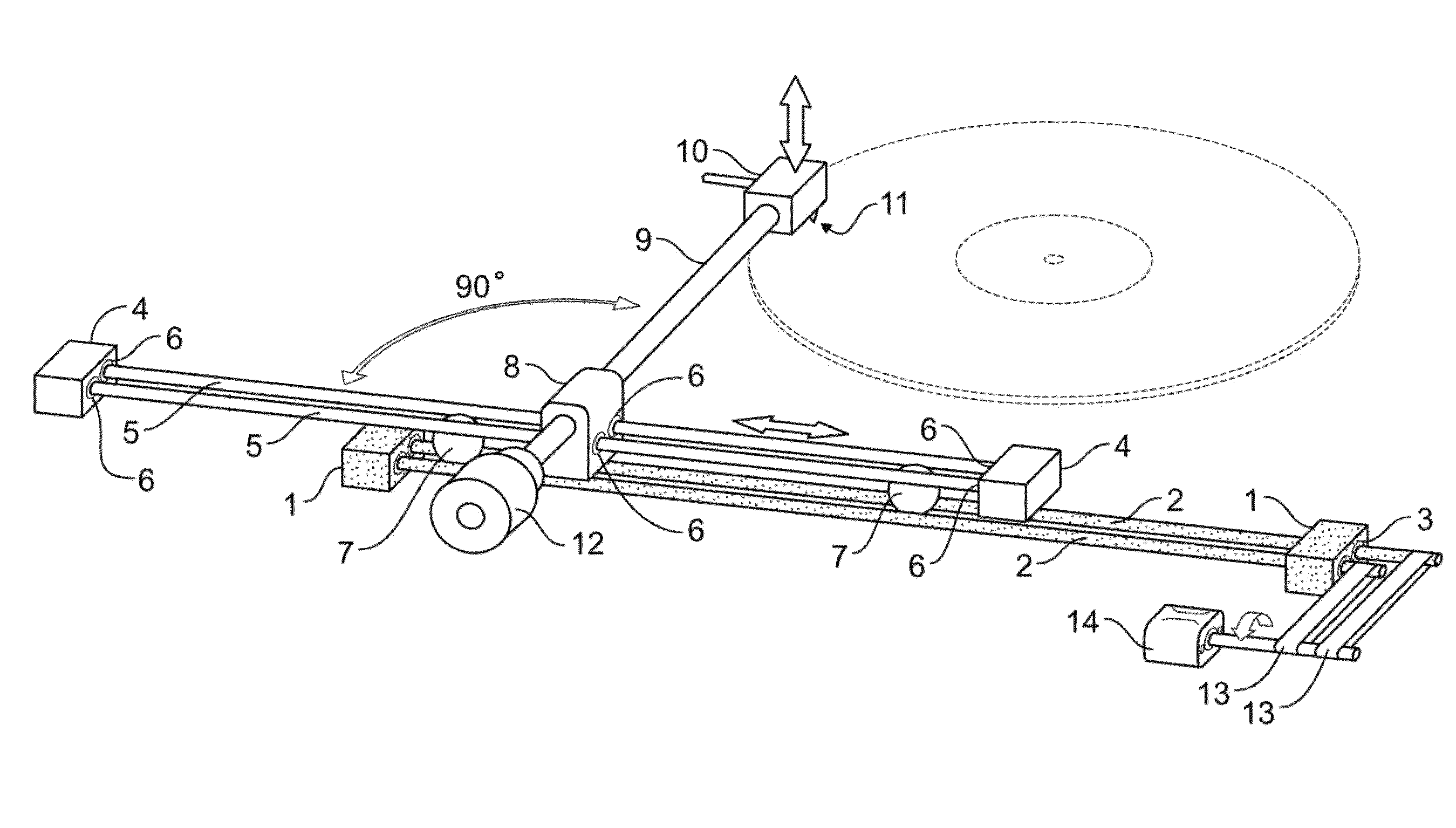

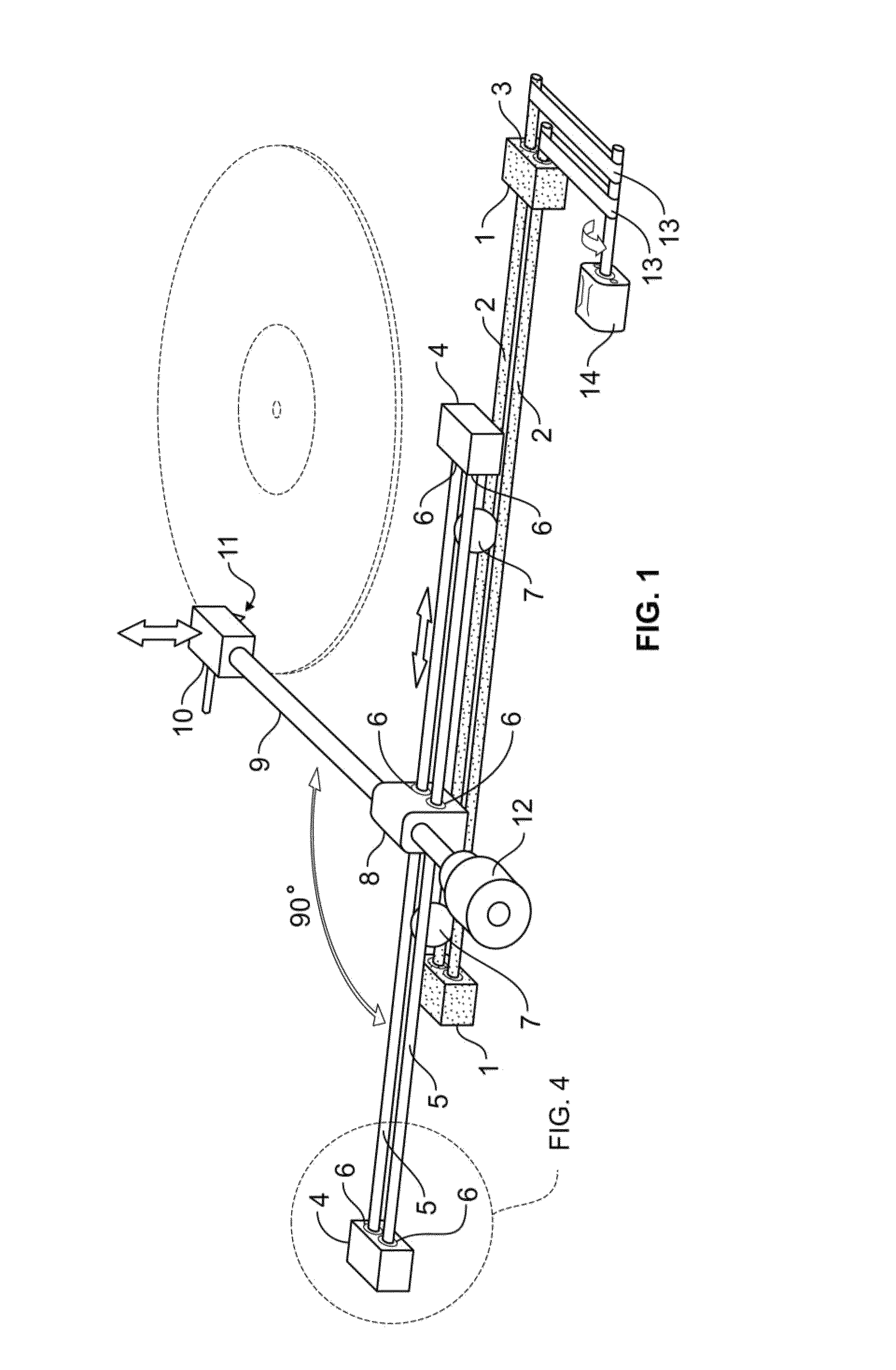

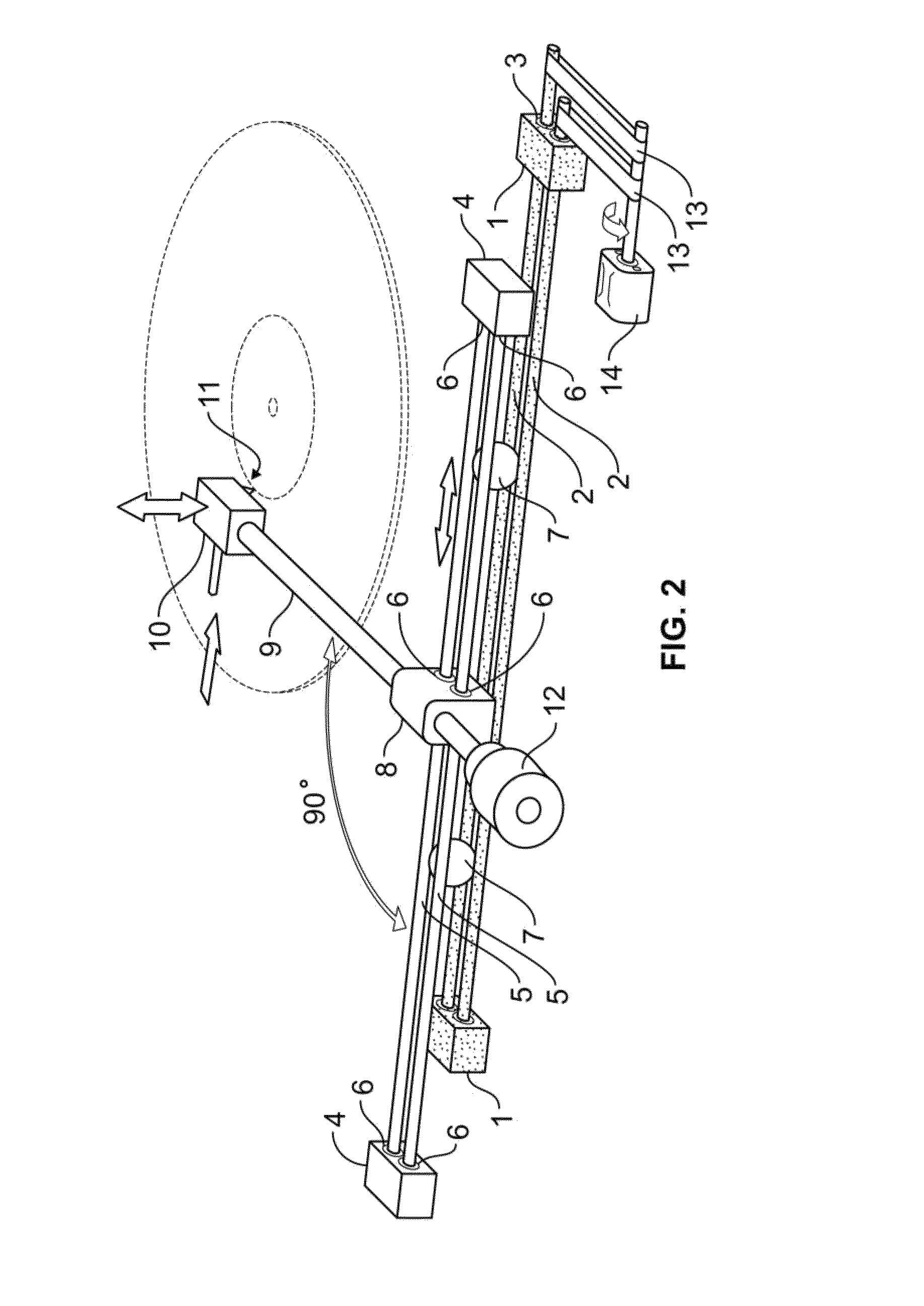

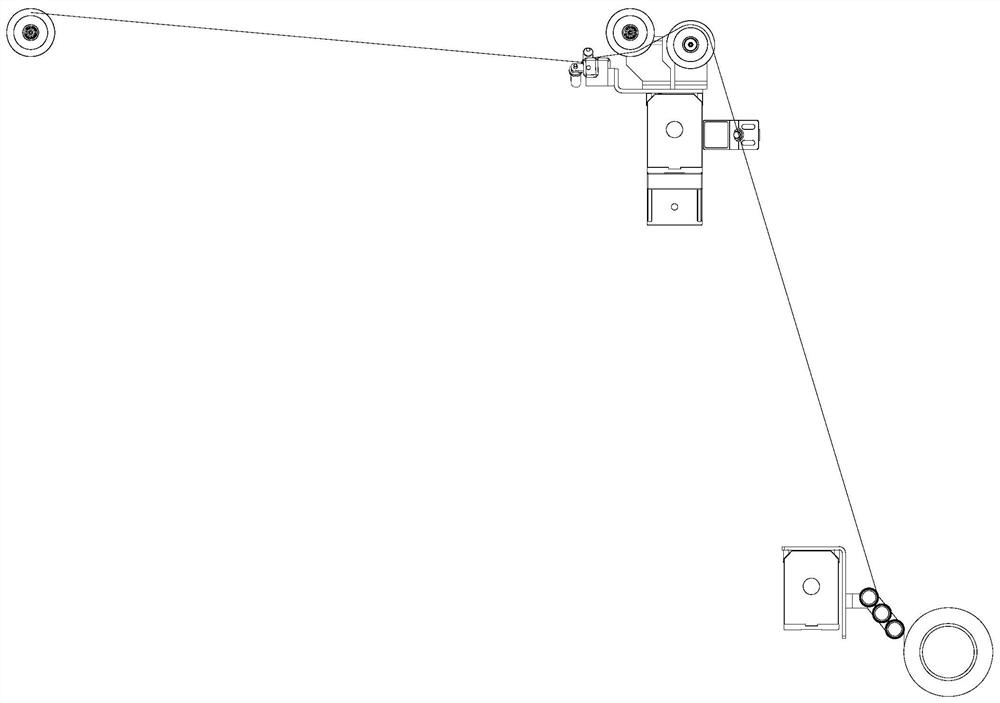

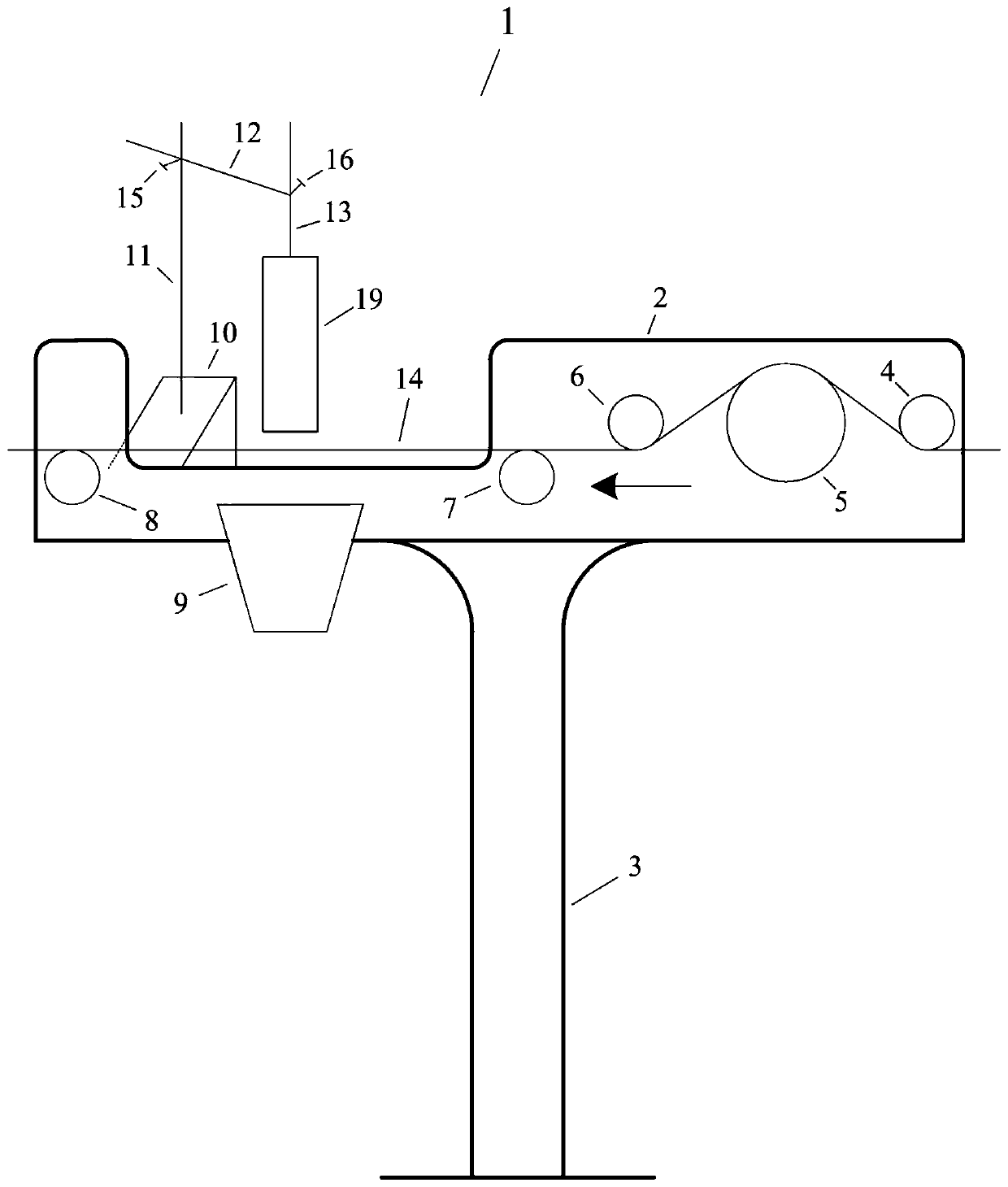

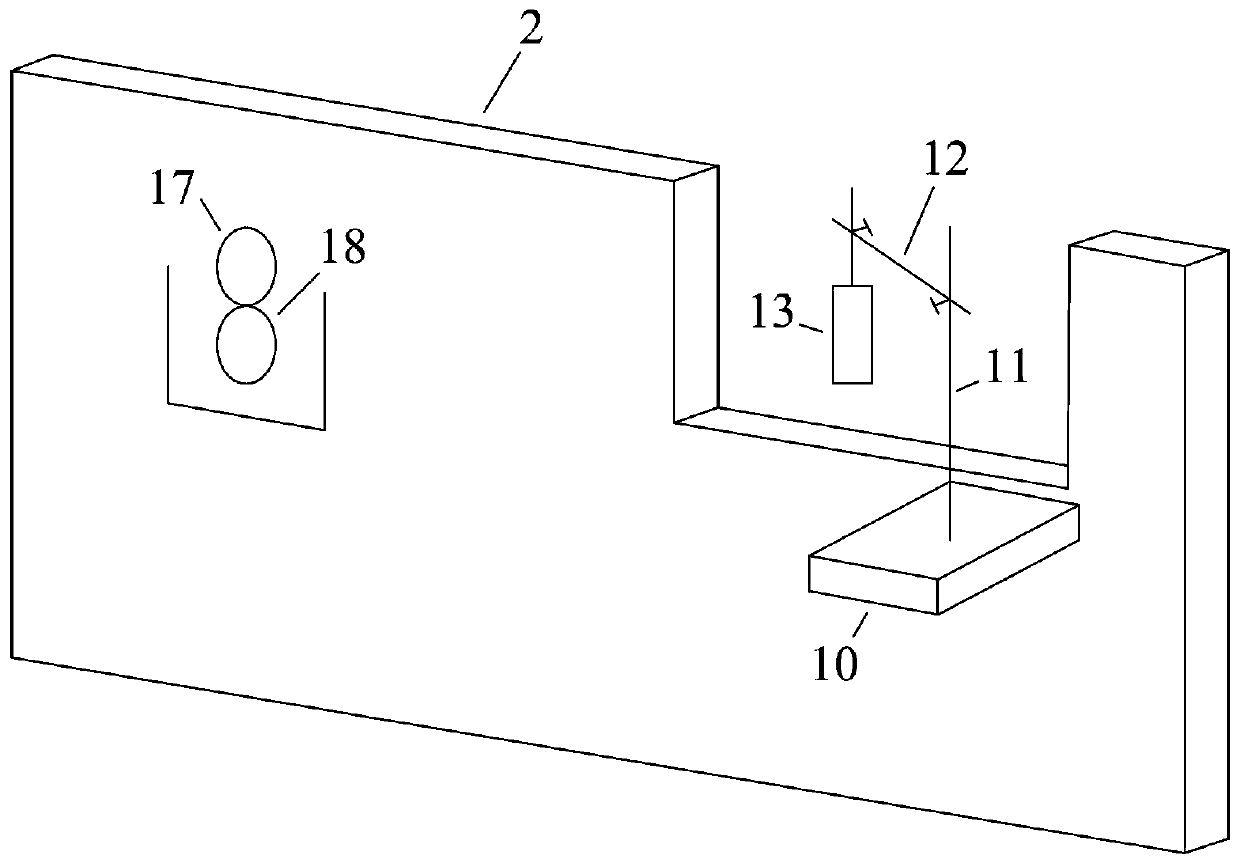

Low friction linear tracking tone arm

InactiveUS9019806B1Reduce weightReduce lateral frictionTrack finding/aligningRecord information storageRolling resistanceLow distortion

This invention is provides a means of playing LP records with minimal distortion. Low distortion is achieved by eliminating tracking error normally associated with pickup cartridges mounted to pivoting tone arms. This invention discloses a tone arm that constrains the motion of the stylus to straight radial path, mimicking the cutting path of the record lathe, supported on parallel rails by free rolling spherical bearings. Unlike many previous linear tracking tone arms, this invention does not rely on air pressure or servo motor mechanisms. The use of free rolling bearings or axles between parallel tracks fashioned from rails, rods or tubes, eliminates all sources of lateral friction other than pure static and rolling friction of the balls on the rails, rods or tubes. In the preferred embodiment, the fixed rods or tubes are driven synchronously, thereby eliminating static friction of the supporting rolling balls. Friction is further reduced using magnetic or buoyant support of the tone arm to reduce bearing load to that amount minimally sufficient to maintain full contact between the rolling balls and the upper and lower rods.

Owner:BOWDEN SR THOMAS LLOYD

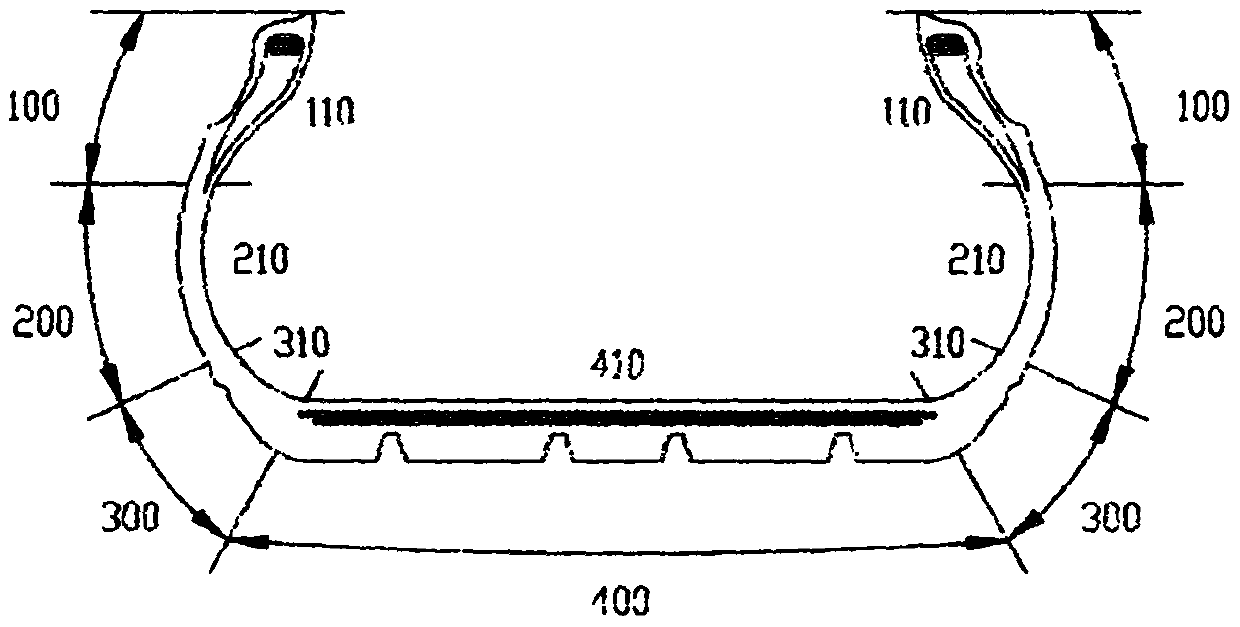

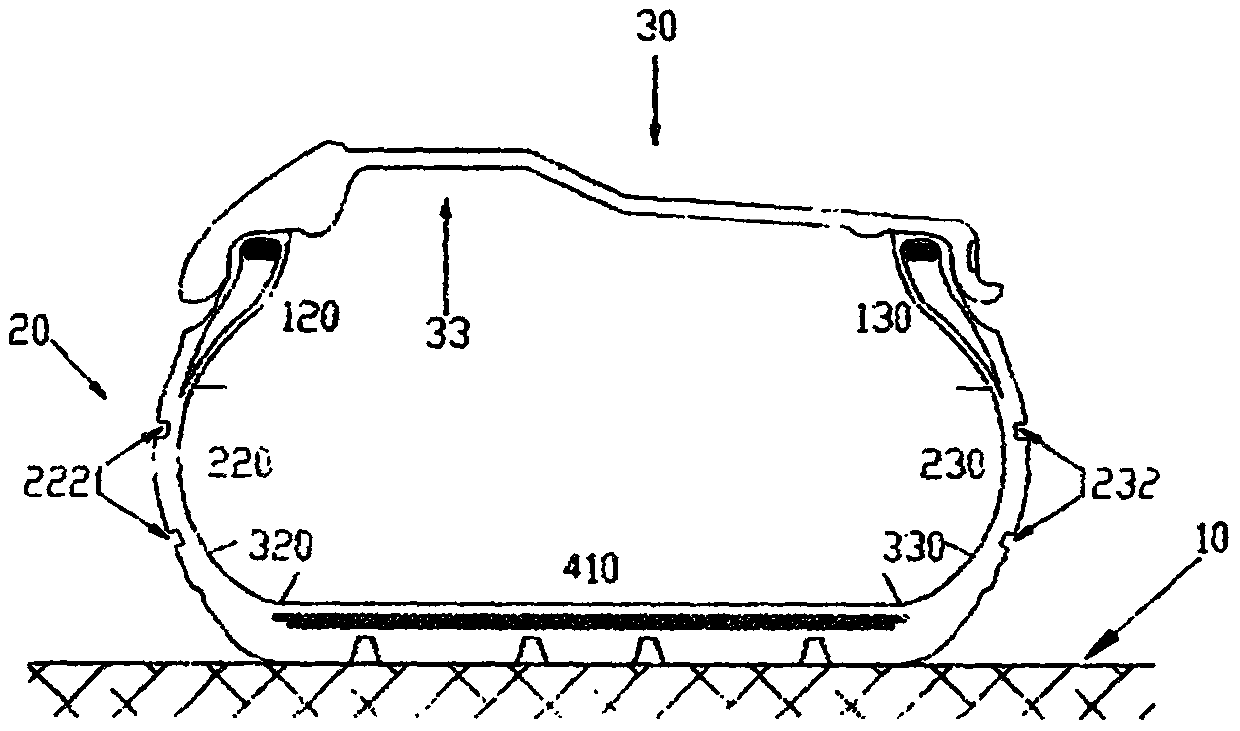

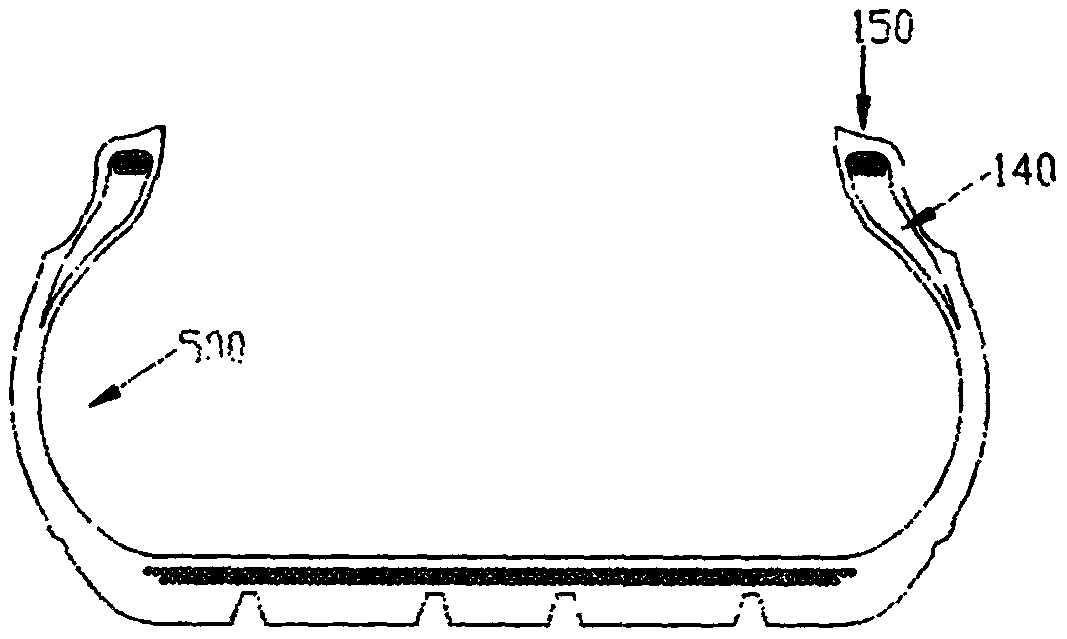

Novel tubeless pneumatic tire without sidewall supporting

PendingCN109733129AGuaranteed comfortImprove handlingWithout separate inflatable insertsCoatingsRolling resistanceWear resistant

The invention discloses a novel tubeless pneumatic tire without sidewall supporting. Part of the inner surfaces of beads of the tire, and / or the inner surfaces of sidewalls, and / or the inner surfacesof shoulders are provided with wear-resistant layers and / or wear-resistant lubricating layers. After the zero-pressure tire is flattened, two inner surfaces of the inner layer of the tire are in contact with each other; the wear-resistant layers are arranged at the contact position so as to improve the wear resistance and increase the driving mileage and driving speed of the tire; the wear-resistant lubricating layers are arranged at the contact position so as to reduce the friction coefficient of a contact surface, reduce the friction and reduce the risk of detachment of the tire; the reduction of the friction can improve the wear resistance and increase the driving mileage of the tire; the reduction of the friction is capable of reducing the rolling resistance of the tire, reducing the situation of unbalanced stress on wheels on two sides, and improving the handling of a vehicle; and in the contact position, when a tread slides towards one of the shoulders, two steeply-sloped side surfaces of a protrusion structure on the side adjacent to the corresponding shoulder are in contact with each other so as to prevent the tread from sliding towards the corresponding shoulder and improve the handling of the vehicle.

Owner:卫向坡

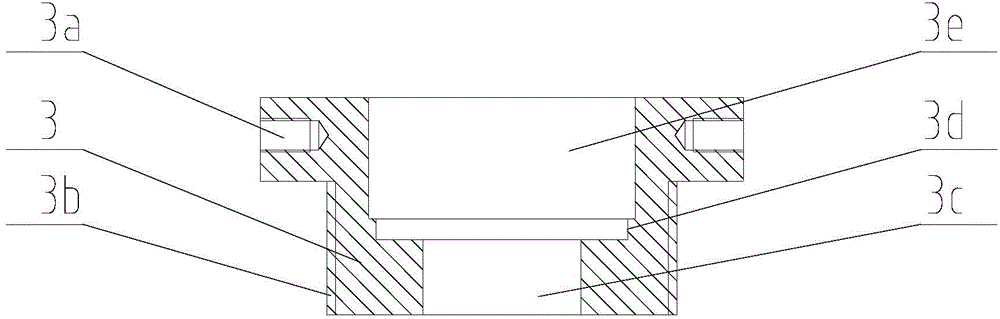

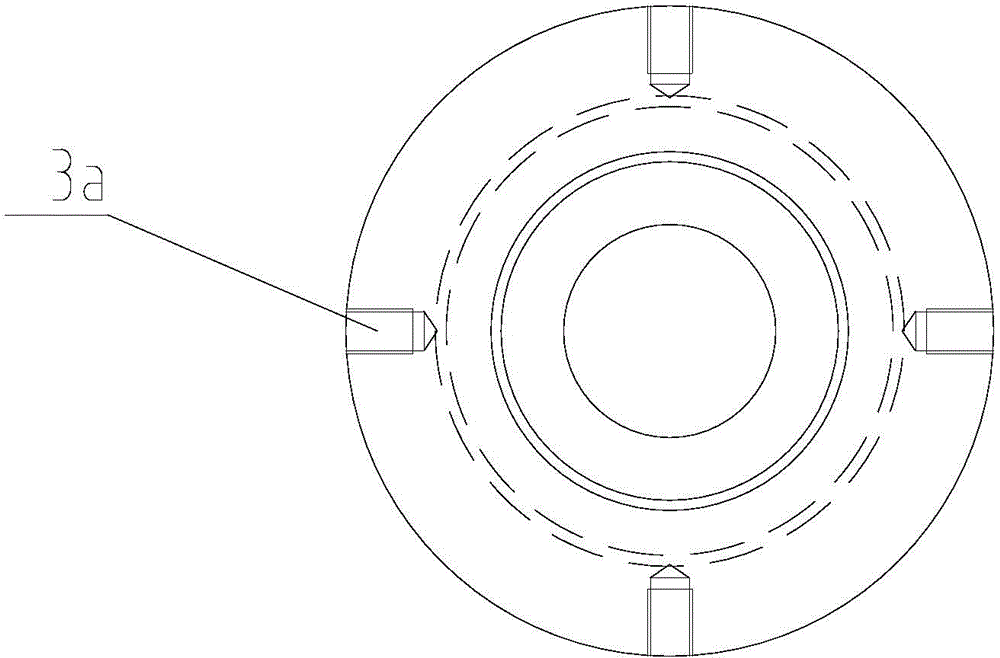

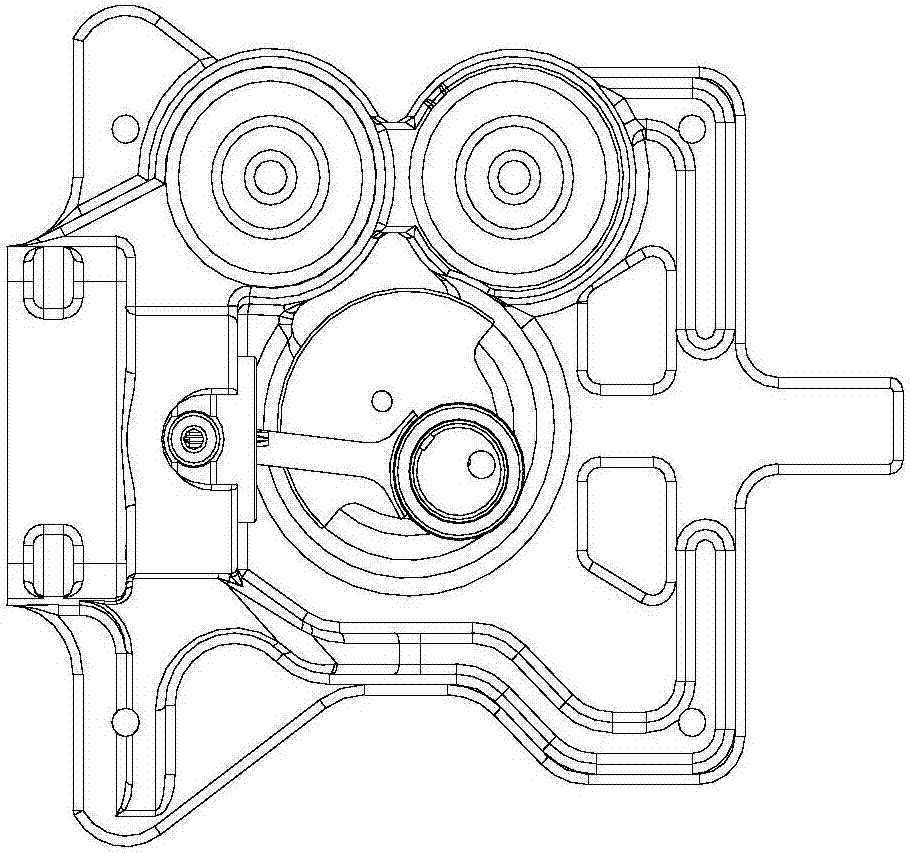

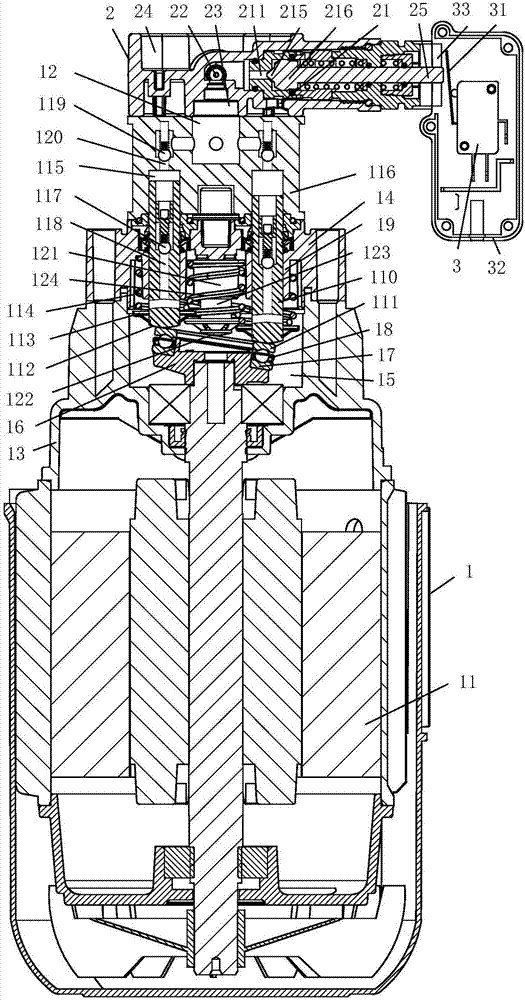

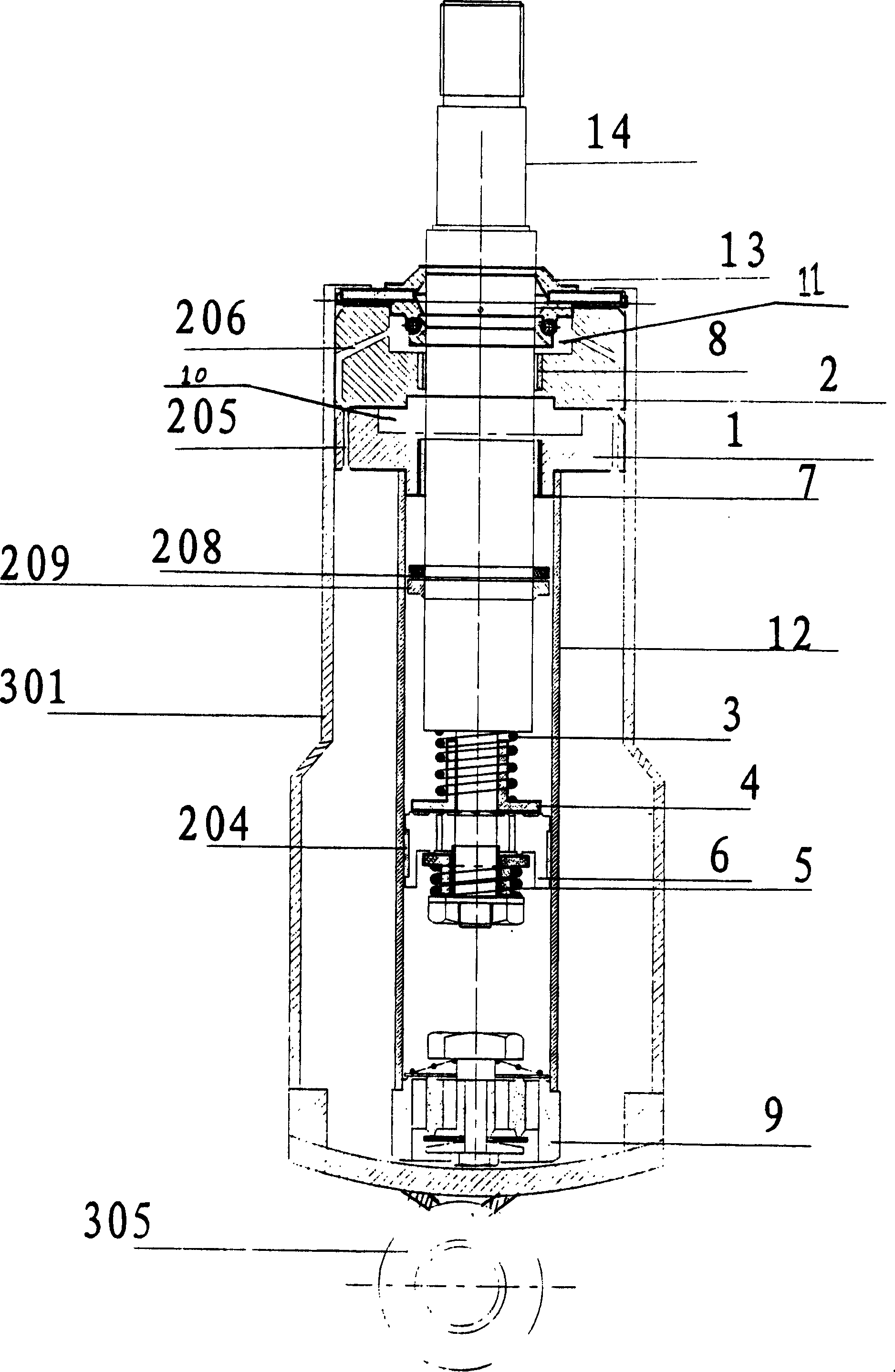

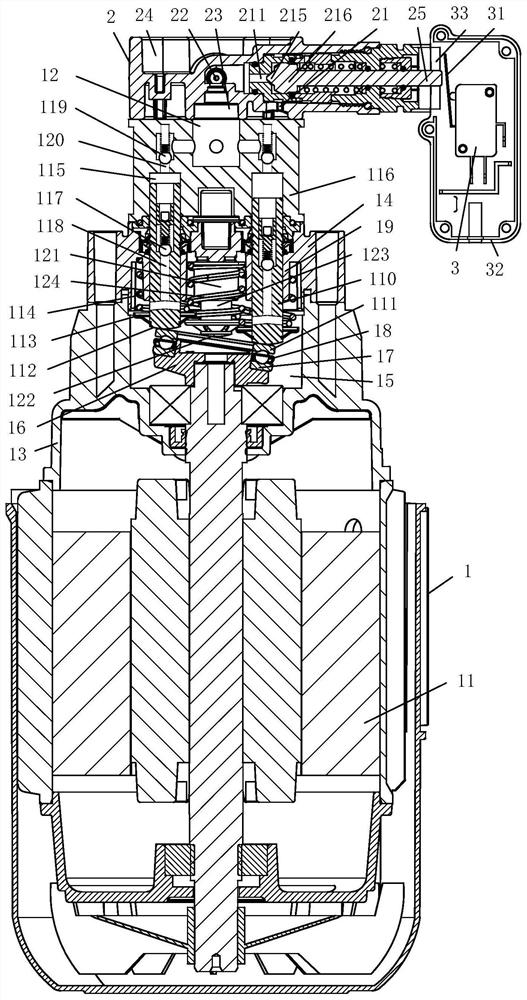

High-speed-rotation atomizer with vibration protection function

PendingCN109603503AReduce lateral frictionReduce shear forceDispersed particle separationEngineeringFlange

The invention discloses a high-speed-rotation atomizer with the vibration protection function. The high-speed-rotation atomizer comprises an atomizer body, a supporting flange and a controller, wherein a vibration measurement device is installed at the top of the supporting flange; the supporting flange comprises an upper supporting flange body and a lower supporting flange, a damping gasket is installed between the upper supporting flange body and the lower supporting flange body, an atomization wheel is installed at the bottom of the atomizer body through a retracting nut, and multiple windage resistance baffles are installed at the bottom of the atomization wheel through a rotating mechanism in the circumferential direction; the rotating mechanism comprises baffle bases, baffle supportsand stretchable rods, the baffle bases are fixed at the bottom of the atomization wheel through small base bolts, the bottom ends of the baffle supports are fixed on the side walls of the windage resistance baffles, and the top ends of the baffle supports are rotationally installed on the baffle bases through rotating shaft pin bolts. According to the high-speed-rotation atomizer with the vibration protection function, the braking time of the atomization wheel can be greatly shortened, and more-serious damage of acute vibration to the atomizer is reduced.

Owner:JIANGSU CTIEC ENVIRONMENTAL PROTECTION RES INST +1

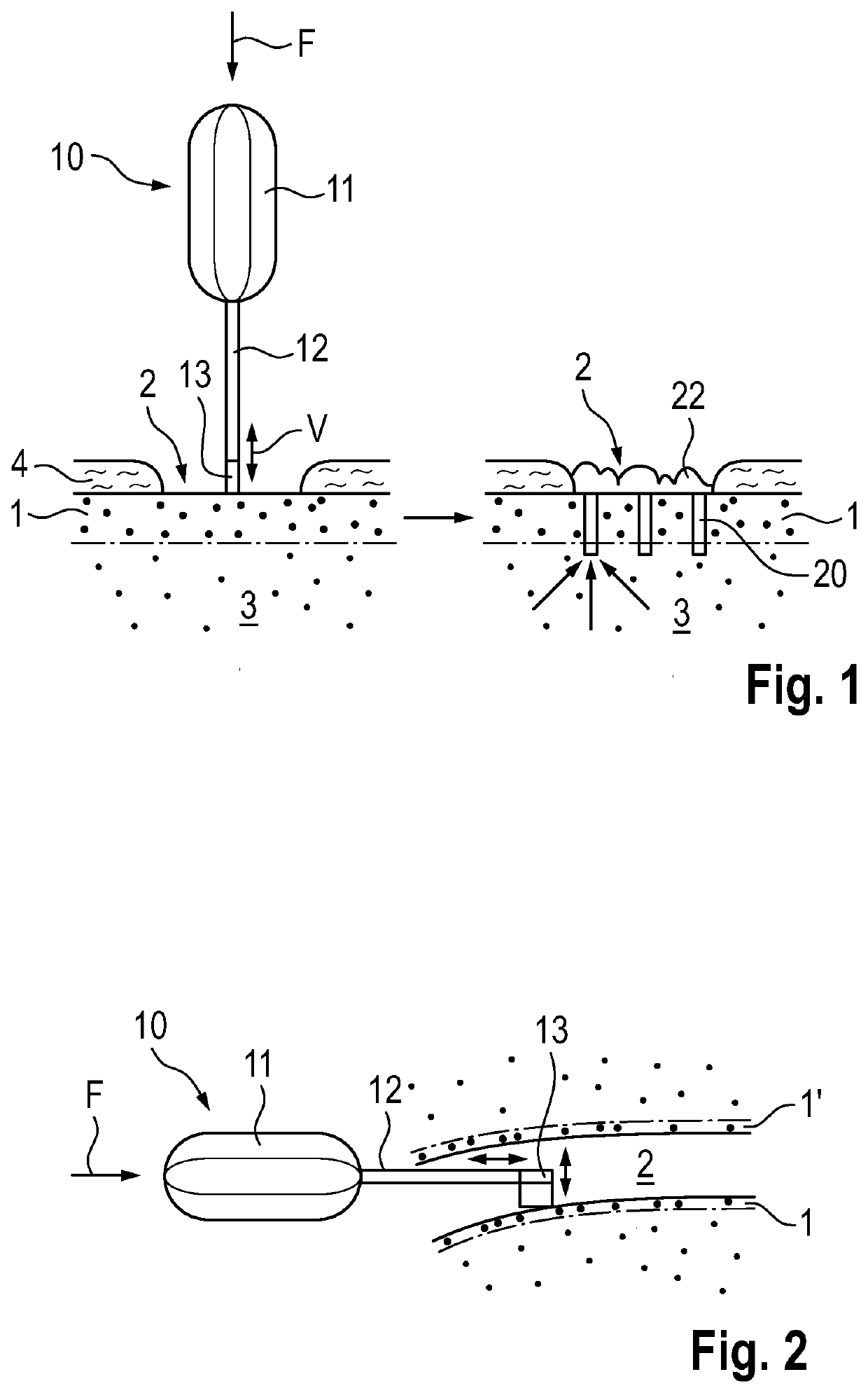

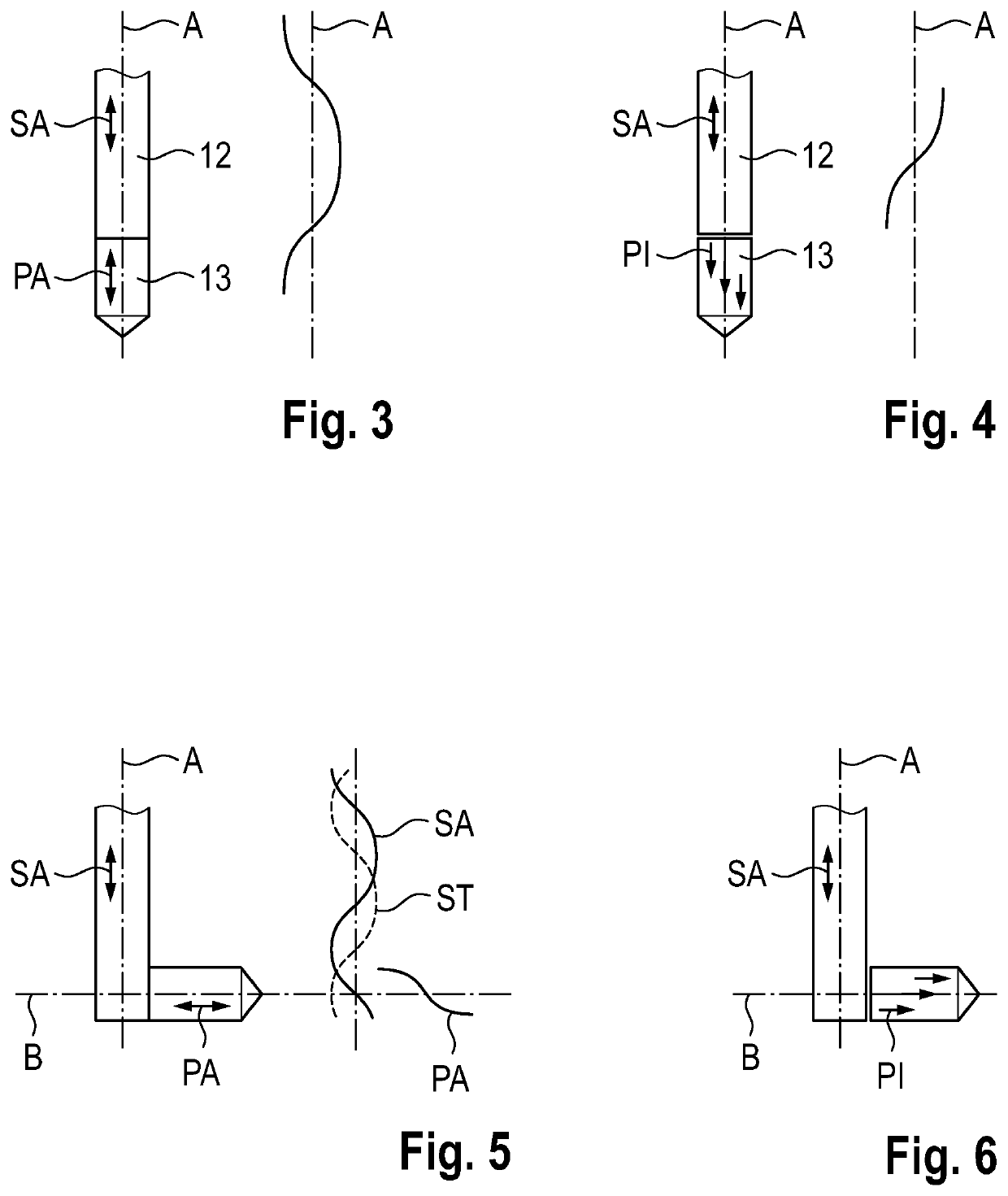

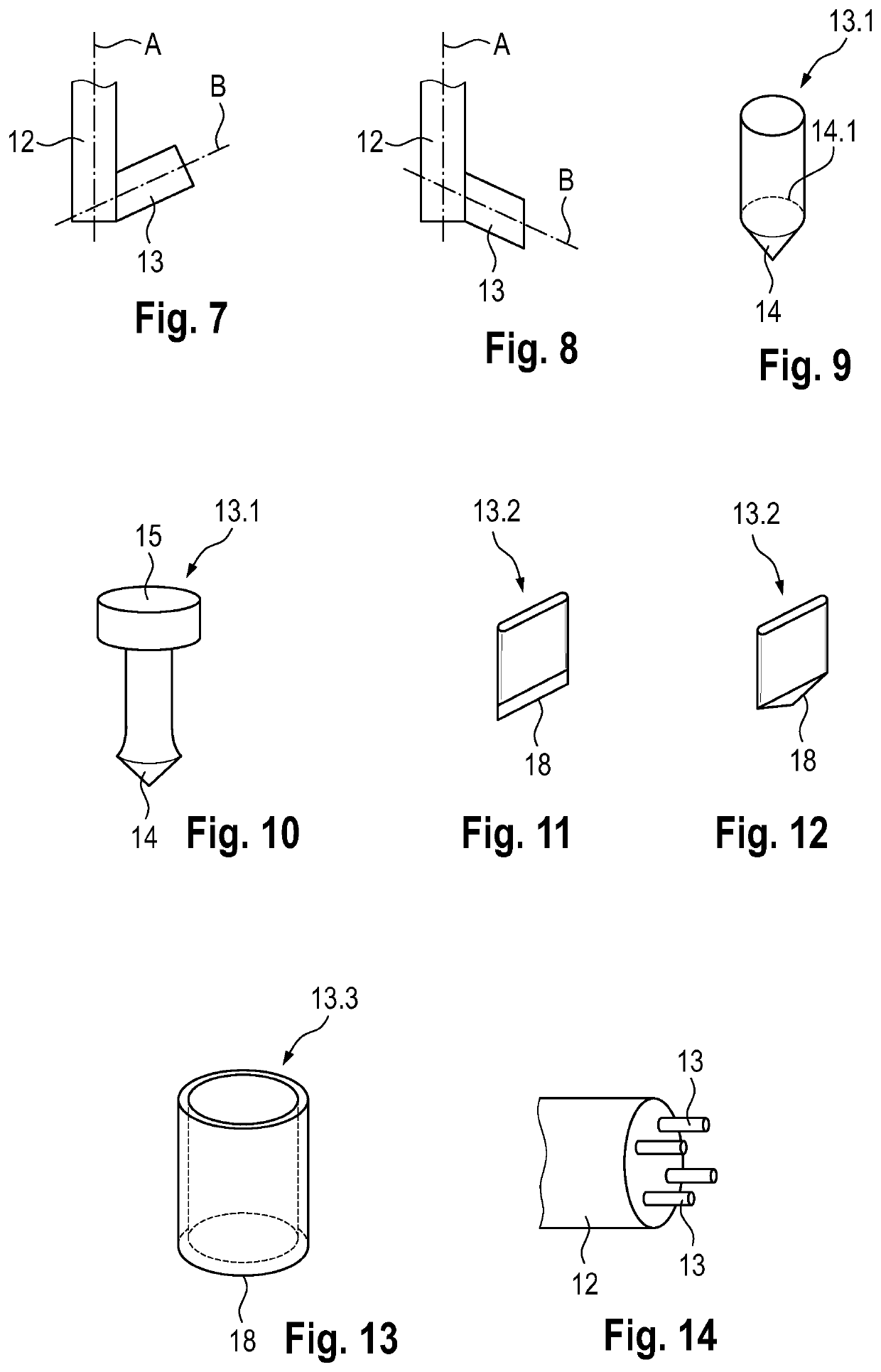

Device and method for perforating a dense bone layer

A device and method for perforating a dense bone layer. The device includes a vibration generator for generating mechanical vibration, in particular ultrasonic vibration, and an instrument with an elongated shaft and a distal end piece including a perforator. The distal end piece is arranged at a distal end of the shaft and the proximal end of the shaft is connected or connectable to the vibration generator. The perforator has the form of a solid or a hollow cylinder. The vibration generator, the shaft and the distal end piece are adapted to each other for the shaft to transmit, when connected to the activated vibration generator, mechanical vibration from the vibration generator to the distal end piece and for vibrating the perforator in a direction parallel to its cylinder axis.

Owner:BOSONIC AG

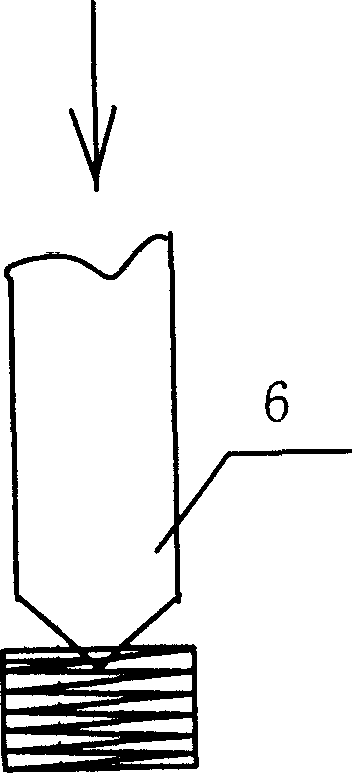

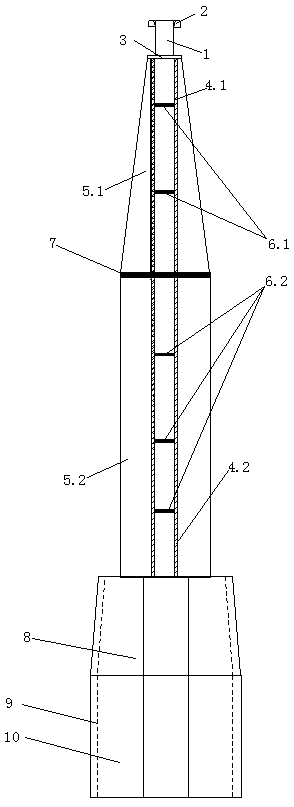

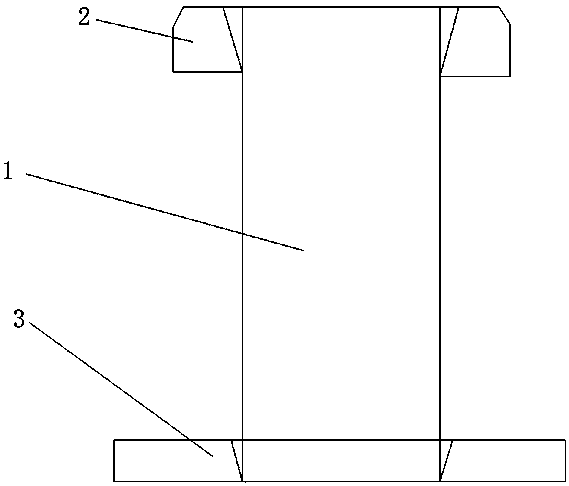

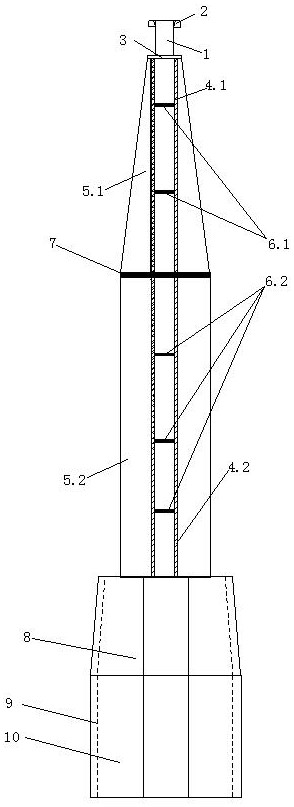

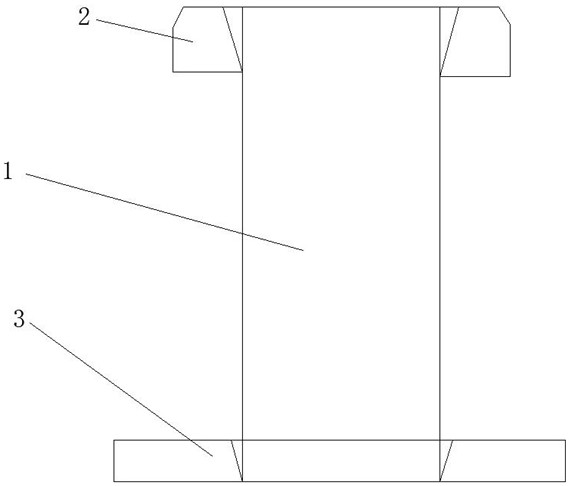

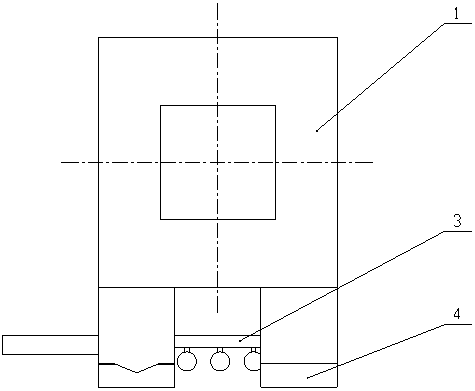

Special rammer for dynamic compaction replacement treatment of flow plastic-soft plastic clay

ActiveCN110904945AReduce lateral frictionReduce lossesSoil preservationDynamic compactionStructural engineering

The invention belongs to the technical field of rammers for foundation treatment in constructional engineering, and particularly relates to a special rammer for dynamic compaction replacement treatment of flow plastic-soft plastic clay. The special rammer comprises a hook device part, an anti-burying hammer lengthening body part and a rammer body part, wherein the height of the anti-burying hammerlengthening body part is 2.8 m or above; the rammer body part comprises an upper trapezoidal circular truncated cone structure and a lower cylindrical structure; and a plurality of semicircular ventholes are uniformly distributed in the outer wall of the rammer body part. According to the special rammer, the problem of hammer burying in the dynamic compaction replacement of the flow plastic-softplastic clay foundation is solved, the rammer can be used for solving the problem that dynamic compaction deep replacement cannot be carried out due to hammer burying in the dynamic compaction replacement treatment of the flow plastic-soft plastic clay, the application range of the dynamic compaction which is an environment-friendly and low-cost treatment technology can be further expanded, and the application market and the development prospect are wide.

Owner:山西机械化建设集团有限公司

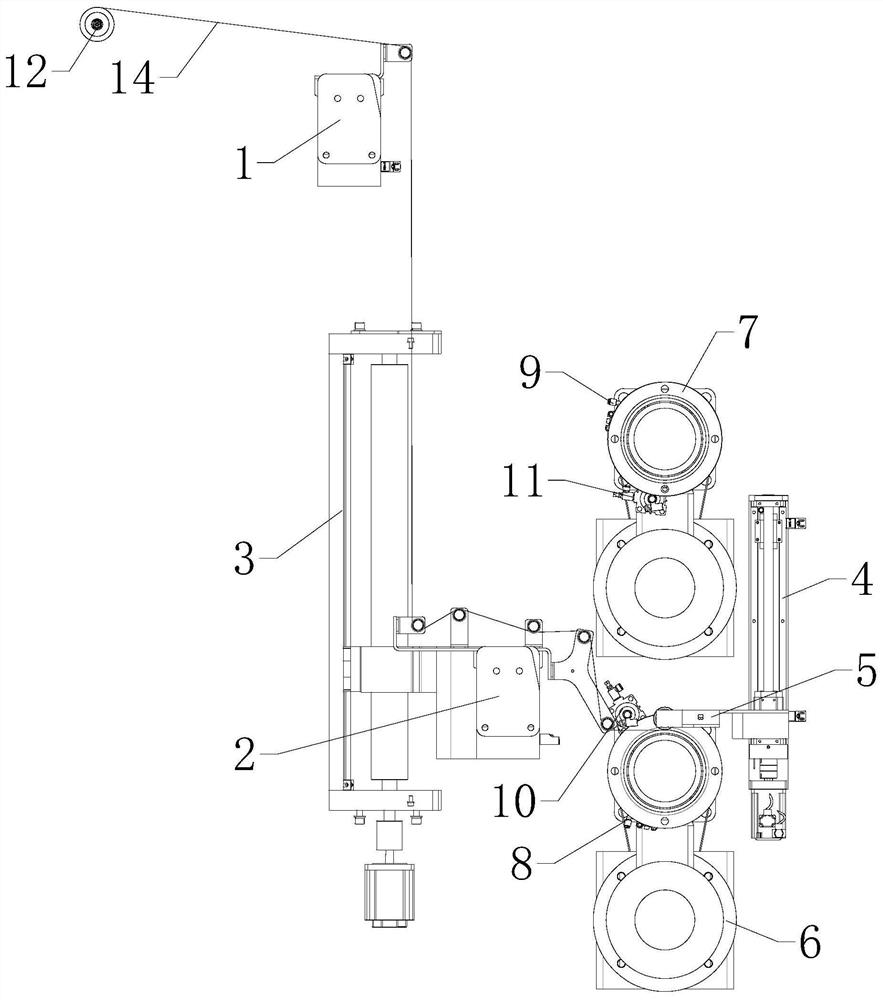

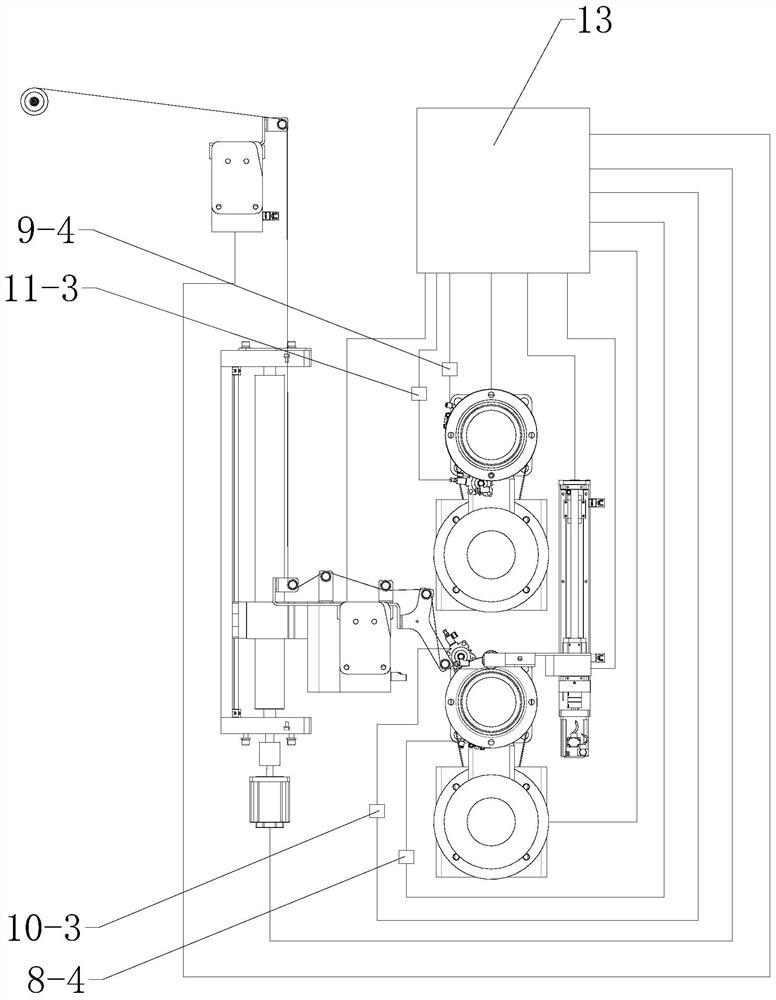

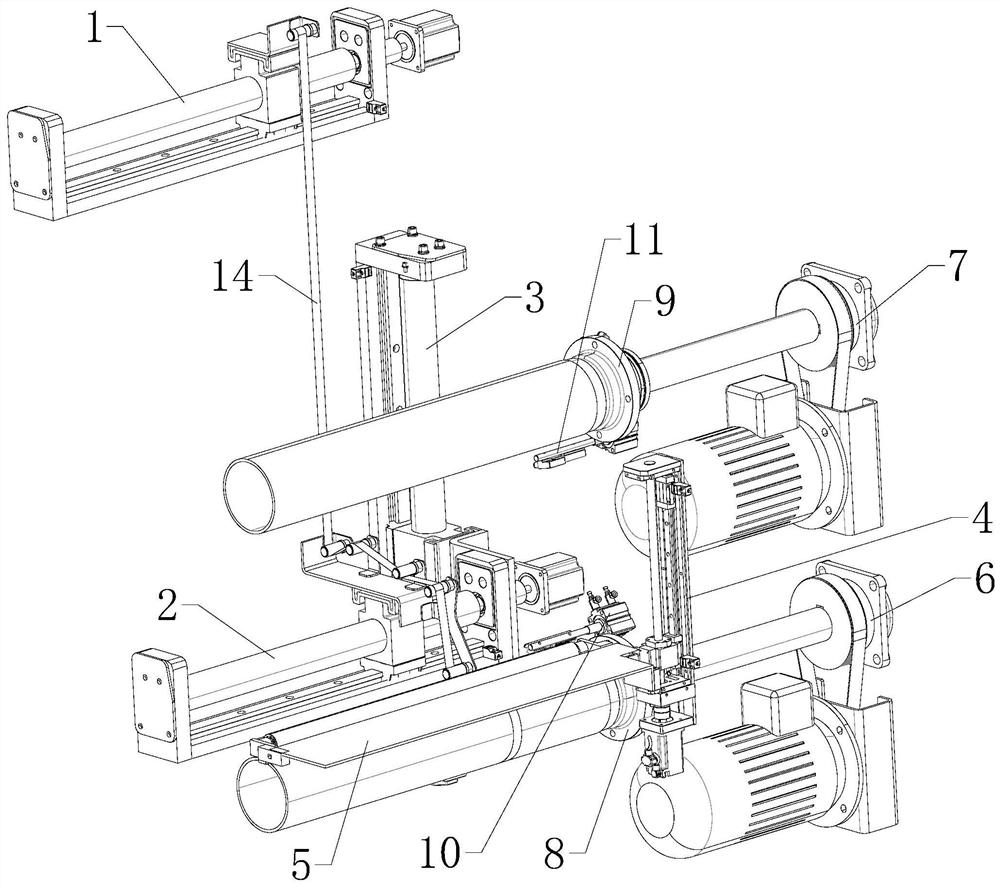

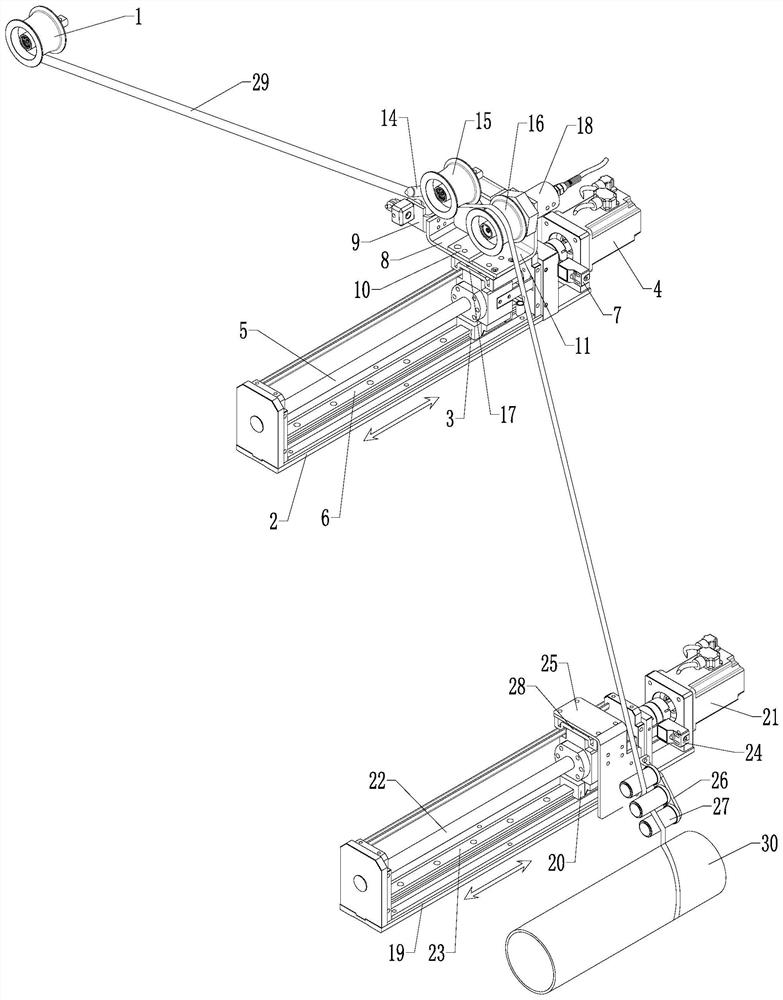

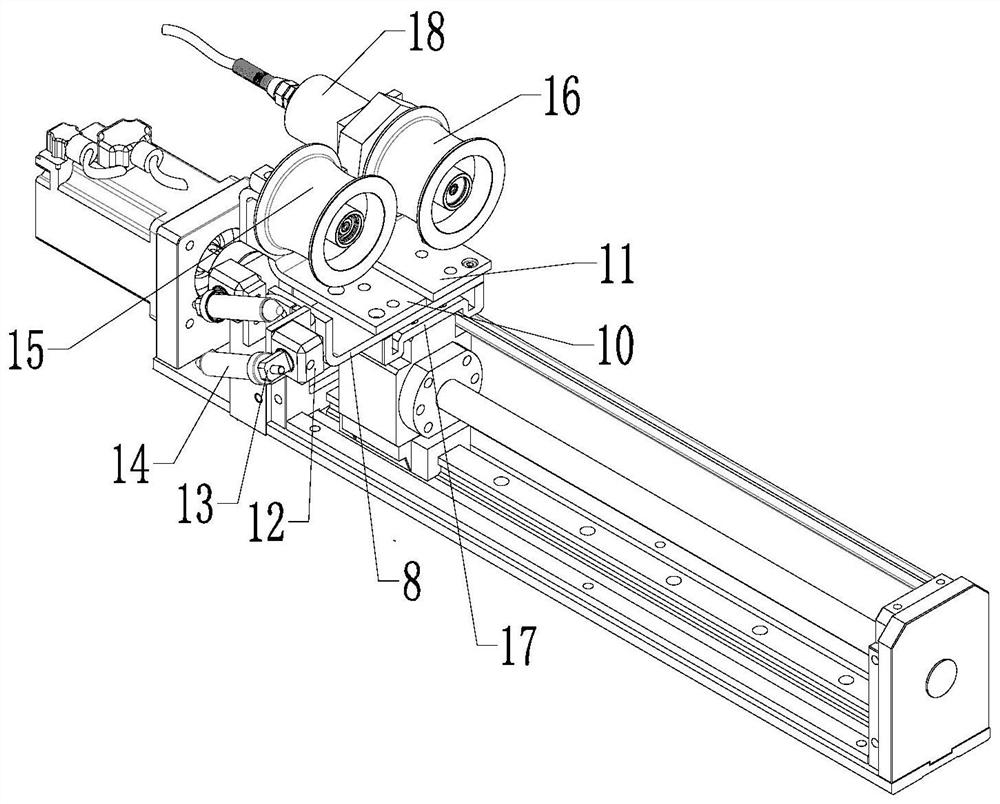

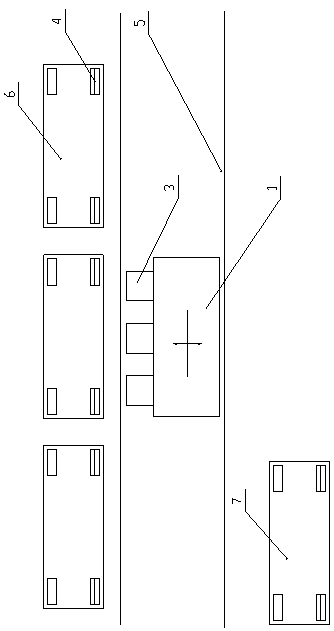

Winding machine capable of automatically changing rolls of protofilaments

PendingCN113716393ARealize automatic roll change and windingSave manpower and material resourcesFilament handlingWinding machineEngineering

The invention relates to the technical field of fiber winding machines, in particular to a winding machine capable of automatically changing rolls of protofilaments. The winding machine comprises a filament leading wheel, a controller, and a first reciprocating filament guide device, a second reciprocating filament guide device, a first translation device, a second translation device, a first winding device, a second winding device, a filament pressing device, a first filament clamping device, a second filament clamping device, a first filament cutting device and a second filament cutting device which are connected with the controller. A filament tow is led in through the filament leading wheel, sequentially passes through the first reciprocating filament guide device and the second reciprocating filament guide device and is alternately wound on the first winding device and the second winding device. Automatic roll changing and winding of protofilaments can be achieved, operation is convenient and fast, manpower and material resources are saved, and working efficiency is greatly improved.

Owner:广州赛奥智能装备有限公司

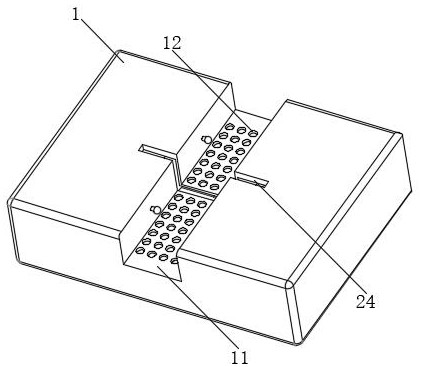

Efficient automatic cutting machine for metal square and rectangular pipes

ActiveCN114669796AAvoid damageReduce lateral frictionTube shearing machinesMaintainance and safety accessoriesStructural engineeringIndustrial engineering

The efficient metal square and rectangular pipe automatic cutting machine comprises a base, a containing groove is formed in the center axis of the top of the base, and a plurality of small holes are formed in the outer wall of the top of the containing groove. According to the efficient automatic cutting machine for the metal square and rectangular pipes, when a rectangular pipe is cut by a cutting blade, vibration can be generated, extrusion rods on the two sides can transversely move due to vibration, and an arc-shaped gas pipe can drive friction cleaning balls to transversely move back and forth under the effect of transverse movement of the extrusion rods; the friction cleaning ball is in clearance contact with the cutter face of the cutting blade in the transverse movement process, under the contact effect, waste chips adsorbed on the cutting blade can be cleaned, and the situation that a large number of waste chips are adsorbed on the cutting blade and the cutting effect is affected is prevented; in this way, the transverse friction force between the cutting blade and the friction cleaning ball can be reduced, and the cutting blade is prevented from being damaged.

Owner:博恩德智能装备(江苏)有限公司

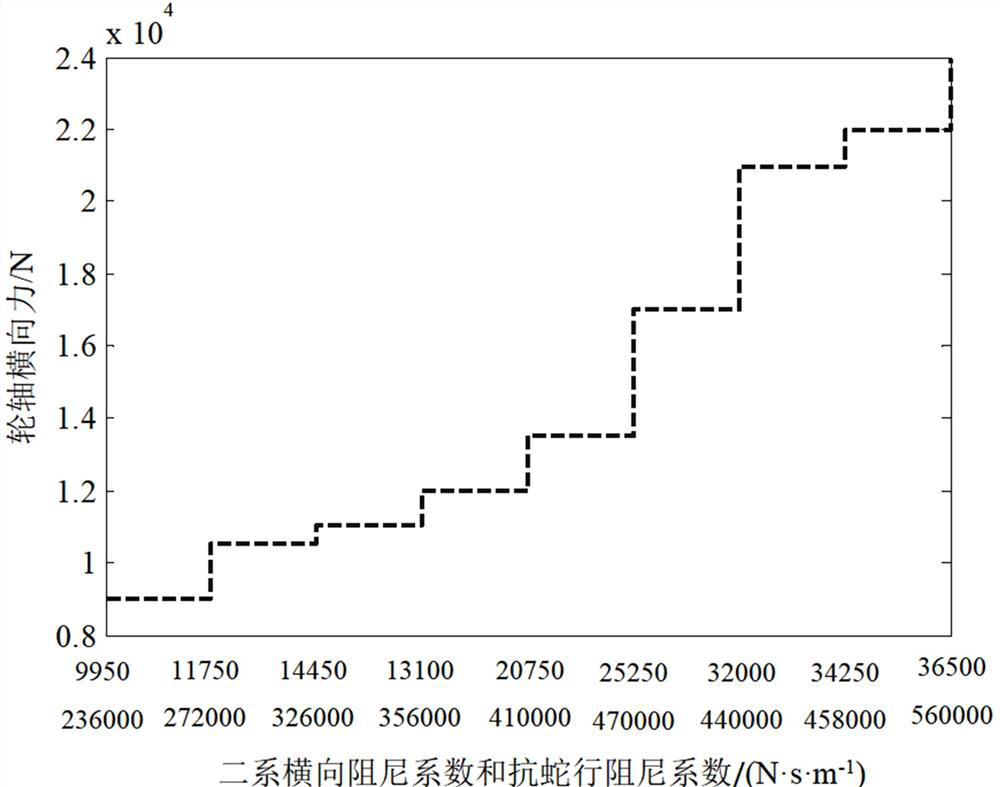

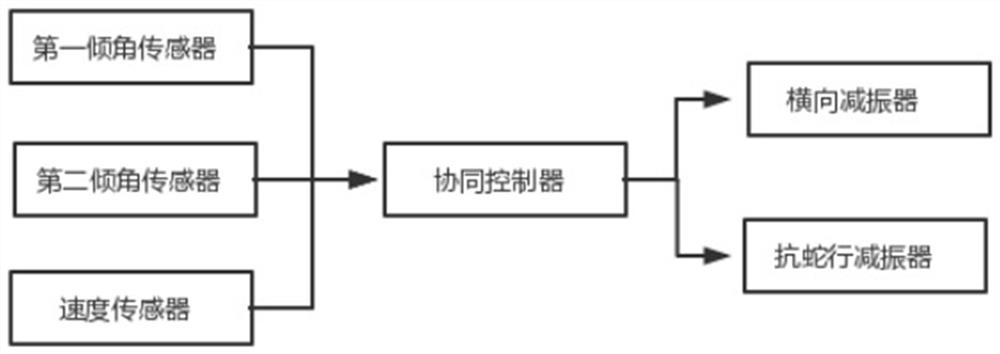

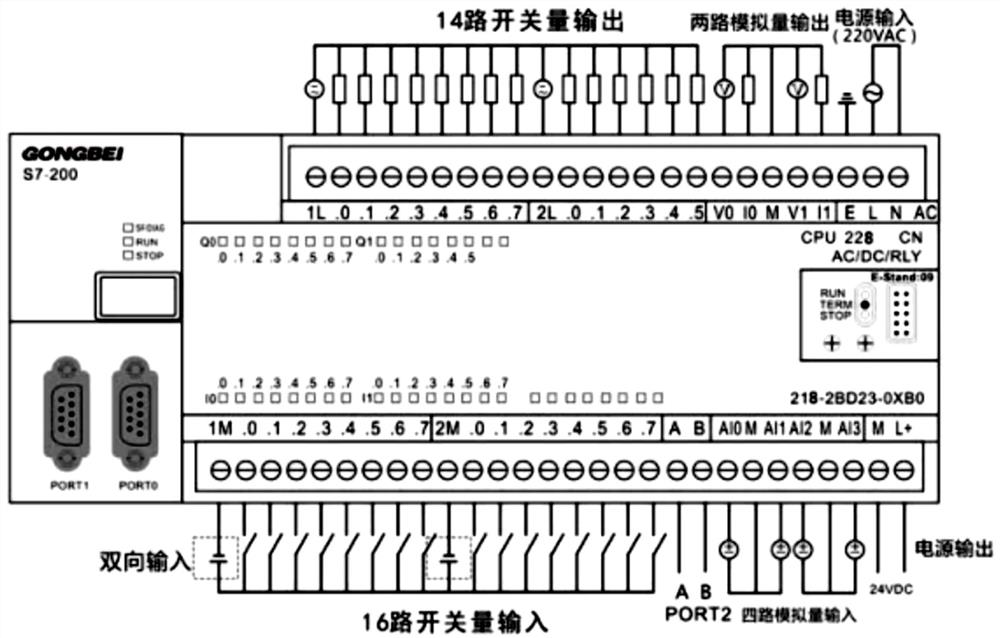

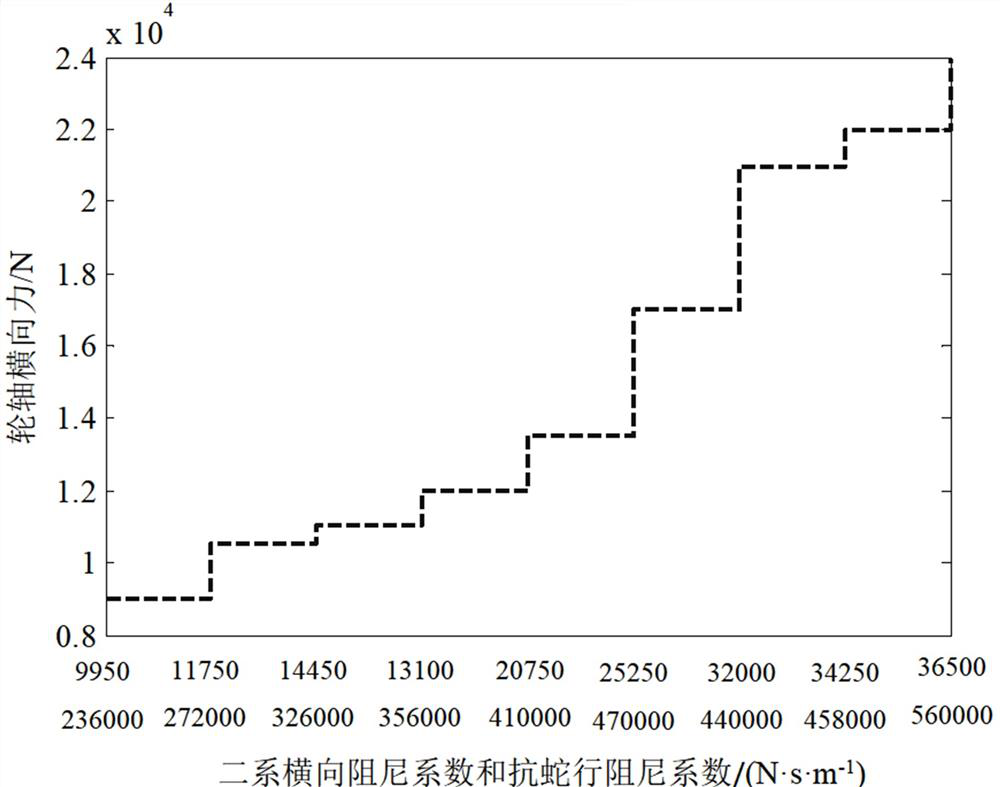

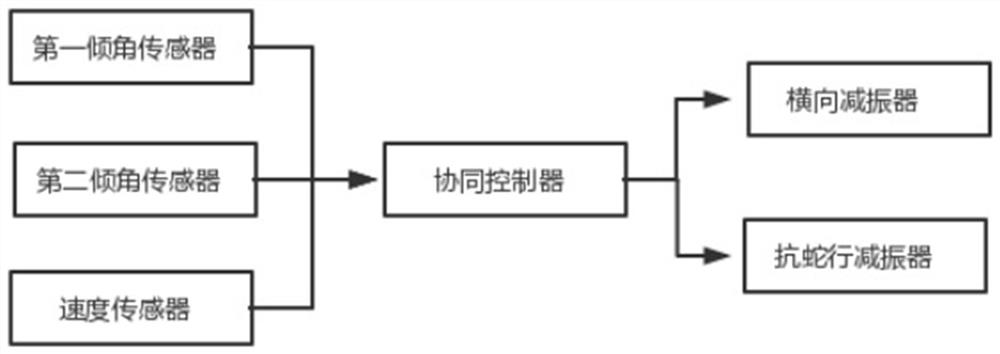

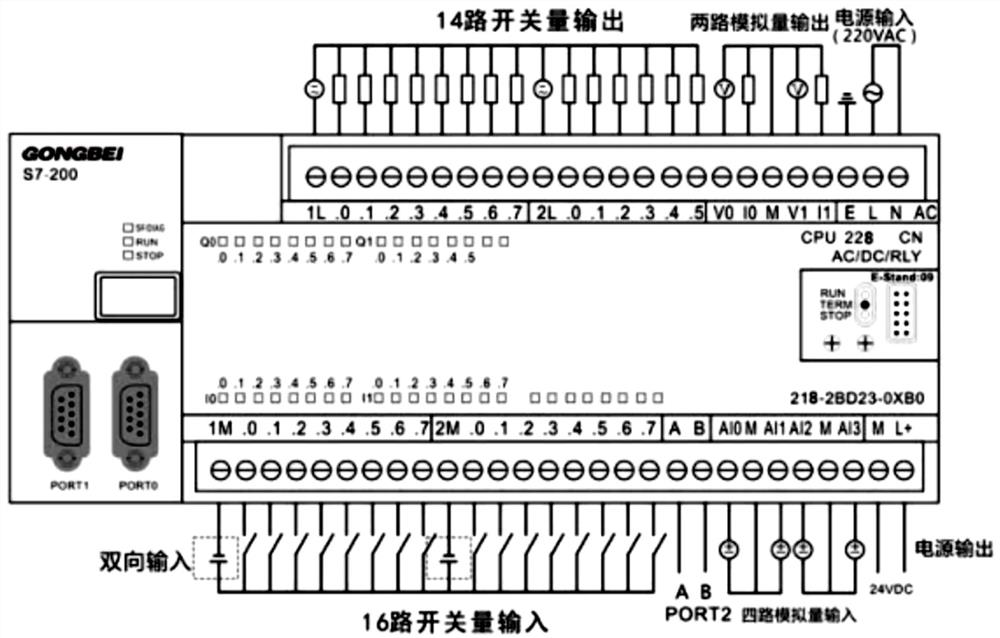

Intelligent vibration reduction cooperative system applied to high-speed train and control method of intelligent vibration reduction cooperative system

ActiveCN114537460AMaintain or improve dynamic performanceReduce frictionBogie-underframe connectionsControl engineeringControl theory

The invention relates to an intelligent vibration reduction cooperative system applied to a high-speed train and a control method of the intelligent vibration reduction cooperative system, and belongs to the technical field of rail train control, the intelligent vibration reduction cooperative system comprises vibration reduction units, the vibration reduction units are arranged in all carriages respectively, the intelligent vibration reduction cooperative system is characterized by further comprising a sensing unit and a cooperative controller, and the sensing unit comprises a tilt angle sensor and a speed sensor; the sensing unit is used for detecting the gradient and the speed of a train, the output end of the sensing unit is connected with the signal input end of the cooperative controller, and a time delay module is arranged between every two carriages and used for controlling the train according to the time difference when each carriage of the train passes through the same point. The damping coefficient output by the damping unit of each carriage is adjusted by adjusting the damping coefficient output by the damping unit of each carriage, the wheel state can be actively adjusted to adapt to the rails according to the actual condition of the railway, the acting force between the rails and the wheels is reduced when the motion state is changed, the service life of the wheels and the rails is prolonged, and the comfort and running safety and stability of the train are improved.

Owner:SHIJIAZHUANG TIEDAO UNIV

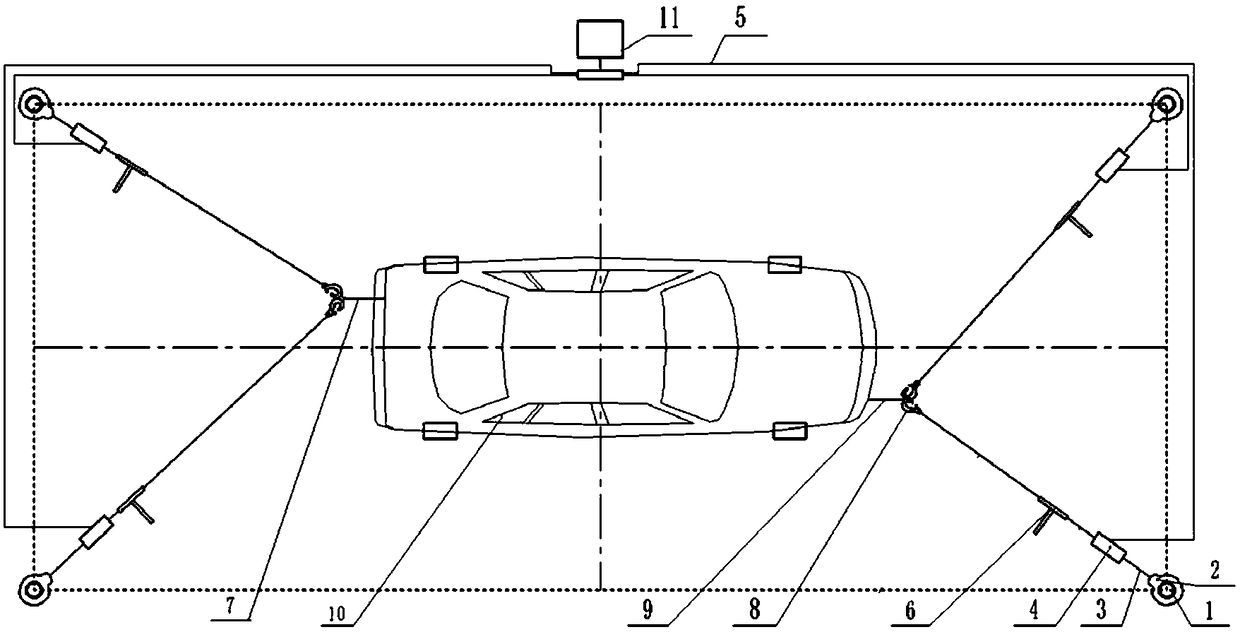

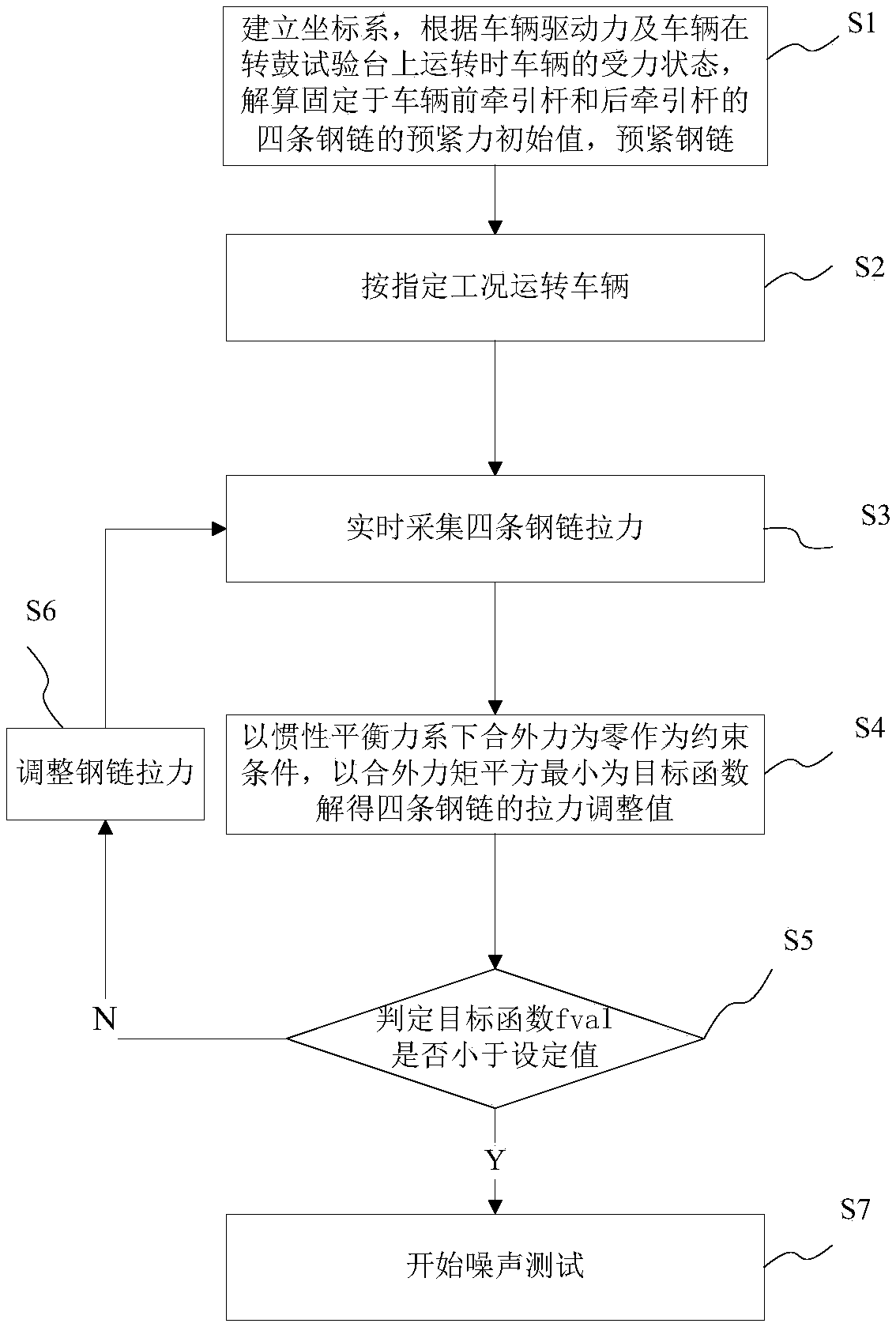

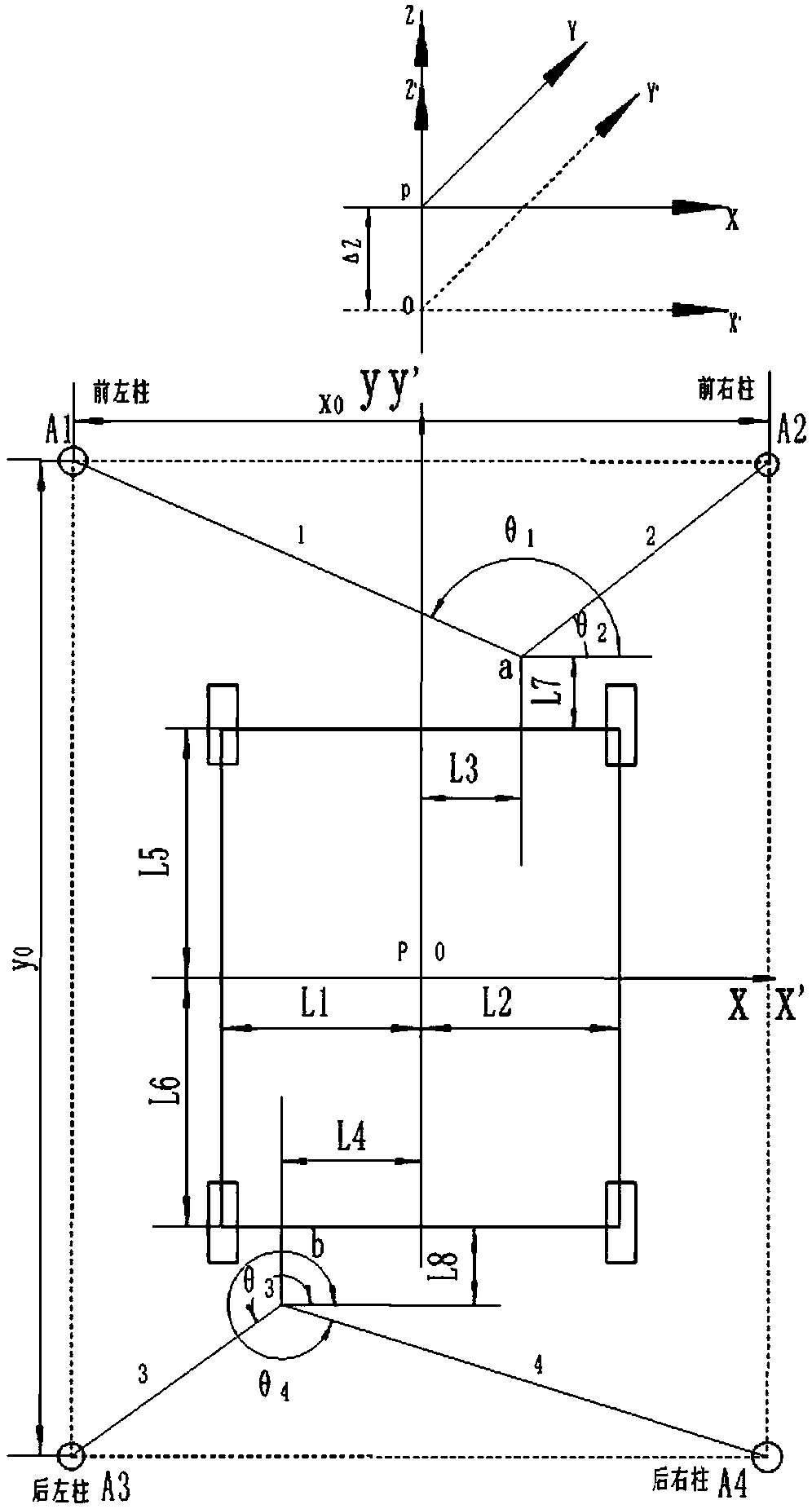

Vehicle dynamic balance tensioning method and tightening device on chassis dynamometer in anechoic room

ActiveCN109141917ARealize dynamic balance tighteningReduce lateral frictionVehicle testingVehicle dynamicsEngineering

The invention provides a vehicle dynamic balance tensioning method and a vehicle dynamic balance tightening device on a chassis dynamometer in an anechoic room. The vehicle dynamic balance tensioningmethod comprises the steps of: establishing a coordinate system, calculating pre-tightening force initial values of four steel chains connected to front and rear traction rods of a vehicle according to a vehicle driving force and a vehicle stress state when the vehicle is stationary on the chassis dynamometer, and pre-tightening the steel chains; running the vehicle according to a specified working condition; acquiring tension of the four steel chains in real time; retarding a condition that a resultant external force in an inertia balance force system is zero as a constraint condition, regarding the square minimization of a resultant external moment as an objective function, and calculating tension adjustment values of the four steel chains, so as to adjust tension of the steel chains; and launching a noise test when determining that the objective function is less than a set value. The vehicle dynamic balance tensioning method and the vehicle dynamic balance tightening device realizethe balanced fixation of a tested vehicle on the chassis dynamometer, reduce the possibility of vehicle swing and lateral friction between tyres and the surface of a drum in the testing process, reduce the additional tyre noise, provide a more realistic simulation environment for indoor noise measurement, and improve the measurement precision.

Owner:HEFEI UNIV OF TECH

A special rammer for dynamic compaction replacement treatment of fluid-plastic to soft-plastic clay

ActiveCN110904945BReduce lateral frictionReduce lossesSoil preservationDynamic compactionStructural engineering

The invention belongs to the technical field of a rammer for foundation treatment in construction engineering, and specifically relates to a special rammer for dynamic compaction replacement treatment of flow-plastic to soft-plastic clay, including a hook part, an anti-buried hammer extension part and a rammer For the hammer body, the height of the anti-buried hammer extension is more than 2.8 meters. The rammer body includes an upper trapezoidal circular table structure and a lower cylindrical structure. The outer wall of the rammer body is evenly distributed with a number of semicircular ventilation holes. The present invention solves the problem of "buried hammer" in the dynamic compaction replacement of flow-plastic to soft-plastic clay foundations. For the problem that it is impossible to carry out dynamic compaction depth replacement due to hammering, dynamic compaction, an environmentally friendly and low-cost treatment technology, can further expand the scope of application, and has a broad application market and good development prospects.

Owner:山西机械化建设集团有限公司

Prewhirl spray auxiliary pile sinking construction method

This invention discloses a method of assistant stake sinking by revolving spray, in this method we ensure the thickness of underground revolving spray before stake sinking, and use revolving spray to drill to move to the resistance layer of stake sinking in stake sinking point, then pass syrup liquid to the drill pole to carry the head of spray using the high pressure pump, with the high pressure level shoot to flow to spray to go in to resistance layer with jet pressure above 30 Mpas, at the same time the drill pole revolving at 15-30 r / min, promoting with 15-30 cm / min speed, to the resistance layer of underground sinking stake to harass revolving spray, then using the sinking stake equipments. The method of the invention avoided taking the soil from top to bottom in the beginning from the natural horizon, lowering resistance of sinking, raised sinking speed and protected stake body, increased the side rub resistance of the stake after the formation of stake. The invention is applicable to the processing of preparing stake used in underground stake sinking resistance layer in engineering construction.

Owner:MCC TIANGONG GROUP

A hot press device for high temperature adhesive curing

The invention relates to a hot pressing device for high temperature adhesive curing. Including: end cover (1), bolt (2), force bar (3), base (4), magnet (5), high temperature rubber pad (7), electric heater (8), electrode (9), lead hole (10), bearing (11), mandrel (12); the base (4) is a cylindrical structure with an inverted "U" shape in cross section, and the upper bottom surface is provided with a through hole, and the inner wall of the through hole is provided with a thread; the base The seat (4) provides support, and the magnet (5), high-temperature rubber pad (7), and electric heater (8) are arranged inside it; the magnet (5) provides attractive force, and the upper end of the magnet (5) has an internal thread, and the direct core The mandrel thread (12c) of axle (12) connects. The advantage of the invention is that both the temperature and the applied force can be adjusted to meet the condition of multiple curing of the high-temperature glue. The device is simple in design, precise in control and easy to operate.

Owner:TIANJIN AEROSPACE RELIA TECH +3

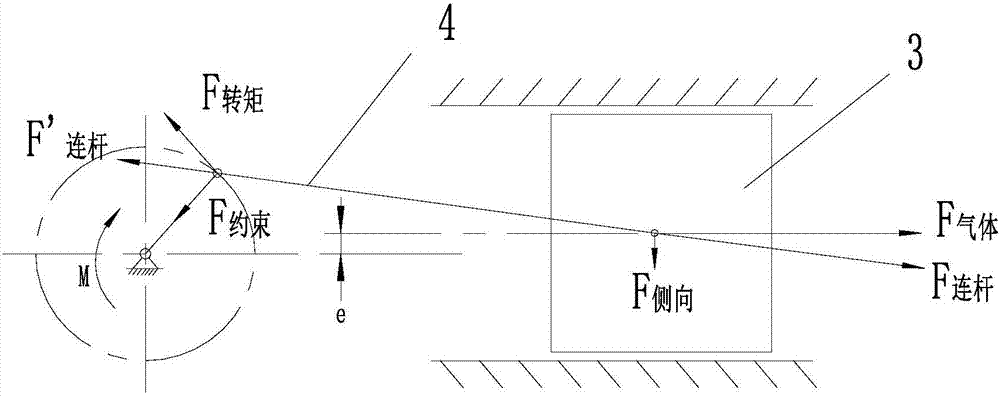

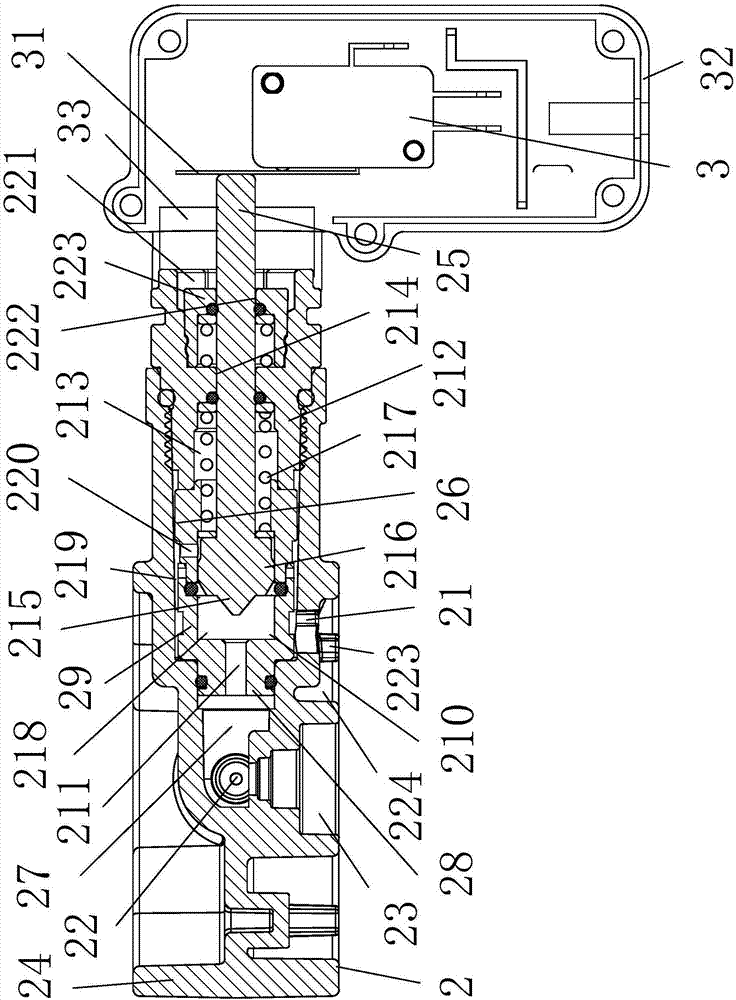

A piston, a compressor having the same and a processing method for the piston

ActiveCN105604915BReduce lateral frictionImprove reliabilityPositive displacement pump componentsPositive-displacement liquid enginesEngineeringFriction force

The invention discloses a piston. The piston comprises a piston body, wherein grooves are formed in the peripheral faces of the piston body. Each groove includes a first groove section and a second groove section, wherein the first groove section is located in one side of a first central plane of the piston body, the second groove section is located in the other side of the first central plane, and the area of the second groove section is larger than the area of the first groove section; the first central plane is a plane of axes passing through the piston body. Since the grooves in the peripheral faces on the two sides of the piston body are different in area, a difference value exists between air force generated by air pressure in the grooves in the two sides; the difference value can be used for offsetting lateral component force of external force borne by the piston, so that lateral friction force of the piston is reduced, and reliability of the piston is improved. The invention also discloses a compressor and a machining method of the piston.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Double-yarn guide device of winding machine

PendingCN112850335AReduce the angle of reciprocating swingAvoid rubbingFilament handlingYarnWinding machine

The invention particularly relates to a double-yarn guide device of a winding machine. The double-yarn guide device comprises a first reciprocating yarn guide device and a second reciprocating yarn guide device, the first reciprocating yarn guide device comprises a first reciprocating mechanism and a first yarn guide mechanism, and the first yarn guide mechanism is fixedly connected to the first reciprocating mechanism through a first sliding block connecting piece; the second reciprocating yarn guide device comprises a second reciprocating mechanism and a second yarn guide mechanism, and the second yarn guide mechanism is fixedly connected to the second reciprocating mechanism through a second sliding block connecting piece; and fibers are led in through a yarn guide wheel, sequentially pass through the first yarn guide mechanism and the second yarn guide mechanism and are wound on a spindle of the winding machine, and the first reciprocating yarn guide device and the second reciprocating yarn guide device are controlled through a controller and achieve synchronous reciprocating motion. The first reciprocating yarn guide device and the second reciprocating yarn guide device are controlled through the controller and achieve synchronous reciprocating motion, the angle of reciprocating swinging of the fibers driven by the reciprocating yarn guide devices is reduced, and yarn rubbing and yarn damage are avoided.

Owner:广州赛奥智能装备有限公司

A method for replacing a wind tunnel test section

ActiveCN108896267BQuick changeSafe replacementAerodynamic testingMode of transportMarine engineering

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

An intelligent vibration reduction coordination system applied to high-speed trains and its control method

ActiveCN114537460BMaintain or improve dynamic performanceReduce frictionBogie-underframe connectionsControl theoryCarriage

The invention relates to an intelligent vibration reduction coordination system applied to high-speed trains and a control method thereof, belonging to the technical field of rail train control, comprising a vibration reduction unit, the vibration reduction unit being respectively arranged in each carriage, and characterized in that it further comprises: an induction unit and a cooperative controller, the induction unit includes an inclination sensor and a speed sensor, the induction unit is used to detect the train inclination and the speed of the train, the output end of the induction unit is connected to the signal input end of the cooperative controller, A delay module is arranged between each car, and the delay module is used to adjust the damping coefficient output by the vibration reduction unit of each car according to the time difference when each car of the train passes the same point. According to the actual situation, actively adjust the state of the wheel to adapt to the rail, reduce the force between the rail and the wheel when the motion state changes, improve the service life of the wheel and the rail, and improve the comfort and operational safety and stability of the train.

Owner:SHIJIAZHUANG TIEDAO UNIV

A four-cylinder horizontally opposed engine with variable compression ratio

ActiveCN110219734BLower center of gravityReduce noiseEngine controllersMachines/enginesGear wheelControl system

The invention relates to an engine, in particular to a four-cylinder horizontal opposed variable compression engine. The compression ratio can be changed. The engine comprises an upper frame, a lowerframe, a gradient gear and a crankshaft, a variable compression ratio control system comprises a servo motor, an adjusting rod connecting piece I, a left control arm, a right control arm and a third piston, so that the effective compression stroke of a piston I in a piston cylinder II changes, the ratio of the effective compression stroke of the piston I in the piston cylinder II to the effectivestroke of the piston I in the piston cylinder II is changed (the effective compression ratio), so that the effective compression ratio of the engine is adjusted; the piston connecting rod I and a piston connecting rod II or a piston connecting rod III and a piston connecting rod IV are horizontally opposite, so that the gravity center of the engine is lowered, and the overall balance is easier toachieve; and a limiting boss is fixedly connected to the inner end of a lower frame body, so that damage to a motor due to overload caused by excessive deflection when a servo motor controls the maximum peak value and the minimum peak value during compression ratio changing can be prevented.

Owner:HEILONGJIANG INST OF TECH

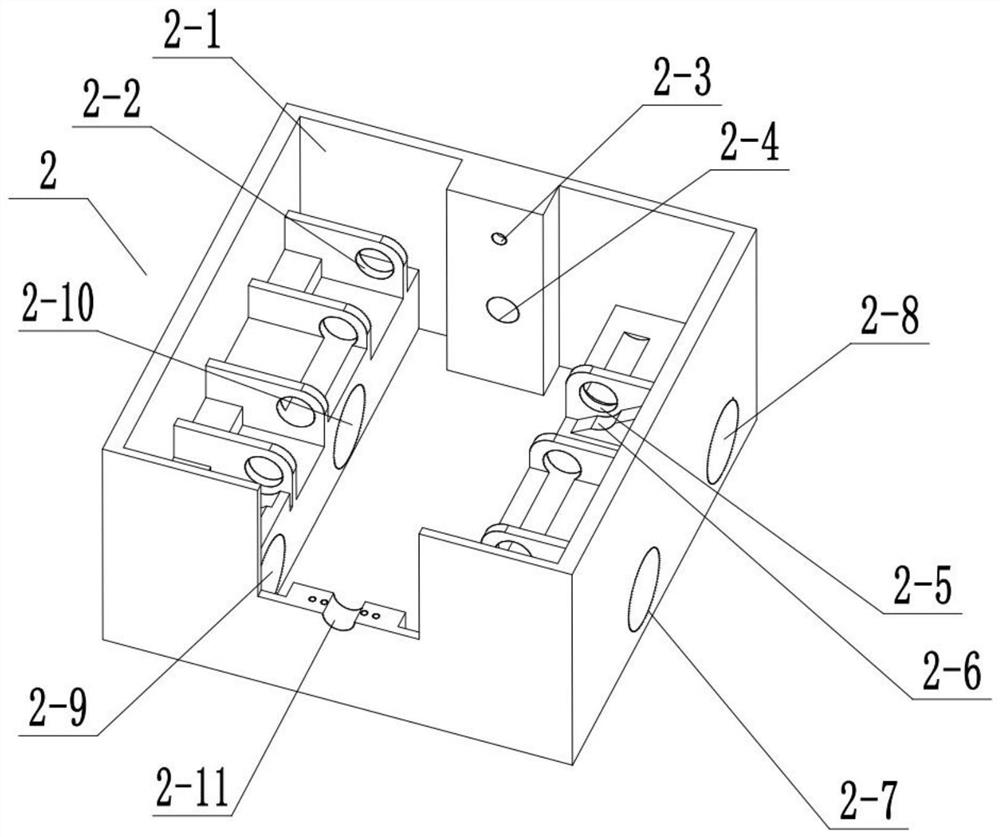

Low-pressure maintaining high-pressure washing device and low-pressure maintaining method

ActiveCN107570459AReduce lateral frictionSmooth up and down movementPositive displacement pump componentsPump controlElectricityEngineering

The invention relates to the field of washing equipment and aims at providing a low-pressure maintaining high-pressure washing device. The low-pressure maintaining high-pressure washing device comprises a high-pressure pump which is provided with a motor. The low-pressure maintaining high-pressure washing device further comprises a low-pressure maintaining device. The low-pressure maintaining device comprises a valve body, a low-pressure maintaining valve and a control switch, wherein the valve body is provided with a pressure relief outlet, a high-pressure outlet and a high-pressure inlet communicating with an outlet hole of the high-pressure pump, the rear end of the low-pressure maintaining valve extends out of a valve rod at the rear end of the valve body, and the control switch is provided with a drive rod which is opposite to the rear end of the valve rod and is electrically connected with the motor. According to the low-pressure maintaining high-pressure washing device, when a high-pressure washing machine pauses, the high-pressure pump can achieve pressure maintaining with relatively low pressure, and no damage is caused.

Owner:宁波可利尔电器科技有限公司

Optical cable stabilizing frame used during soft optical cable text printing and implementation method thereof

PendingCN109850675AStable structureStable cableFilament handlingTypewritersThree stageOptical fiber cable

The invention discloses an optical cable stabilizing frame used during soft optical cable text printing and an implementation method thereof. The optical cable stabilizing frame comprises an optical cable stabilizing frame main body, wherein an optical cable stabilizing plate, a supporting rod, a first-stage optical cable pressing wheel, a meter counting wheel, a second-stage optical cable pressing wheel, a first-stage optical cable stabilizing wheel, a supporting plate, a first-stage angle adjusting rod, a second-stage angle adjusting rod, a back wheel, a coding wheel and a nozzle are arranged on the optical cable stabilizing frame main body; the first-stage optical cable pressing wheel is fixedly arranged on the leftmost side of the optical cable stabilizing plate, and the meter countingwheel is arranged at the process rear stage of the first-stage optical cable pressing wheel; the back side of the meter counting wheel is in communication with the back wheel, and the lower end of the back wheel is rotationally connected with the upper end of the coding wheel; the supporting plate is arranged on the right side of the back side of the optical cable stabilizing plate, the first-stage angle adjusting rod is vertically arranged and fixed on the supporting plate, the upper end of the first-stage angle adjusting rod is vertically arranged on the second-stage angle adjusting rod inan embedding mode, and the tail end of the second-stage angle adjusting rod is vertically arranged on a three-stage angle adjusting rod in an embedding mode. According to the optical cable stabilizingframe used during soft optical cable text printing and the implementation method thereof, in actual use, the structure is firm, the optical cable body is stable, the text printing effect is good, slipping is avoided during meter counting, the accuracy is high, and the optical cable stabilizing frame and the implementation method thereof are suitable for popularization and application.

Owner:ANHUI UNIV OF SCI & TECH

Seat angle adjusting device and seat with same

A seat angle adjustment device includes a ratchet wheel, a stop plate, a locking slipper and a pawl, wherein a first stop position limiting part and a second stop position limiting part are arranged on the stop plate, when the first stop position limiting part is subjected to a rotating torque in a rotational direction, the locking slipper in a locking position circumferentially abuts against the first stop position limiting part; when the rotating torque is higher than a first preset torque value, the pawl in an extended state is driven by the ratchet wheel to rotate until the tooth part on one side of the pawl is completely engaged with the ratchet wheel; and when the rotating torque is higher than a second preset torque value, the second stop position limiting part abuts against the pawl. A seat having the seat angle adjustment device is also provided.

Owner:HUBEI AVIATION PRECISION MASCH TECH CO LTD

Damping device with two-rider for lubricating for automobile

InactiveCN1280554CShutoff speed sensitiveImprove vibration damping effectSpringsResilient suspensionsPulp and paper industryGuide tube

The utility model relates to a two-guided and lubricated automobile shock absorber capable of reducing wear and enhancing vibration damping effect. The technical solution is: including an oil storage cylinder, a working oil cylinder is arranged inside the oil storage cylinder, the bottom of the oil storage cylinder and the bottom of the working oil cylinder are connected through a bottom valve, a piston device is arranged in the working oil cylinder, and a first guide is set on the upper part of the working oil cylinder. There is a second guide sleeve on the top of the first guide sleeve, the upper and lower end faces of the two guide sleeves are connected, the two guide sleeves are sleeved on the piston rod through the guide bearing, and an oil seal is arranged on the top of the second guide sleeve. The feature is that conduits are respectively arranged on the connecting rod shafts at both ends of the piston, and shut-off spring brackets are arranged on the two end faces of the conduits connected to the piston, and shut-off springs are arranged oppositely on the shut-off spring brackets, and on the top of the first guide sleeve An oil storage tank is provided, an oil return hole of the first guide sleeve is provided on the first guide sleeve through the upper and lower surfaces of the first guide sleeve, a ring groove is provided on the top of the second guide sleeve, and a second guide sleeve is provided on the inner wall of the ring groove. The oil return hole of the guide sleeve, the oil return hole of the first guide sleeve communicates with the oil return hole of the second guide sleeve, and the lower end of the oil return hole of the first guide sleeve communicates with the oil storage cylinder.

Owner:范勇

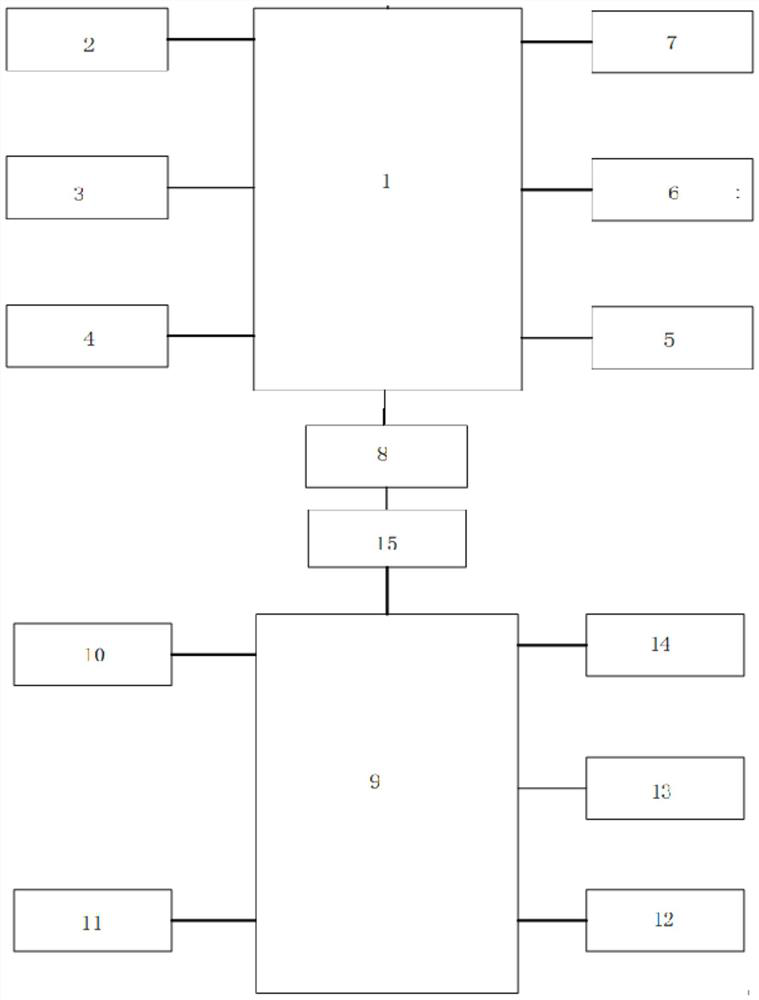

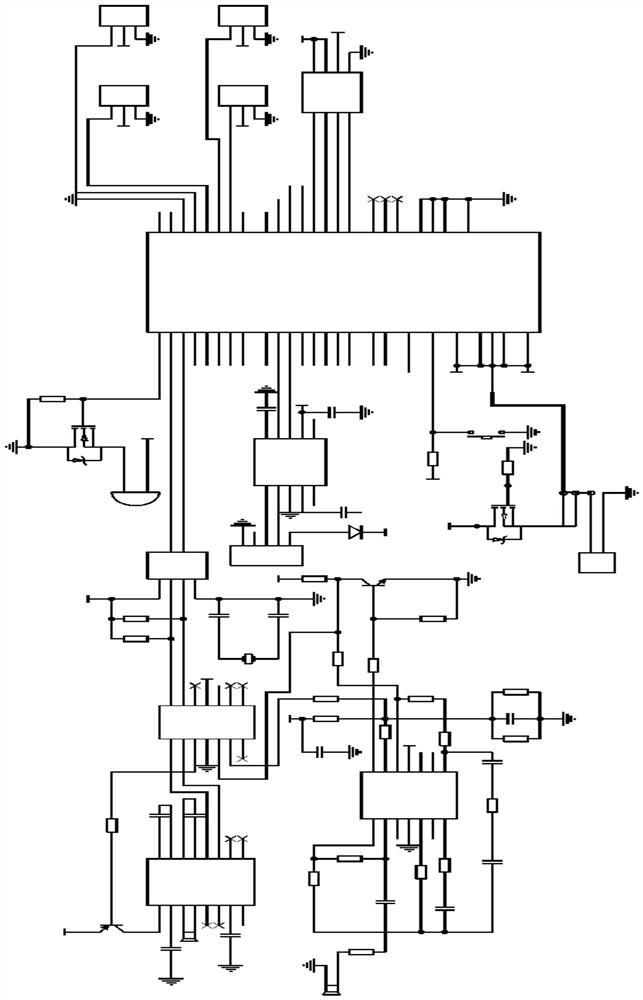

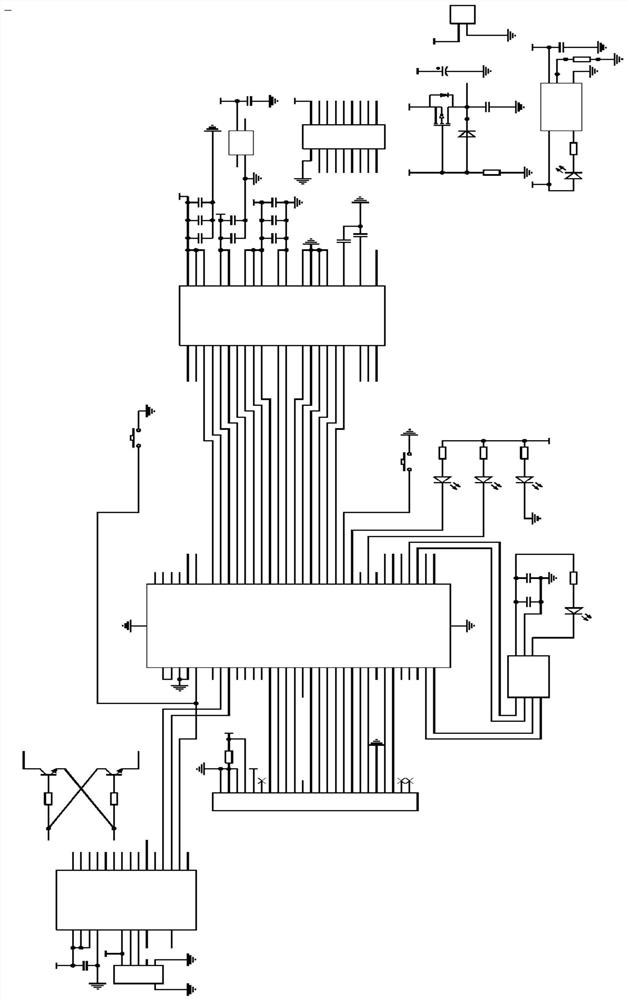

Online detection robot control system based on neural network

PendingCN114115054ASmall and lightLow priceProgramme controlComputer controlMicrocontrollerStatic random-access memory

The invention relates to the field of industrial nondestructive testing, in particular to an online detection robot control system based on a neural network. The lower computer comprises an stm32 singlechip minimum control system, an SRAM (Static Random Access Memory) memory extension, a starting mode setting interface module, a USB (Universal Serial Bus) communication serial port I, an ultrasonic sensor, a buzzer, a switching circuit module, a serial port communication module and a stepping motor driver, and the upper computer adopts a pyAI-K210 singlechip and comprises a camera, an LED (Light Emitting Diode) indicator lamp, an LCD (Liquid Crystal Display), a minimum control system and the like. According to the method, the surface defects can be detected, the recognized defects can be classified, manual defect information processing is reduced, a basis is provided for repairing of various types of defects, and therefore extension of human vision is achieved, and manpower and material resources are reduced and saved.

Owner:SHENYANG POLYTECHNIC UNIV

Low pressure maintaining high pressure cleaning device and low pressure maintaining method

ActiveCN107570459BWon't hurtSmooth motionPositive displacement pump componentsPump controlElectric machineControl switch

The invention relates to the field of washing equipment and aims at providing a low-pressure maintaining high-pressure washing device. The low-pressure maintaining high-pressure washing device comprises a high-pressure pump which is provided with a motor. The low-pressure maintaining high-pressure washing device further comprises a low-pressure maintaining device. The low-pressure maintaining device comprises a valve body, a low-pressure maintaining valve and a control switch, wherein the valve body is provided with a pressure relief outlet, a high-pressure outlet and a high-pressure inlet communicating with an outlet hole of the high-pressure pump, the rear end of the low-pressure maintaining valve extends out of a valve rod at the rear end of the valve body, and the control switch is provided with a drive rod which is opposite to the rear end of the valve rod and is electrically connected with the motor. According to the low-pressure maintaining high-pressure washing device, when a high-pressure washing machine pauses, the high-pressure pump can achieve pressure maintaining with relatively low pressure, and no damage is caused.

Owner:宁波君禾清洁科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com