Patents

Literature

82results about How to "Smooth up and down movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

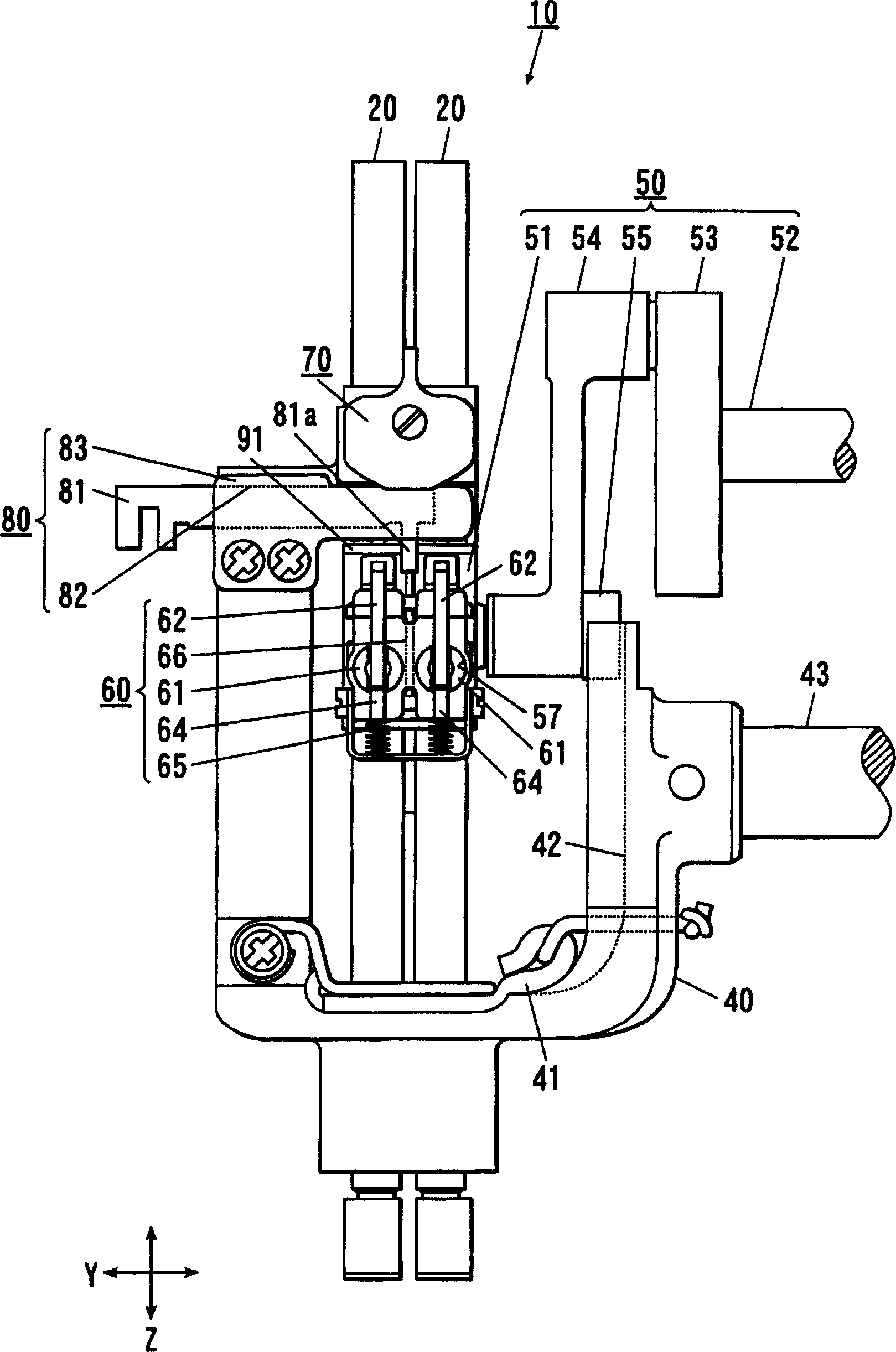

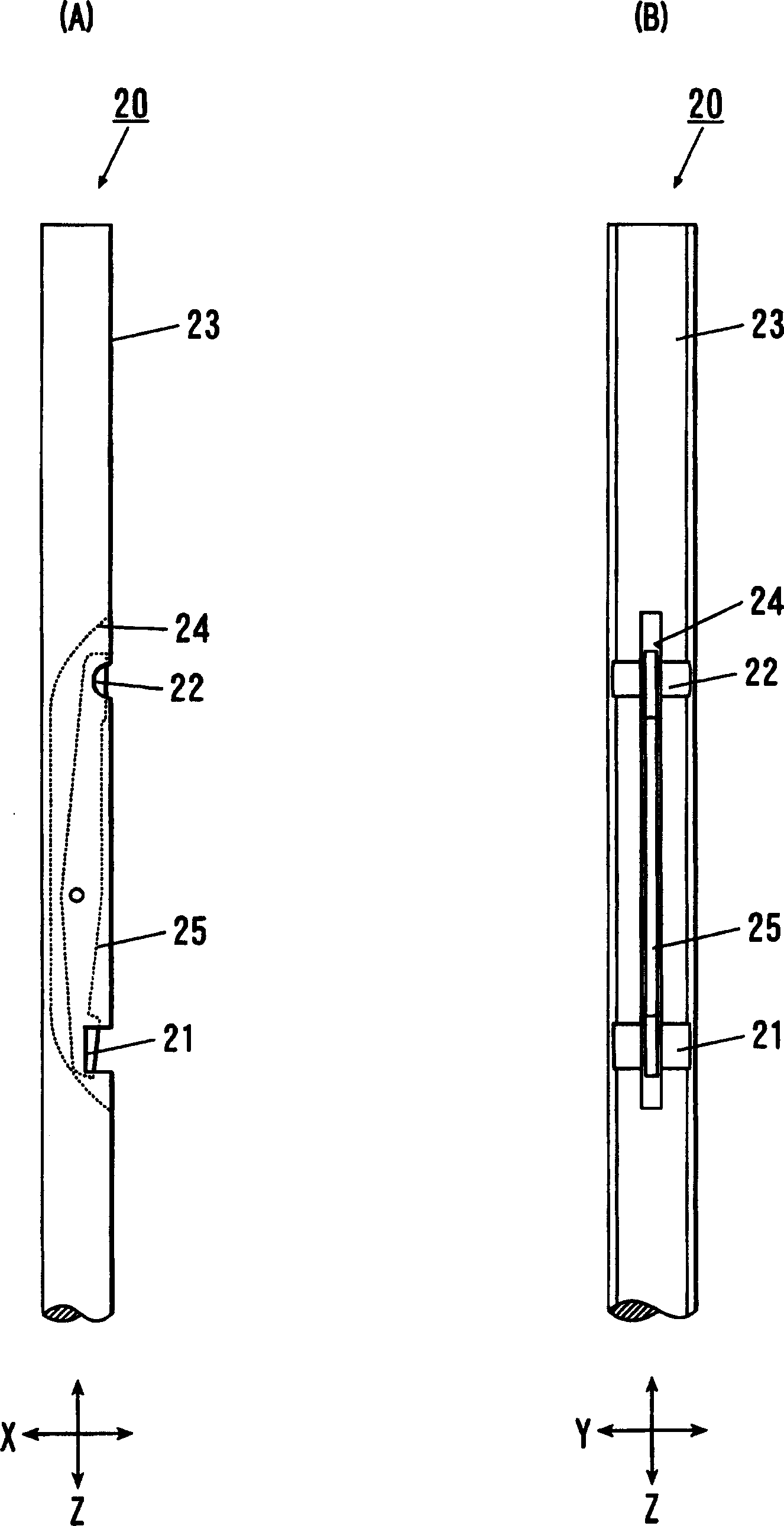

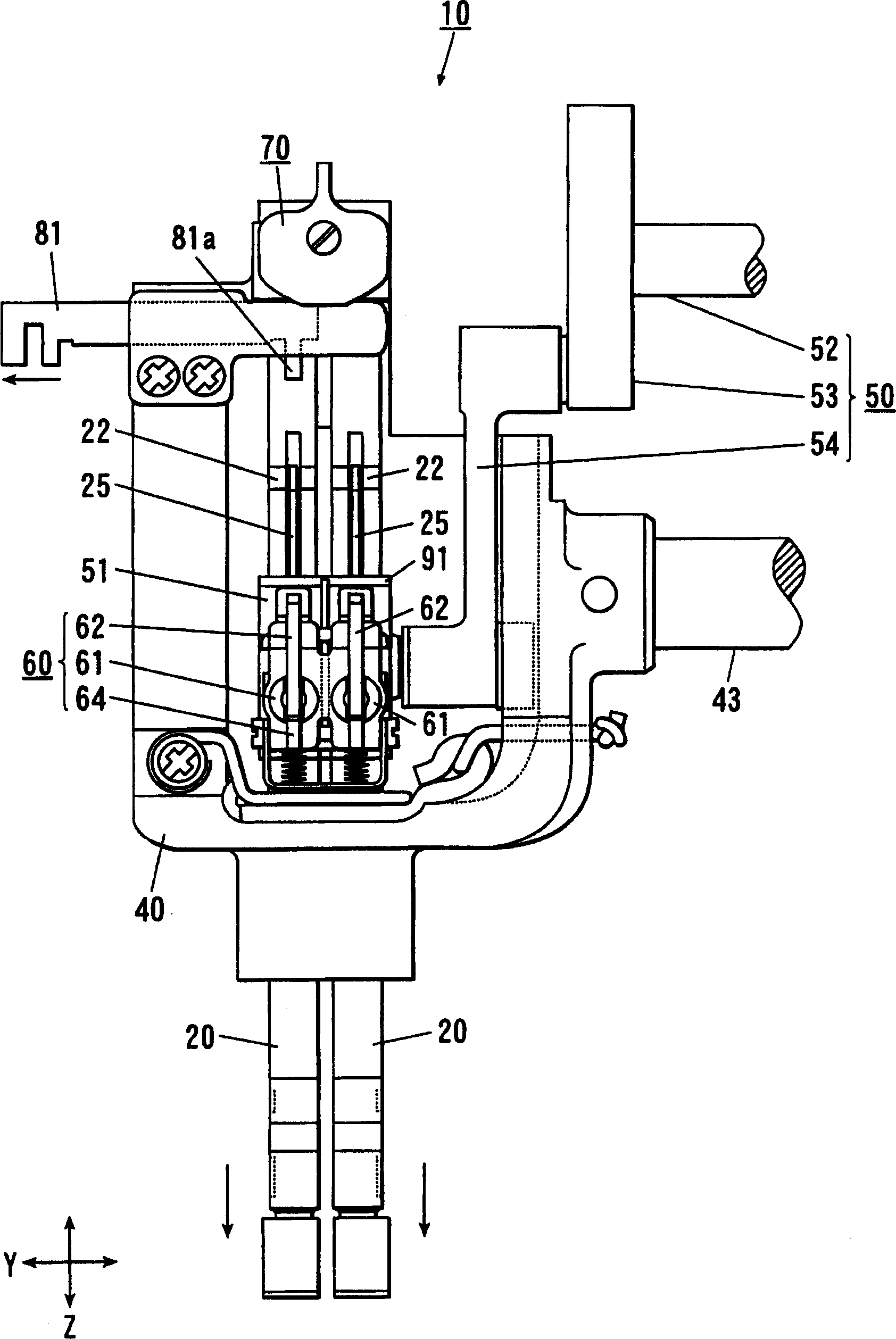

Needle stem mechanism of double-needle sewing machine

InactiveCN1776066AEven sewingSmooth up and down movementLubrication/cooling devicesNeedle barsBiomedical engineeringClutch

A needle bar mechanism for a double-needle sewing machine, comprising: a needle bar support body (40) supporting a pair of needle bars (20) capable of moving up and down; A needle bar up and down movement mechanism (50) for each needle bar to move up and down; a clutch mechanism (60) equipped with a plurality of input parts (62, 66) that accept the holding and release input of each needle bar; a switching part (81), the switching Parts (81) are selectively docked on each input part that carries out the lifting action and carry out the switching of holding or releasing the needle bar; and also have a grease supply mechanism (91), and the grease supply mechanism (91) is set On the needle bar abutment, at the same time, it is used to supply grease to the sliding parts of the needle bar abutment and each needle bar. The needle bar mechanism of this double needle sewing machine increases the durability of the unit.

Owner:JUKI CORP

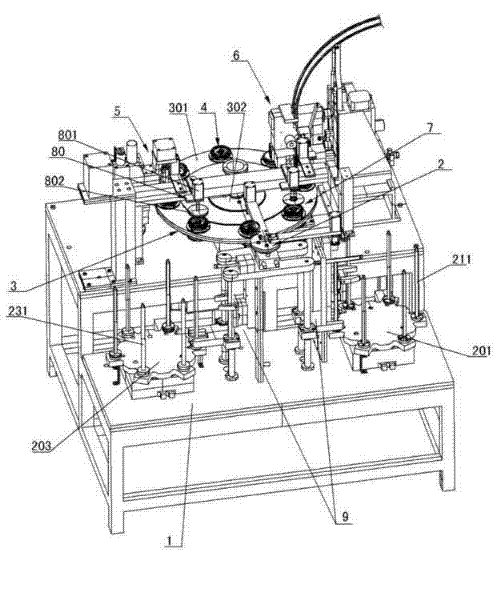

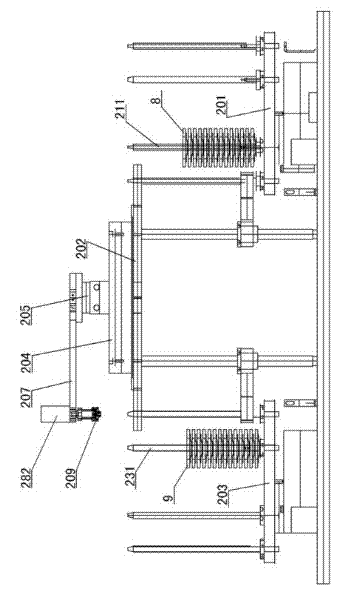

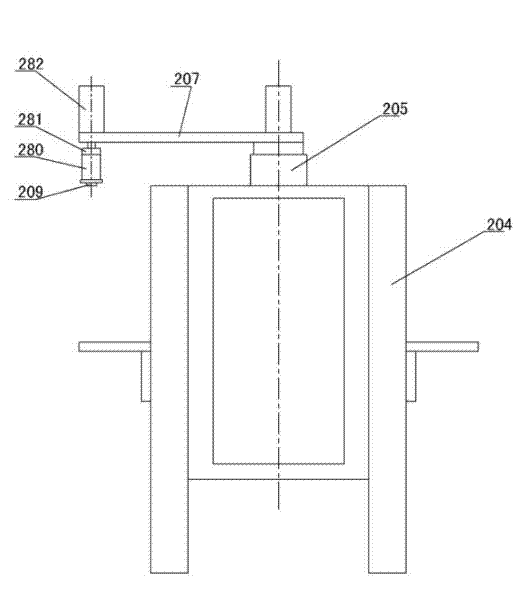

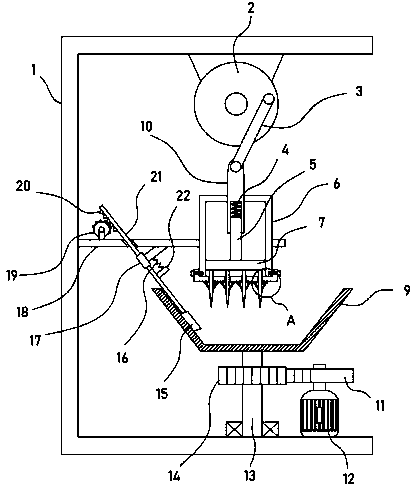

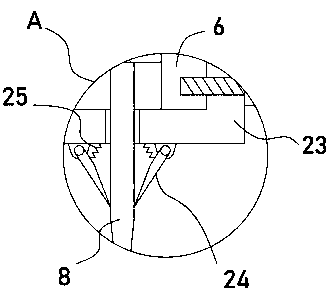

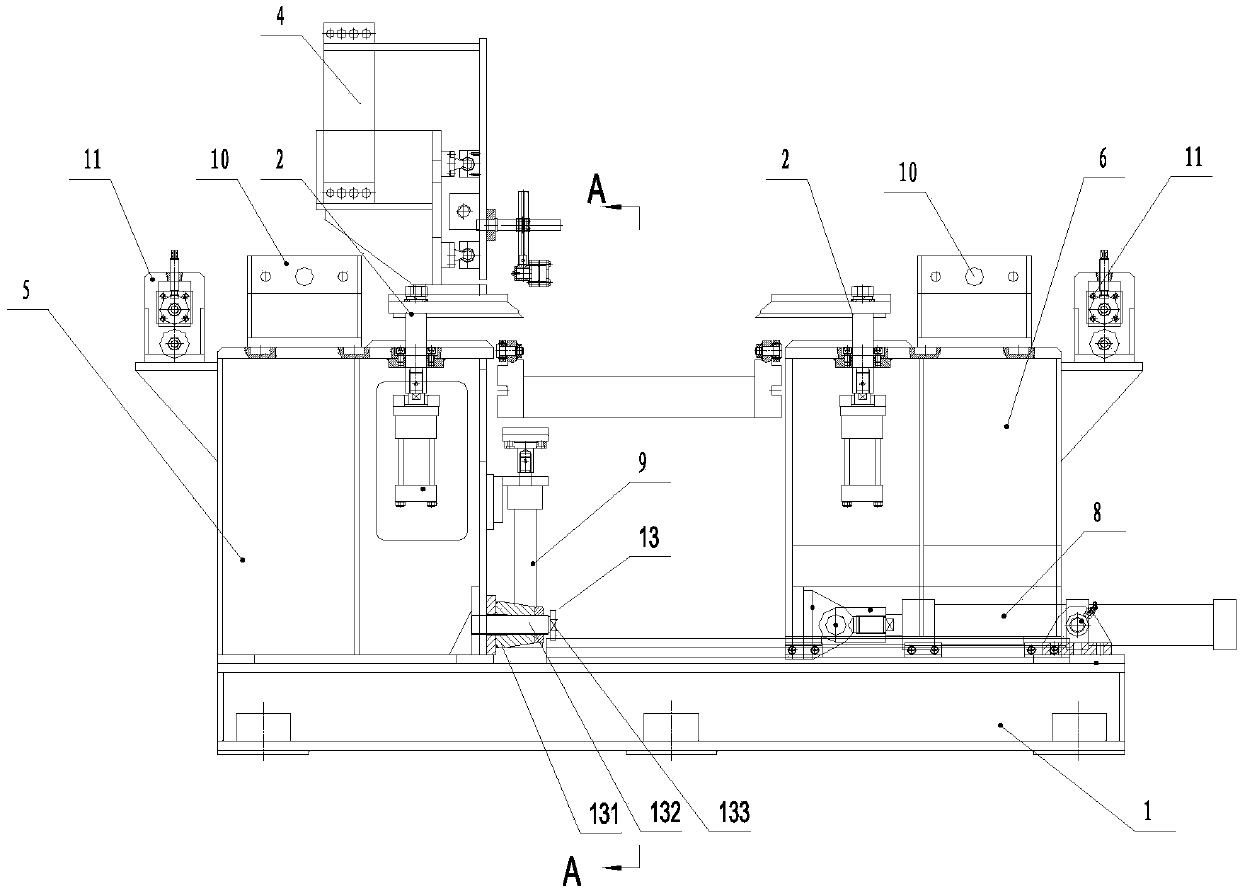

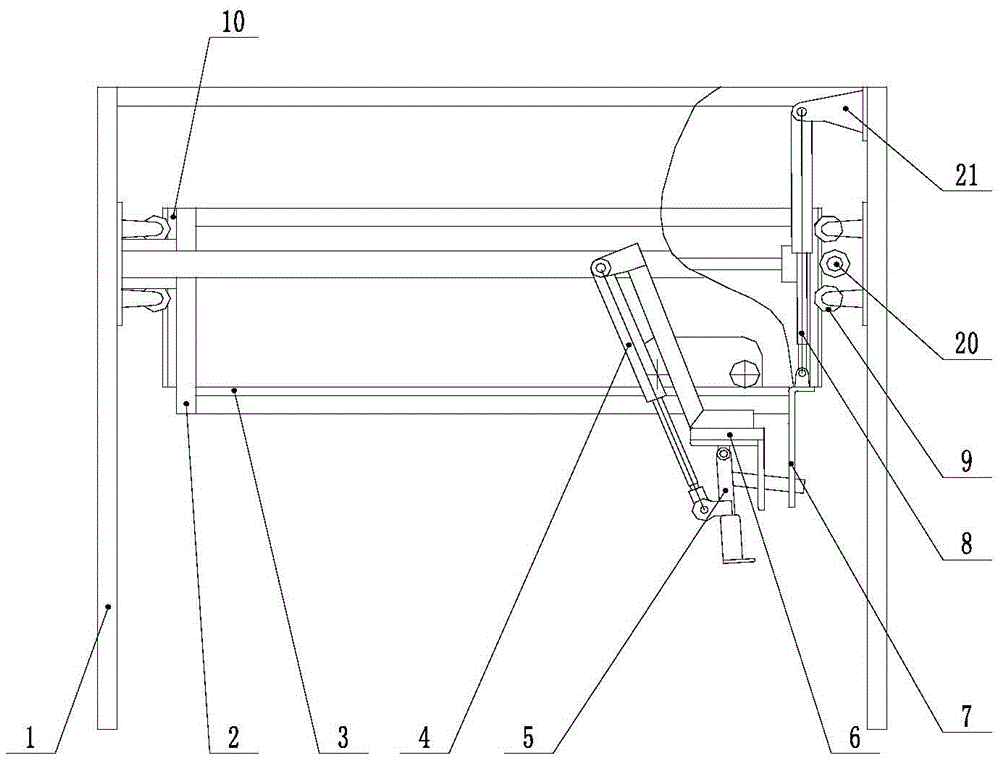

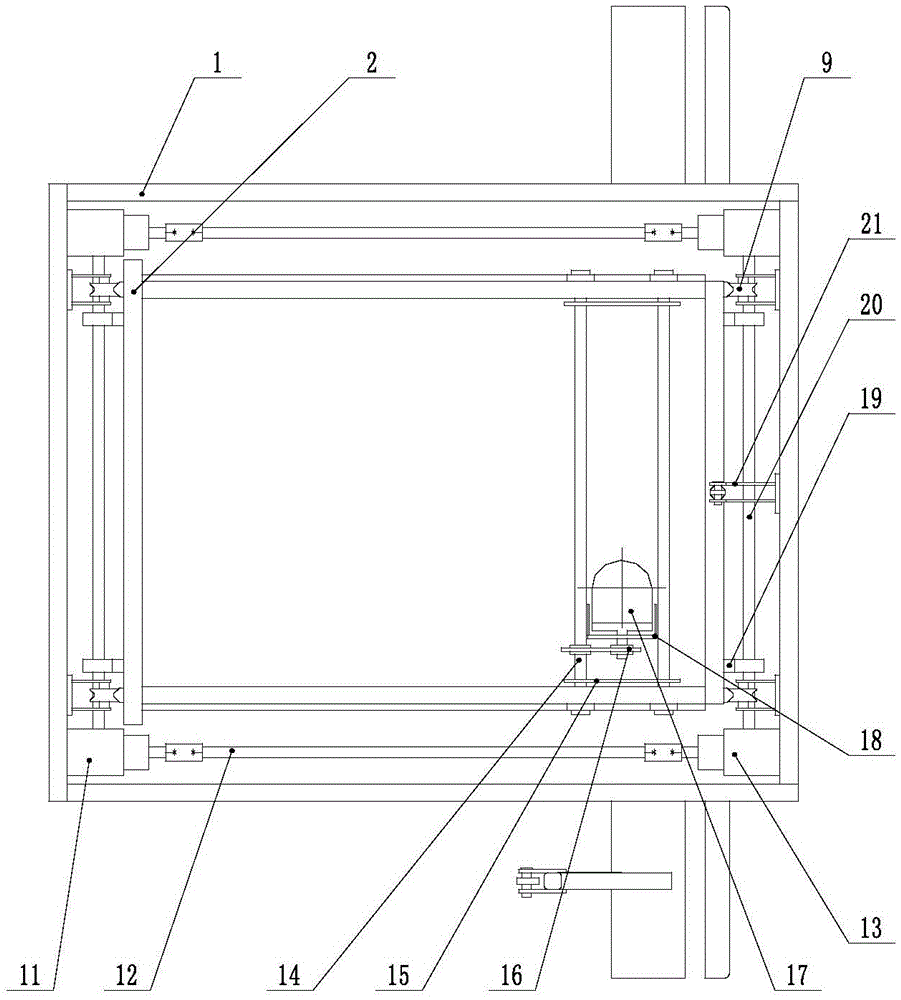

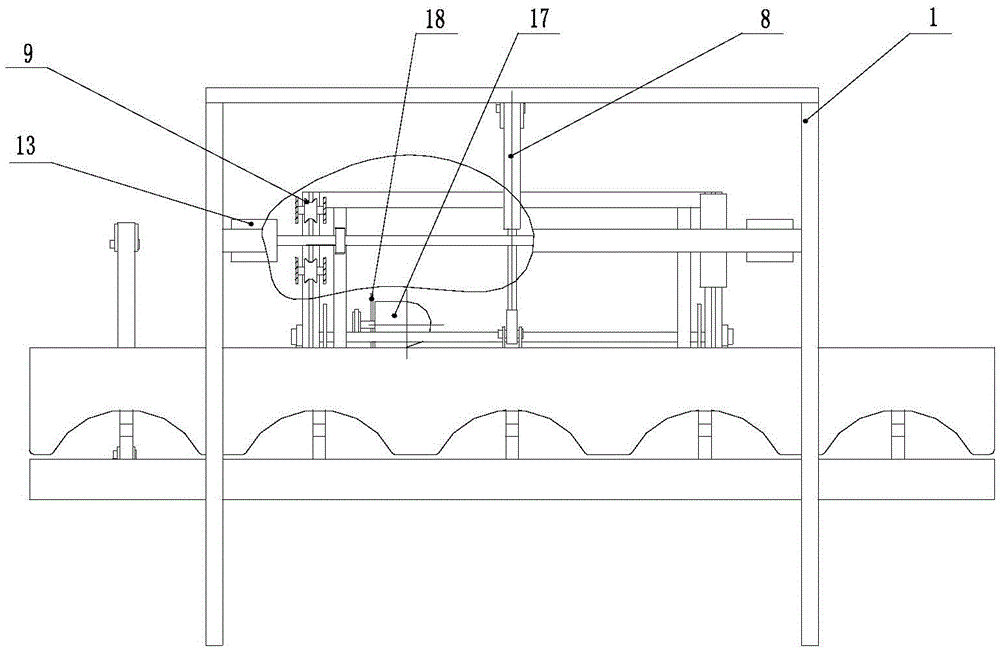

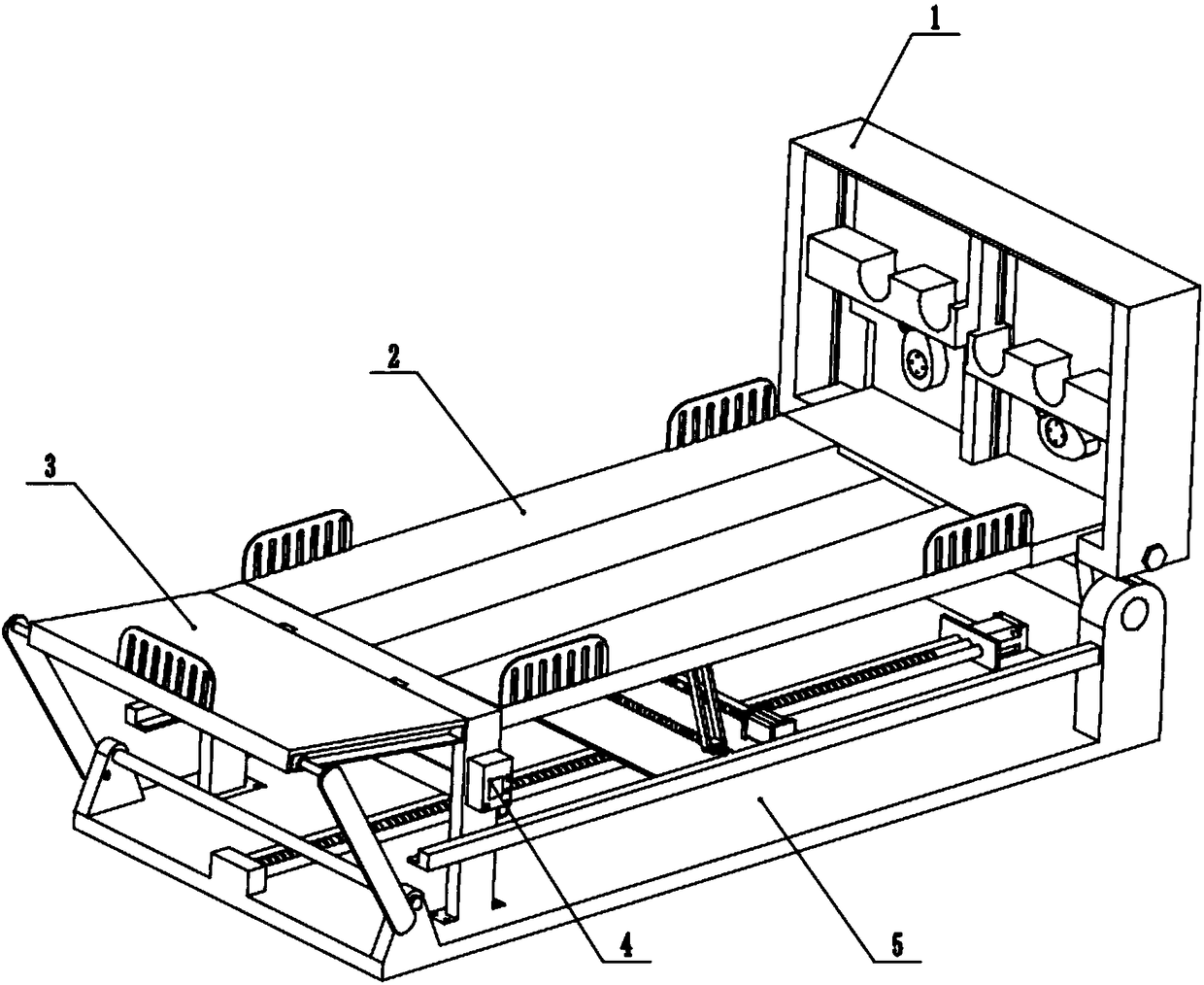

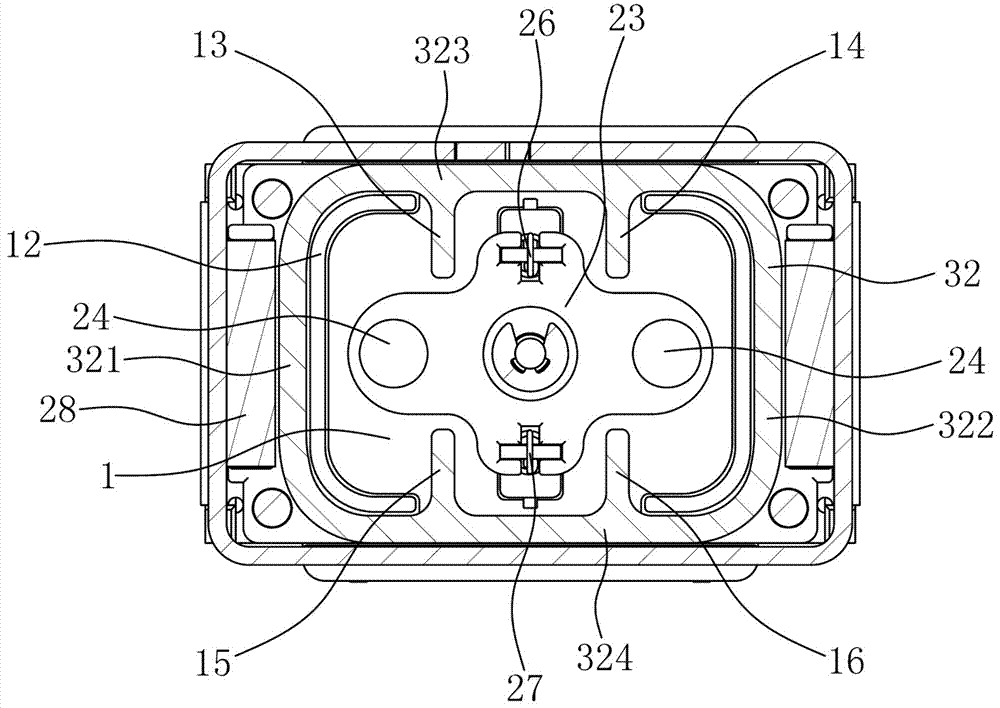

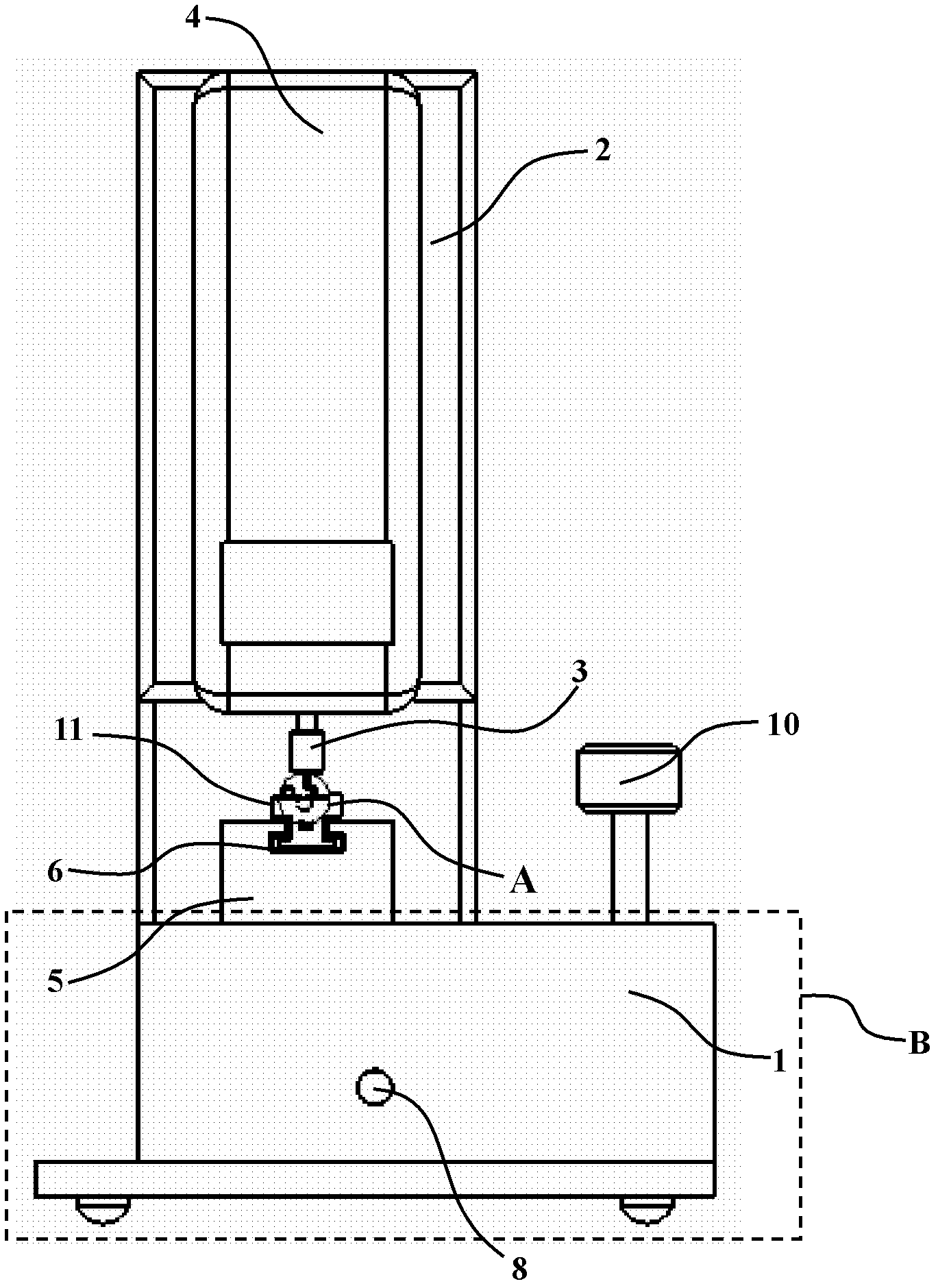

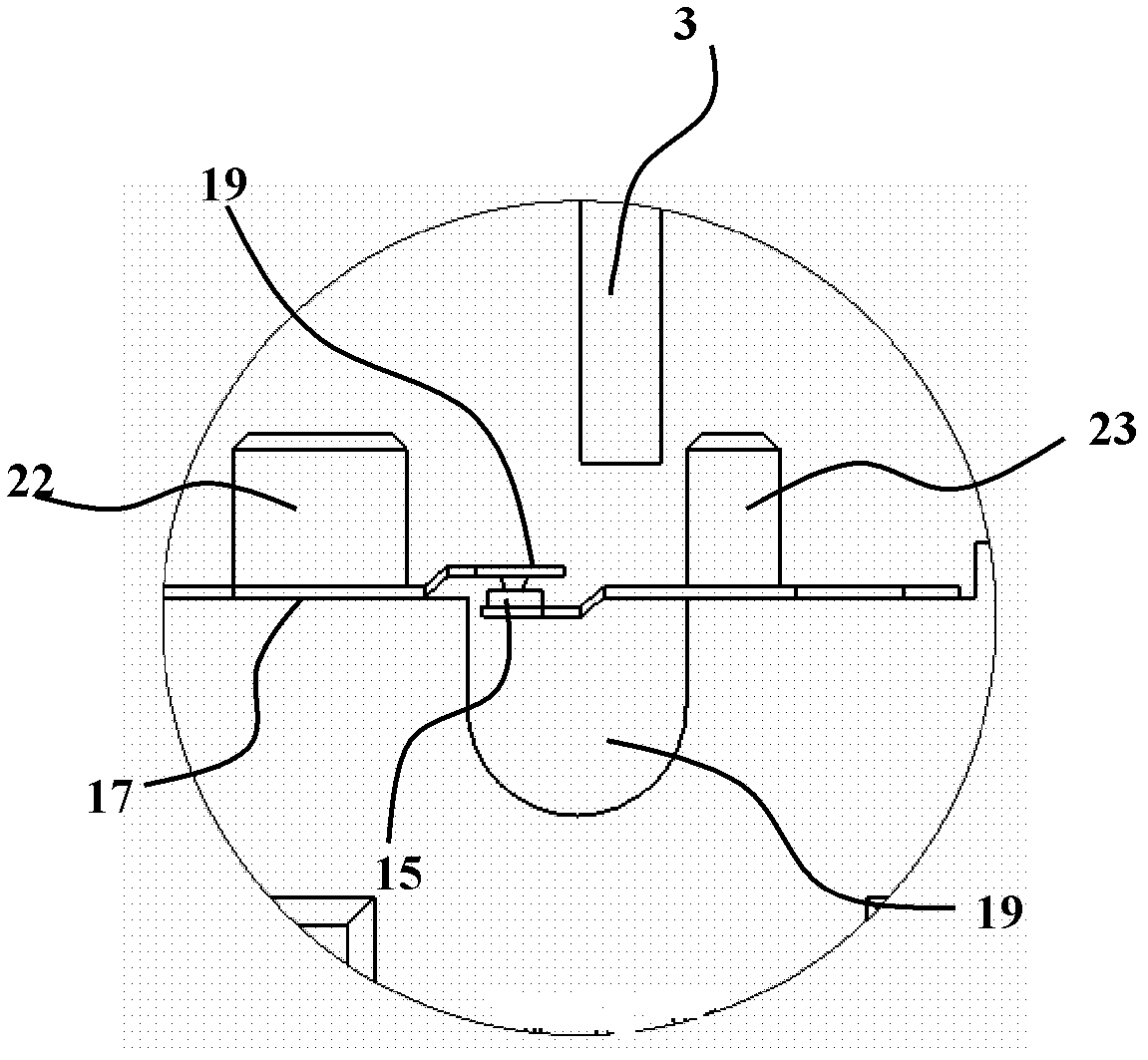

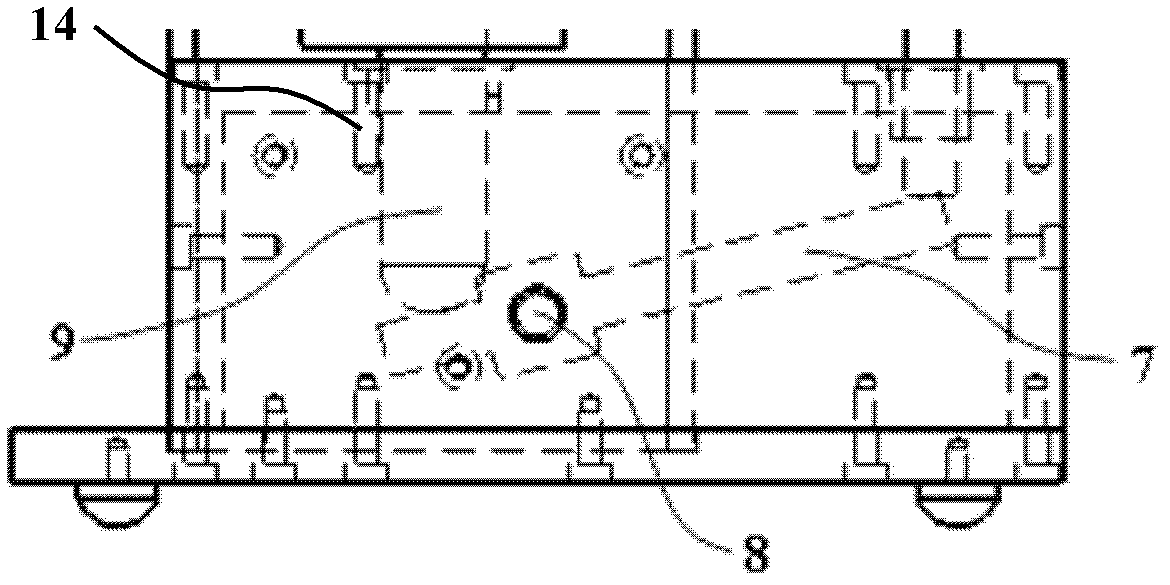

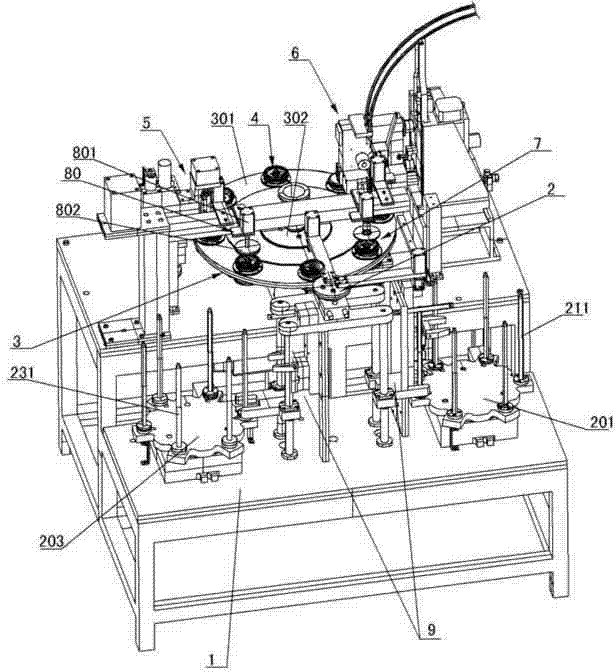

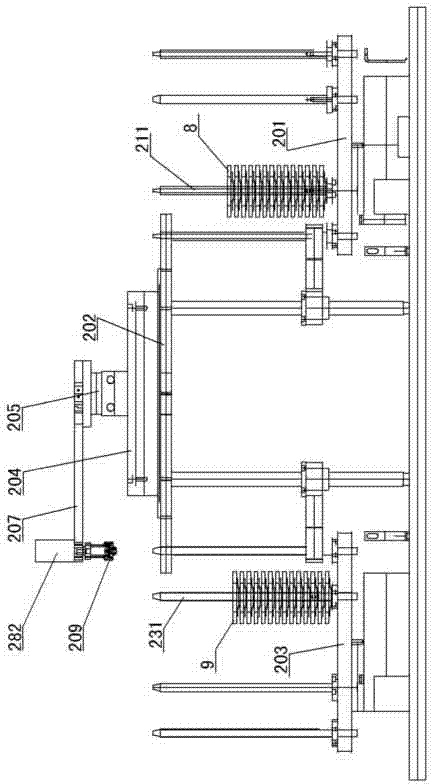

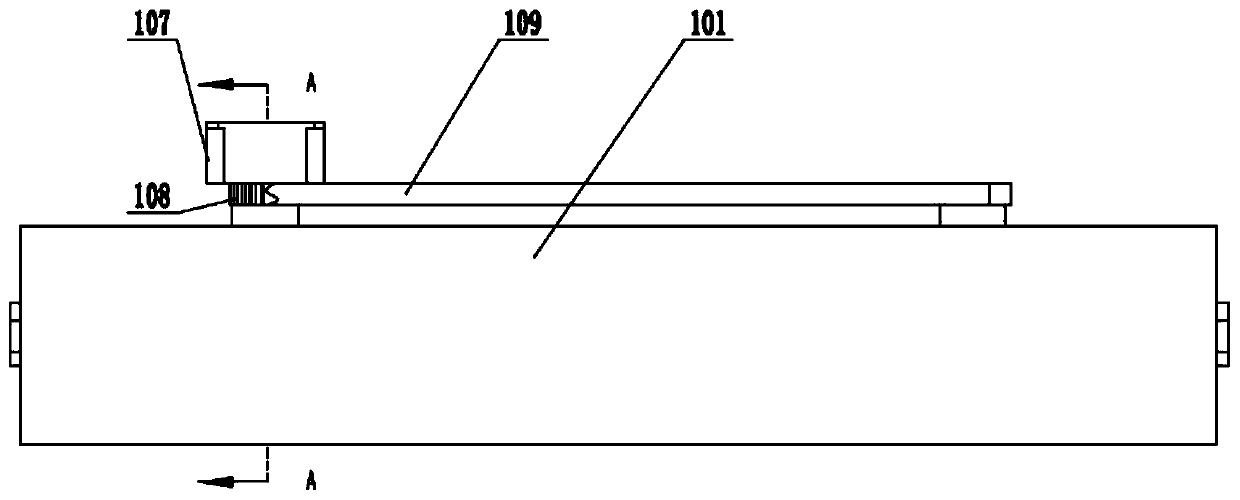

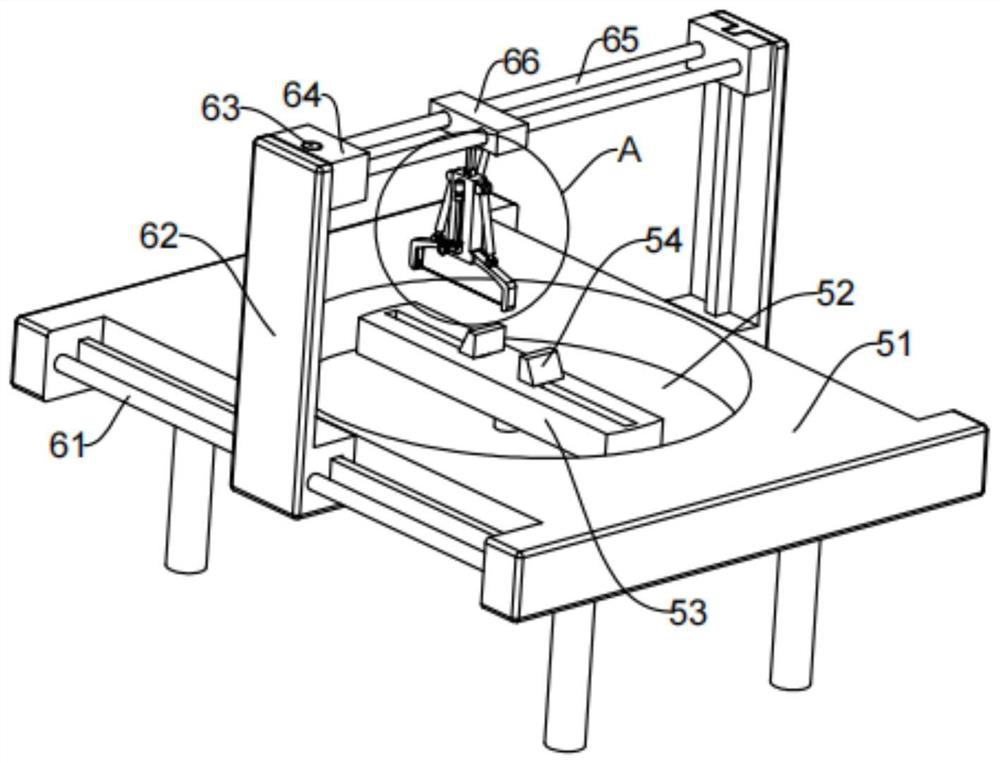

Full-automatic abrasive cloth flap disc machining equipment

The invention discloses full-automatic abrasive cloth flap disc machining equipment, which comprises a frame; a feeding and discharging storage mechanism of a flap disc, a conveying rotary device, a flap disc autorotation mechanism, a glue dripping device, a slice mounting device and a reshaping mechanism are arranged on the frame; and when the machining equipment works, the flap disc is fetched and placed on the flap disc autorotation mechanism arranged on the conveying rotary device by the feeding mechanism of the flap disc, a small turntable and the flap disc are driven by a main turntableto rotate below the glue dripping device, the glue dripping device drips glue to the flap disc, then the main turntable continuously rotates to drive the flap disc coated with the glue to rotate below the slice mounting device, the slice mounting device slices an abrasive cloth tape, the slices are stuck to the flap disc coated with the glue, the main turntable continuously rotates to drive the flap disc stuck with abrasive cloth sheets to rotate below a reshaping device, the flap disc is reshaped by the reshaping device, finally, the main turntable drives the finished flap disc to rotate below the discharging storage mechanism, the finished disc is grabbed and discharged by the discharging storage mechanism, and machining of the whole process is finished.

Owner:台州市黄岩豪林抛光磨具有限公司

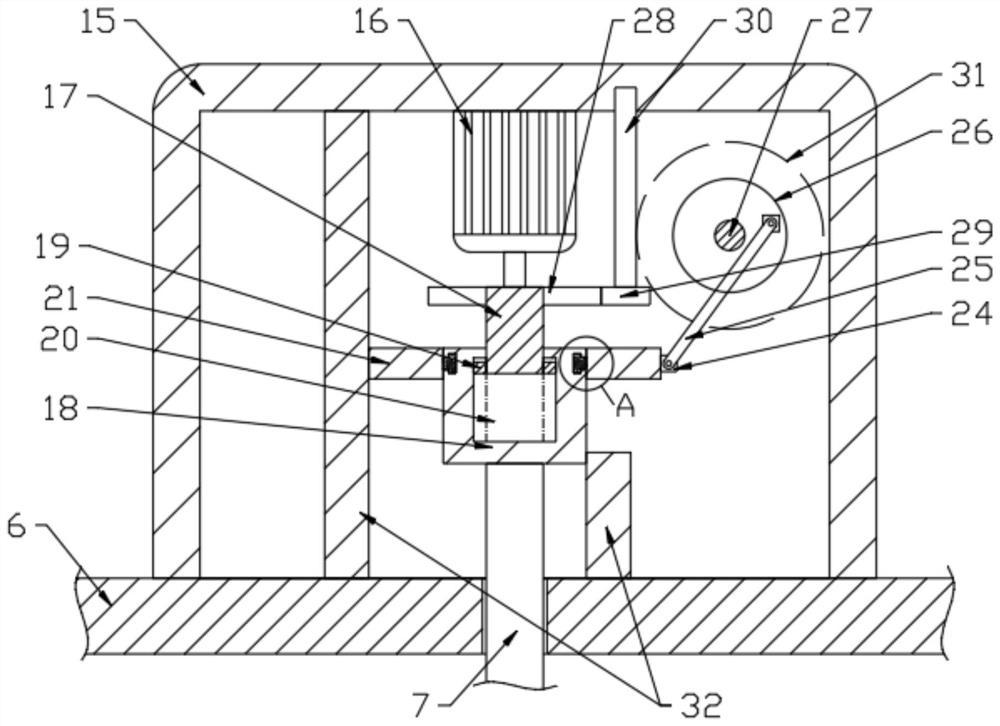

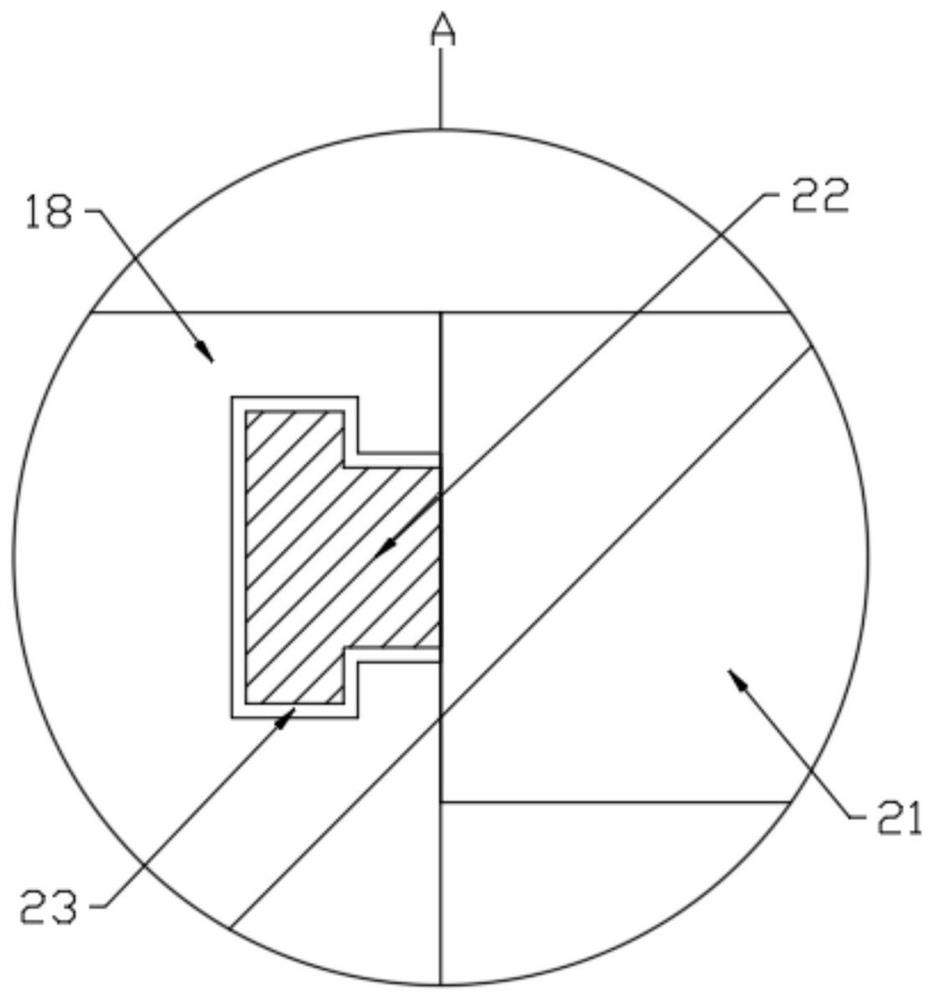

Meat stuffing chopping device for food processing

The invention discloses a meat stuffing chopping device for food processing, and relates to the technical field of food processing machinery. The device comprises an operation frame, and a meat mincing groove is rotationally formed in the operation frame; a chopping mechanism is arranged on the meat mincing groove and comprises a plurality of crushing knives uniformly fixed at the bottom of a knife holder; a bottom plate for allowing the crushing knives to slide through is arranged below the knife holder, a scraper which abuts against the crushing knives is hinged to the bottom of the bottom plate, and the crushing knives are eccentrically installed in the meat mincing groove. The crushing knives are driven by the knife holder to move up and down to conduct repeated cutting and crushing onmeat in the meat mincing groove, and the meat mincing groove can be intermittently rotated so that meat in the meat mincing groove can comprehensively and repeatedly chopped; the minced meat adheringto the side walls of the crushing knives can be fully scraped away by the scraper, so that the up-down movement of the crushing knives is smoother, and the meat chopping effect is improved. The arranged scraper can scrape away meat blocks adhering to the inner wall of the meat mincing groove, so that the meat is more thoroughly chopped.

Owner:JIANGSU FOOD & PHARMA SCI COLLEGE

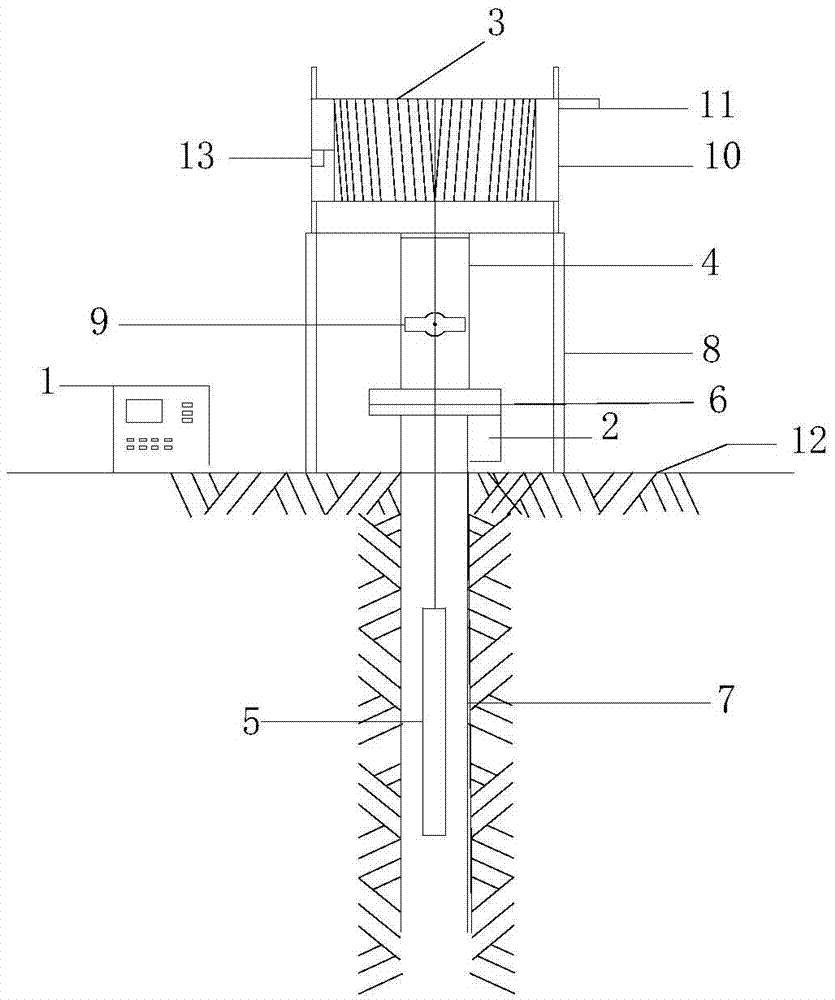

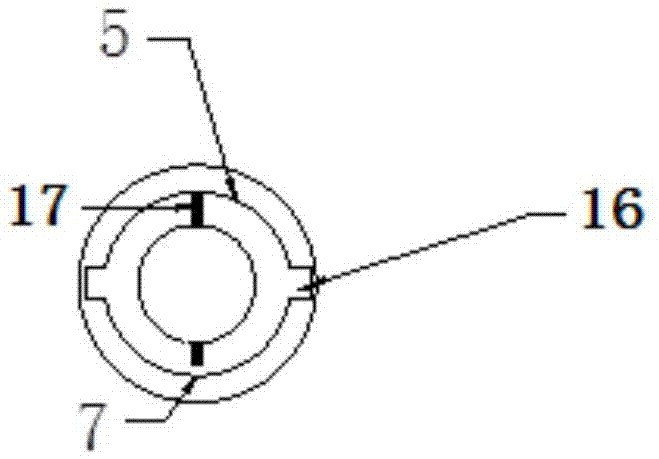

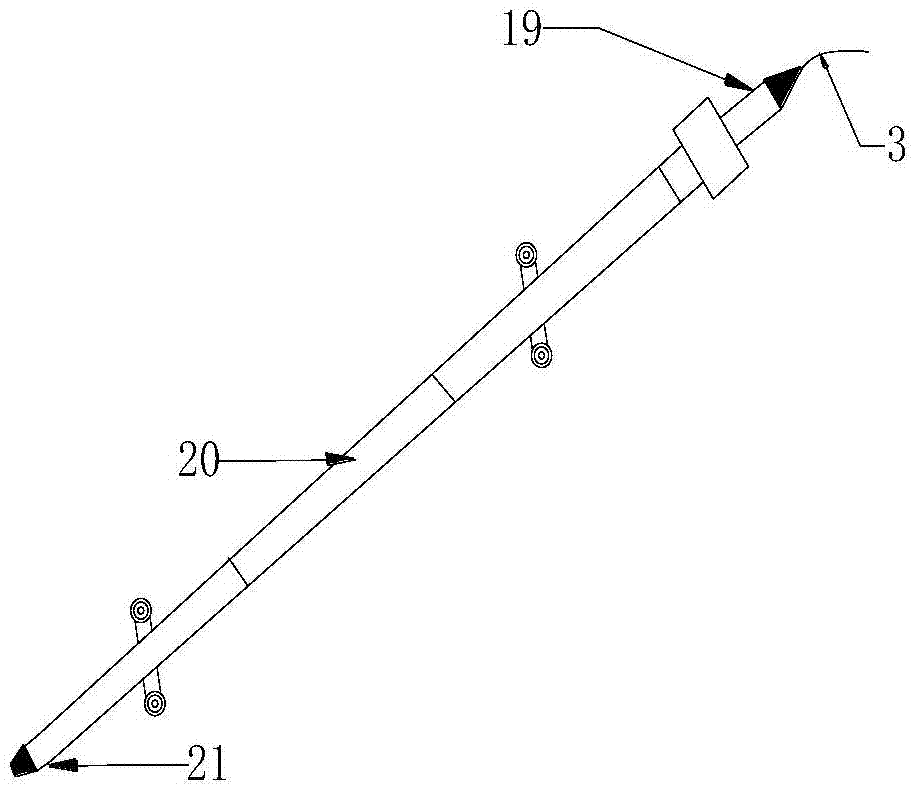

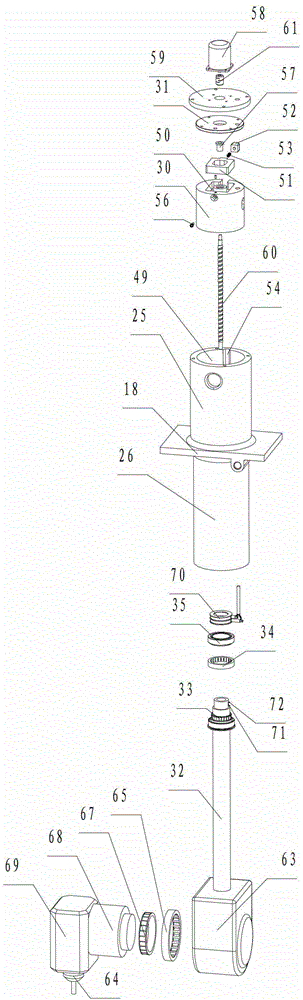

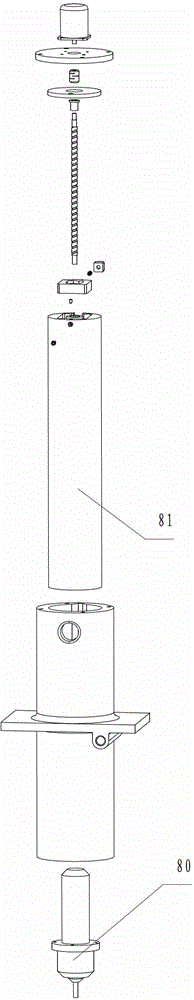

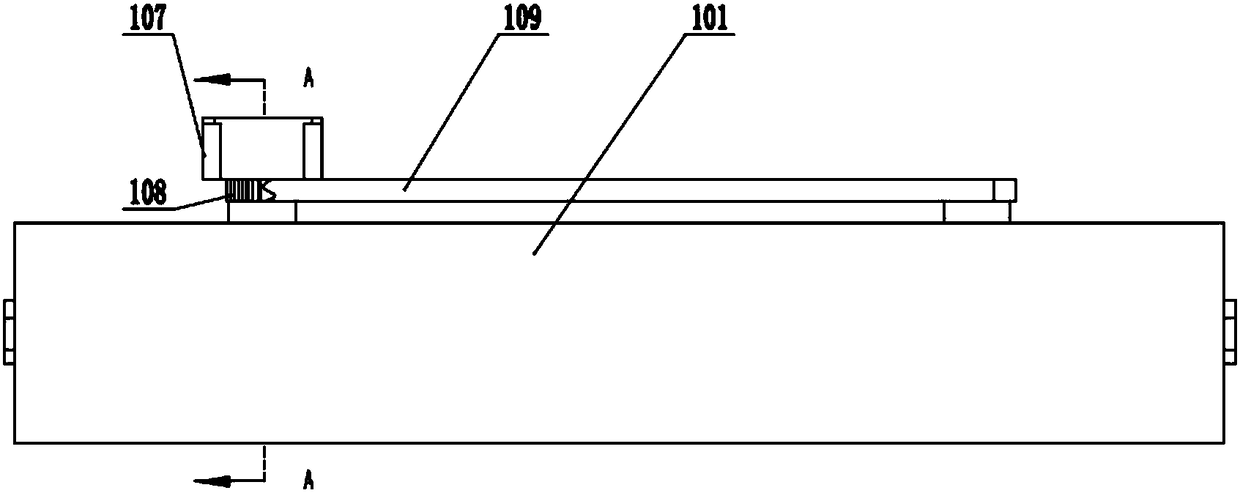

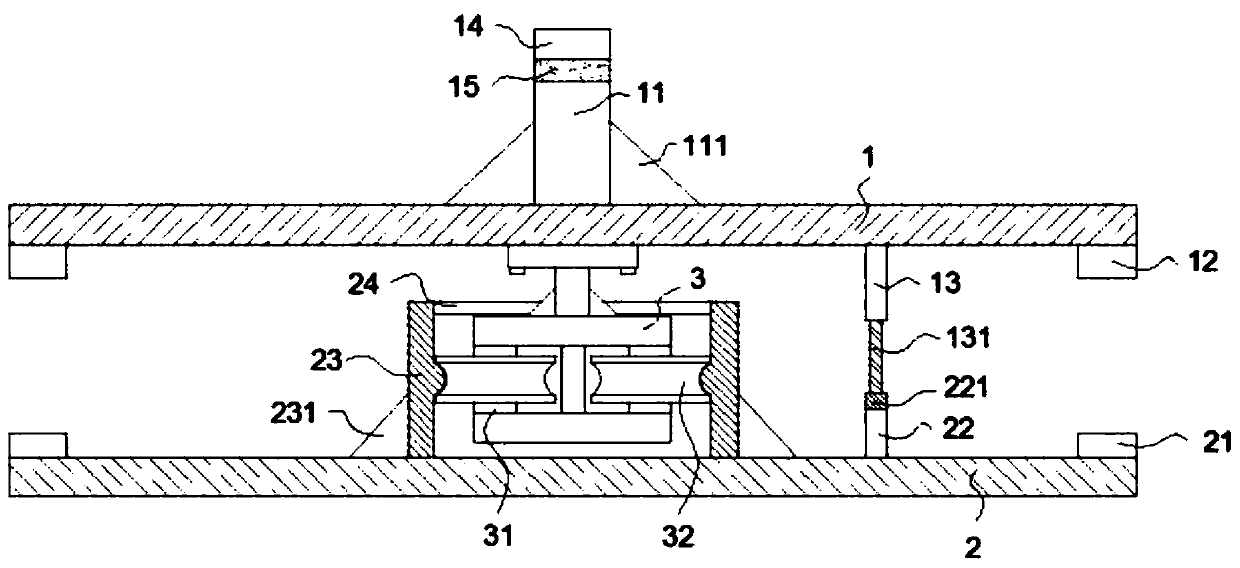

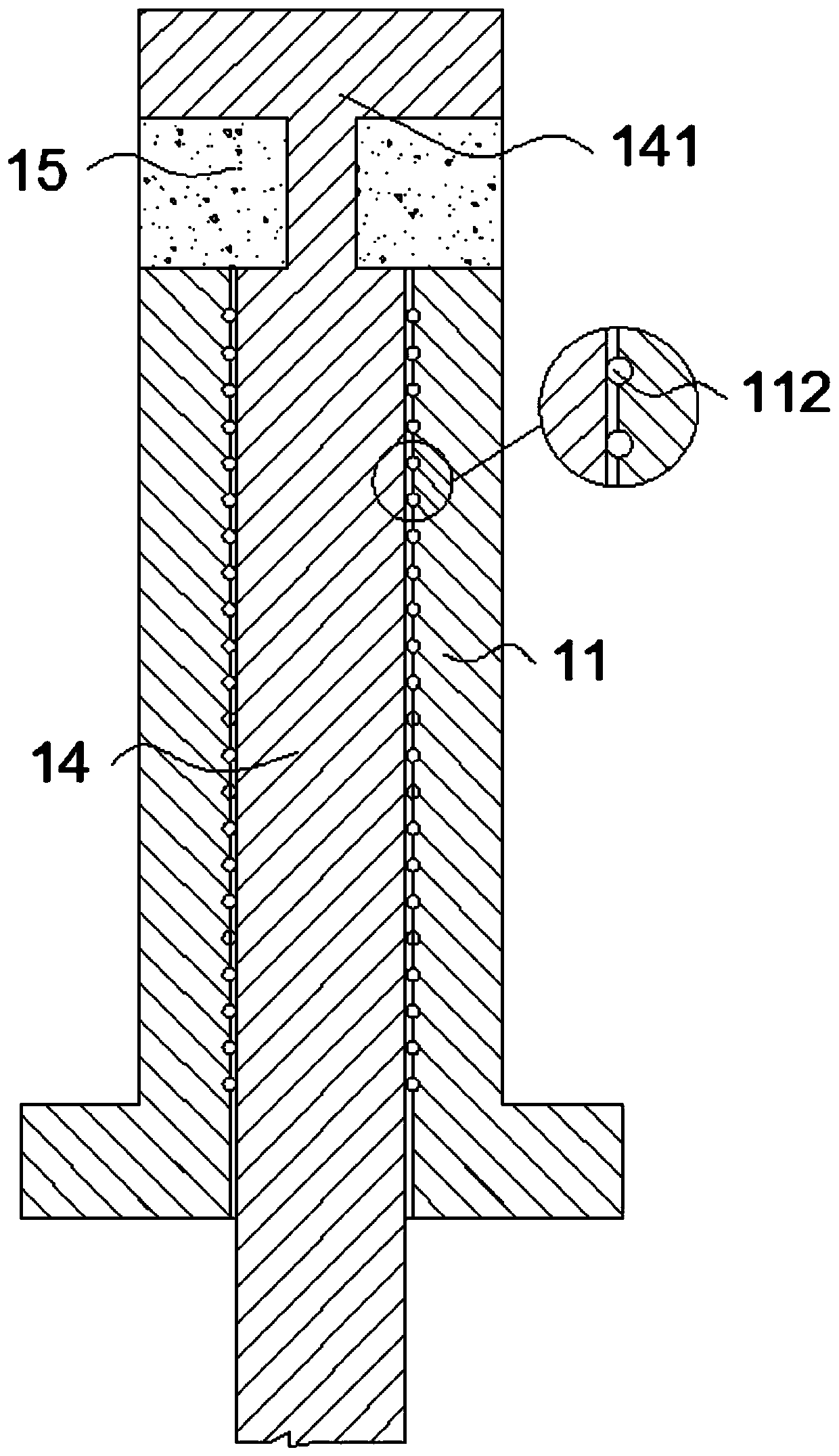

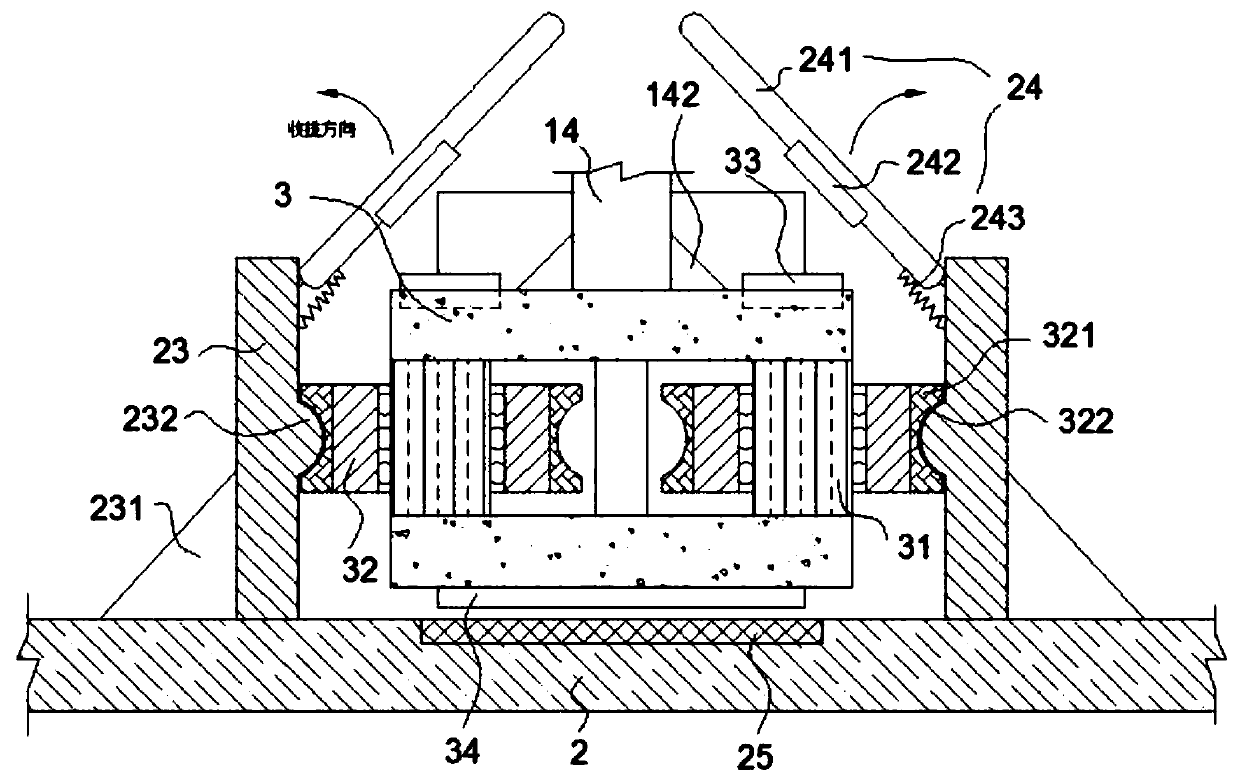

Method for measuring horizontal displacement of stratum through movable inclinometer and movable inclinometer

InactiveCN105444738ASmooth up and down movementImprove accuracySurveying instrumentsIncline measurementCost (economic)Inclinometer

The invention discloses a method for measuring horizontal displacement of a stratum through a movable inclinometer. The movable inclinometer is used for measuring total horizontal displacement and horizontal shift displacement, and the horizontal displacement of the stratum is calculated according to measurement numerical values. The invention further discloses the movable inclinometer. The movable inclinometer comprises a measurement reader, a GPS position finder, an inclinometer tube, an inclinometer cable, a cable support and a GPS position finder connecting sleeve. The measurement reader is located on one side of the inclinometer tube, the measurement reader and the inclinometer tube are independently arranged, the inclinometer cable is installed on the cable support, the GPS position finder connecting sleeve is fixed to the upper end of the inclinometer tube, one end of the inclinometer cable penetrates through the GPS position finder connecting sleeve and is connected with a movable probe in the inclinometer tube, at least one GPS position finder is arranged on the GPS position finder connecting sleeve, and the cable support is provided with Bluetooth used for transmitting signals received by the inclinometer cable to the measurement reader. By means of the method for measuring the horizontal displacement of the stratum through the movable inclinometer and the movable inclinometer, the drilling depth can be effectively reduced, economic cost can be reduced, the measurement data can better conform to field reality, and a more reliable base is provided for slope and foundation pit retaining and protection construction.

Owner:SHANDONG UNIV OF SCI & TECH

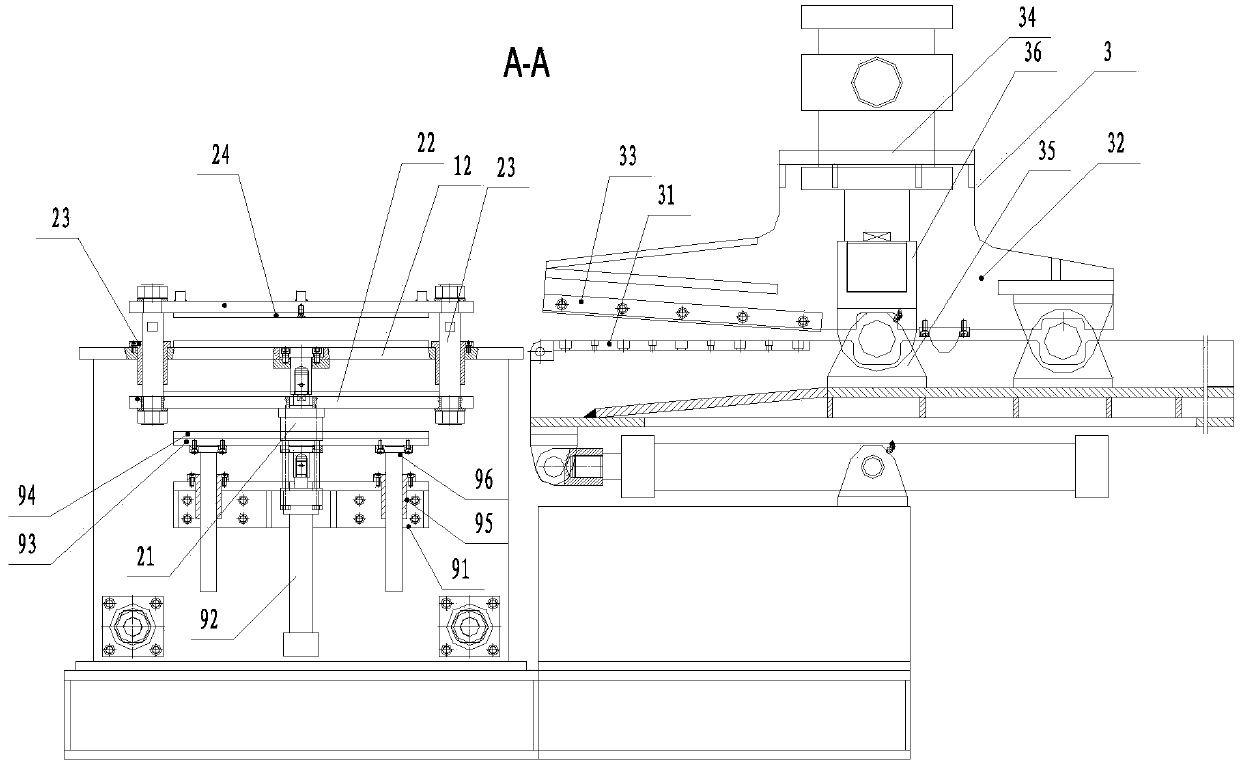

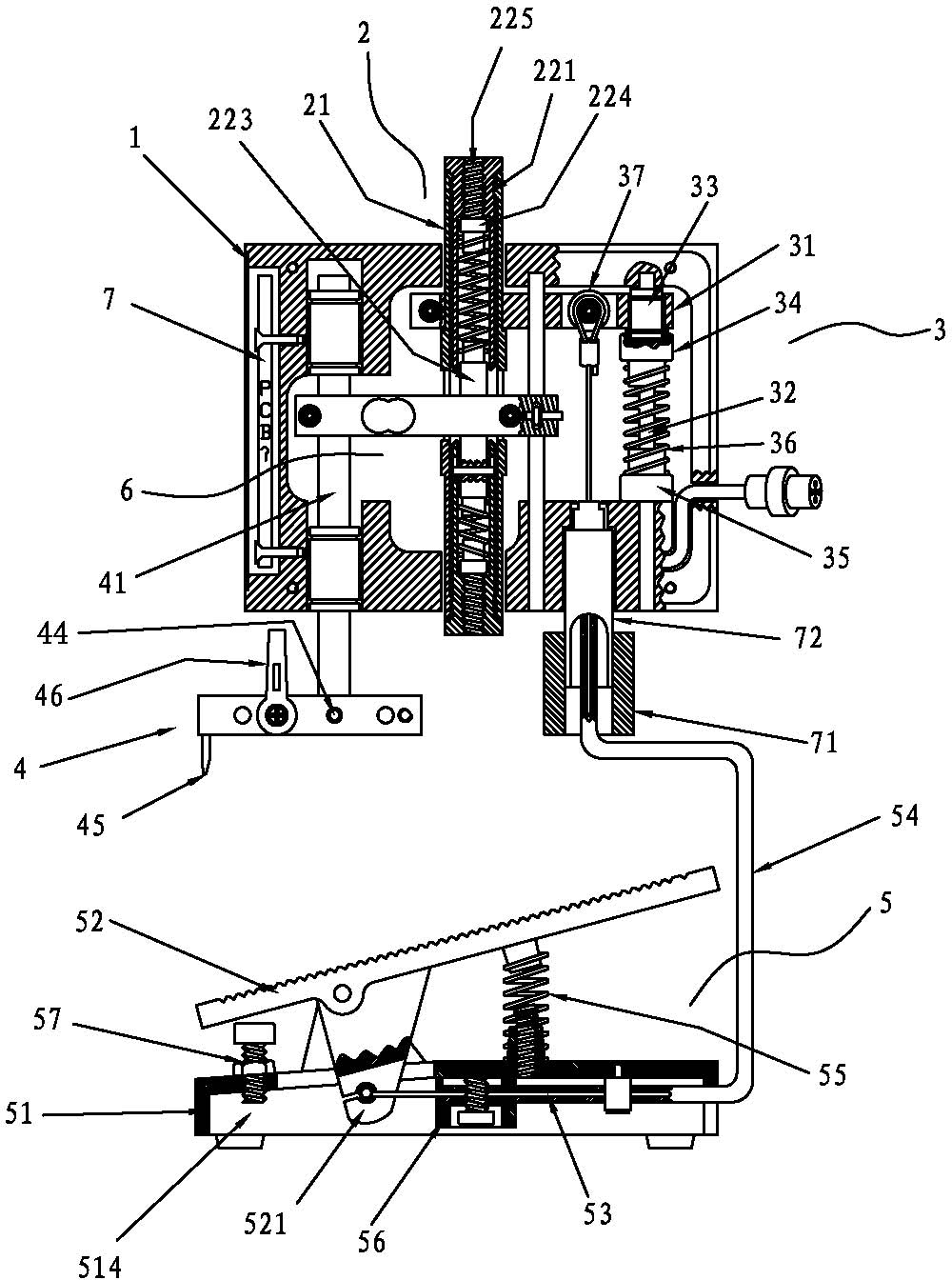

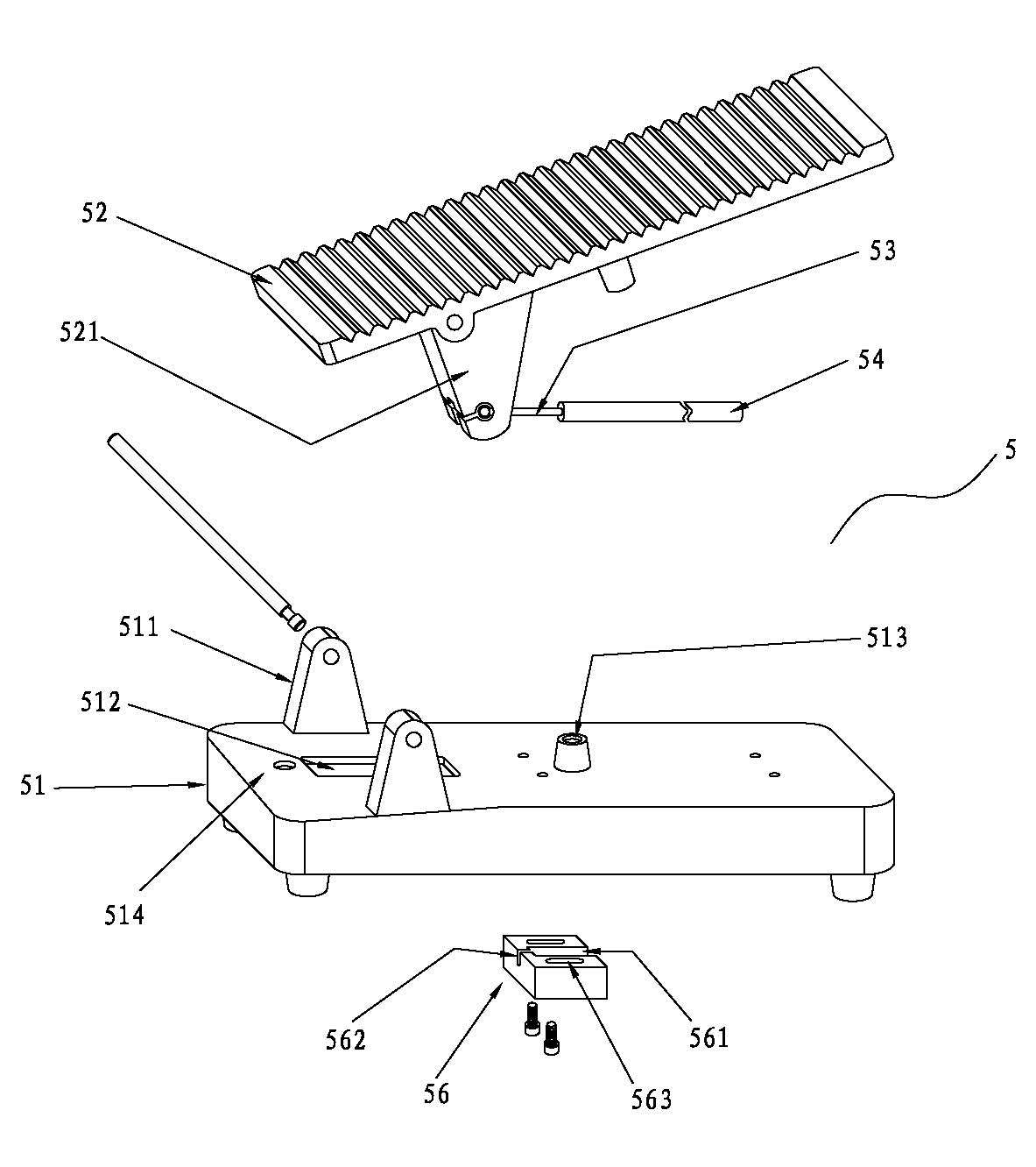

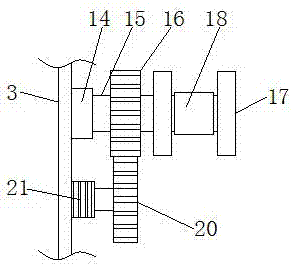

Shearing butt welding machine

InactiveCN103737331ARealize automatic cuttingEasy to press and positionWork clamping meansWelding/cutting auxillary devicesButt weldingEngineering

The invention discloses a shearing butt welding machine. The shearing butt welding machine can automatically shear butt welding steel strips and comprises a base, a left compressing mechanism, a right compressing mechanism, a shearing mechanism and a welding mechanism. The left compressing mechanism and the right compressing mechanism are arranged on the base, and the shearing mechanism and the welding mechanism are arranged on the base. The base is provided with an installation seat and a sliding seat, wherein the installation seat and the sliding seat are oppositely arranged. The left compressing mechanism and the welding mechanism are arranged on the installation seat, and the right compressing mechanism is arranged on the sliding seat. The base is provided with a sliding shearing seat vertically arranged on the installation seat and connected with the sliding seat, and a power device driving the sliding shearing seat. The shearing mechanism is arranged on the sliding shearing seat, and a base plate welding mechanism is movably arranged in the position, below the left compressing mechanism, on the base. The base plate welding mechanism comprises a support arranged on the installation seat, an ejection oil cylinder is arranged on the support in the vertical direction, and the end of a piston rod of the ejection oil cylinder is provided with a base plate.

Owner:江苏中港冶金设备科技有限公司

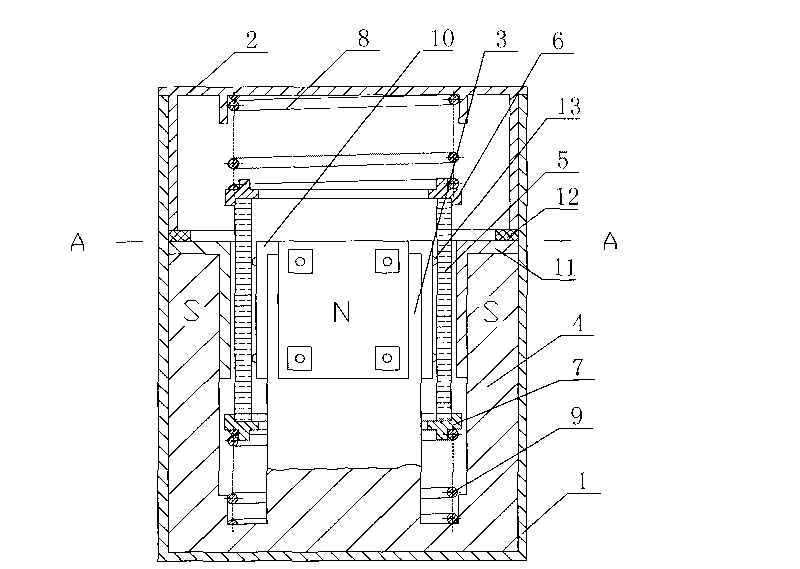

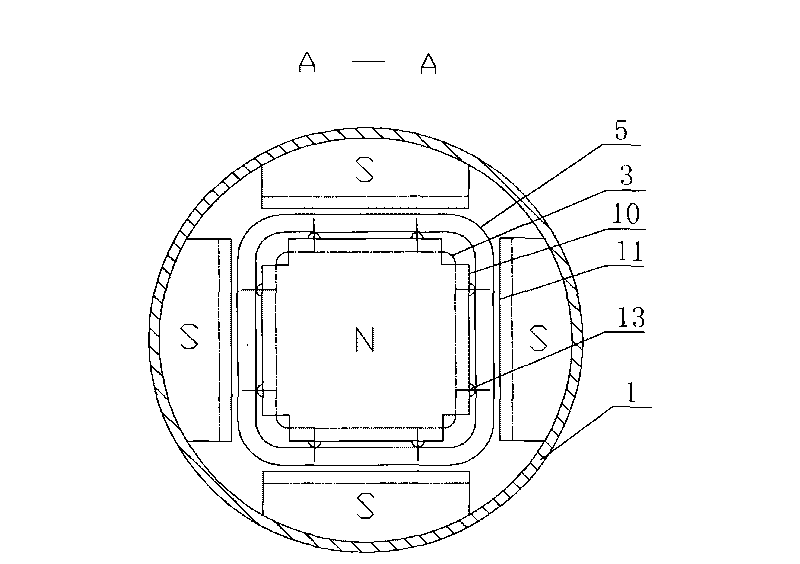

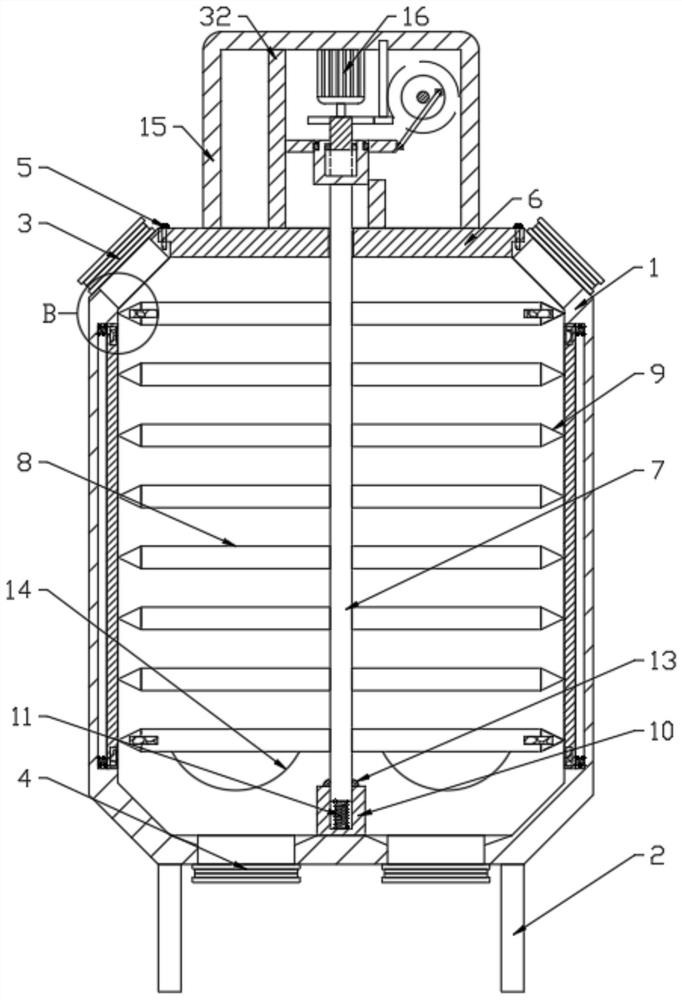

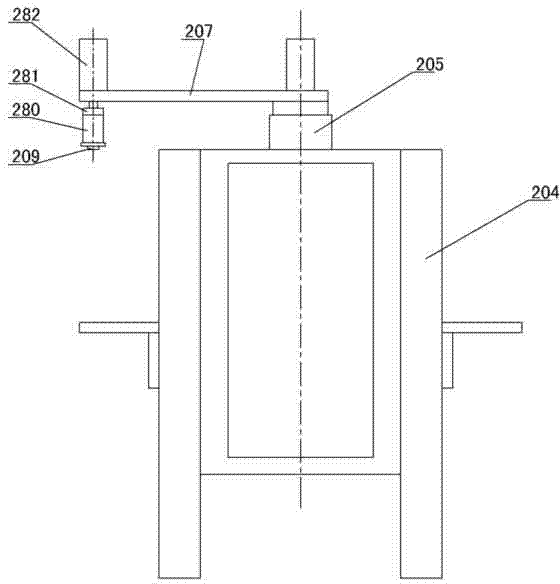

Encircling type vibration generating device

ActiveCN101764495ASmooth up and down movementImprove the efficiency of vibration power generationDynamo-electric machinesElectricityPhysics

The invention relates to an encircling type vibration generating device which comprises a shell, wherein a cover is arranged on the shell; a flower-shaped bonding permanent magnet is arranged in the shell; a square N pole is arranged in the middle of the permanent magnet, and four S poles are arranged around the permanent magnet; a first ferromagnetic material cushion layer and a second ferromagnetic material cushion layer are covered on the S poles and the N pole; the first ferromagnetic material cushion layer is pressed on the S poles through a rubber washer at the lower end of the cover; a coil is installed between the N pole and each of the S poles; square cassette frames which are connected with springs are arranged at the upper end and the lower end of the coil; the lower end of the lower spring is connected with the bottom of each of the S poles, and the upper end of the upper spring is fixed on the cover; a closed main magnetic circuit which starts from the N pole, passes through the second ferromagnetic material cushion layer, air gaps, the first ferromagnetic material cushion layer and the S poles, and then backs to the N pole is formed in the device; and the coil cuts the main magnetic circuit up and down along with the external vibration to generate electricity. The invention has the beneficial effects of improving the utilization ratio of the magnetic circuit and the coil and the generating efficiency, and has compact structure and wide application range.

Owner:日照瑞达建设集团有限公司

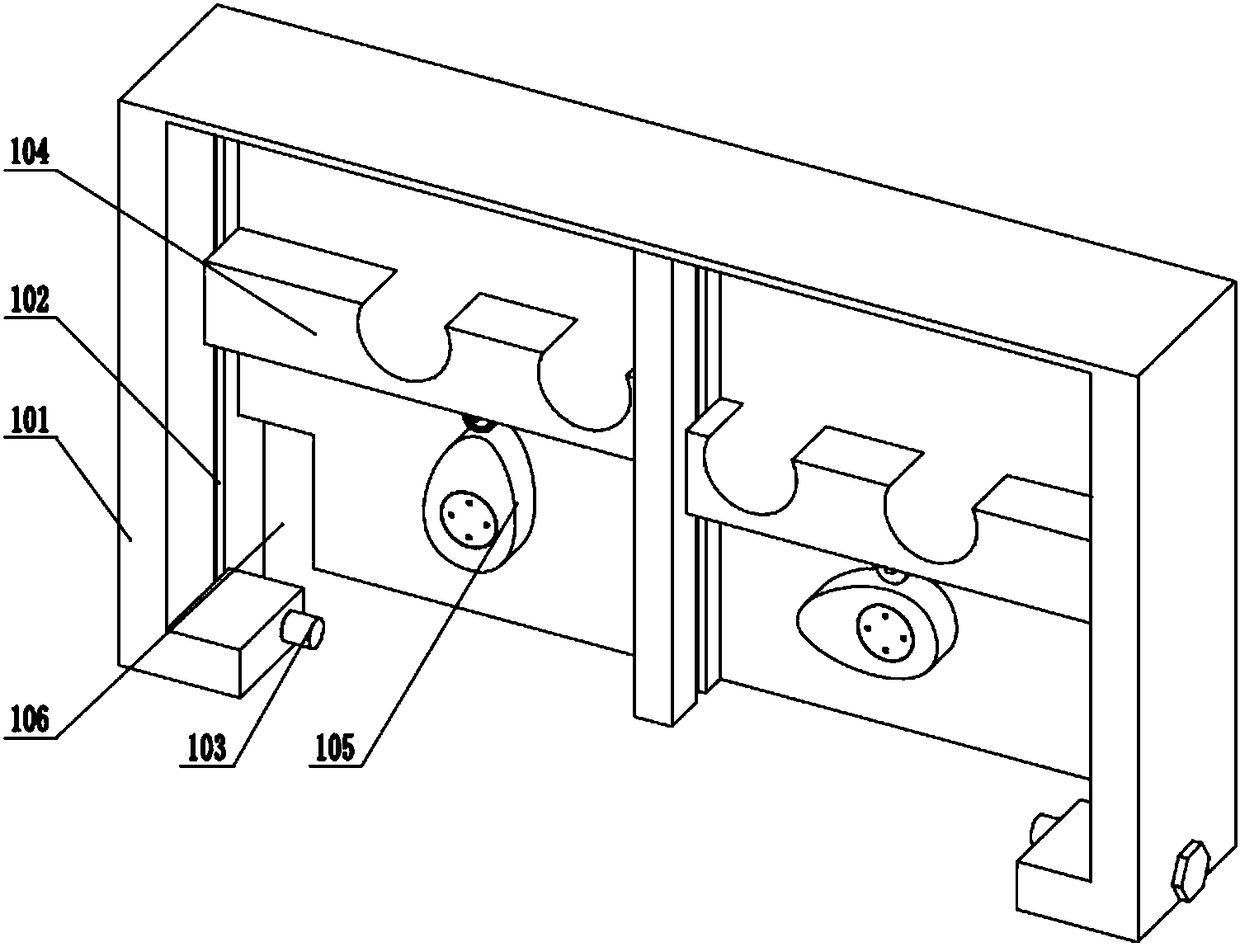

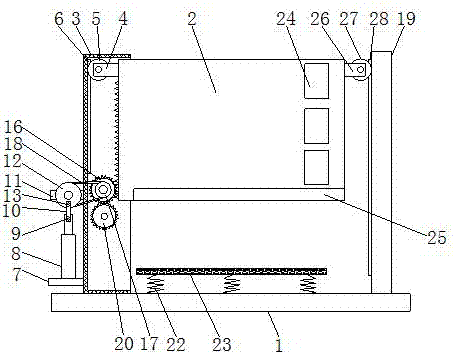

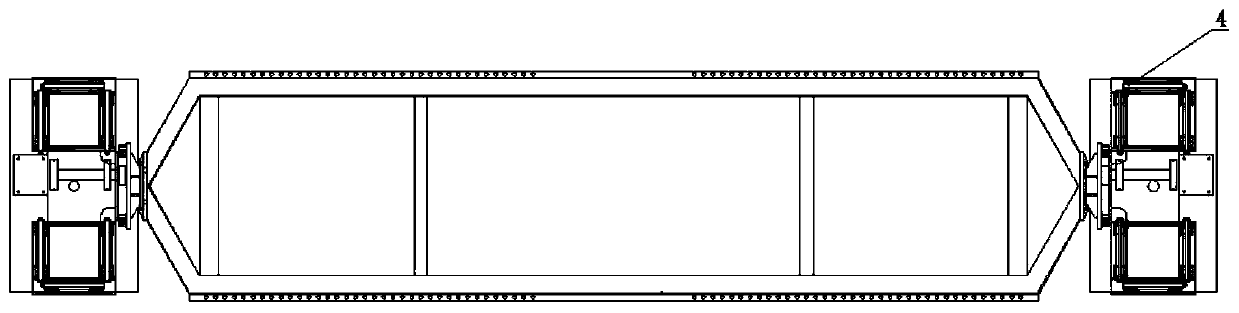

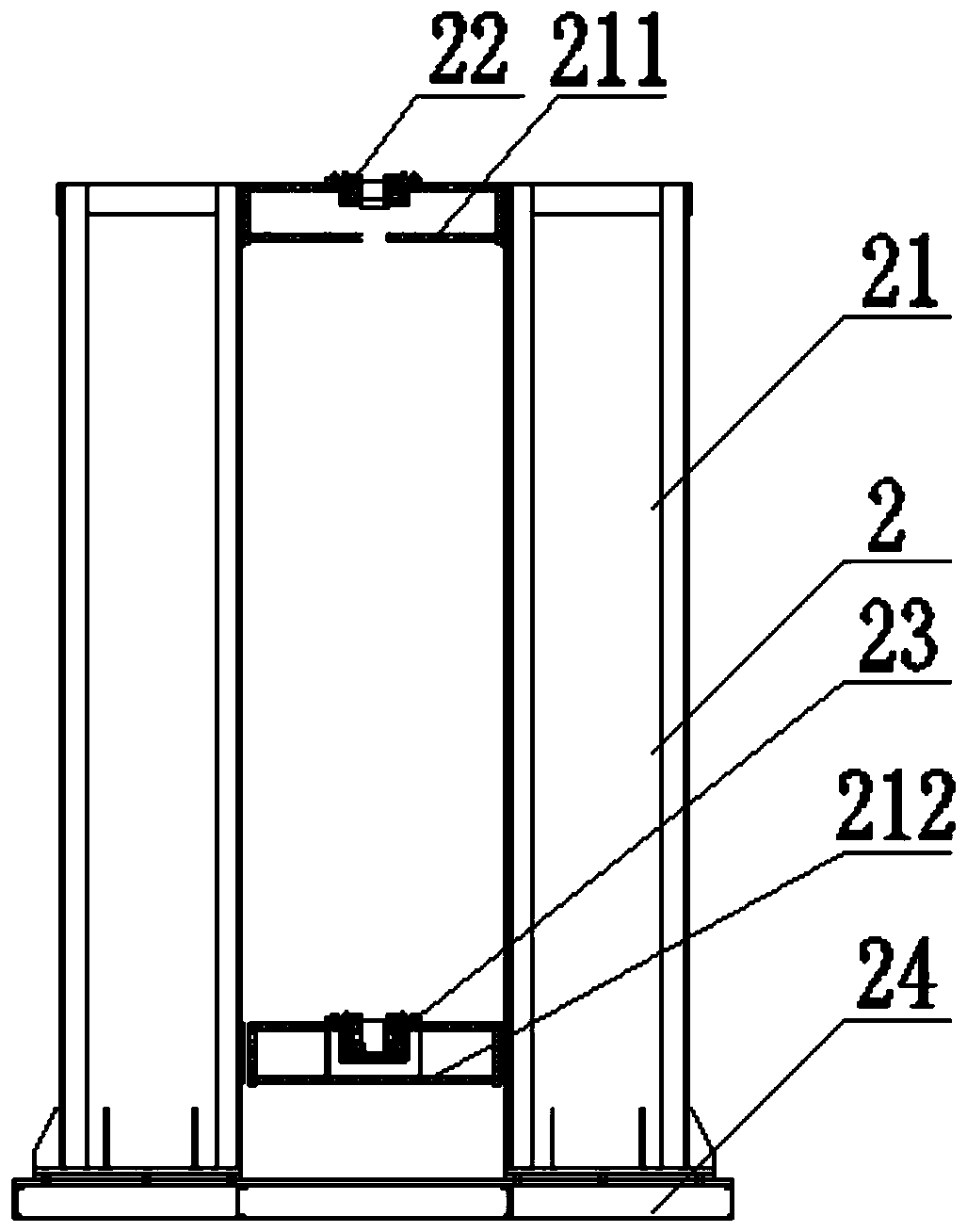

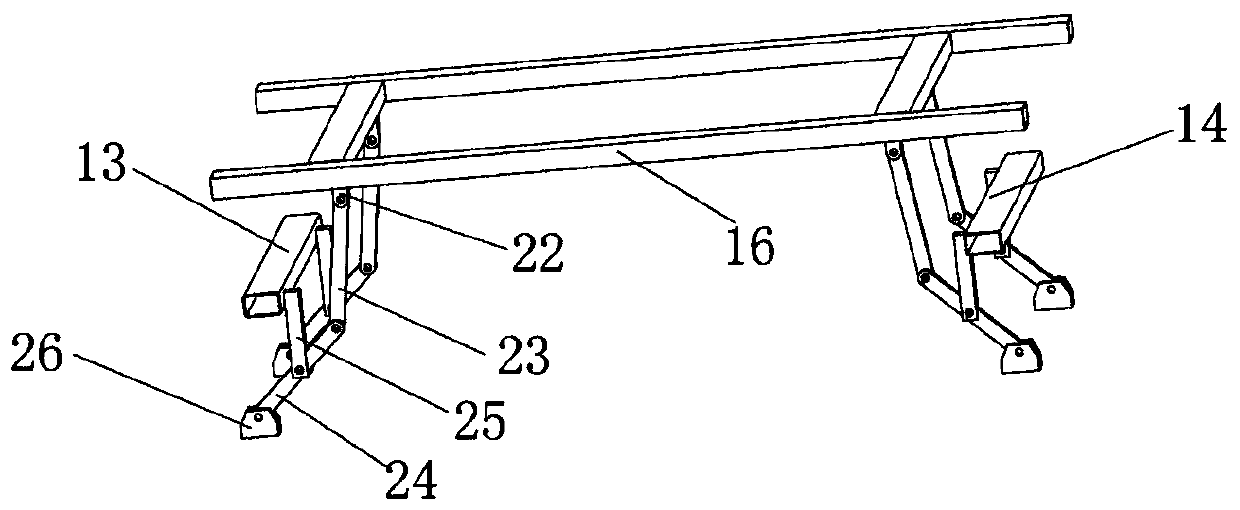

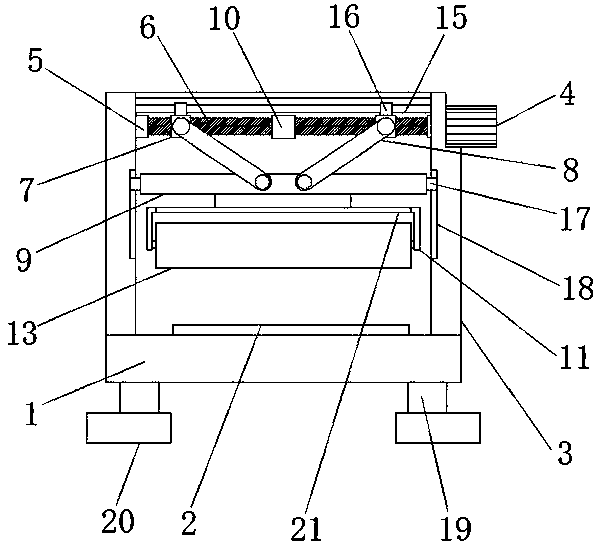

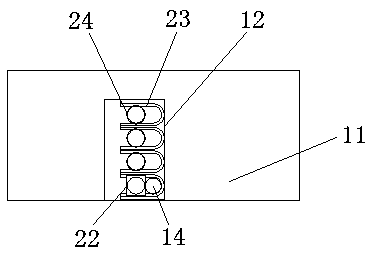

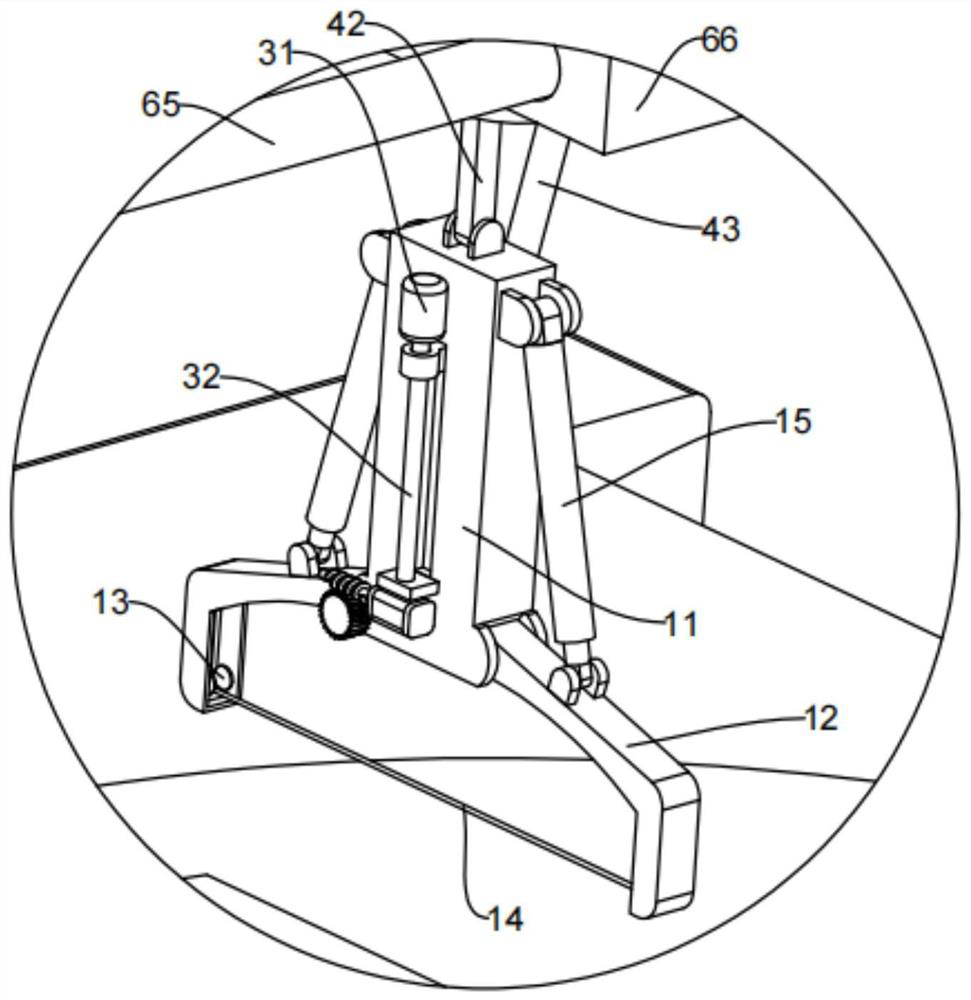

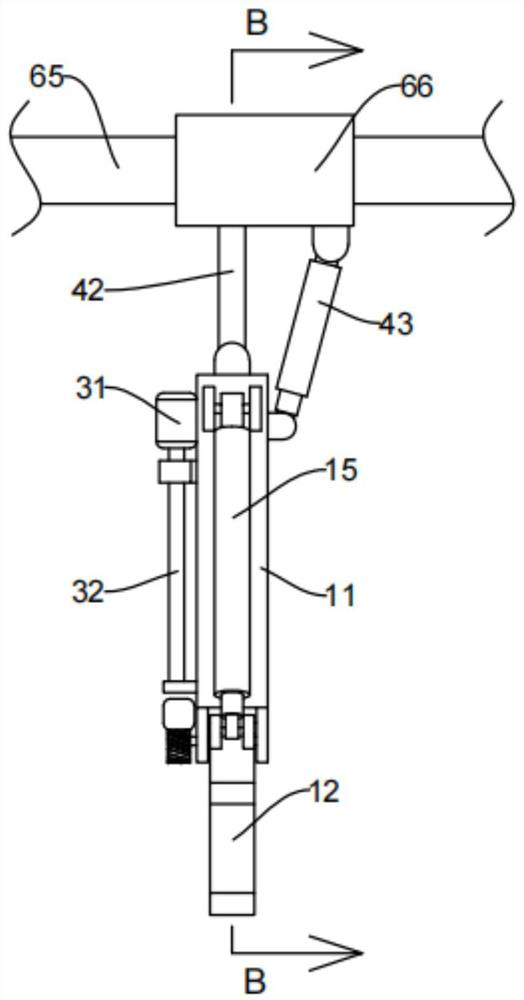

Traffic cone separation and warehousing device

ActiveCN105672160ASmooth up and down motionSmooth up and down movementTraffic signalsRoad signsLinear motionFixed frame

Disclosed is a traffic cone separation and warehousing device. The traffic cone separation and warehousing device is characterized in that a lifting mechanism connected with a lifting frame is arranged on a fixed frame; a driving motor fixedly arranged on a movable frame is connected with the lifting frame through a transmission mechanism; a separation plate is arranged at the bottom of the right side of the lifting frame; a clamping hand is arranged at the bottom of the movable frame, and a linear motion mechanism is arranged on the front side of the movable frame; the motion end of the linear motion mechanism is hinged to the clamping hand. According to the traffic cone separation and warehousing device, through four mechanical reversers and a gear-rack transmission mechanism, power output by a lifting frame oil cylinder is divided into four parts, force is evenly applied to four points surrounding the lifting frame, and thus stable up-down motion of the lifting frame is ensured. The traffic cone separation and warehousing device has the advantages that motion is smooth, the structure is simple and compact, cone separation and warehousing are accurate and in place, energy consumption is low and pollution is avoided.

Owner:HENAN GAOYUAN ROAD MAINTENANCE EQUIP

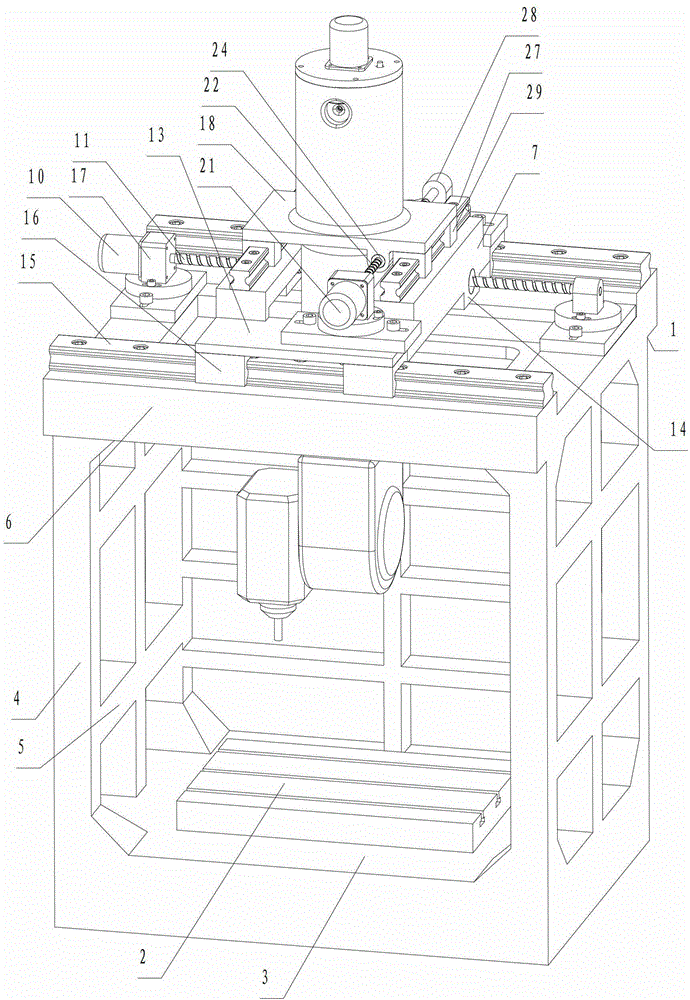

Numerical control equipment

InactiveCN102941512AImprove carrying capacityImprove rigidityFeeding apparatusLarge fixed membersNumerical controlClosed loop

The invention provides numerical control equipment, wherein a main supporting frame is in a closed loop structure of which the opening faces the vertical direction; an X forward guide rail and an X backward guide rail which are matched with each other are arranged between the main supporting frame and an X-direction sliding seat; a Z-direction guide rod is a round guide rod; the Z-direction guide rod only can be installed together with a Y-direction sliding seat in an up-and-down movement way; a rotation stopping structure for preventing the Z-direction guide rod from rotating along the horizontal direction of the axis of the guide rod is also arranged; the rotation stopping structure comprises a third rotation stopping block, a fourth rotation stopping block, a third spring and a limit mechanism; an accommodation groove is formed in the top part of the Z-direction guide rod; the limit mechanism limits the third rotation stopping block and the fourth rotation stopping block to move in the setting range of the accommodation groove; a rotation stopping groove is formed in a guide hole matched with the Z-direction guide rod; the third spring is installed between the third rotation stopping block and the fourth rotation stopping block; and the third rotation stopping block protrudes from the outer periphery of the Z-direction guide rod and is matched with the rotation stopping groove. The numerical control equipment has the advantages that when a main processing head moves up and down, the stability is good and the imbalance torsion is not easy to generate.

Owner:杨东佐

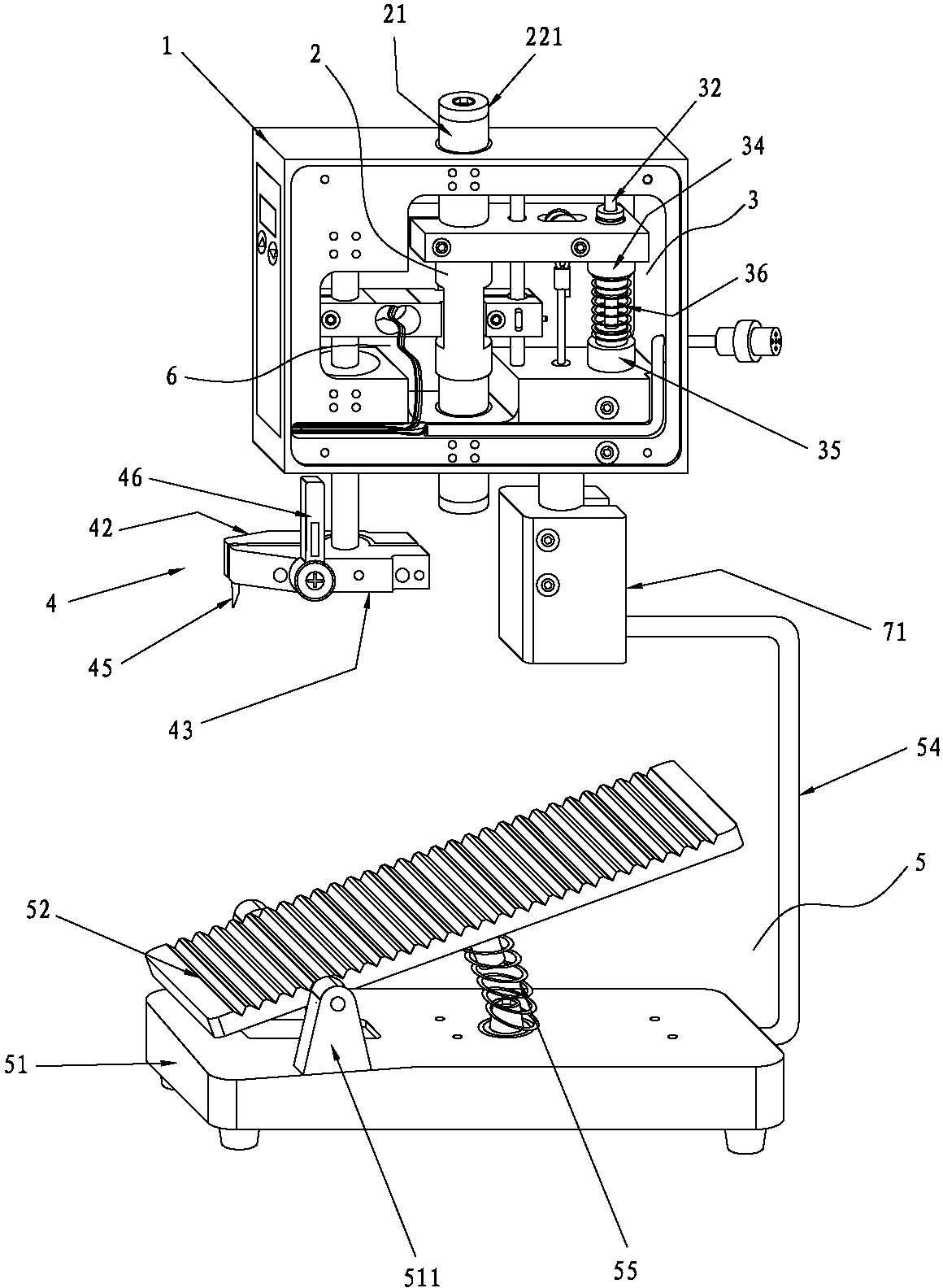

Pedal buffered type electronic spot welding device

ActiveCN102632332AImprove reliabilityAdjust the height at willResistance electrode holdersFine lineThick line

The invention relates to a pedal buffered type electronic spot welding device, in particular to an electronic spot welding machine head and a pedal device. The pedal buffered type electronic spot welding device comprises a machine head, a buffer device, a pressure transmission device, a pressure control device, a welding head clip, a machine head lifting device and the pedal device. The welding pressure can be automatically adjusted by the buffer device according to the size of a welded workpiece, a fine line can be welded perfectly, a thick line can also realize good welding effect, the lines can not be welded to be broken, false weld does not exist, and the welding quality is improved. According to the pedal device, a steel wire rope does non-contact movement in a steel wire slot so that the steel wire rope is durable and the reliability of the pedal device is strengthened. A localizator is installed in the pedal device so that the height of the welding head clip can be adjusted and the diastema of the machine head also can be adjusted.

Owner:ZHONGSHAN VIHAN ELECTRONICS EQUIP

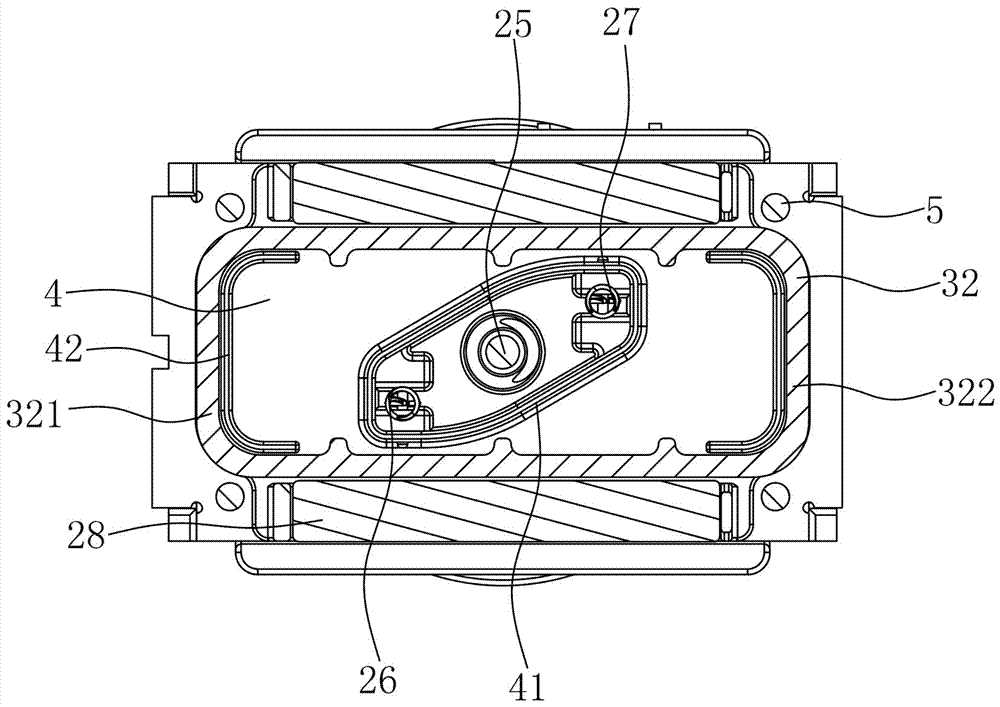

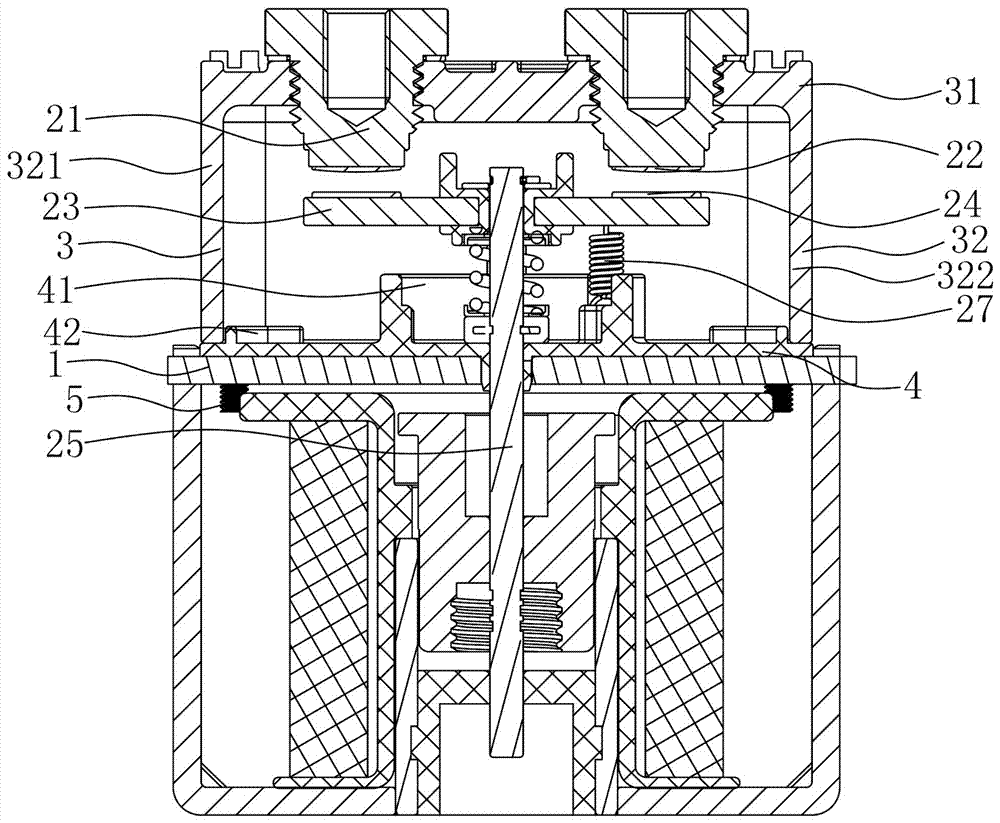

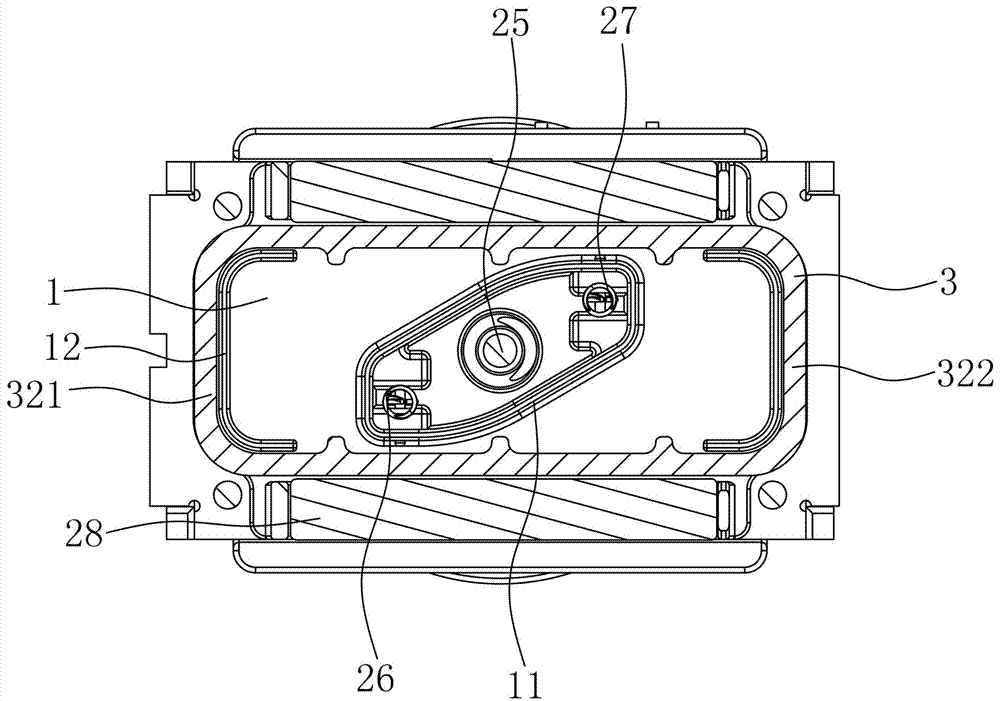

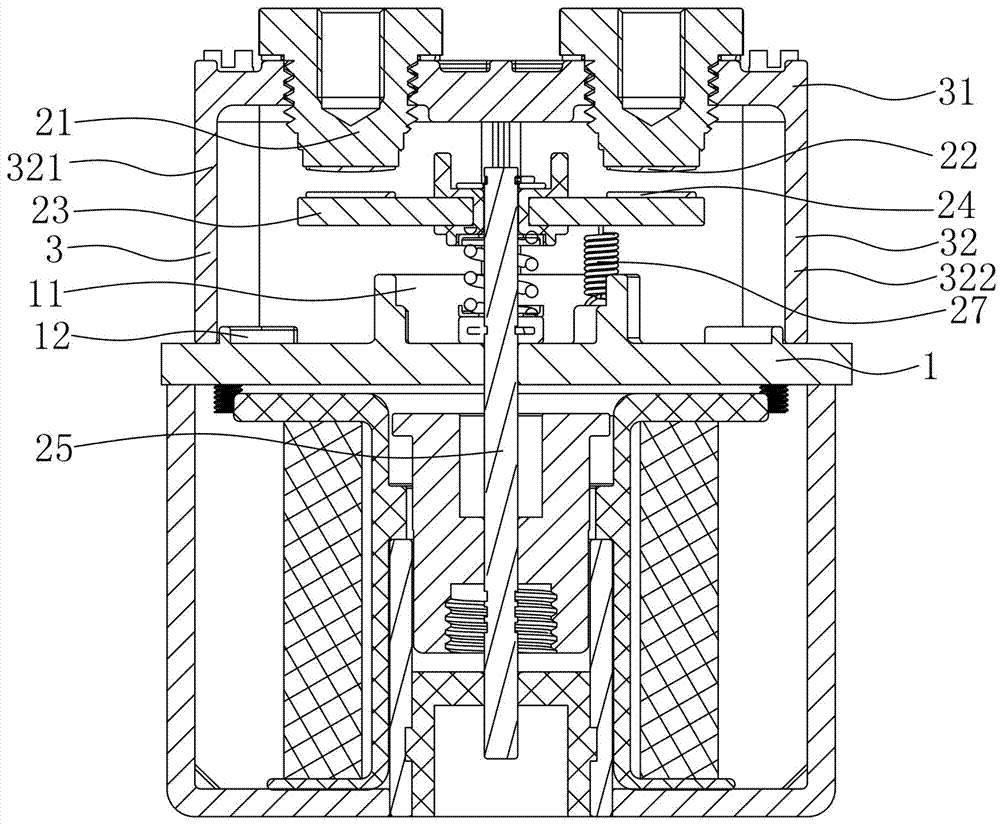

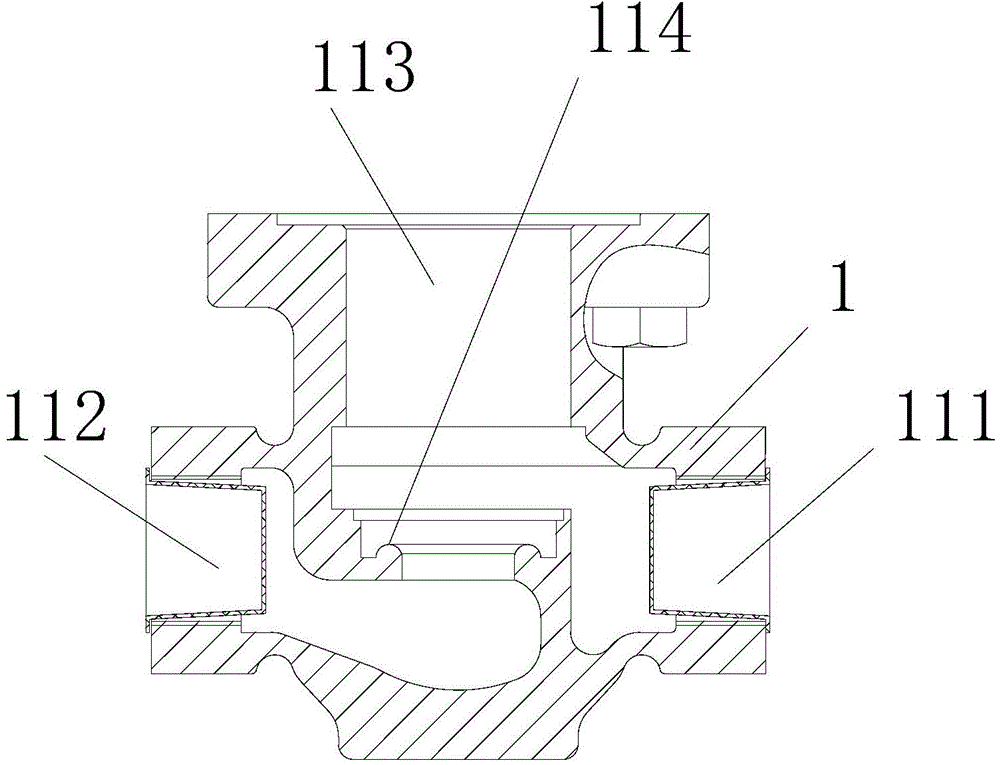

High-voltage relay

ActiveCN106981400AAvoid stickingAvoid damageElectromagnetic relay detailsEngineeringMechanical engineering

The invention discloses a high-voltage relay, and the relay comprises a yoke, a static contact assembly and a moving contact assembly, wherein the static contact assembly and the moving contact assembly are disposed above the yoke. The static contact assembly comprises a leading-out end and a static contact. The moving contact assembly comprises a moving contact spring and a moving contact, wherein the moving contact spring is fixed with the upper end of a push rod, and the lower end of the push rod is located below the yoke. The upper side of the yoke is provided with a positioning plate and an insulating cover. The insulating cover and the yoke are fixed to form a cavity for accommodating the moving contact assembly and the static contact assembly. The insulating cover comprises a top plate and an enclosing part. The top plate is used for fixing the static contact assembly, and the positioning plate is provided with a vertical positioning plate through hole so as to push the push rod to pass. A protection projection which extends upwards is formed on the positioning plate. The section of the protection projection along the radial direction of the push rod is of an enclosing structure, and the positioning plate through hole is located at an inner side of the protection projection.

Owner:ZHEJIANG LINIX MOTOR

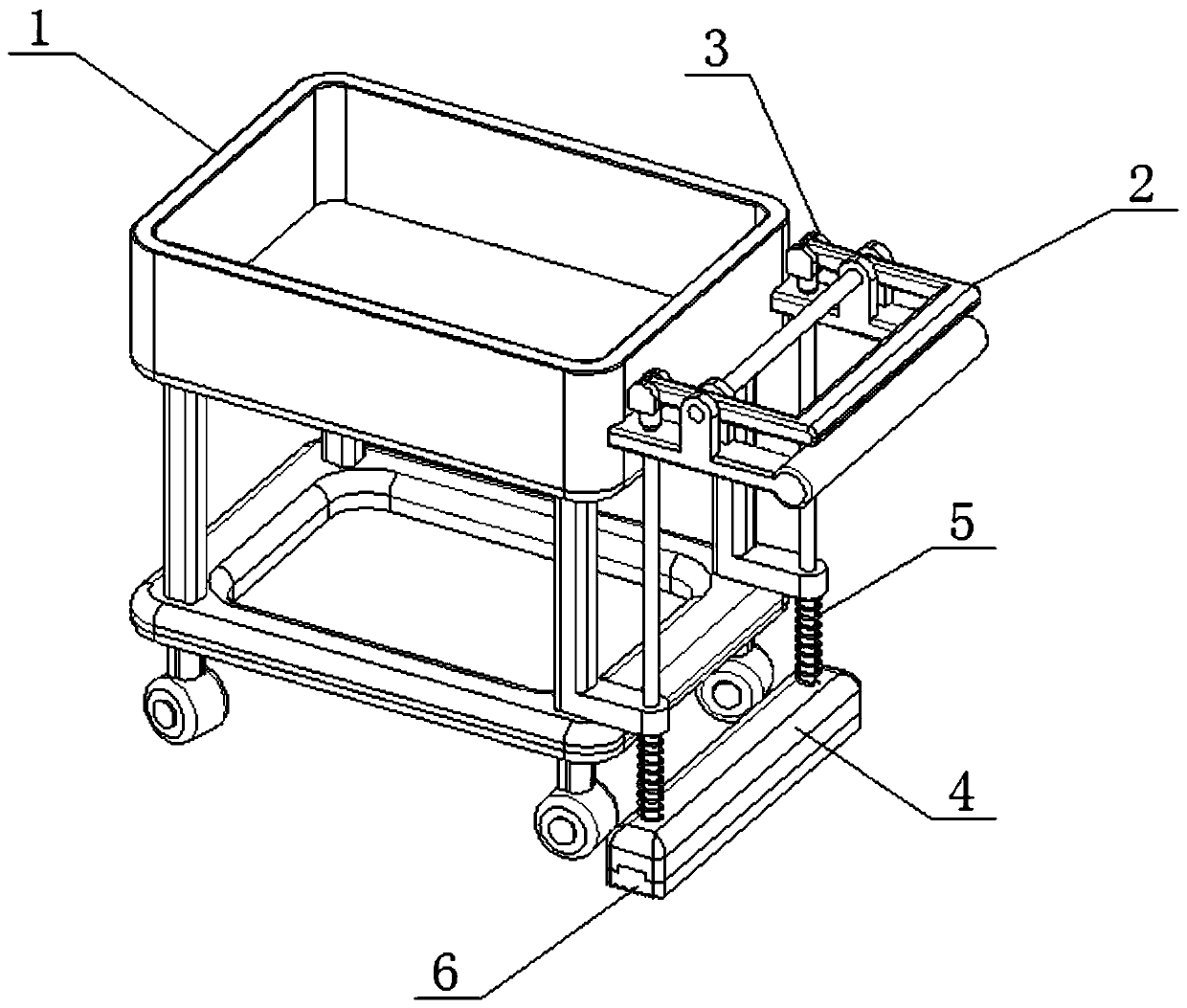

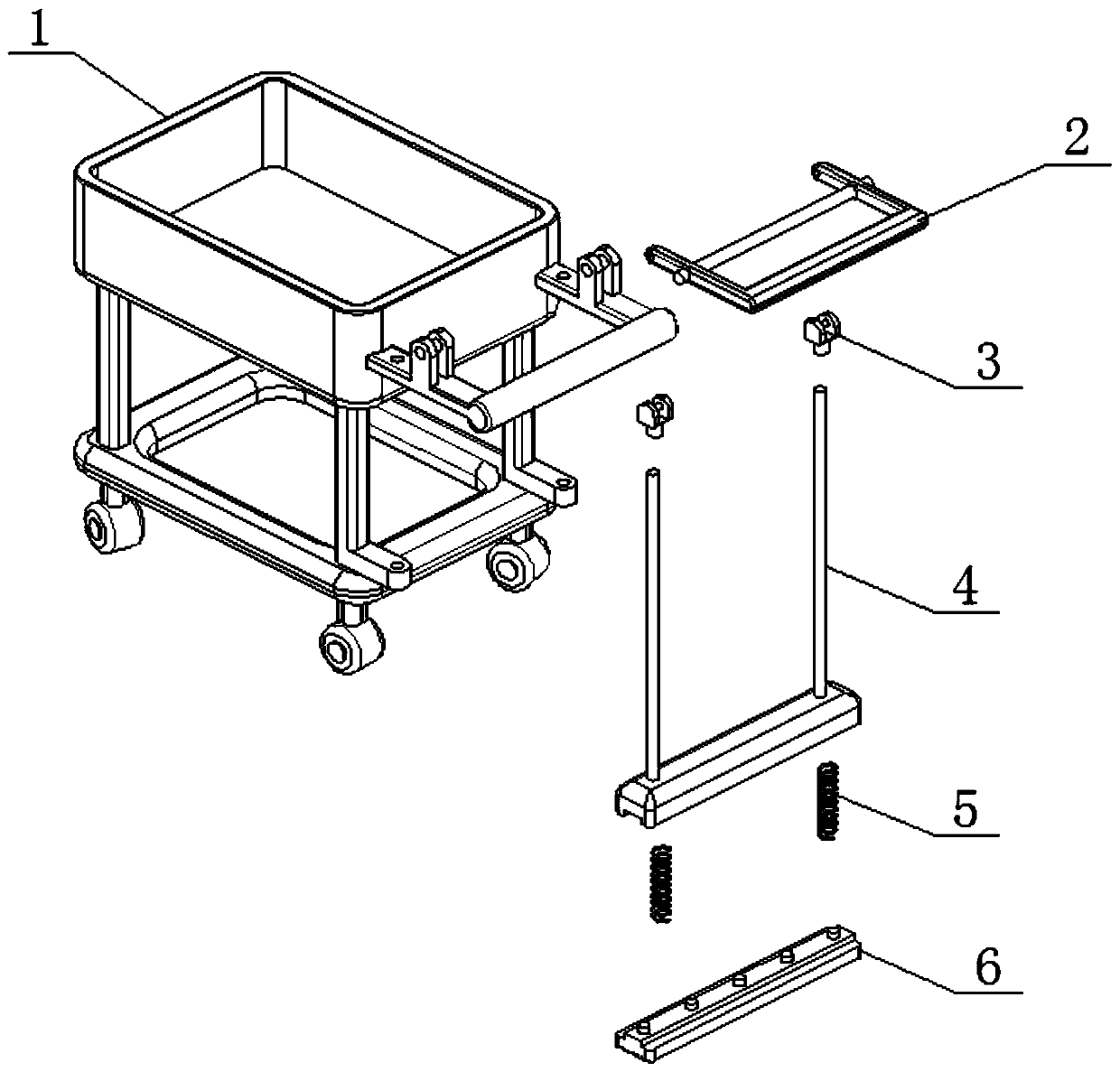

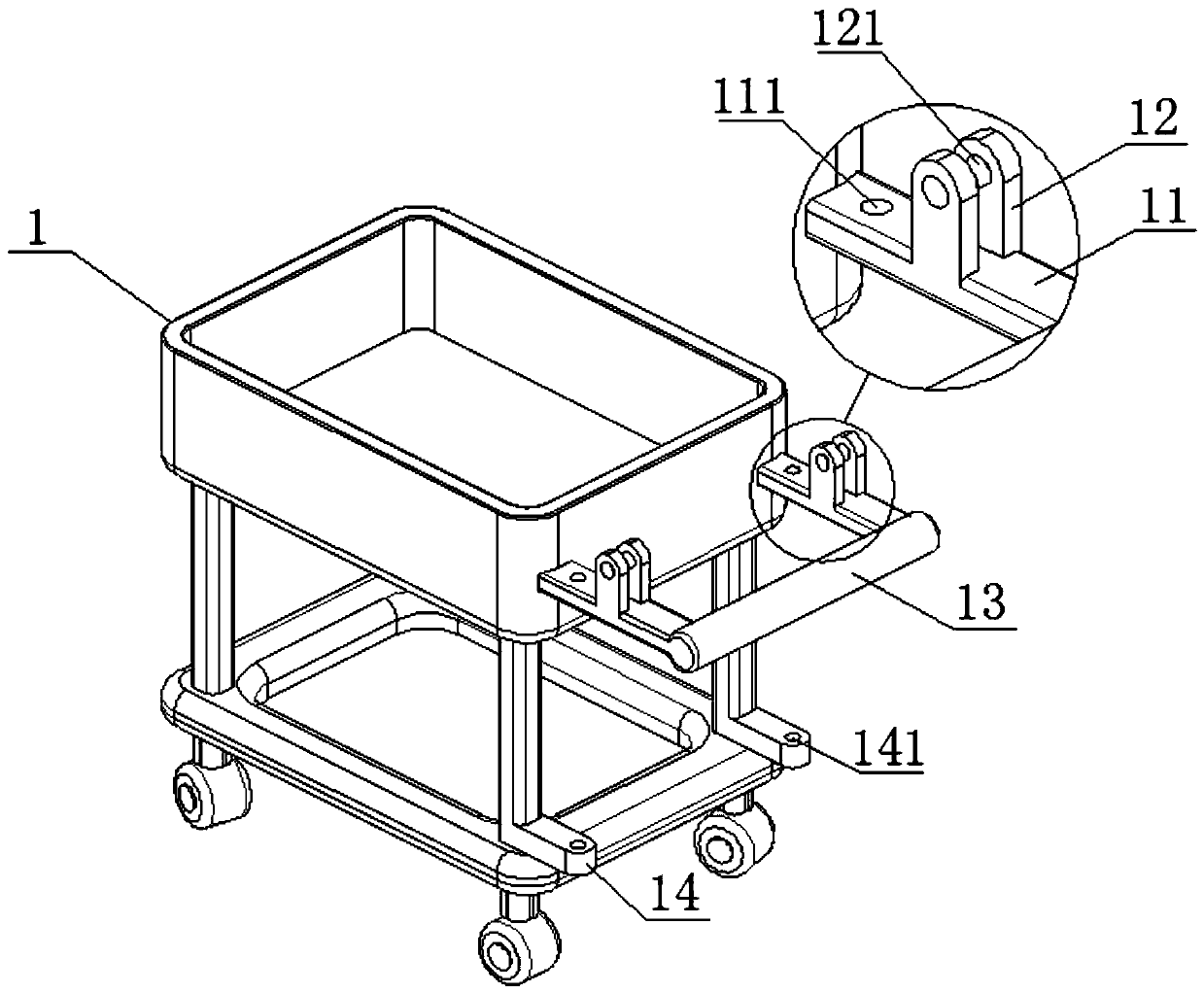

Self-locking braking device for mobile cart

InactiveCN110843895AEasy to installSmooth up and down movementHand cart accessoriesStructural engineeringControl theory

The invention discloses a self-locking braking device for a mobile cart. The device comprises a cart body, wherein supporting rods are symmetrically arranged on one side of the cart body; the supporting rods and the cart body are fixedly connected through a welding mode; one ends of the supporting rods are fixedly connected to a grab rail; pull rod limiting pieces are symmetrically arranged on oneside of the cart body; the pull rod limiting pieces and the cart body are fixedly connected through a welding mode; mounting bases are symmetrically arranged on the upper end of each supporting rod;the mounting bases and the supporting rod are fixedly connected through a welding mode; and a press support is rotationally connected to the mounting bases through a plugging mode. The cart has the characteristics of being reasonable in structure and convenient to use; through mutual cooperation of the press supports, connectors, brake components, reset springs and a brake pad, the self-service braking can be performed when the cart is not in use, so that a condition of cart sliding can be prevented, and thus the cart can be prevented from hurting a patient in a process of cart sliding.

Owner:常州久沐医疗科技有限公司

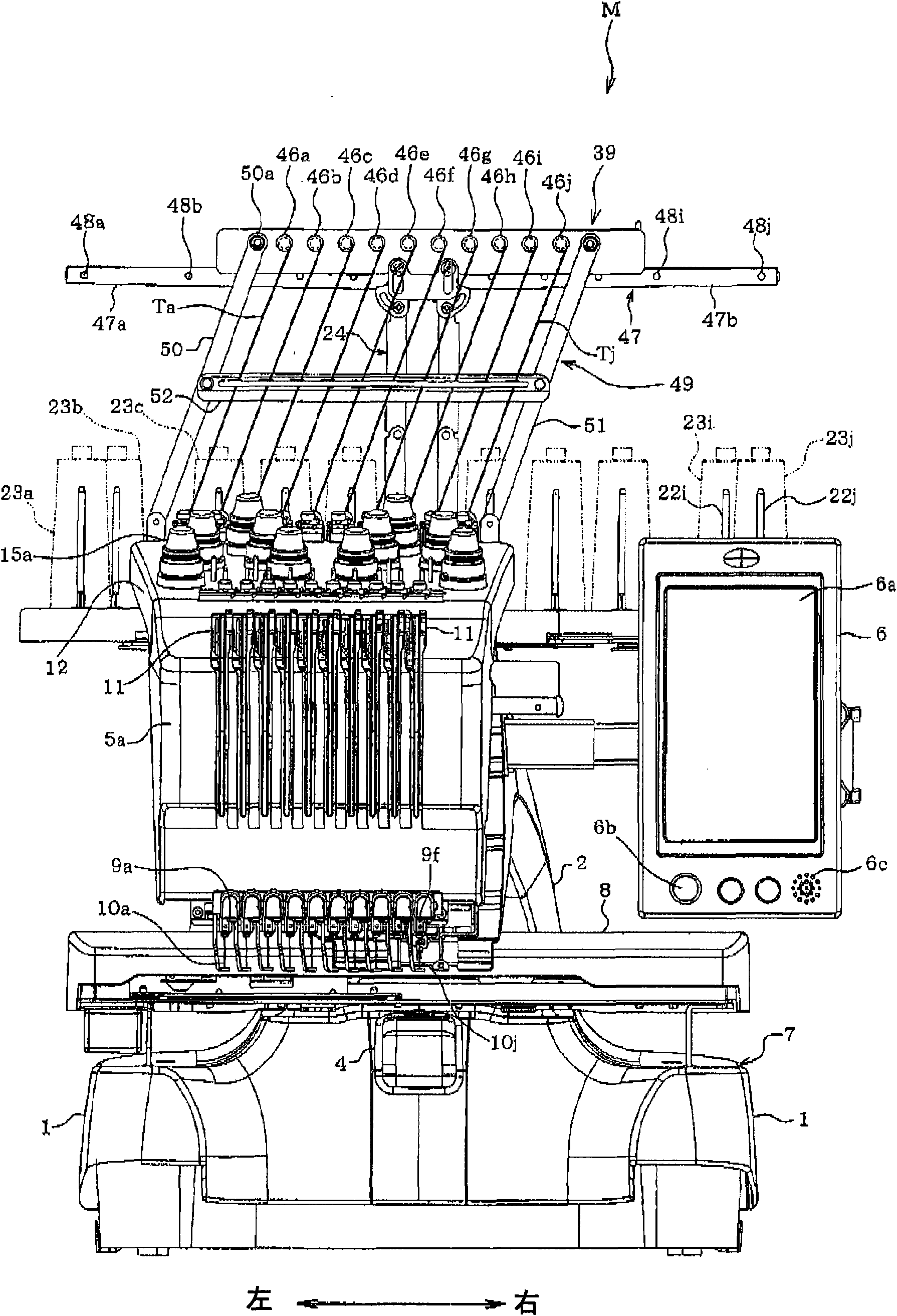

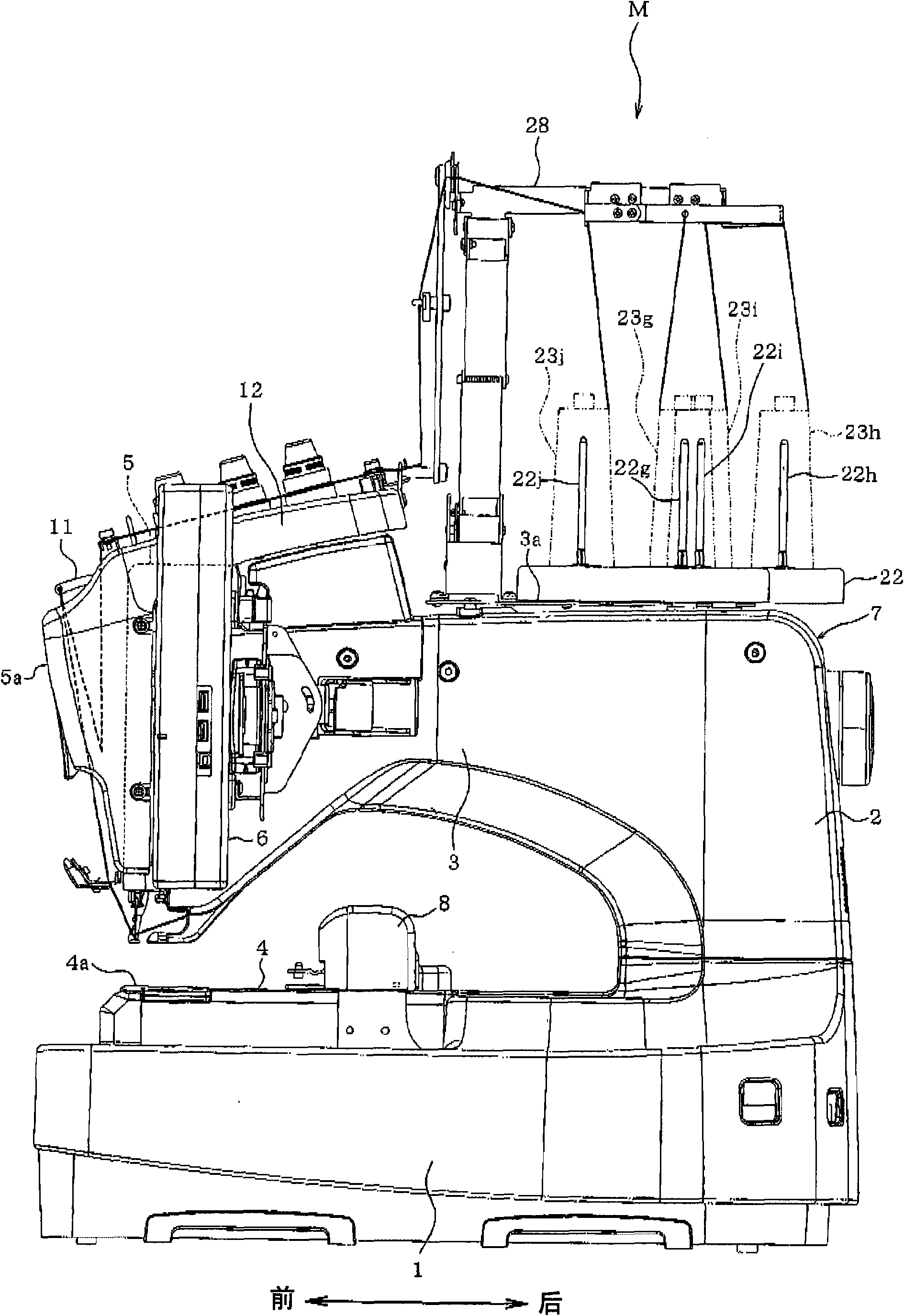

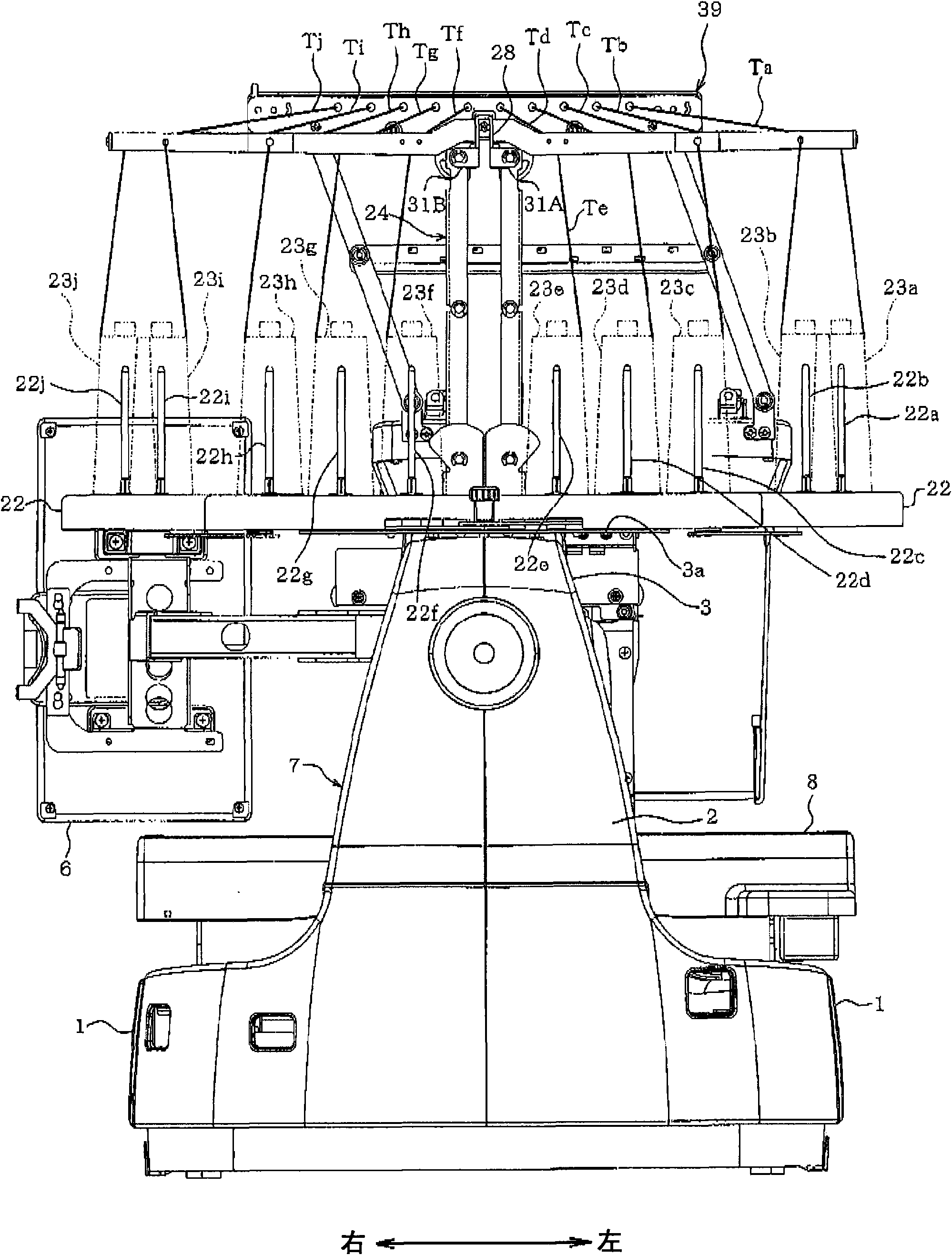

Multi-needle sewing machine

InactiveCN102140741ASmooth up and down movementSmooth movementThread-break detectorsTensioning devicesEngineeringTransfer mechanism

A multi-needle sewing machine includes a needle-bar case that supports needle bars; a needle-bar case transfer mechanism that transfers the needle-bar case to place a predetermined needle bar to a needle drop position; a thread guide member that is movable up and down, the thread guide member being provided with thread guide sections spaced by a predetermined distance and that guide a plurality of threads; a plurality of thread inlets that are provided at the needle-bar case, each thread inlet being uniquely associated with one of the thread guide sections and that introduces the threads guided by the thread guide sections toward the needle bars; and a lifting / lowering mechanism that moves the thread guide member up and down during transfer of the needle-bar ease and the thread inlets such that the thread guide sections and the associated thread inlets maintain a constant distance therebetween.

Owner:BROTHER KOGYO KK

Medical-care sickbed for critical patient

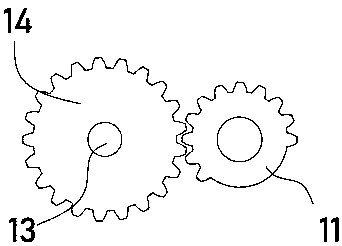

ActiveCN108578108AReduce workloadEasy programmingChiropractic devicesNursing bedsGear wheelSide lying

The invention provides a medical-care sick bed for a critical patient, and belongs to the field of medical-care sick bed equipment. Specifically, a stretching mechanism, a side swing mechanism, a bent-up mechanism, a controller and a base are applied to realize auxiliary side turning, turning-up of the upper bodies and exercise of legs and the hip of the patients. The stretching mechanism is mounted on a bottom plate through a pivoted joint, wedge-shaped sliding grooves are formed in a stretching frame, foot-placing frames are slidably connected with the wedge-shaped sliding grooves, a reserved putting-down groove is further formed in the stretching frame, and the lower portions of the foot-placing frames makes contact with a cam; and a stretching motor is mounted on the back face of the stretching frame, an output shaft of the stretching motor is provided with a gear, the output shaft of the stretching motor and the stretching frame are connected through a rotating bearing, and a synchronous belt drives another gear to rotate and further drives another cam to rotate. The medical-care sick bed can realize the functions of automatic leg and hip muscle stretching of the critical patients, and assisting medical workers for turning-over and regular side-lying of the patients, and assisting turn-up of the upper bodies of the patients.

Owner:宋子康

High-voltage relay

ActiveCN106992100ALifting and moving smoothlyAvoid stickingElectromagnetic relay detailsEngineeringHigh pressure

The invention discloses a high-voltage relay. The high-voltage relay comprises a yoke, a static contact assembly and a moving contact assembly, wherein the static contact assembly and the moving contact assembly are arranged on the yoke. The static contact assembly comprises lead-out ends and static contacts. The moving contact assembly comprises moving spring sheets and moving contacts. The moving spring sheets are fixed with the upper end of a pushing rod. The lower end of the pushing rod is arranged below the yoke. An insulation cover is arranged on the upper side of the yoke. The insulation cover cooperates with the yoke to form a chamber for accommodating the moving contact assembly and static contact assembly. The insulation cover comprises a top plate and an enclosure part. The top plate is used for fixing the static contact assembly. An upwards extending protection projection is formed on the yoke. The cross section, in the radial direction of the pushing rod, of the protection projection is of an enclosure structure. The pushing rod is arranged on the inner side of the protection projection.

Owner:ZHEJIANG YINGLUOHUA NEW ENERGY TECH CO LTD

Detection device used for testing welding pulling force of patch type diode

ActiveCN102539324ASimple structureEasy to operateSemiconductor/solid-state device testing/measurementUsing mechanical meansPush and pullPull force

The invention discloses a detection device used for testing welding pulling force of a patch type diode. The detection device includes a push and pull force gauge used for testing pressure and provided with an ejecting block at the lower end, wherein an inverted T-shaped mounting groove is arranged at the upper end of a lifting platform; a lever positioned in a fixing base is positioned with the fixing base through a fixed rotating shaft; a jacking rod is fixed on the lower end surface of the lifting platform; the other end of the jacking rod is positioned above one end of the lever; the other end of the lever is installed below an adjusting screw nut; the adjusting screw nut can drive the lever to rotate around the fixed rotating shaft during vertical movement; the lower end part of an assembly fixing seat is embedded in the inverted T-shaped mounting groove; a dislocation groove positioned at the center of the assembly fixing seat is arranged at the upper end part of the assembly fixing seat; and a first positioning pin and a second positioning pin both positioned on the surface of the upper end part of the assembly fixing seat are arranged on the two sides of the dislocation groove respectively. The detection device provided by the invention can be used for measuring the welding pulling force of a chip and a leading wire frame, has a simple structure, brings convenience foroperation of testing personnel, and can effectively fix the chip and the leading wire frame and guarantee the accuracy of test data, thereby improving the yield.

Owner:SUZHOU GOODARK ELECTRONICS CO LTD

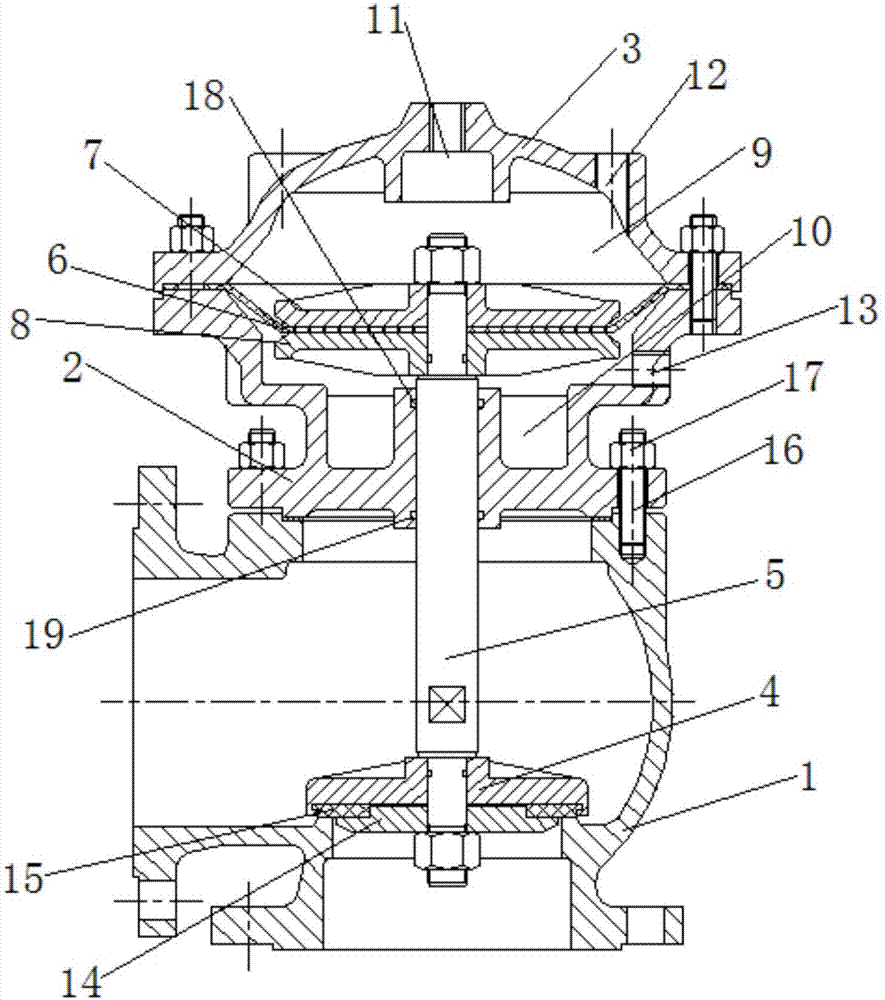

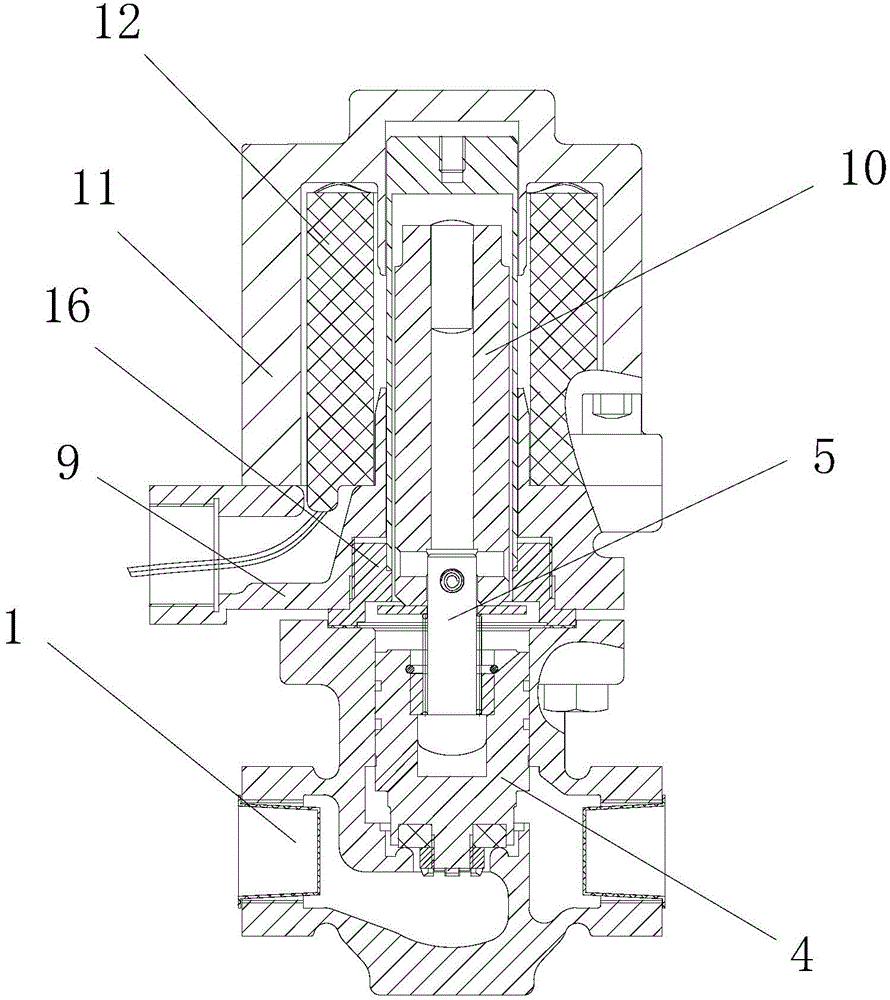

Membrane type quick-opening sludge drainage valve

InactiveCN107514500AReduce installation costsSmooth up and down movementSpindle sealingsOperating means/releasing devices for valvesSludgeOperability

The invention relates to a membrane type quick-opening sludge drainage valve comprising a valve body, a membrane base and a valve deck. An inlet is formed in one side of the valve body. An outlet is formed in the bottom of the valve body. A valve clack is arranged in the valve body. A membrane piece is arranged between the bottom end of the valve deck and the top end of the membrane base. A water pressure cavity is formed between the membrane piece and the valve deck. A matching cavity is formed between the membrane piece and the membrane base. An upper membrane pressing plate and a lower membrane pressing plate are arranged on the upper face and the lower face of the membrane piece correspondingly. A through hole is formed in the bottom of the membrane base. A valve rod is connected with the valve clack. The upper end of the valve rod penetrates the through hole of the membrane base to be connected with the membrane piece, the upper membrane pressing plate and the lower membrane pressing plate. A water inlet and a water outlet are formed in the top of the valve deck. A filter is arranged at the position of the water inlet and communicates with the inlet end of the valve body through a connection pipe. A pressure balance hole communicating with the outside world is formed in the matching cavity. Compared with the prior art, the membrane type quick-opening sludge drainage valve has the beneficial effects of being good in operability, long in service life, low in installation cost and the like.

Owner:SHANGHAI HONGSHENG SPECIAL VALVE MFG

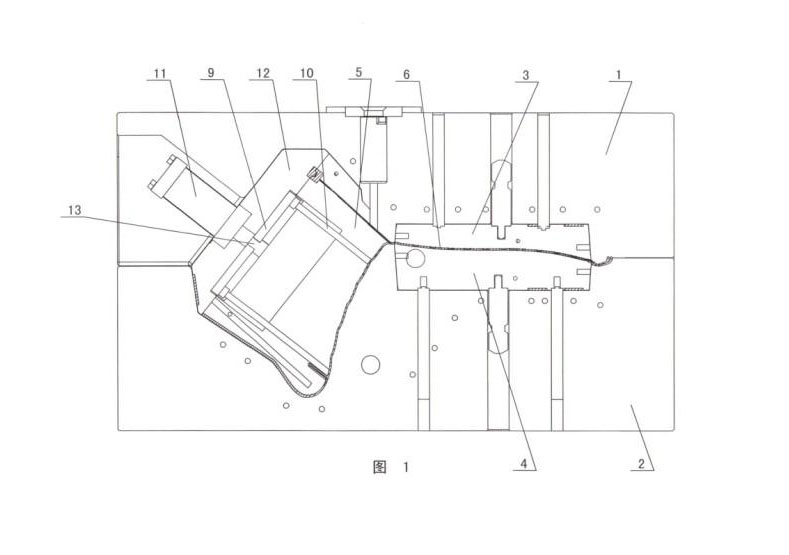

Demolding mechanism of plastic chair mold

InactiveCN102463656AReduce the overall heightShort mold opening strokeDomestic articlesMechanical engineeringEngineering

The invention discloses a demolding mechanism of a plastic chair mold, comprising a mold cavity plate and a core plate, wherein, a chair back cavity insert is arranged in the cavity plate, a chair back core insert is arranged in the core plate, a chair back cavity is formed between the chair back cavity insert and the chair back core insert, a chair leg-chair seat cavity insert is laterally arranged between the cavity plate and the core plate, a chair leg-chair seat cavity is formed between the chair leg-chair seat cavity insert and the cavity plate and between the chair leg-chair seat cavity insert and the core plate, the chair leg-chair seat cavity and the chair back cavity form a plastic chair mold cavity, a shaped plastic chair is arranged in the plastic chair mold cavity, demolding oil cylinders are arranged at the outer wall of the two sides of the chair leg-chair seat cavity insert, piston rods of the demolding oil cylinders are connected with the cavity plate, the end portion of the chair leg-chair seat cavity insert is provided with a top board, the top board is connected with a push rod, the push rod contacts with the plastic chair back by passing through the chair leg-chair seat cavity insert, the bottom of the push rod is connected with a push piston rod of a push oil cylinder, and the push oil cylinder drives the push rod on the top board to push out.

Owner:ZHEJIANG KAIHUA MOLDS

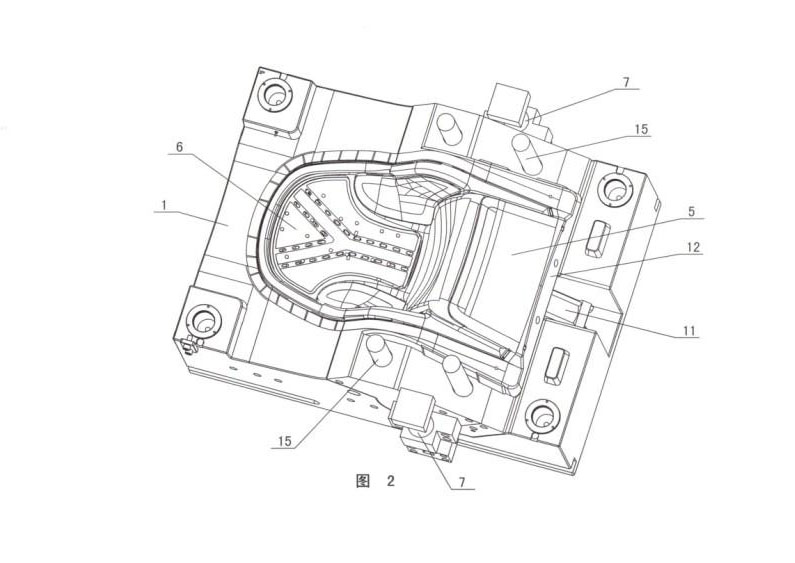

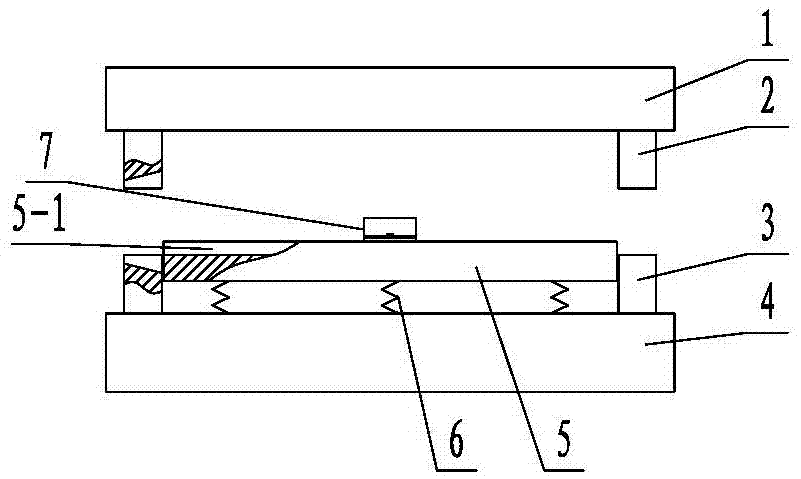

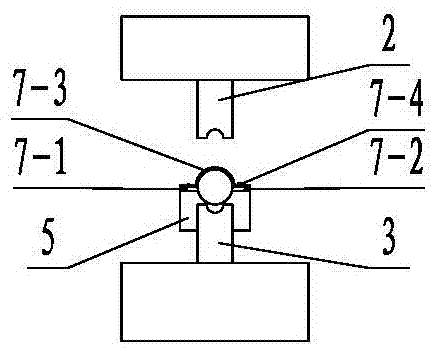

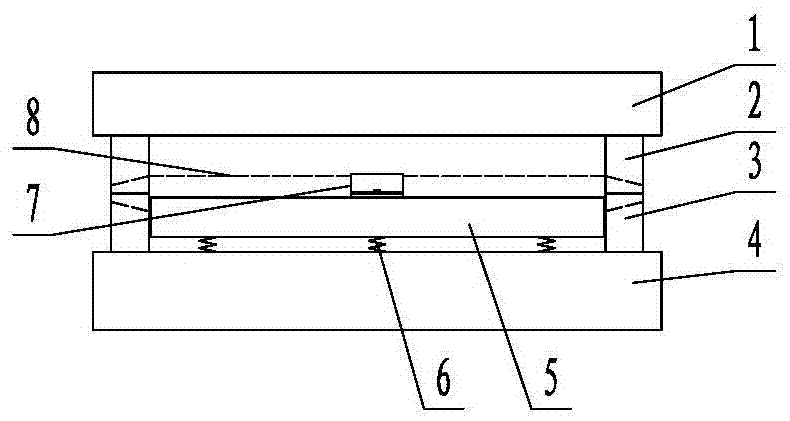

Stamping necking mold for pipe fittings

InactiveCN107096834AAvoid deformationShort work scheduleShaping toolsMetal-working feeding devicesPipe fittingEngineering

The invention discloses a stamping necking mold for pipe fittings and relates to the technical field of stamping molds. The stamping necking mold comprises two lower female mold bodies which are oppositely fixed to a lower mold seat. A support block is arranged between the two lower female mold bodies. The support block is supported above the lower mold seat through multiple springs. A limiting groove for horizontally containing the pipe fittings is formed in the upper end face of the support block. Two upper female mold bodies corresponding to the lower female mold bodies are fixedly arranged on an upper mold plate. A necking mold cavity is defined by the upper female mold bodies and the lower female mold bodies. The stamping necking mold for the pipe fittings solves the problems that by means of an existing necking mold for the pipe fittings, necked openings of overlong pipe fittings deform easily, and the working stroke is large.

Owner:柳州市御朗机械制造有限公司

Concrete stirring device for constructional engineering

PendingCN112873547AEffective stirringAvoid shakingHollow article cleaningCement mixing apparatusGear wheelClassical mechanics

The invention discloses a concrete stirring device for constructional engineering. The concrete stirring device comprises box body feeding interfaces, a plurality of discharging interfaces and supporting columns arranged at the lower end of the box body, and a box cover is connected with the upper end of the box body through connecting bolts. A rotating rod, stirring columns and scraping blocks are arranged on the box body, a case arranged at the upper end of the box body, and a rotating assembly, a displacement assembly and a connecting assembly are arranged in the case. A moving cylinder is arranged on the side wall of the box body, and a vibration assembly is arranged in the box body. A motor drives a connecting column to rotate, so that a connecting cylinder rotates under the action of a clamping block and a sliding groove, then the rotating rod rotates, and the rotating rod rotates to stir concrete in the box body. A connecting column rotates to enable a driving gear to rotate, then the connecting cylinder and the rotating rod move up and down while rotating through a driven gear, a worm gear, a worm, a rotating disc, a long rod, a connecting block and other components, then the stirring columns move up and down while stirring is conducted, and concrete in the box body is effectively stirred.

Owner:龙凤

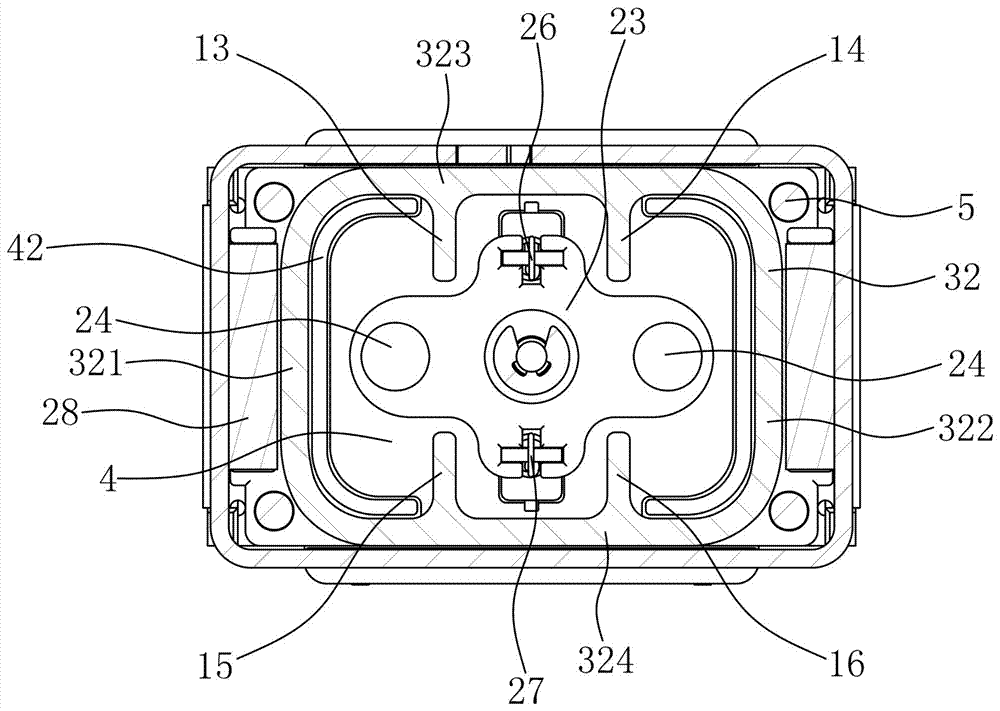

Full-automatic abrasive cloth flap disc machining equipment

The invention discloses full-automatic abrasive cloth flap disc machining equipment, which comprises a frame; a feeding and discharging storage mechanism of a flap disc, a conveying rotary device, a flap disc autorotation mechanism, a glue dripping device, a slice mounting device and a reshaping mechanism are arranged on the frame; and when the machining equipment works, the flap disc is fetched and placed on the flap disc autorotation mechanism arranged on the conveying rotary device by the feeding mechanism of the flap disc, a small turntable and the flap disc are driven by a main turntableto rotate below the glue dripping device, the glue dripping device drips glue to the flap disc, then the main turntable continuously rotates to drive the flap disc coated with the glue to rotate below the slice mounting device, the slice mounting device slices an abrasive cloth tape, the slices are stuck to the flap disc coated with the glue, the main turntable continuously rotates to drive the flap disc stuck with abrasive cloth sheets to rotate below a reshaping device, the flap disc is reshaped by the reshaping device, finally, the main turntable drives the finished flap disc to rotate below the discharging storage mechanism, the finished disc is grabbed and discharged by the discharging storage mechanism, and machining of the whole process is finished.

Owner:台州市黄岩豪林抛光磨具有限公司

Teaching board for computer education

InactiveCN107344465AAchieve the effect of rotationEasy to useWriting boardsFurniture partsEngineering

Owner:苏州艾虎数码科技有限公司

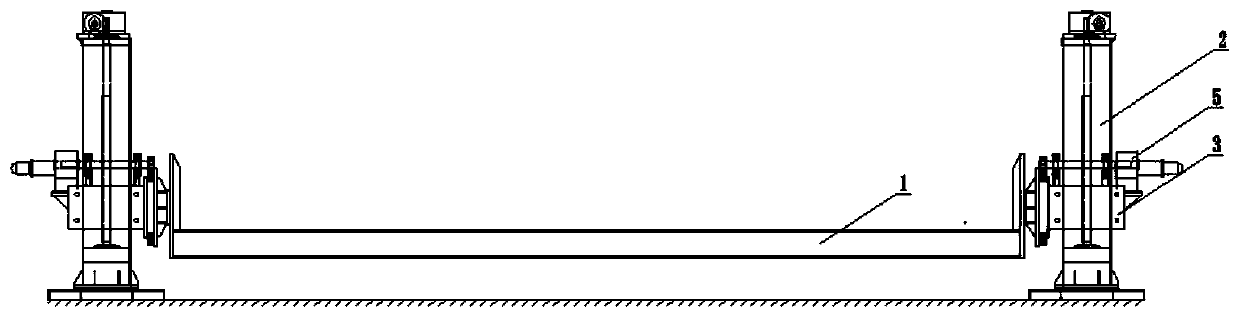

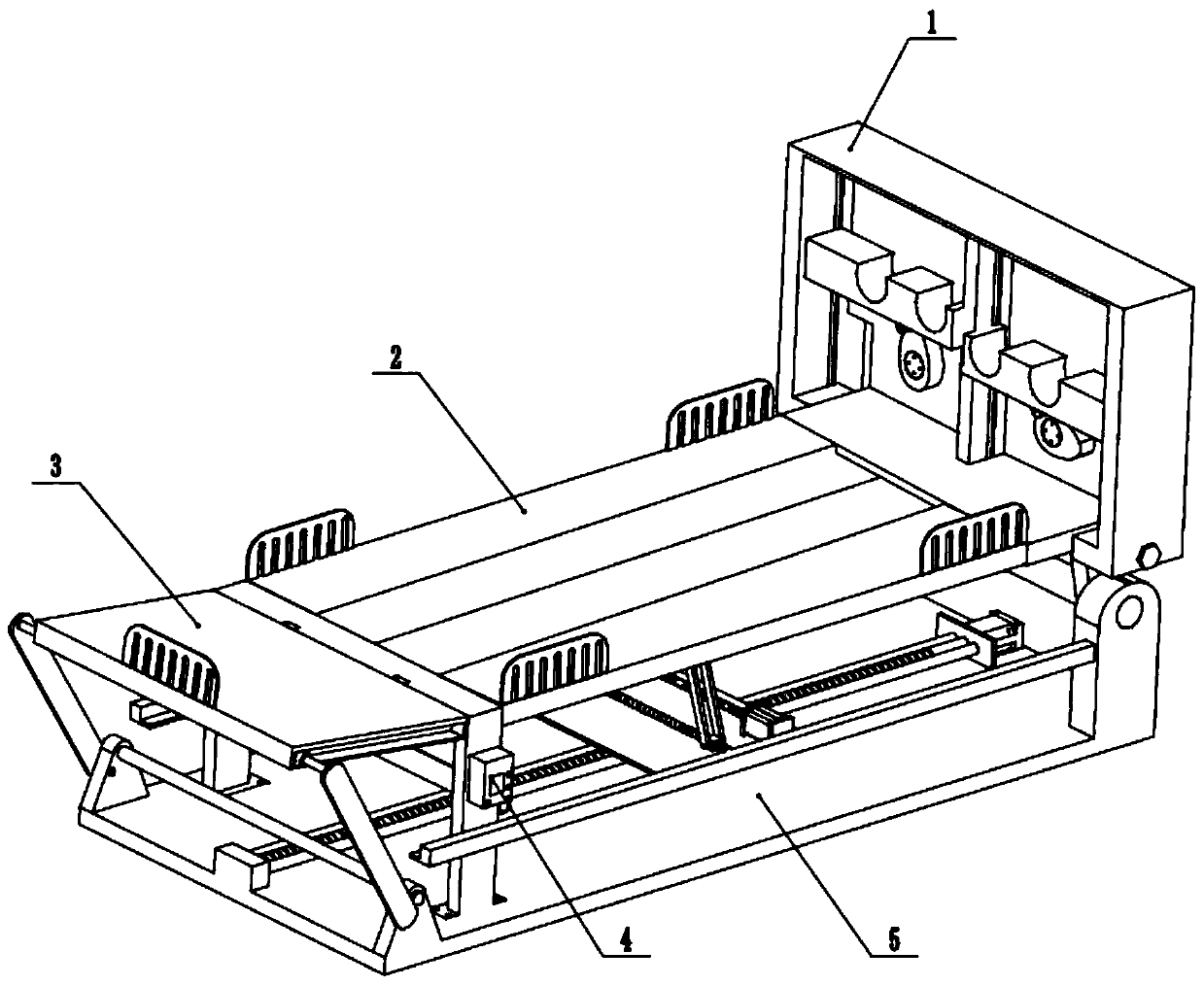

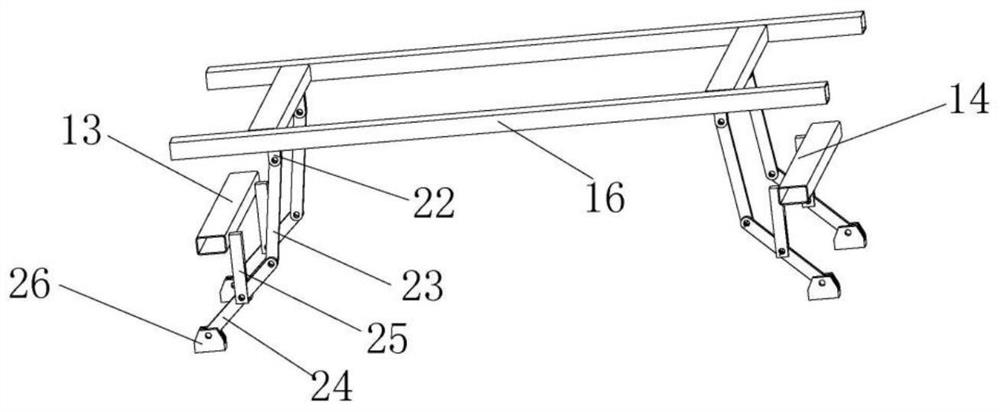

Turnover device for large workpiece

The invention provides a turnover device for a large workpiece. The turnover device comprises a girder, a frame, a lifting mechanism, a guide mechanism and a turnover mechanism; the two ends of the girder are fixedly connected with the turnover mechanism correspondingly; the turnover mechanism is fixedly mounted on the lifting mechanism; the lifting mechanism is positioned at the middle part of the frame and is rotatably connected with the frame; the two ends of the lifting mechanism are fixedly connected with guide mechanisms; the guide mechanisms wrap the frame inside; the turnover mechanismcomprises a first motor, a turnover assembly and a turnover connector; the first motor is positioned on the upper plane of the lifting mechanism and is fixedly connected with the lifting mechanism; the first motor is fixedly connected with the turnover assembly; the turnover assembly is fixedly connected with one side of the turnover connector; and the other side of the turnover connector is fixedly connected with the girder. The turnover mechanism is fixedly connected with the girder through a rotary bearing, and the turnover moment of the rotary bearing is relatively high, so that a large radial load can be borne, and the turnover device is suitable for the turnover of the large workpiece.

Owner:常州戚墅堰机车车辆配件工业有限公司

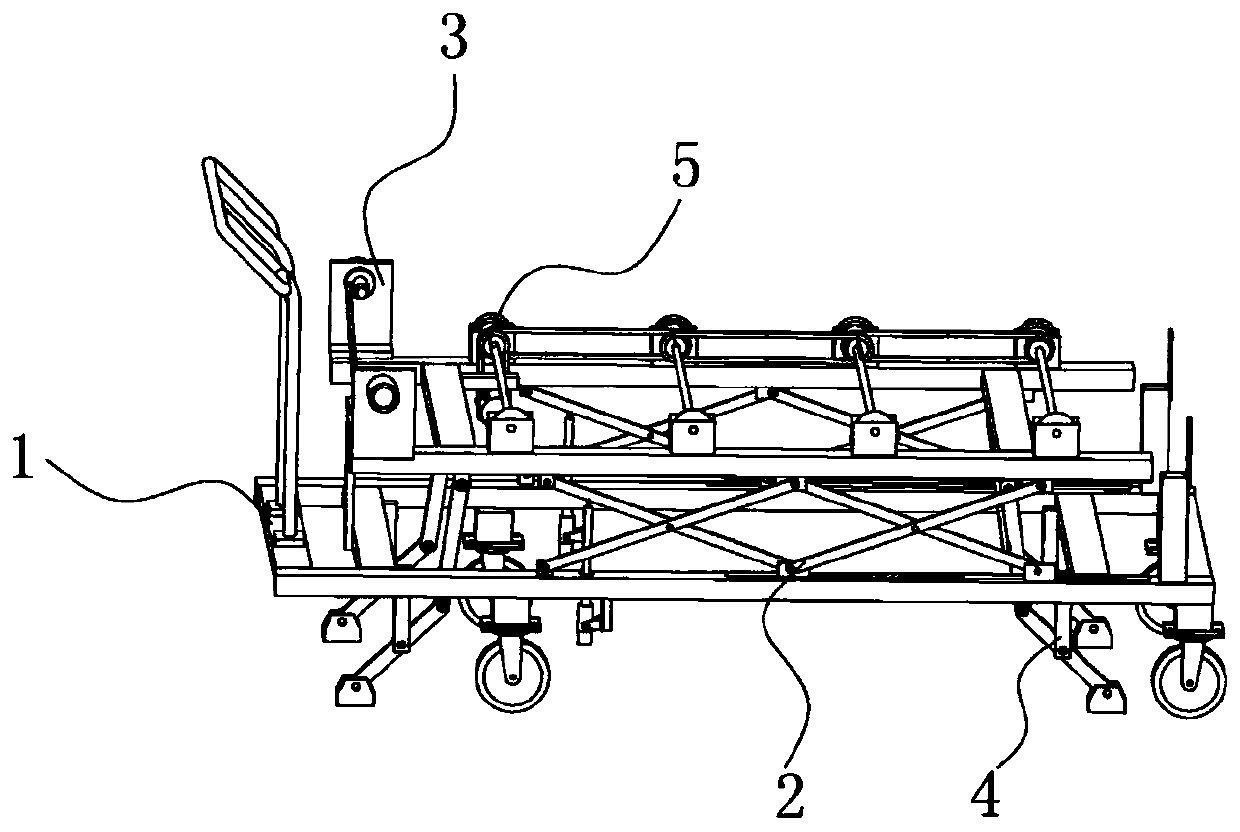

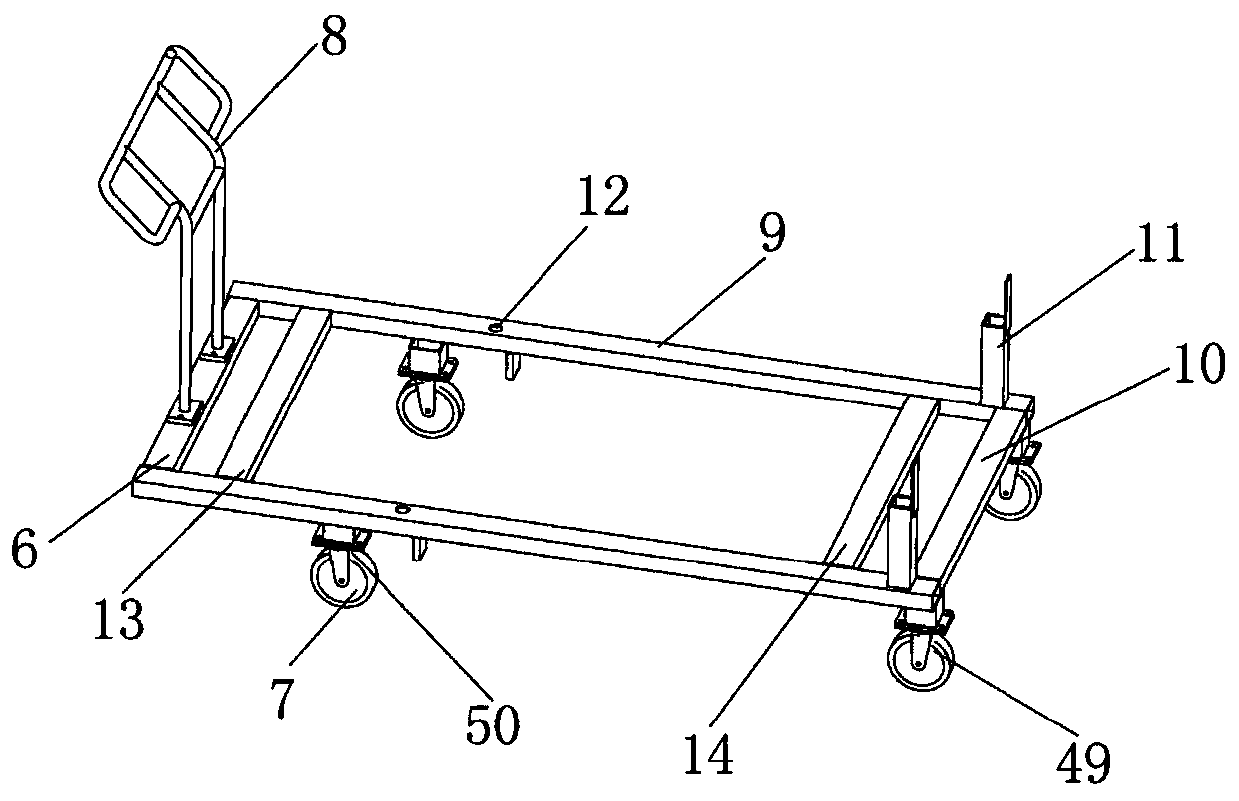

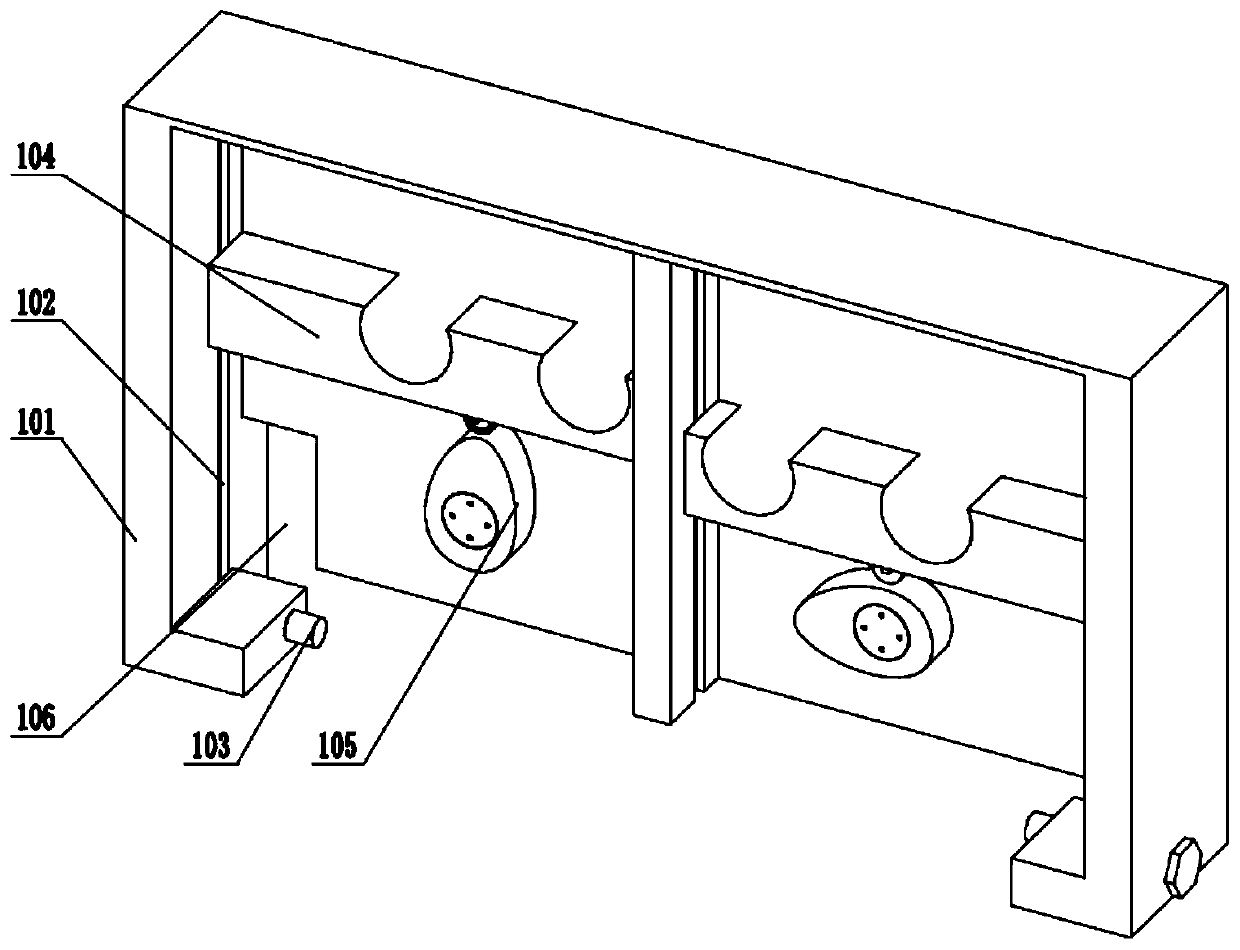

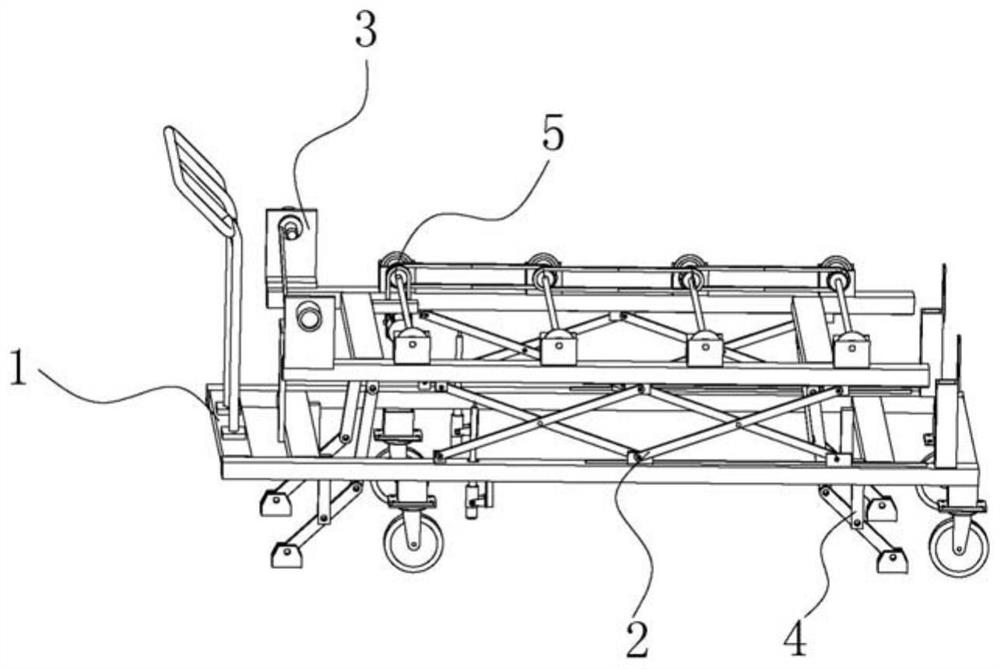

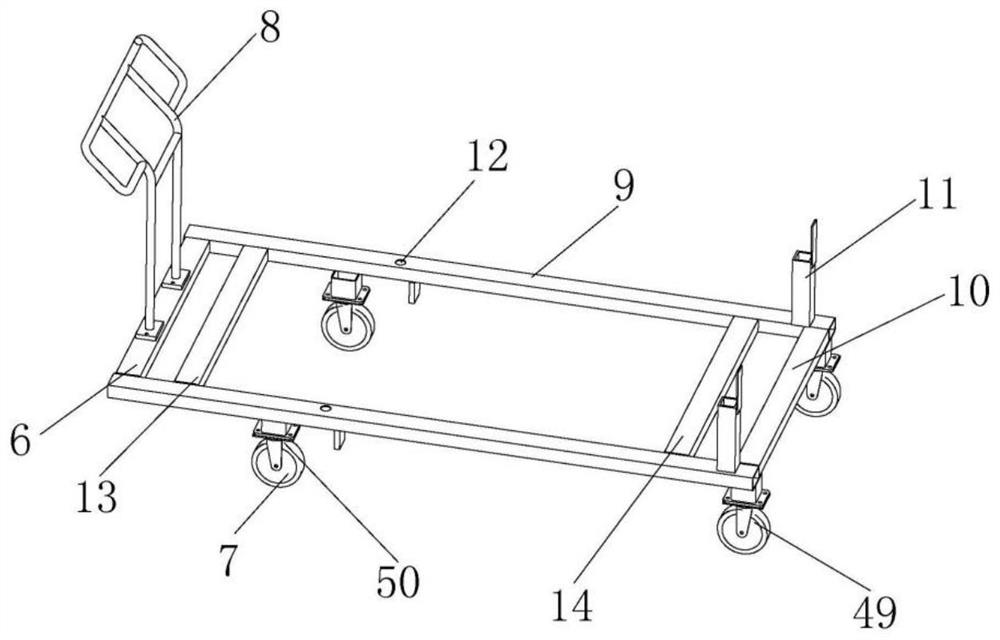

Logistics transportation vehicle suitable for automatic production line

ActiveCN110510544AIncrease the support areaWeight increaseLifting framesTotal factory controlProduction lineVehicle frame

The invention discloses a logistics transportation vehicle suitable for an automatic production line, and relates to the field of logistics transportation equipment. The logistics transportation vehicle comprises a frame, a lifting module, a limiting module, a support module and a conveying module; the lifting module adopts a double-shear fork lifting mechanism, so that the support area of a lifting platform is increased, the bearing weight of the lifting platform is increased, and the stable ascending-descending movement of the lifting platform during bearing heavy-load shelves is guaranteed;along with the lifting motion of the lifting module, the functions of the limiting module and the support module can be synchronously and orderly achieved; when the shelves are placed on the transportation vehicle or transferred, the transportation vehicle can be fixed without shaking along with external disturbances, and the shelves in the transportation vehicle are limited to guarantee the transportation safety; and meanwhile, through linkage mechanisms, the transportation vehicle is simpler and more reasonable in structure, and can stably, safely and smoothly convey the shelves onto the automatic production line.

Owner:安徽共生众服供应链技术研究院有限公司

Magnetic suspension trolley

PendingCN110406385AIncreased durabilitySmooth up and down movementElectric propulsionEngineeringWelding

The invention discloses a magnetic suspension trolley, which comprises a trolley body, a base and a guide frame. The magnetic suspension trolley is characterized in that sliding rails are correspondingly arranged on the base; a guide frame is arranged between the two sliding rails; the trolley body is arranged at the top of the guide frame; a dustproof component is arranged at the top of each sliding rail; a fixed shaft is correspondingly fixed in the guide frame through welding; a bearing is arranged outside the fixed shaft; an outer ring is fixed outside the bearing through welding; a semicircular groove is arranged in the outer ring; a semicircular guide rail is arranged at one side of each sliding rail; each semicircular groove is in contact with the corresponding semicircular guide rail; a second rib plate is connected between one side of each sliding rail and the base; a spindle is fixed at the top of the guide frame through welding; a third rib plate is connected between the spindle and the guide frame; a shaft sleeve is fixed in the middle of the trolley body through a bolt; and balls are uniformly arranged on the inner wall of the shaft sleeve. The magnetic suspension trolley has the characteristics of stable operation and good dustproof effect.

Owner:北京首旺科技有限公司

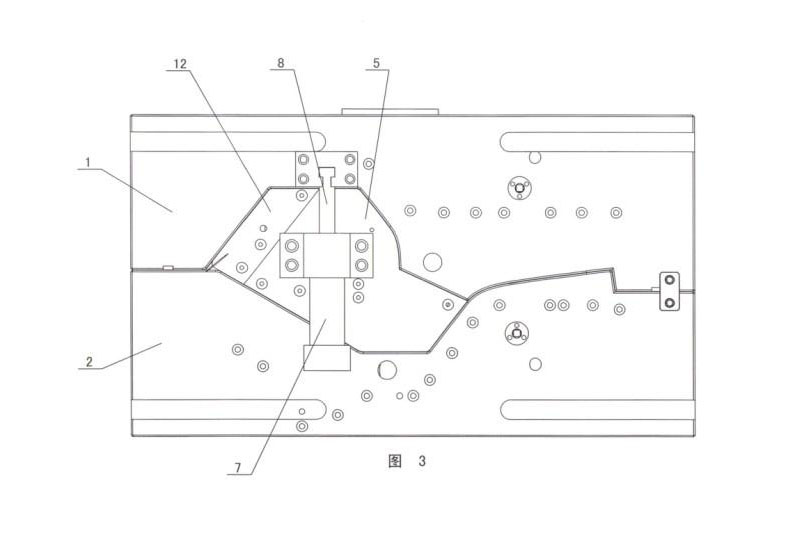

Punching device for metals

The invention provides a punching device for metals and relates to the technical field of metal machining equipment. The punching device for metals comprises an operating table; a placement plate is disposed at the top of the operating table; fixed plates are fixedly mounted on the two sides of the top of the operating table, one fixed plate is provided with a motor, and a bearing seat is fixedlymounted on the inner side of the other fixed plate; and a threaded rod is fixedly mounted at the output end of the motor through a coupler. According to the punching device for metals, a punching roller is indirectly driven through forward-backward rotation of the motor, thus the punching roller regularly punches a tension part, punching through driving of a traditional oil cylinder is avoided, contamination to the tension part is effectively prevented, the operation workload of maintainers is relieved, and time and labor are saved; and by arranging a punching frame, the up-and-down moving range of the punching roller can be changed, thus punching can be performed on tension parts which need different punching sizes, and the application properties of the punching device are wider.

Owner:陈婷

A hospital bed for critically ill patients

ActiveCN108578108BReduce workloadEasy programmingChiropractic devicesNursing bedsGear wheelElectric machinery

Owner:宋子康

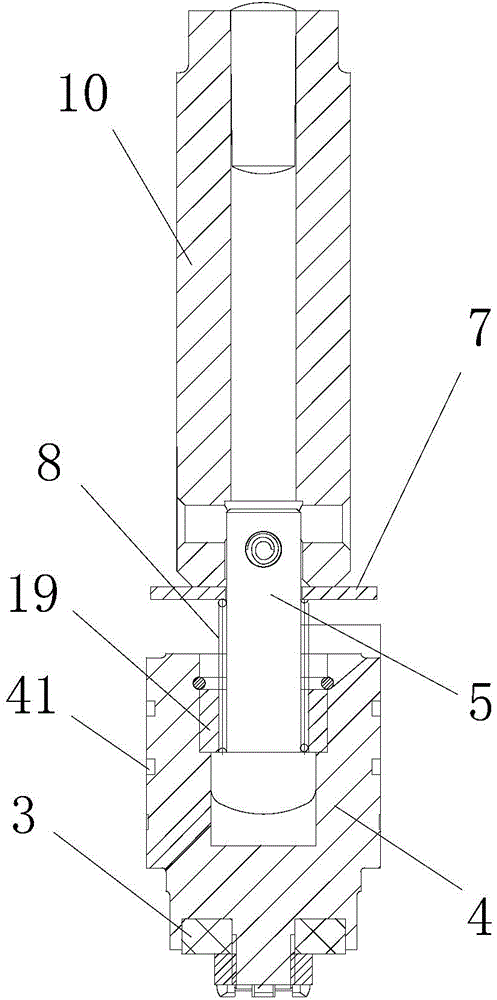

Electromagnetic valve for low temperature pipeline

ActiveCN104696575AReduce resistanceSmooth up and down movementOperating means/releasing devices for valvesLift valveMechanical engineeringElectromagnetic valve

The invention relates to an electromagnetic valve for a low temperature pipeline. The electromagnetic valve comprises a valve body, a valve cover, a valve rod and valve clacks. A pilot assembly is arranged on the valve cover, an iron core capable of moving vertically is arranged in the pilot assembly, the upper end of the valve rod is connected with the iron core, a protection cover is arranged on the outer portion of the valve cover, and an electromagnetic coil is arranged in the protection cover. A spring and a washer sleeve the valve rod. An inlet cavity, a valve clack cavity and an outlet cavity are arranged in the valve body. A valve port is formed in the valve body at the bottom of the valve clack cavity and communicated with the outlet cavity, and the side portion of the valve clack cavity is communicated with the inlet cavity. The valve clacks are arranged in the valve clack cavity, a gap is formed between the outer walls of the valve clacks and the inner wall of the valve clack cavity, and at least one annular groove is formed in the outer walls of the valve clacks. The gap is formed between the valve clacks and the inner wall of the valve clack cavity, so that valve clack moving resistance is reduced, vertical movement of the valve clacks is smooth, air circulation is smooth, freezing cannot happen easily, the electromagnetic valve is applicable to low temperature which can reach -196 DEG C, and the pressure can reach 2.5 MPa.

Owner:ZHANGJIAGANG FURUI SPECIAL EQUIP CO LTD

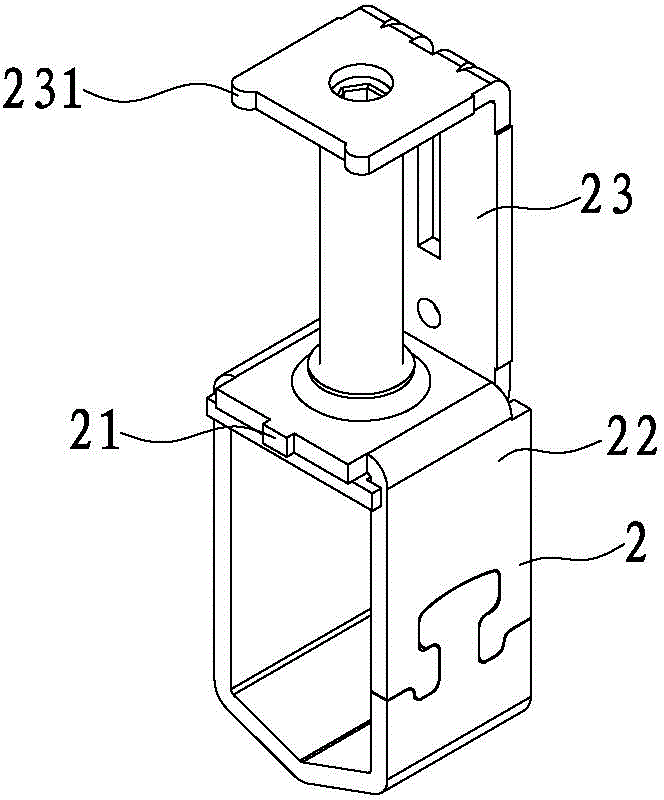

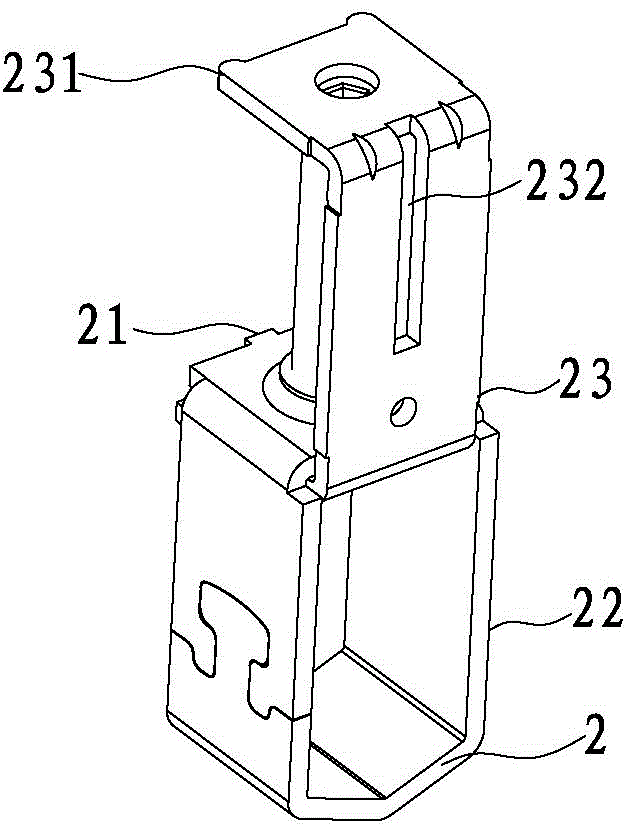

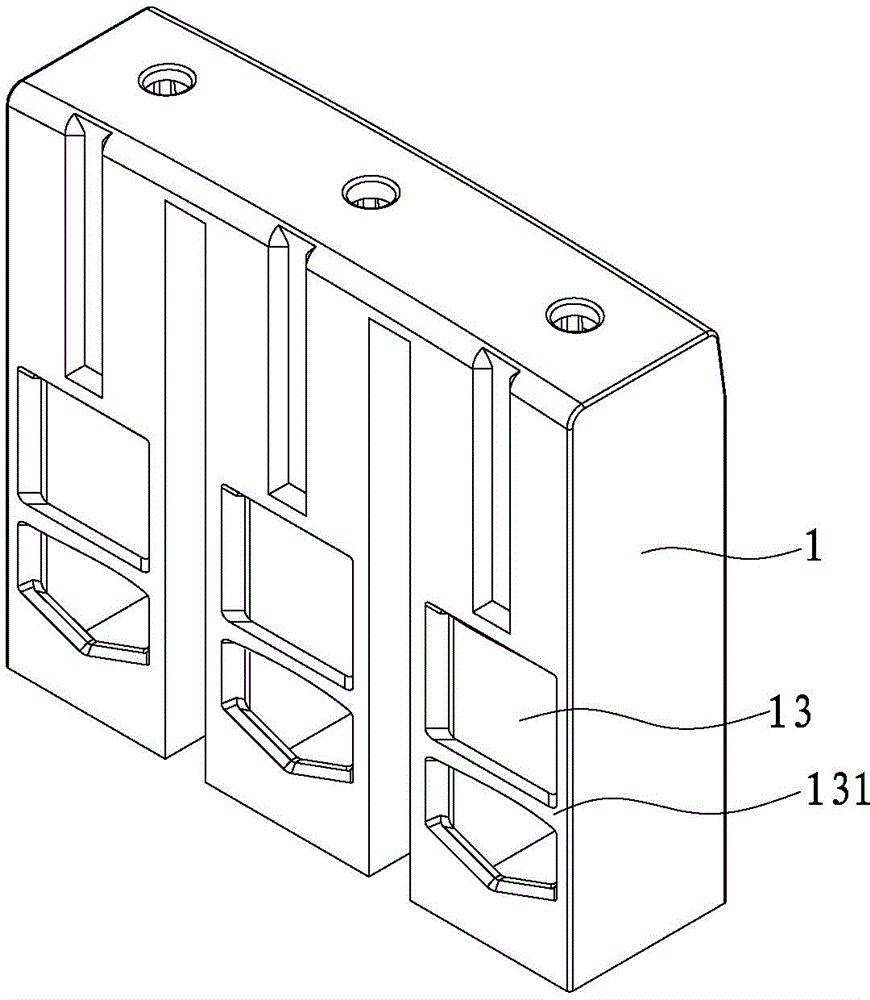

Contactor wire terminal component structure

ActiveCN104576214AThe range of activities is controllableSolve the problem of lifting the wire frameElectromagnetic relay detailsContactor

The invention discloses a contactor wiring terminal component structure which is arranged on a contactor shell. The contactor wiring terminal component structure comprises wiring terminal modules and wiring frames, the wiring terminal modules are installed on the shell and from one or more installation cavities. One end of each installation cavity is closed, and the other end is open. One side wall of each installation cavity of each wiring terminal module is provided with a passing hole, a fixed contact passes through the passing hole, the other side wall is provided with a socket, and a wire is inserted in the socket. A boss is formed on each wiring frame, a through groove is formed in each wiring terminal module, each wiring frame is arranged in each installation cavity of each wiring terminal module, and the boss can move in the through groove. According to the contactor wiring terminal component structure, the fixed contact is convenient to wire, the structure is simple, and the cost is low.

Owner:XIAMEN HONGFA ELECTRICAL SAFETY & CONTROLS CO LTD

Special equipment for ceramic cutting

PendingCN113414879AIncreased cutting freedomReduce jitterWorking accessoriesStone-like material working toolsStructural engineeringManufacturing engineering

The invention relates to the technical field of band sawing machines, in particular to special equipment for ceramic cutting. The equipment comprises a base, a saw bow structure is arranged at the lower end of the base and comprises two opposite saw bows hinged to the lower end of the base, first telescopic rods are hinged to the two saw bows, the other ends of the first telescopic rods are hinged to the base, at least two guide wheels are oppositely arranged in the two saw bows, and a diamond saw rope is jointly wound around the four guide wheels. A diamond saw rope is tensioned through the saw bows and the guide wheels, then the diamond saw rope is driven to act along the guide wheels so as to achieve the cutting function, the principle is similar to that of a band sawing machine, and compared with a saw blade which can only be used for cutting through a tooth-shaped part, all positions on the circumferential face of the diamond saw rope have the cutting function; and it is guaranteed that the saw bows can conduct cutting at all angles, and the cutting freedom degree is increased.

Owner:浙江协力机械工具有限公司

Operation method of logistics transport vehicle suitable for automatic production line

ActiveCN112389520AIncrease the support areaWeight increaseTotal factory controlHand carts with multiple axesProduction lineLogistics management

The invention discloses an operation method of a logistics transport vehicle suitable for an automatic production line, and relates to the field of logistics transportation equipment, the logistics transport vehicle comprises a vehicle frame, a lifting assembly, a limiting assembly, a supporting assembly and a conveying assembly, and the lifting assembly adopts a double-shear-fork lifting mechanism, the supporting area of the lifting platform is enlarged, the weight borne by the lifting platform is increased, it is guaranteed that the lifting platform can stably ascend and descend when bearinga heavy-load goods shelf, the functions of the limiting assembly and the supporting assembly can be synchronously and orderly achieved along with ascending and descending of the lifting assembly, andwhen the goods shelf is placed on a transport vehicle or transferred, the transport vehicle can be fixed and cannot shake along with external interference, the goods shelf in the transport cart is limited, transport safety is guaranteed, meanwhile, the linkage mechanism reflects that the structure of the transport cart is simpler and more reasonable, and the goods shelf can be stably, safely andsmoothly conveyed to an automatic production line.

Owner:ANHUI SYMBIOSIS PUBLIC SERVICE SUPPLY CHAIN TECH RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com