AGV four-wheel independent steering and differential combination control mechanism

A four-wheel independent steering and control mechanism technology, applied in steering mechanisms, electric steering mechanisms, power steering mechanisms, etc., can solve the problems of inflexible differential steering, poor steering adaptability of special tires, etc., to improve the passability and structure. Ingenious, expensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

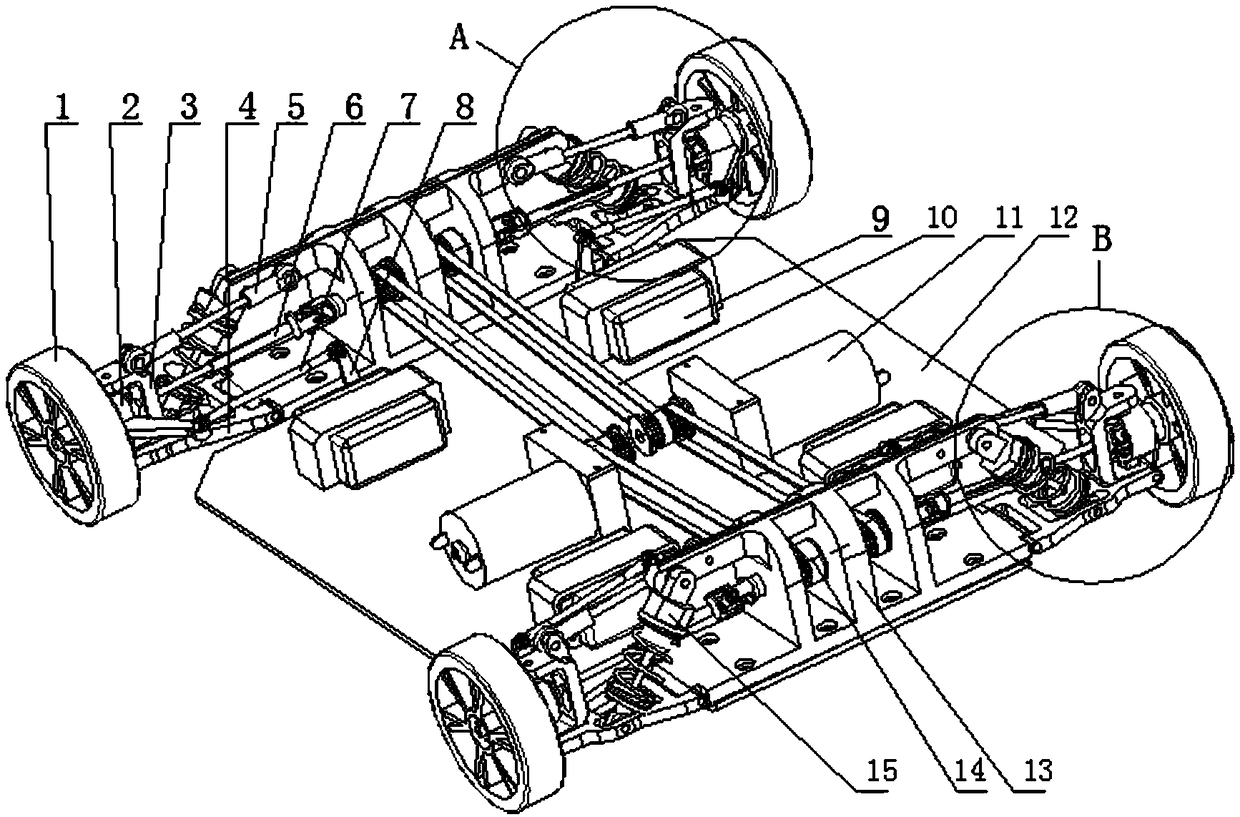

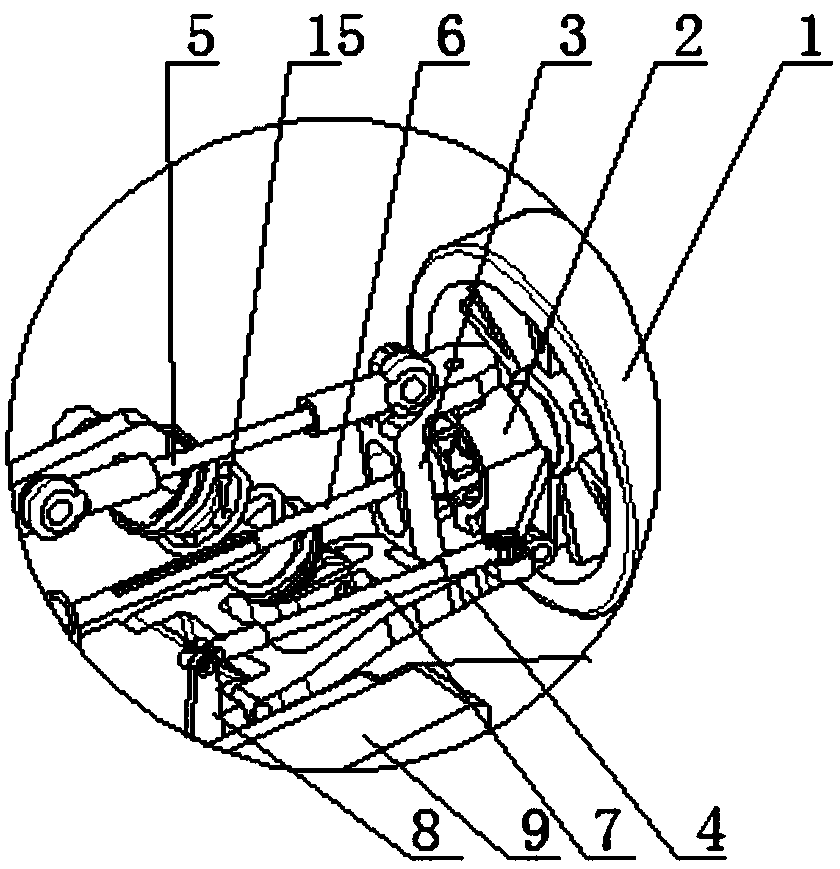

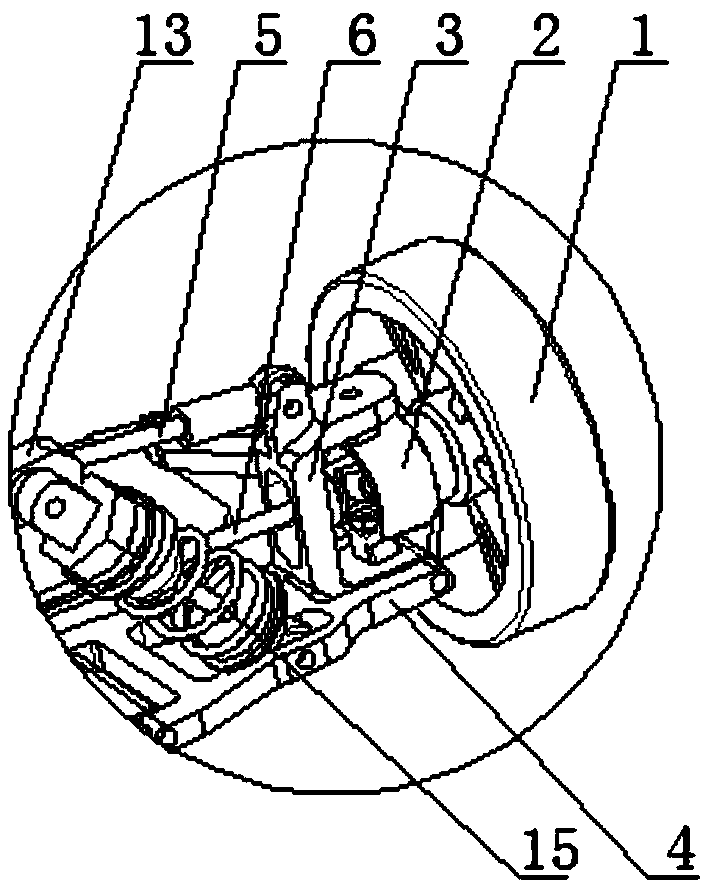

[0026] A control mechanism combining AGV four-wheel independent steering and differential speed, such as figure 1 As shown, it includes a chassis 12, a motor 11, a belt 10, a pulley 14, a steering gear 9, a steering gear arm 8, a fixing seat 13, a transmission shaft 6, a steering cup 2 and a wheel 1, and two Motors, the two motors are arranged symmetrically in mirror image; two fixing seats are fixed horizontally in mirror image symmetry on both sides of the front and back of the chassis, and a transmission shaft is respectively hinged in mirror image symmetry on the two fixing seats laterally to both sides, The drive shafts are hung with their own wheels through the steering cups hinged on their out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com