Online detection robot control system based on neural network

A control system and neural network technology, applied in the field of online inspection robot control system, can solve the problems of inaccurate identification, insufficient inspection accuracy, and inability to classify non-destructive inspection technology, achieving a small and lightweight size, high inspection accuracy, and rich features. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention is further described below in conjunction with accompanying drawing:

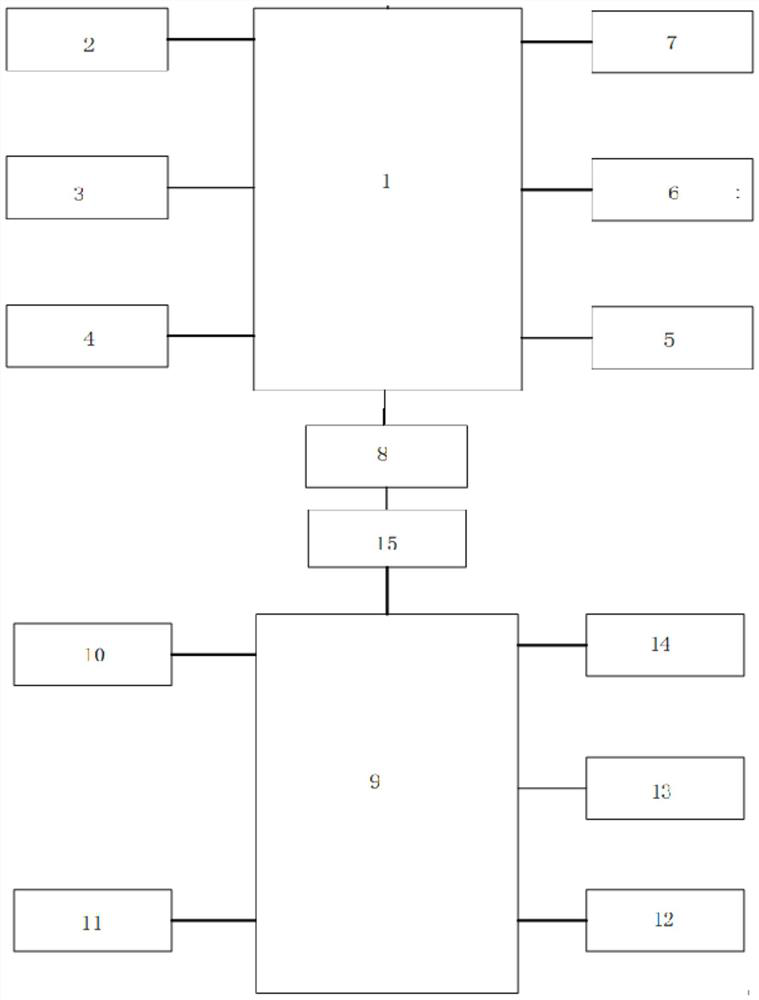

[0055] Such as figure 1 The flow chart of a neural network-based online detection robot control system is shown. This system includes two single-chip microcomputers, namely stm32F103ZET6 single-chip microcomputer and pyAI-K210 single-chip microcomputer. The stm32F103ZET6 includes 1. the minimum control system of stm32 single-chip microcomputer, 2. SRAM memory expansion, 3. USB communication serial port 1, 4. Ultrasonic sensor, 5 buzzers, 6. Stepping motor drive, 7. Startup mode setting interface, 8. Startup mode setting interface switch circuit, pyAI-K210 single chip microcomputer includes: 9. Minimum control System, 10. OV2460 camera, 11. LCD display, 12. Power module, 13. Wireless and 14. LED indicators and other parts

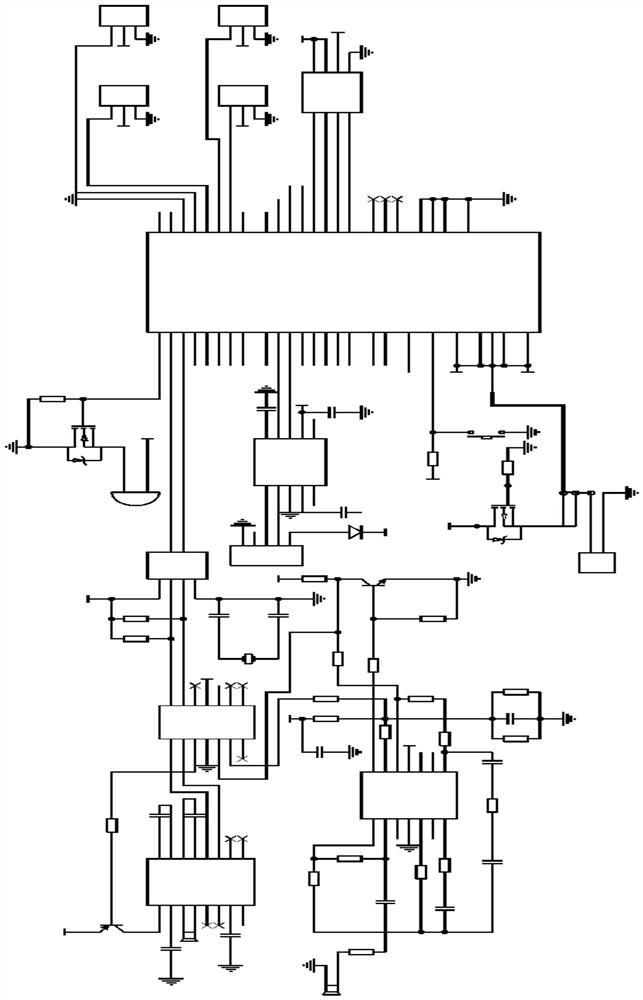

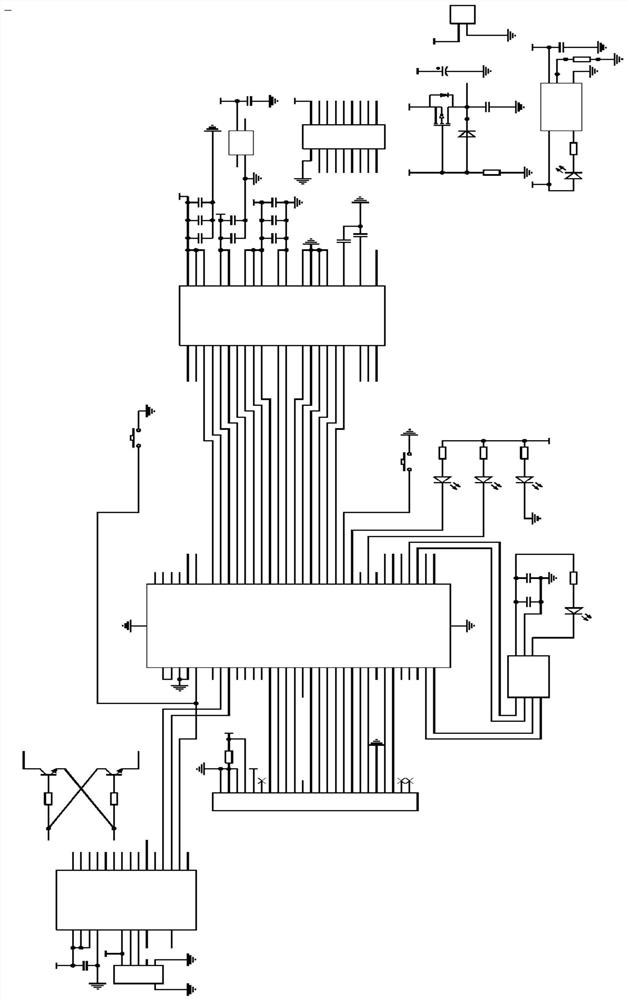

[0056] Such as figure 2 with 3 Shown is a neural network-based online detection robot control system, the lower computer includes stm32 single-chip minimu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com