Traffic cone separation and warehousing device

A technology of traffic cones and separation plates, applied in traffic signals, roads, road signs, etc., to achieve the effects of low energy consumption, simple and compact structure, and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

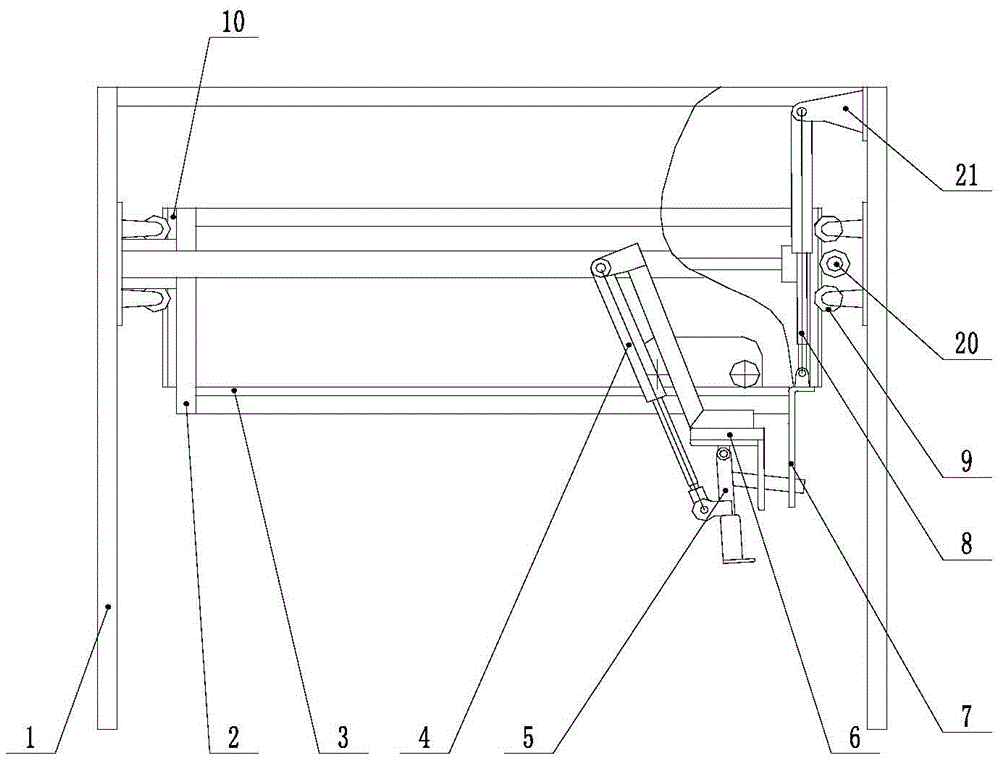

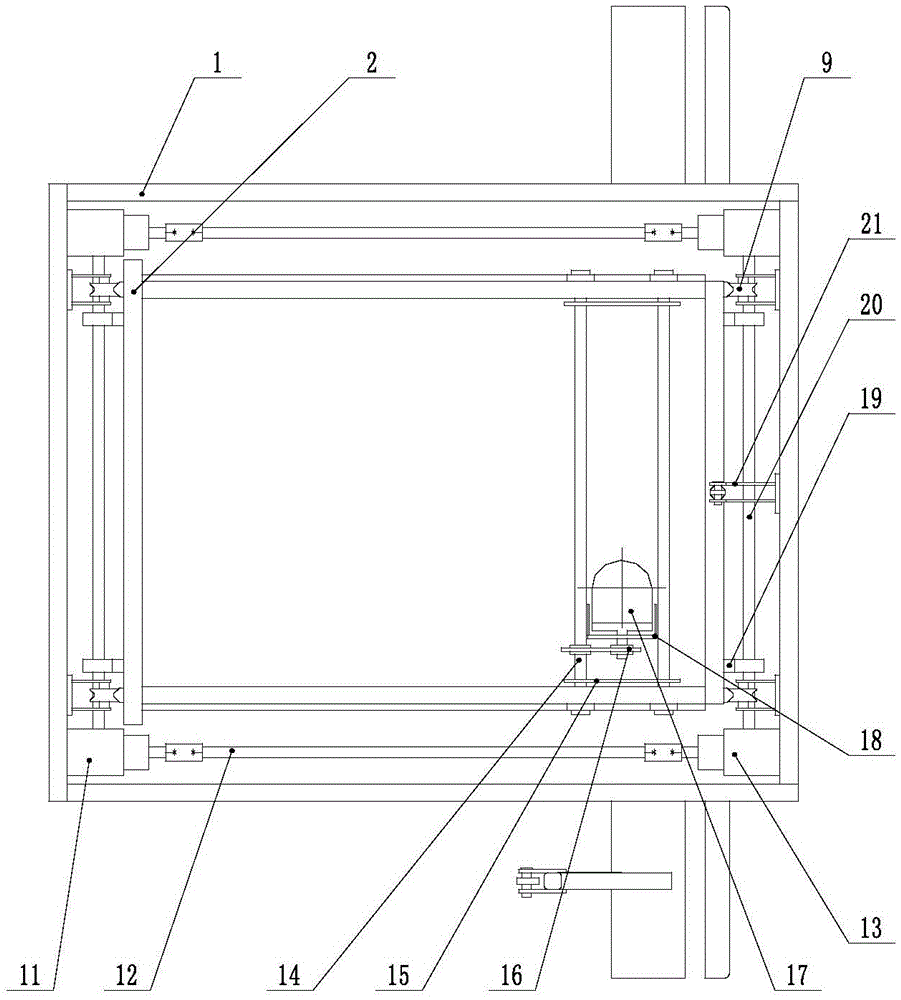

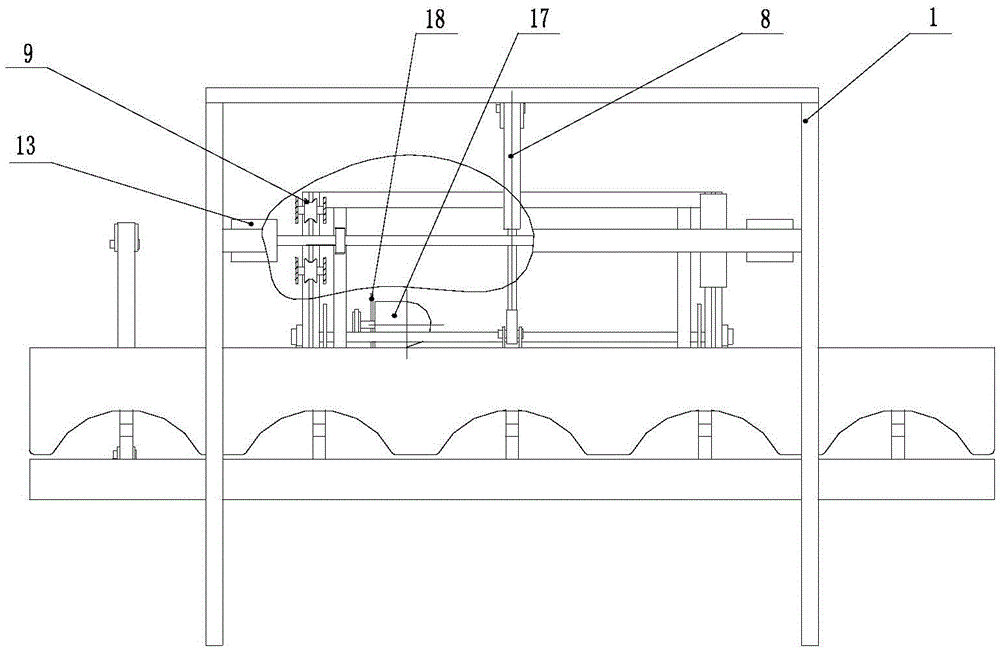

[0024] exist figure 1 , 2 , 3, the traffic cone separation of the present embodiment and the warehousing device are composed of a fixed mount 1, a lifting frame 2, a horizontal rack 3, a swing cylinder 4, a gripper 5, a movable frame 6, a separation plate 7, a lifting frame oil cylinder 8, Roller set 9, guide rail 10, left mechanical commutator 11, first linkage shaft 12, right mechanical commutator 13, second linkage shaft 14, shaft seat 15, sprocket chain transmission mechanism 16, drive motor 17, motor bracket 18, the vertical rack 19, the third linkage shaft 20, and the oil cylinder seat 21 are connected to form.

[0025] The geometric shape of the fixed frame 1 is a rectangular parallelepiped frame, and the cylinder seat 21 is fixedly connected with a threaded fastening connector on the middle part of the upper longitudinal beam on the right side of the fixed frame 1, and the threaded fastened connector is used on the right side middle longitudinal beam of the fixed fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com