Concrete stirring device for constructional engineering

A technology for construction engineering and mixing devices, which is applied in the direction of cement mixing devices, clay preparation devices, cleaning methods and utensils, etc. It can solve the problems of single mixing method and poor finished products, and achieve the effect of preventing shaking, preventing sticking, and smooth up and down displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

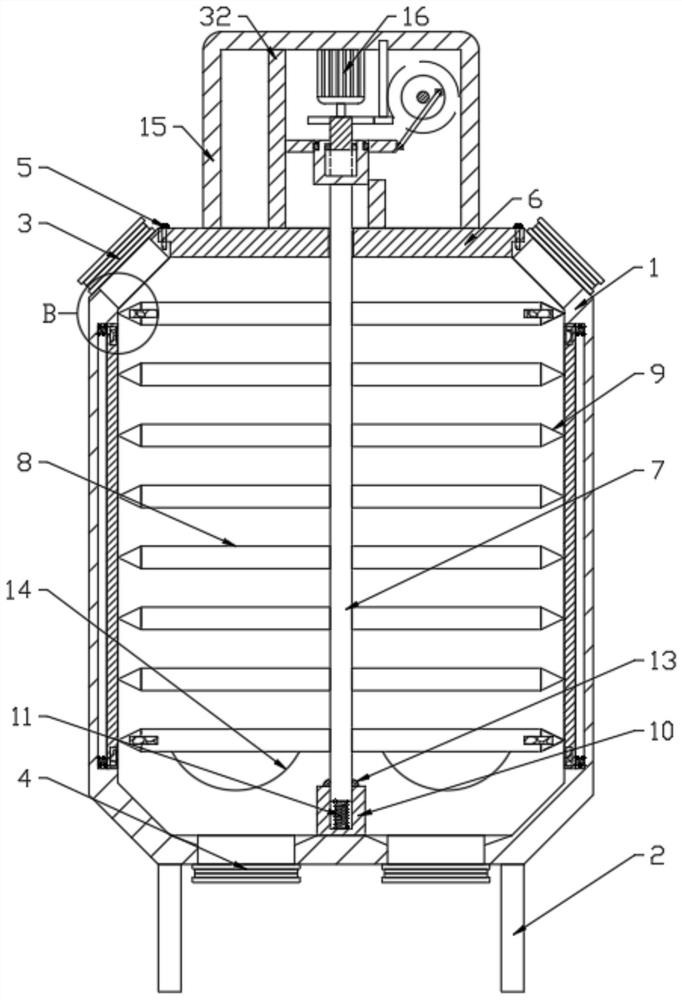

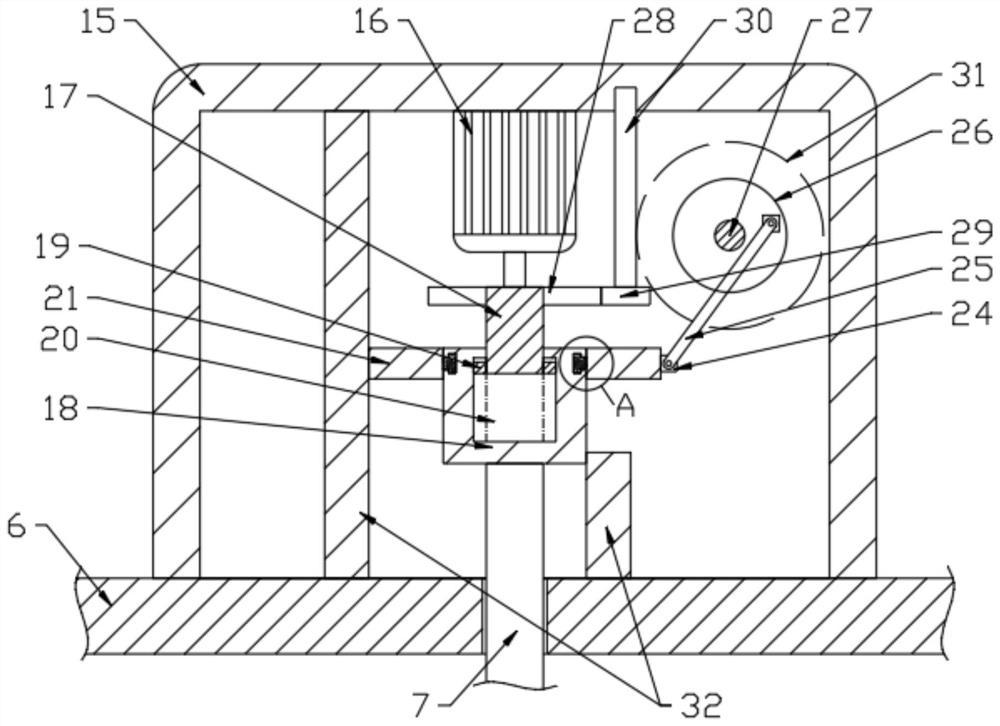

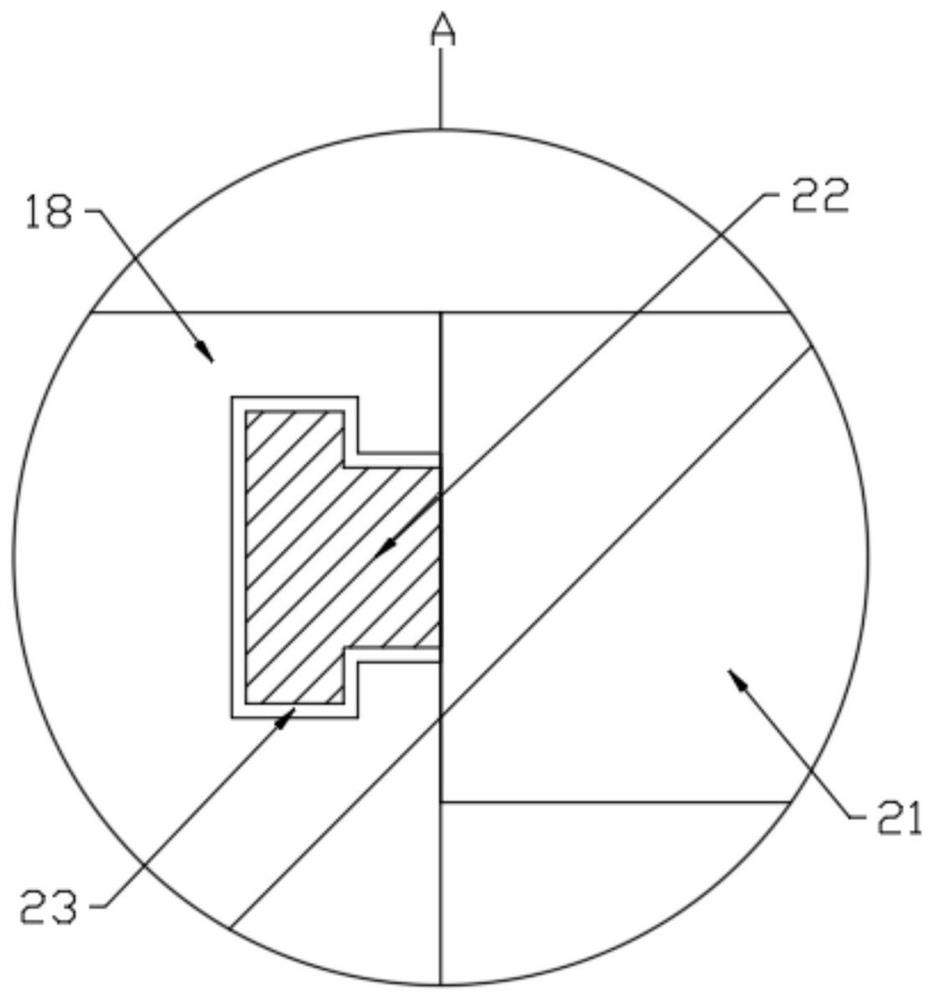

[0025] see Figure 1-5 , a concrete mixing device for construction engineering, comprising a box body 1 and a number of feed ports 3 arranged on the upper side of the box body 1, a number of discharge ports 4 and support columns 2 are provided at the lower end of the box body 1, and the upper end of the box body 1 passes through The connecting bolt 5 is connected with the box cover 6, and the rotating rod 7 is connected to the inside of the box body 1, and a number of stirring columns 8 are fixedly connected to the sides of the rotating bar 7. The casing 15 is provided with a rotating assembly that drives the rotating rod 7 to rotate. The casing 15 is provided with a displacement assembly that drives the rotating rod 7 to move up and down. The casing 15 is provided with a connecting assembly that drives the displacement assembly. The side wall of the casing 1 A moving cylinder 33 is provided, and a vibrating assembly for driving the moving cylinder 33 to vibrate is arranged in...

Embodiment 2

[0042] Further improvements are made on the basis of Embodiment 1, and the improvements are as follows: the lower end of the bottom stirring column 8 is fixedly connected with a briquetting block 14, and the cross-sectional profile of the briquetting block 14 is semicircular, and the bottom stirring column 8 follows the When the rotating rod 7 rotates and displaces up and down, the briquetting block 14 fixedly connected with the mixing column 8 displaces up and down, thereby making the concrete mixing effect on the lower side of the box body 1 better and the quality of the finished product is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com