Novel tubeless pneumatic tire without sidewall supporting

A sidewall support and pneumatic tire technology, applied in the direction of no separate air cushion, tire parts, transportation and packaging, etc., can solve the problems of affecting the dynamic balance of the tire, increasing the rolling resistance of the wheel, and increasing the difficulty of the rim, so as to reduce the The effect of small unbalanced force, increased driving speed, and reduced probability of tripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

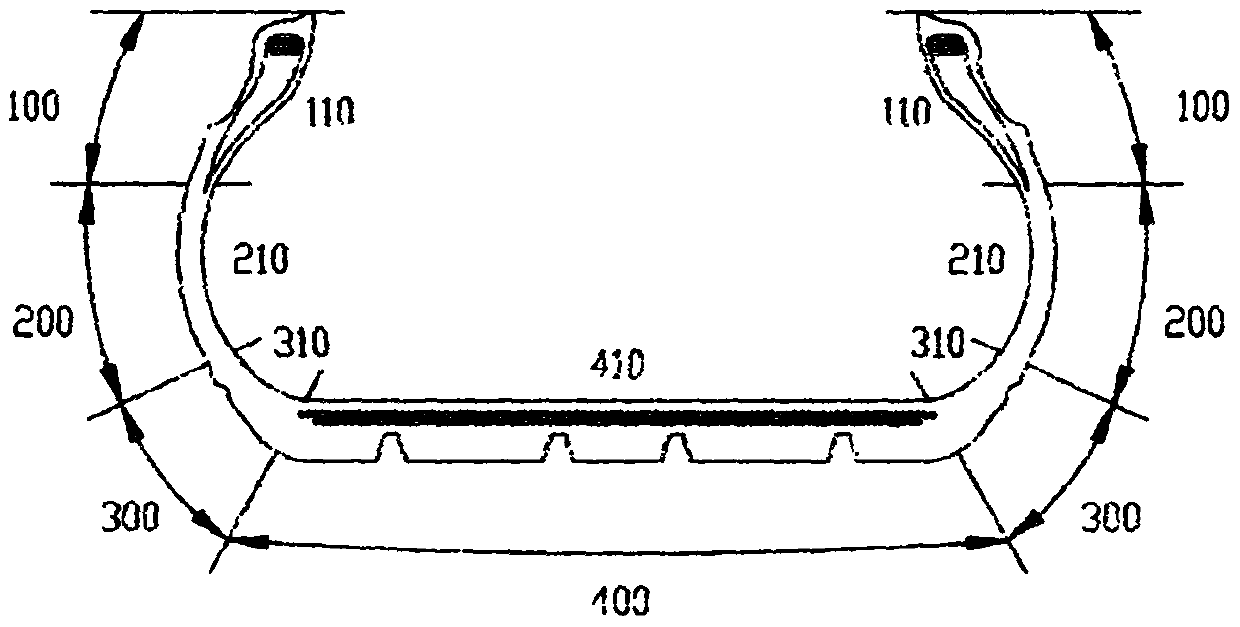

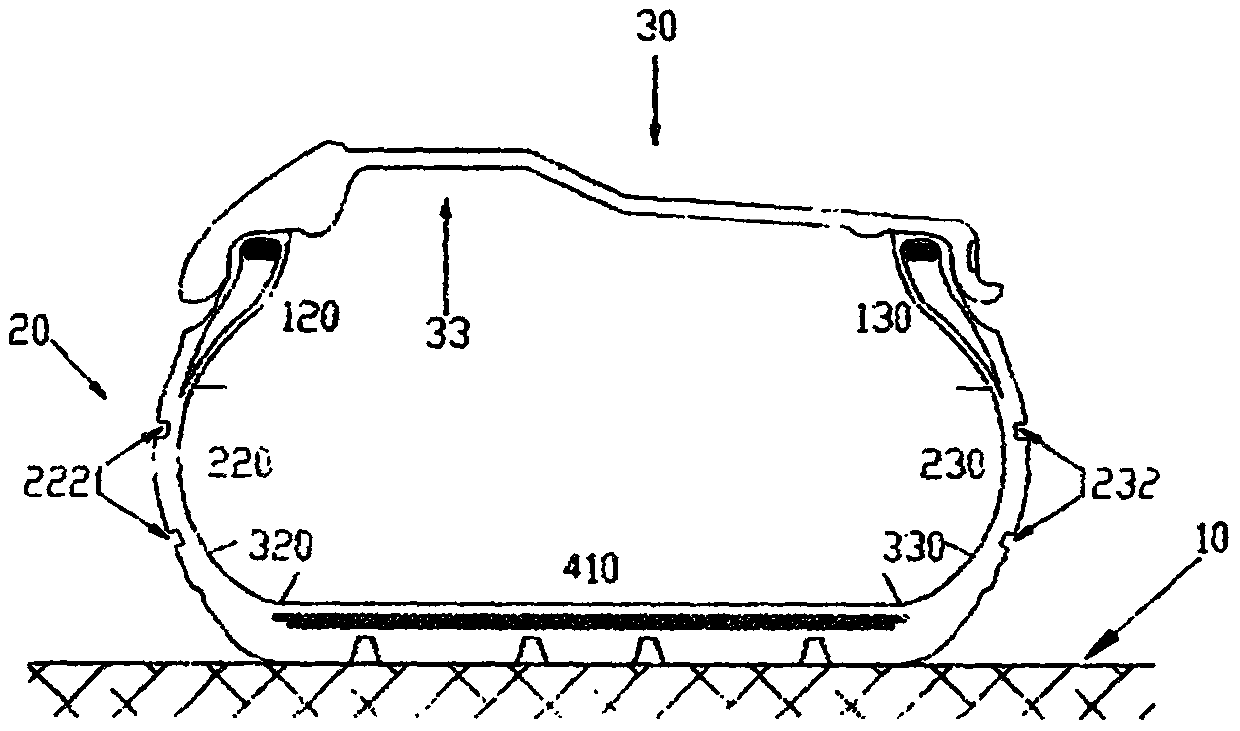

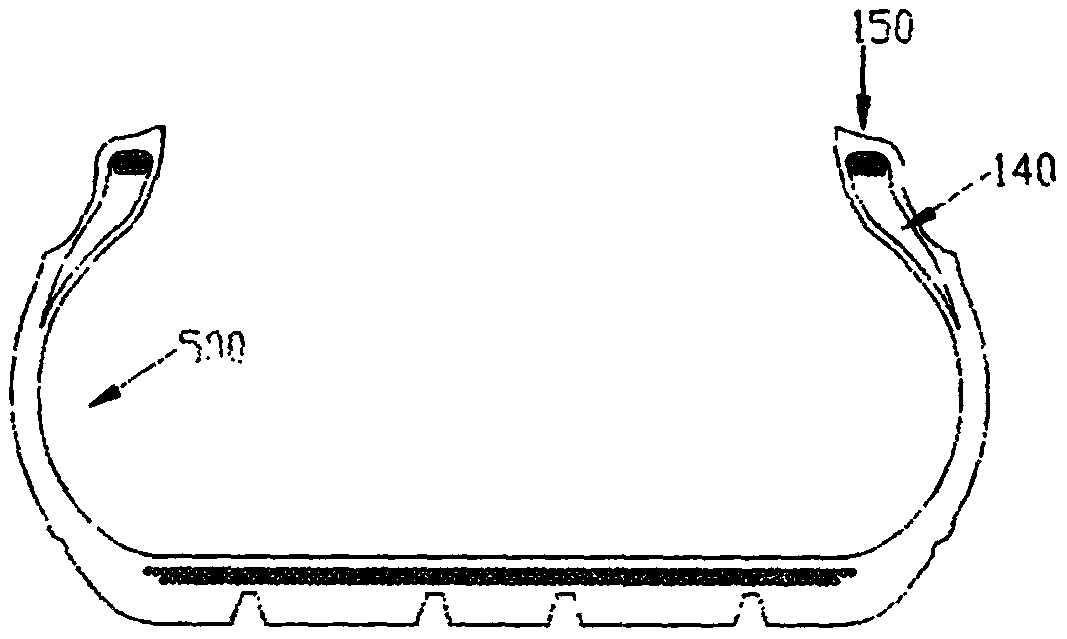

[0066] Reference attachment Figure 1-Figure 3 , Figure 5 , Image 6 , Figure 5 , Image 6 The tire is the left front tire, the vehicle is a family car, and the camber angle of the wheel under normal tire pressure is 0; the tire is a tire with a small aspect ratio, and the sidewall 200 has a small height, and the inner surface of the bead on both sides of the tire is 110, or two A wear-resistant lubricating layer is provided on the inner surface 110 of the side bead part, the inner surface 210 of the sidewall, and the inner surface of the shoulder 310. The wear-resistant lubricating layer is silicone grease + nylon cloth + rubber layer. The rubber layer of the rubber nylon cloth is attached to the inner surface of the tire inner layer 500, and then molded on the tire building drum, and finally vulcanized and molded. After the tire is vulcanized and molded, the nylon cloth is coated with silicone grease; silicone lubrication Grease + nylon cloth has good lubricity and wear resi...

Embodiment 2

[0078] Reference attachment Figure 1-Figure 3 , Figure 5 , Image 6 , Figure 5 , Image 6 The tire is the left front tire. Compared with Example 1, this embodiment is only different from the tire. The differences are: 1. The height of the sidewall 200 is different from that of Example 1, and the height of the sidewall 200 is higher than that of the sidewall 200 described in Example 1. The height is slightly higher, and the cross-sectional height of the tire at standard pressure is higher than that of Example 1. 2. On the inner surface 120 of the vehicle outer bead portion, or on the inner surface 120 of the vehicle outer bead portion, the vehicle outer sidewall inner surface 220, and the vehicle Silicone grease+nylon cloth+rubber layer is set on the inner surface 320 of the outer shoulder. The thickness of the silicone grease+nylon cloth+rubber layer is 1mm; the inner surface of the bead part 130, the inner surface of the sidewall 230, and the inner side of the vehicle The in...

Embodiment 3

[0084] Reference attachment Figure 1-Figure 3 , Figure 5 , Image 6 , Figure 5 , Image 6 The tire is the left front tire. Compared with Example 2, only the tire is different in this embodiment. The difference is: 1. The height of the sidewall 200 is higher than the height of the sidewall 200 described in Example 2. The cross-section of the tire at standard pressure The height is higher than that of Example 2; 2. Set silicone grease on the inner surface 120 of the vehicle outer bead part, or on the inner surface of the vehicle outer bead part 120, the vehicle outer sidewall inner surface 220, and the vehicle outer shoulder inner surface 320. The thickness of nylon cloth + rubber layer, silicone grease + nylon cloth + rubber layer is 1mm. The inner surface 130 of the bead portion inside the vehicle, the inner surface 230 of the sidewall inside the vehicle, and the inner surface 330 of the inner shoulder of the vehicle are not arranged as inner surfaces of the inner liner.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com