Patents

Literature

35results about How to "Good finished product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biological air freshening disinfectant and preparation method thereof

InactiveCN106665669ARaw material natural greenNo side effectsBiocidePest repellentsBiotechnologyDisinfectant

The invention aims at providing a biological air freshening disinfectant, which is characterized by being prepared from the following raw materials in parts by mass: 1 to 3 parts of camphor, 2 to 4 parts of menthol, 2 to 4 parts of eucalyptus oil, 1 to 3 parts of borneol, 0.5 to 1.5 parts of clove oil, 0.5 to 1.5 parts of perilla leaf oil, 0.5 to 1.5 parts of patchouli oil, 0.5 to 1.5 parts of rosemasry oil and 70 to 90 parts of solvents. The biological air freshening disinfectant provided by the invention is applicable to indoor places such as living hours, bedrooms, washrooms, living rooms, kitchens, automobiles and offices, has the effects of killing bacteria and viruses, preventing influenza, expelling parasite, preventing mosquitoes, freshening the air and refreshing the brain, does not have toxic and side effects on human bodies, and belongs to the biological air freshening disinfectant capable of being used by old people, children and weak people.

Owner:湖南铭沃生物科技股份有限公司

Novel degradable composite plastic and preparation method thereof

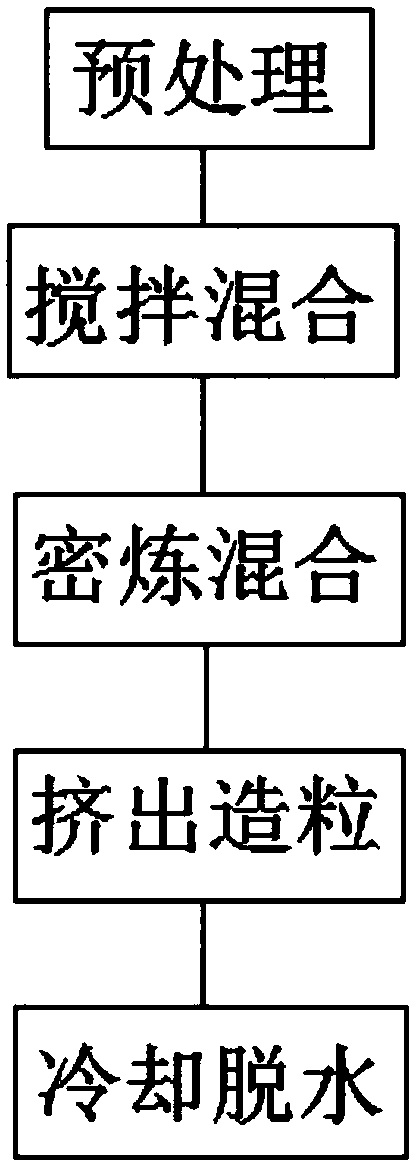

The invention relates to novel degradable composite plastic, comprising, by weight, 40-60 parts of polypropylene compound, 15-45 parts of micron plant short-staple, 5-15 parts of fillers, 3-7 parts ofcompatilizers, 0.4-0.6 part of antioxidant, 0.3-0.5 part of lubricant, 3-5 parts of antibacterial additives and 2-3 parts of biodegradable agents. Under cooperation of photocatalytic degradation andmicro-biological degradation, the composite plastic has excellent degradation performance, mechanic performance and mechanical property. A preparation method of the novel degradable composite plasticincludes pretreatment, mixing with stirring, mixing with a mixer, extrusion and granulation, cooling and dehydration, and the like. Components of the degradable composite plastic are mixed more dispersively By the preparation method, and thus, quality of the finished product is better.

Owner:广东力美新材料科技有限公司

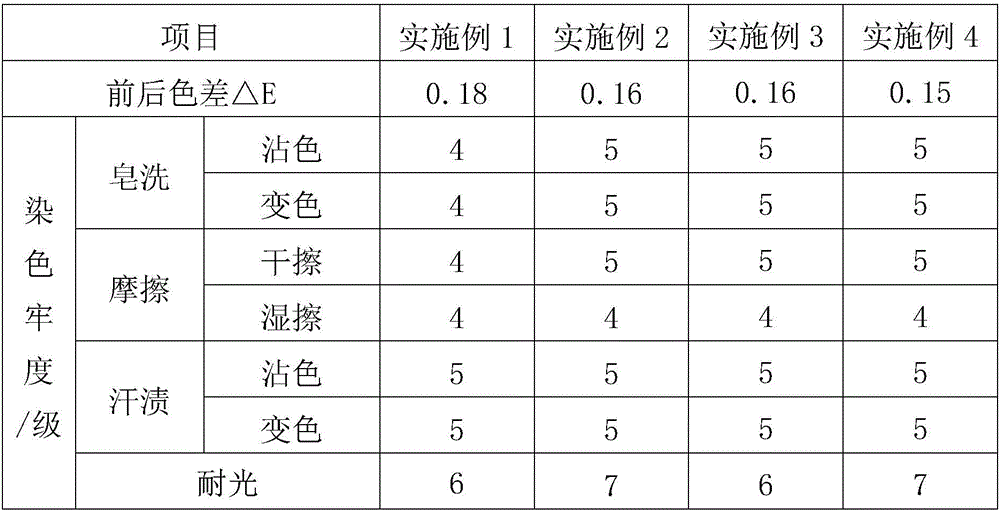

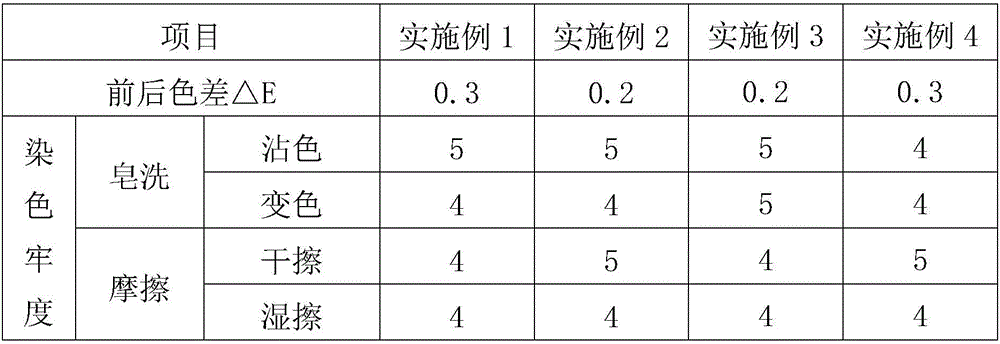

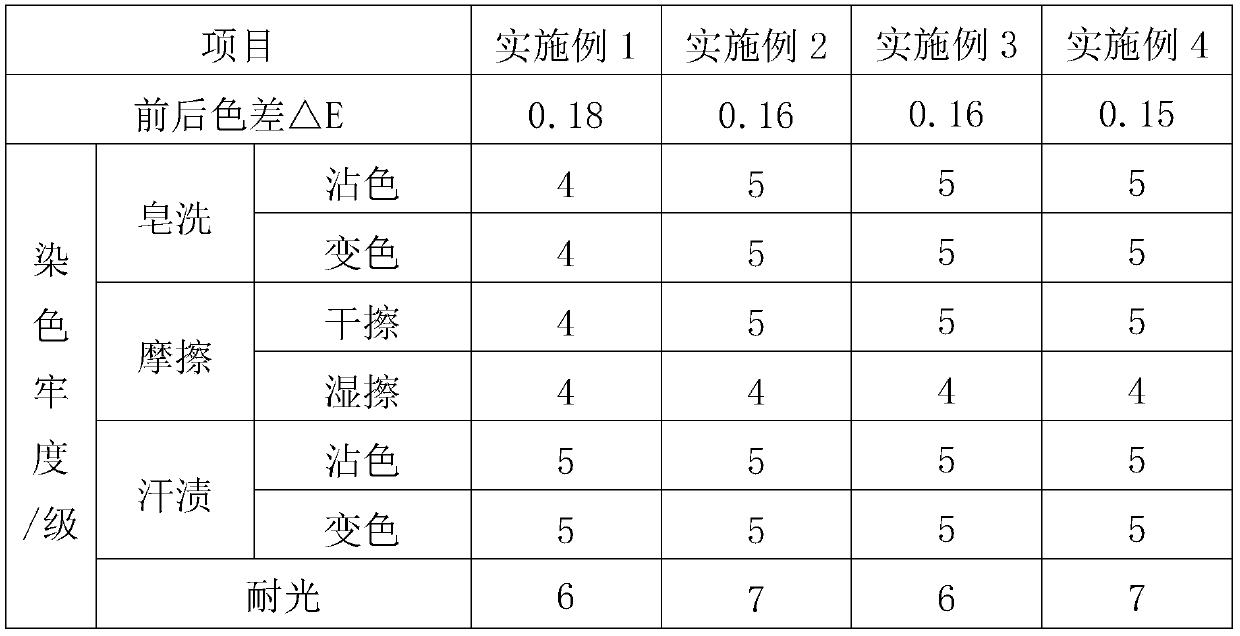

Vat dye suspension wet shortened steaming pad dyeing technology

ActiveCN106012587AImprove dye uptakeImprove stabilityDyeing processLiquid/gas/vapor textile treatmentDyeingHydrogen peroxide

The invention discloses a vat dye suspension wet shortened steaming pad dyeing technology. The technology includes the following steps of 1, dye liquor padding, wherein fabric to be dyed is padded in vat dye suspension dye liquor, dipping and padding are carried out twice respectively, and the vat dye suspension dye liquor is prepared from 0.1-5% of superfine powder vat dye (oxf), 1-20 g / L of a reductant, 1-3 g / L of a penetrant, 1-3 g / L of a dispersant and 5-30 g / L of an accelerant; 2, alkali liquor padding, wherein the fabric to be dyed is directly padded in alkali liquor, dipping and padding are carried out once respectively, and the alkali liquor is prepared from 5-30 g / L of caustic soda and 0-10 g / L of sodium hydrosulfite; 3, steam reduction, wherein saturated steam is adopted for rapid steaming; 4, oxidation, wherein hydrogen peroxide is adopted for oxidation. According to the vat dye suspension wet shortened steaming pad dyeing technology, the level dyeing property and color fastness of the dyeing technology are significantly improved; besides, the technology is simple and saves energy.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

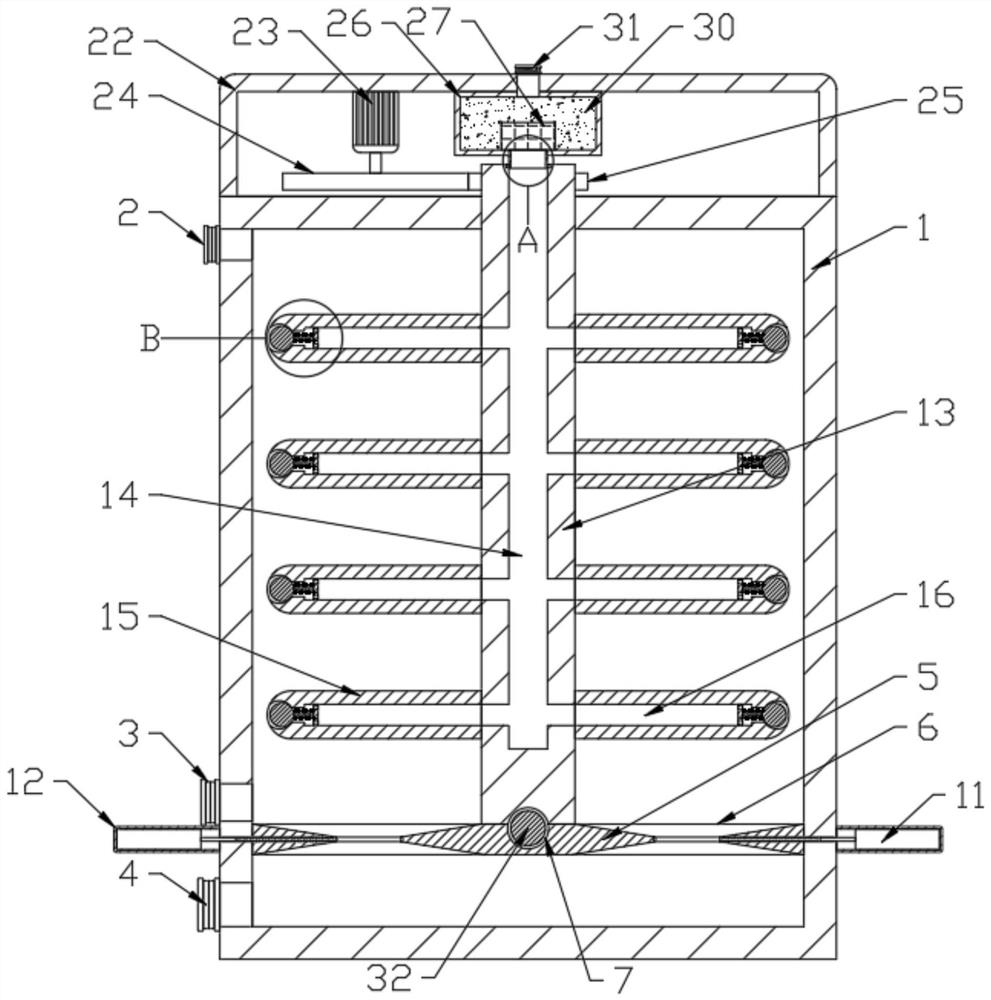

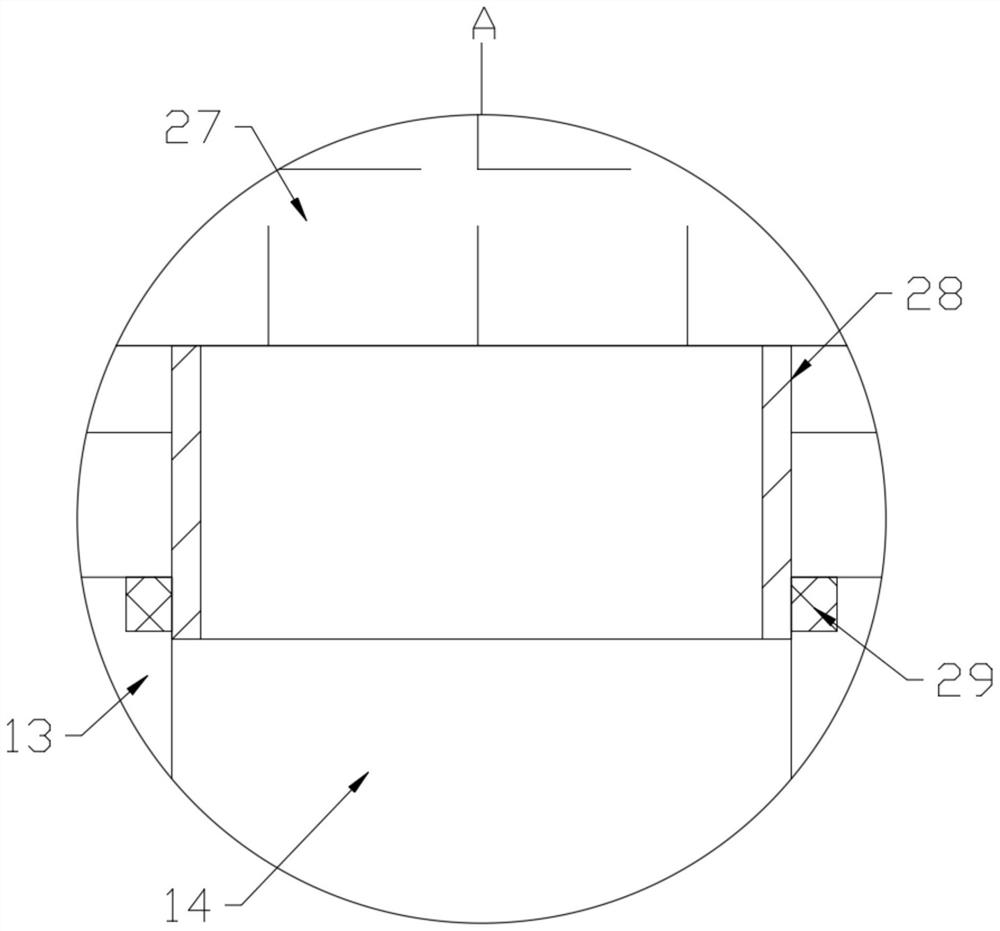

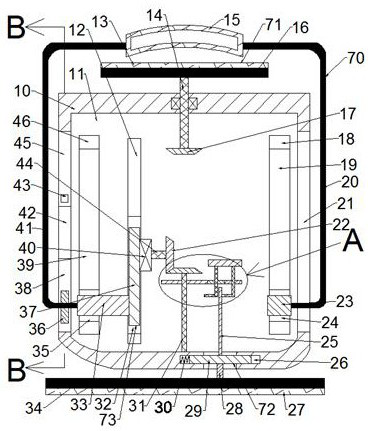

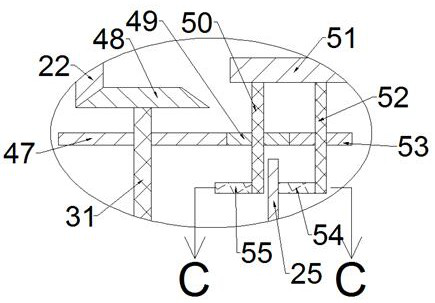

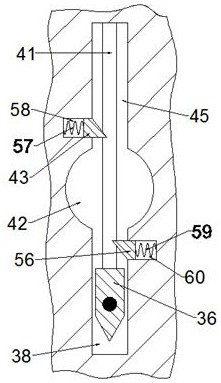

Engineering sewage disposal device

InactiveCN111977765ANo flowGood finished productRotary stirring mixersTransportation and packagingElectric machinerySewage

The invention discloses an engineering sewage disposal device. The engineering sewage disposal device comprises a box body, a water inlet, a water outlet and a sewage outlet, wherein the water inlet,the water outlet and the sewage outlet are formed in the side face of the box body; a fixing plate with two falling grooves and a rotary drum are arranged in the box body; a sealing assembly is arranged on the side face of the box body; a cavity is formed in the rotary drum, and a plurality of stirring rods are arranged on the rotary drum; a transverse cavity which communicates with the cavity isarranged in each stirring rod; a control assembly for controlling whether the transverse cavity communicates with the interior of the box body or not is arranged in each stirring rod; a case is fixedly connected to the upper end of the box body; a driving assembly is arranged in the case; and a conveying assembly for conveying flocculation liquid to the cavity in the rotary drum is arranged in thecase. A motor drives the rotary drum in the box body to rotate, the stirring rods on the rotary drum are driven to stir sewage in the box body, in the stirring process, self-adding of flocculating liquid is achieved through elasticity of a first spring, work of a liquid conveying pump in a liquid storage box and rotation speed adjustment of the rotary drum, and the flocculating liquid is added while stirring is conducted; and the flocculation liquid can be effectively mixed with the sewage for reaction, and impurities in the sewage are removed.

Owner:苏州和必尔斯电子科技有限公司

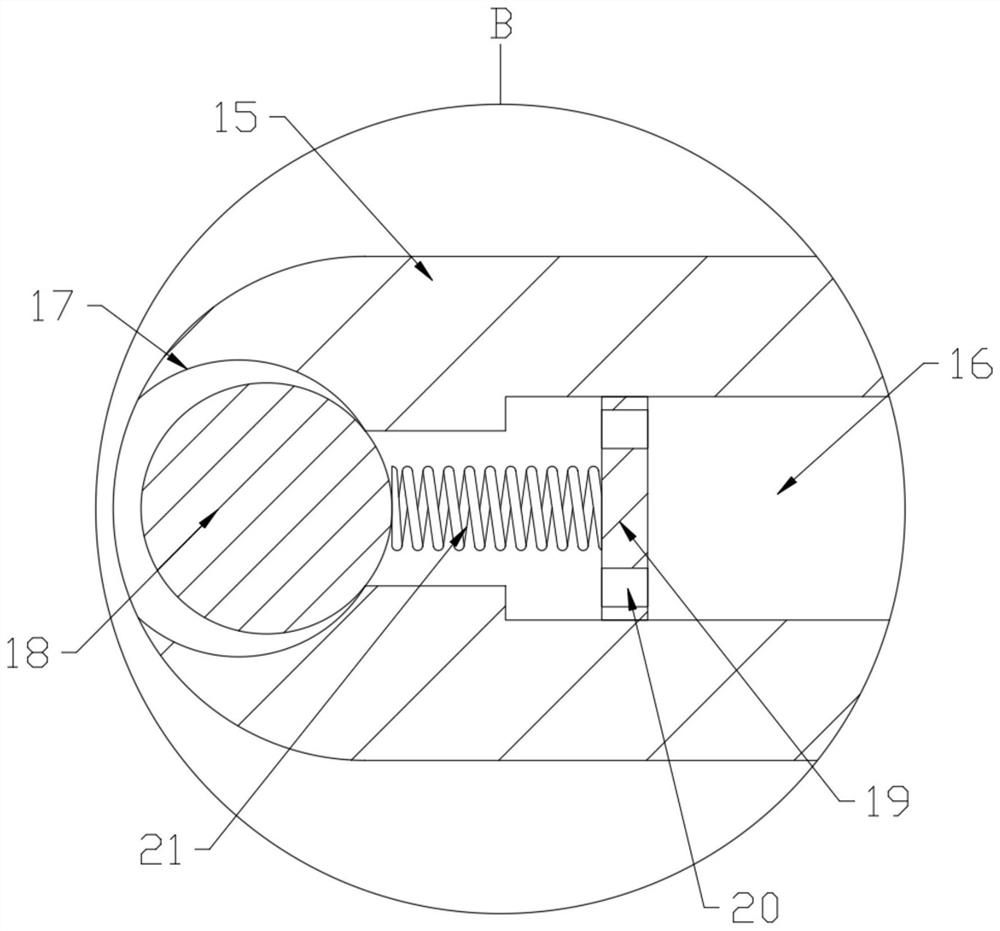

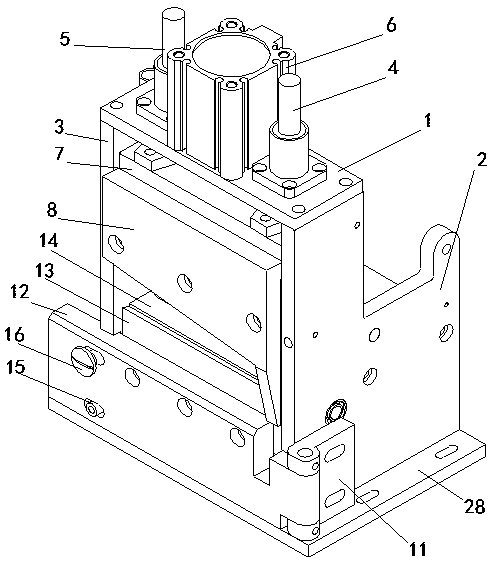

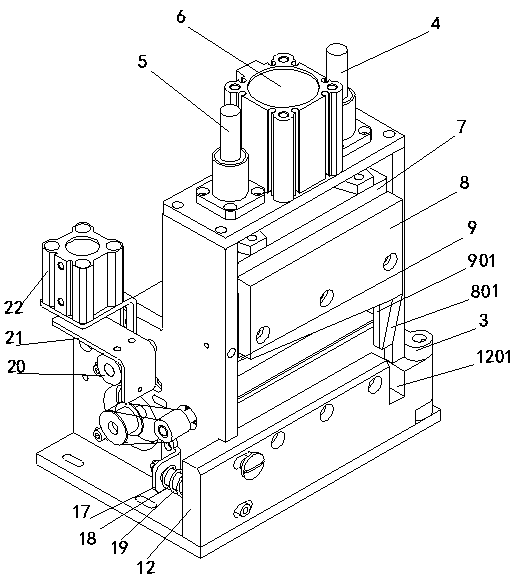

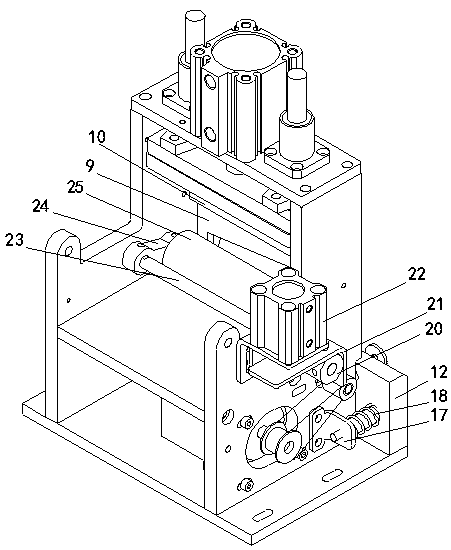

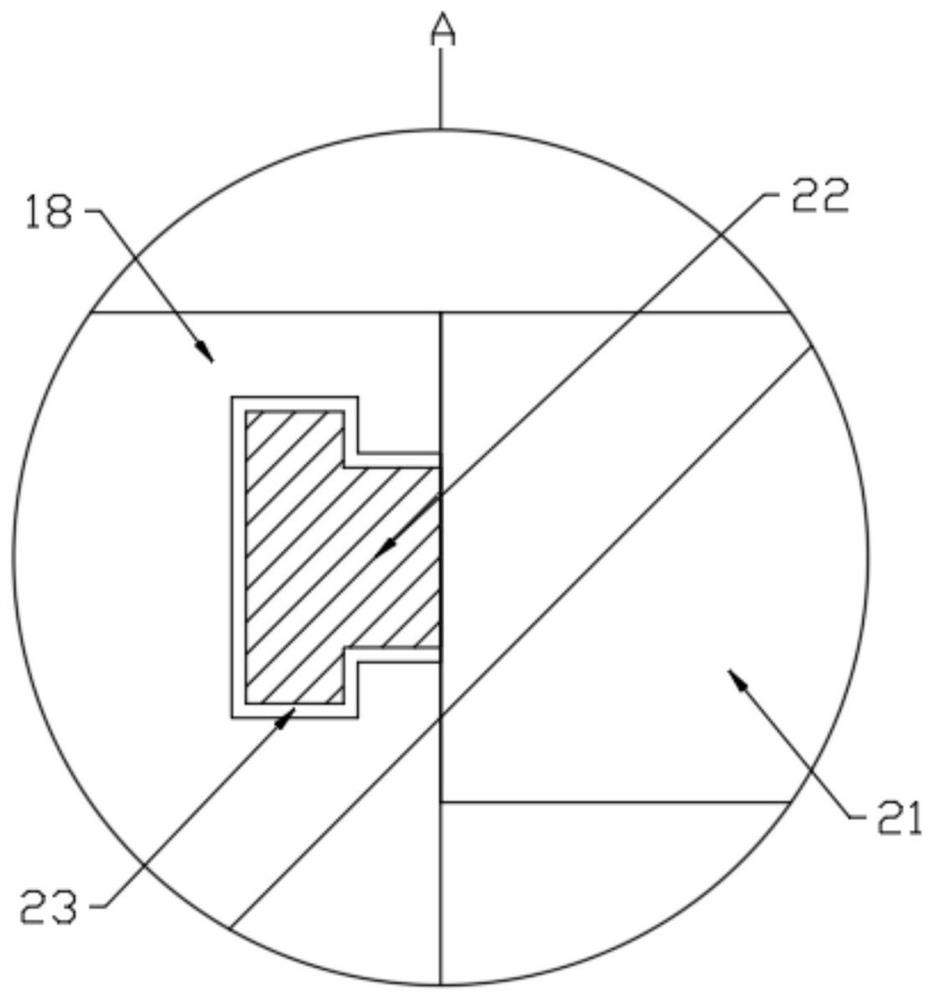

Material cutting device of rubber band machine

PendingCN108312194AMiniaturization and low costEasy to driveMetal working apparatusEngineeringMechanical engineering

The invention discloses a material cutting device of a rubber band machine. A feeding and fixing support comprises a support plate, and a left connecting plate and a right connecting plate arranged ontwo sides of the lower end surface of the support plate; an upper cutter group is arranged at the lower end of the support plate and is an ultrasonic cutter group; a driving mechanism comprises a driving air cylinder and a guiding pillar connected with the upper cutter group and penetrating through the support plate, and can drive the upper cutter group to displace up and down; a lower cutter group is arranged at the lower end of the upper cutter group in a matching way; one end of the lower cutter group is connected with the left connecting plate; and the other end of the lower cutter groupis connected with an adjustable position of the right connecting plate. The material cutting device of the rubber band machine provided by the invention adopts the driving air cylinder and the guidingpillar for driving the ultrasonic cutter to cut a rubber band, and is simple in overall driving manner, good in stability, and excellent in effect on obtaining a finished product through ultrasonic cutting; the overall material cutting device is small in size and low in cost so as to adapt to the overall assembling of the rubber band machine; and in addition, through designing the lower cutter group, the left connecting plate and the right connecting plate, a cutting angle and a cutting position can be conveniently adjusted, so that the material cutting device is applicable to the requirements of different cutting environments.

Owner:台州安卓缝纫机有限公司

Wet short steaming pad dyeing process adopting vat dye microcapsules

ActiveCN106012376AImprove stabilityImprove dyeing effectTextile treatment containersTextile treatment machine arrangementsColour fastnessPh buffering

The invention discloses a wet short steaming pad dyeing process adopting vat dye microcapsules. The wet short steaming pad dyeing process comprises procedures as follows: S1, padding and rolling in a dyeing : to-be-dyed fabric is padded in the dyeing for double padding and double rolling, and the dyeing is prepared from 0.1%-10% (owf) of the vat dye microcapsules, 1-20 g / L of thiourea dioxide, 1-3 g / L of a pH buffering agent, 1-3 g / L of a penetrant and 5-30 g / L of an accelerator; S2, padding and rolling in an alkaline : the to-be-dyed fabric obtained through treatment in S1 is directly padded and rolled in the alkaline for single padding and single rolling, and the alkaline is prepared from 5-30 g / L of caustic soda and 0-10 g of sodium dithionite; S3, reduction and steaming: saturated steam is used for rapid steaming; S4, oxidization: hydrogen peroxide is adopted for oxidation. By means of the wet short steaming pad dyeing process adopting the vat dye microcapsules, the level dyeing property and the color fastness are remarkably improved, the process is simple and energy is saved.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

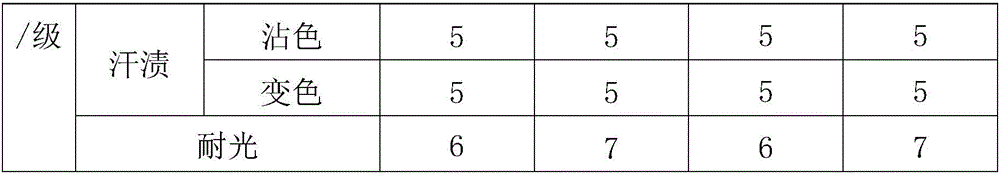

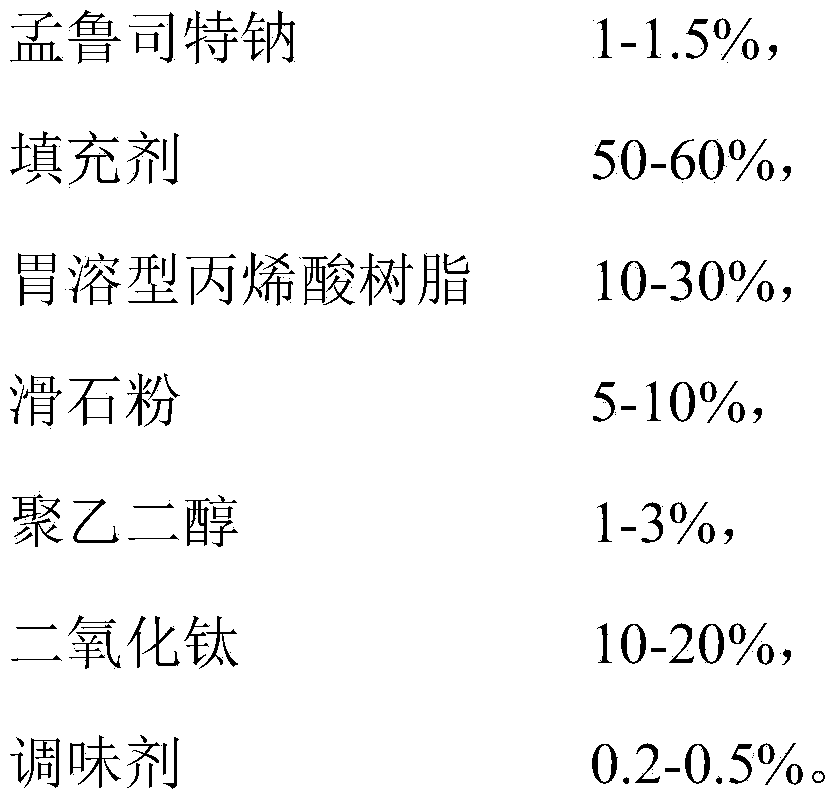

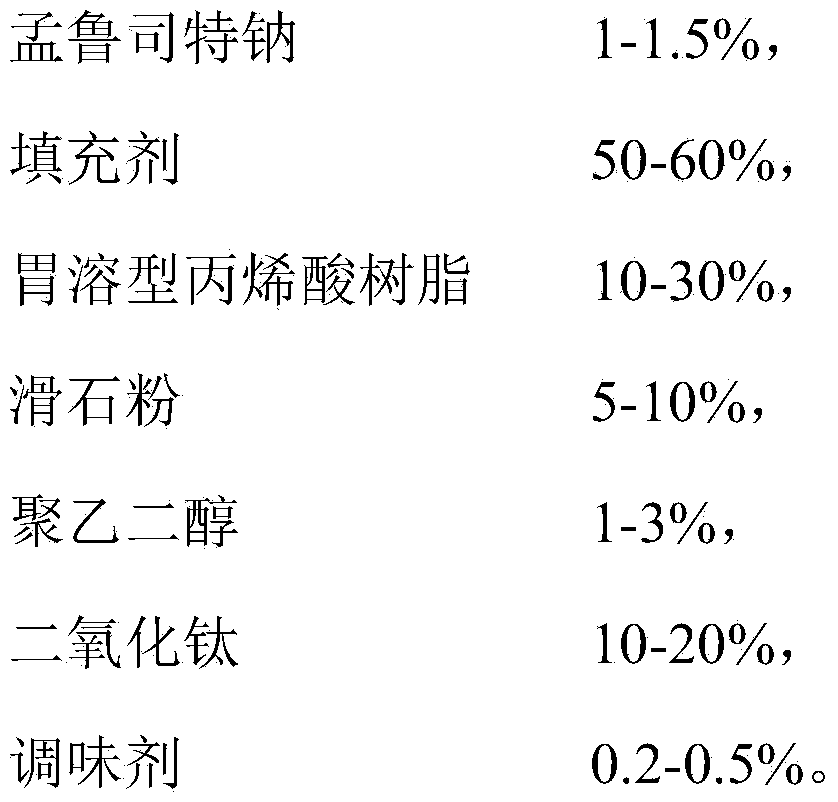

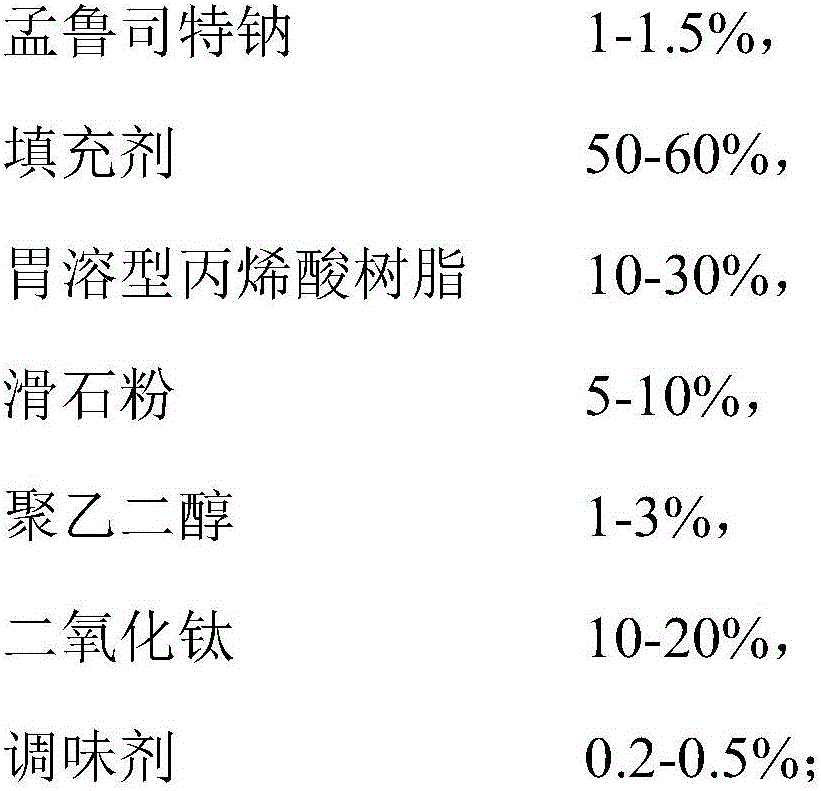

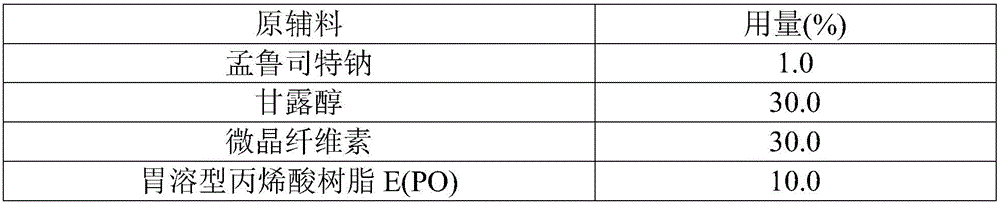

Montelukast granule machine and preparation method of montelukast granule

InactiveCN103860480AReduce the impactSafe to takeInorganic non-active ingredientsGranular deliveryPolyethylene glycolMontelukast Sodium

The invention provides a montelukast granule. The montelukast granule is prepared from the components in percentage by weight: 1-1.5 percent of montelukast, 50-60 percent of filler, 10-30 percent of gastric-soluble acrylic acid resin, 5-10 percent of talc, 1-3 percent of polyethylene glycol, 10-20 percent of titanium dioxide and 0.2-0.5 percent of flavoring agent. With the adoption of the montelukast granule, with the gastric-soluble acrylic acid resin as a coating material and the titanium dioxide as an opacifying agent, as the gastric-soluble acrylic acid resin is difficult to be dissolved in water, and due to the shading action of the titanium dioxide, the influence on the gastric-soluble acrylic acid resin under illumination is retarded, so that the montelukast granule is stable within 1 hour as well as is more safe and convenient to take. The invention also discloses a preparation method of the montelukast granule.

Owner:珠海天翼医药技术开发有限公司

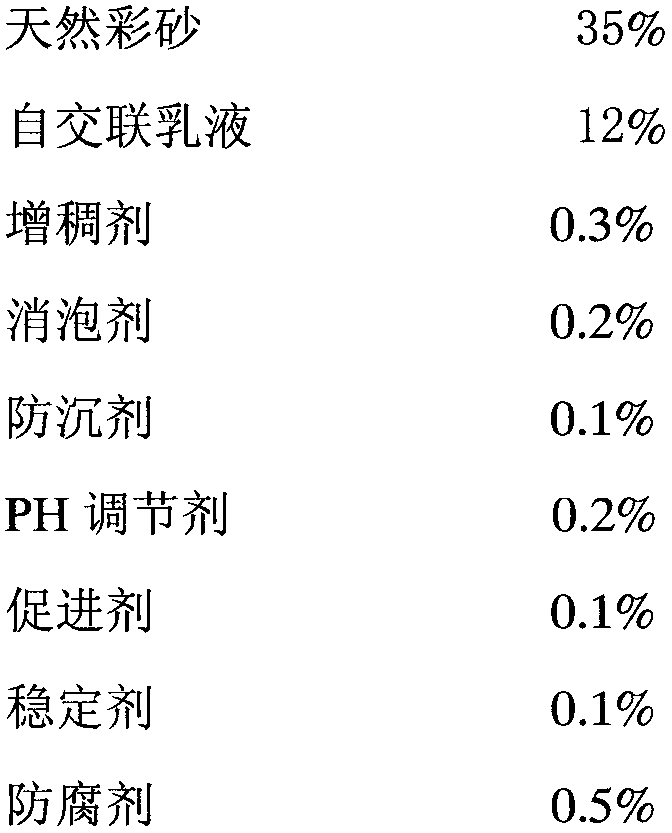

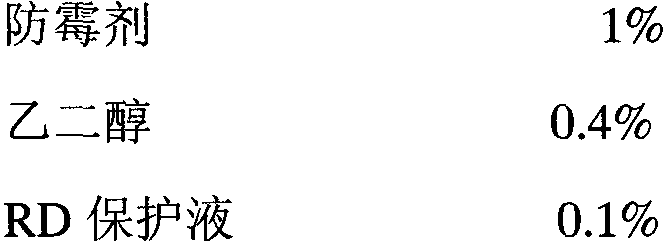

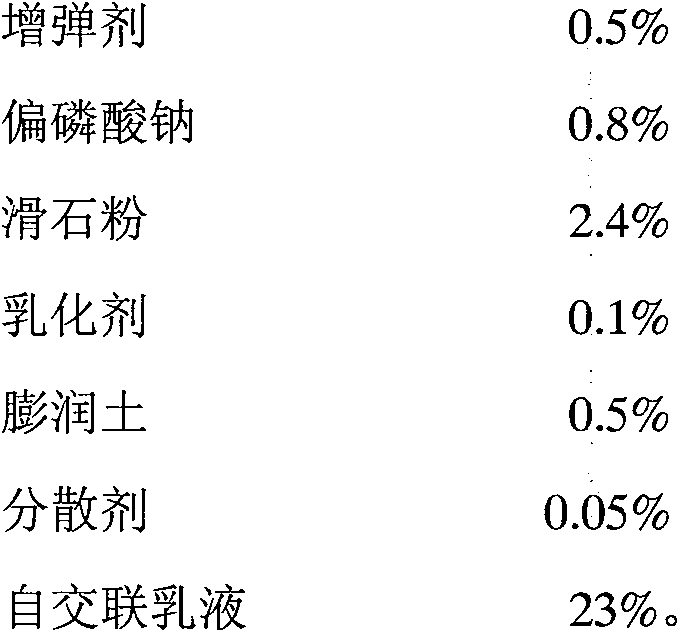

Rock color coating and preparation method thereof

ActiveCN103396035AImprove crack resistanceTo increase crack resistance, increase the amount of self-crosslinking emulsionChemistryCoating

The invention discloses a rock color coating. The coating is a composition of an agent A and an agent B, wherein the weight ratio of the agent A to the agent B is 1:1. A preparation method of the coating comprises the following steps: preparing the agent A and the agent B respectively and then uniformly mixing the agent A and the agent B according to the weight ratio of 1:1 to obtain the rock color coating. The rock color coating has the characteristics of energy conversation, environment-friendliness, ultra acid / alkali resistance, durability, water resistance, attractive appearance, safety, and reliability.

Owner:杭州潮头建材有限公司

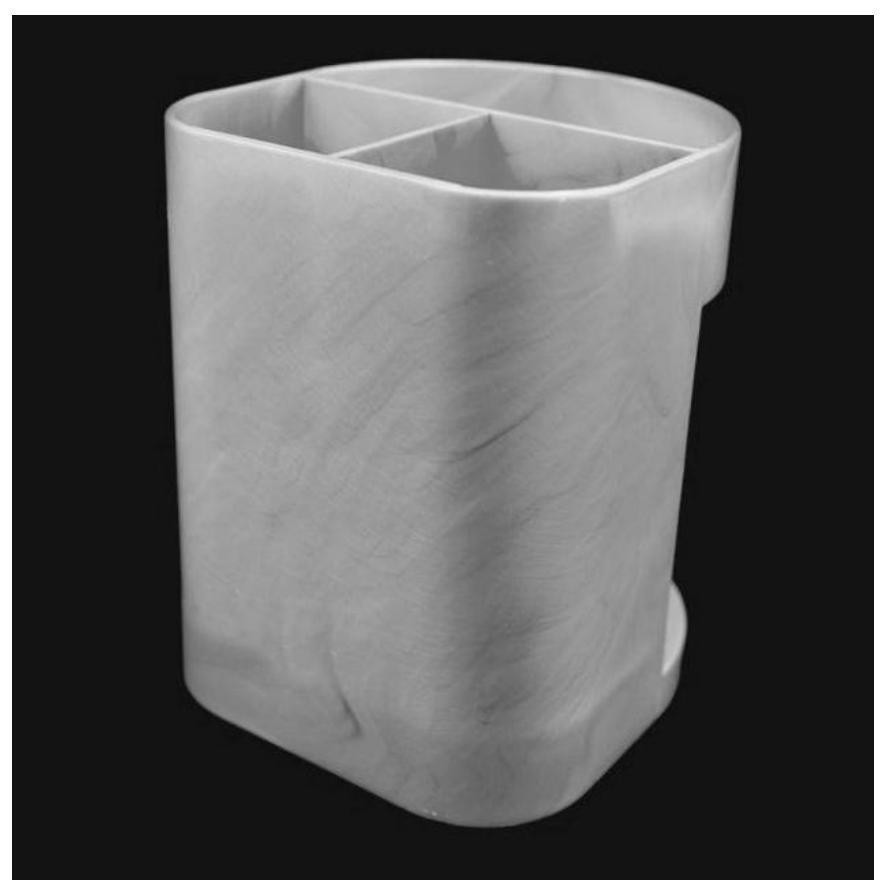

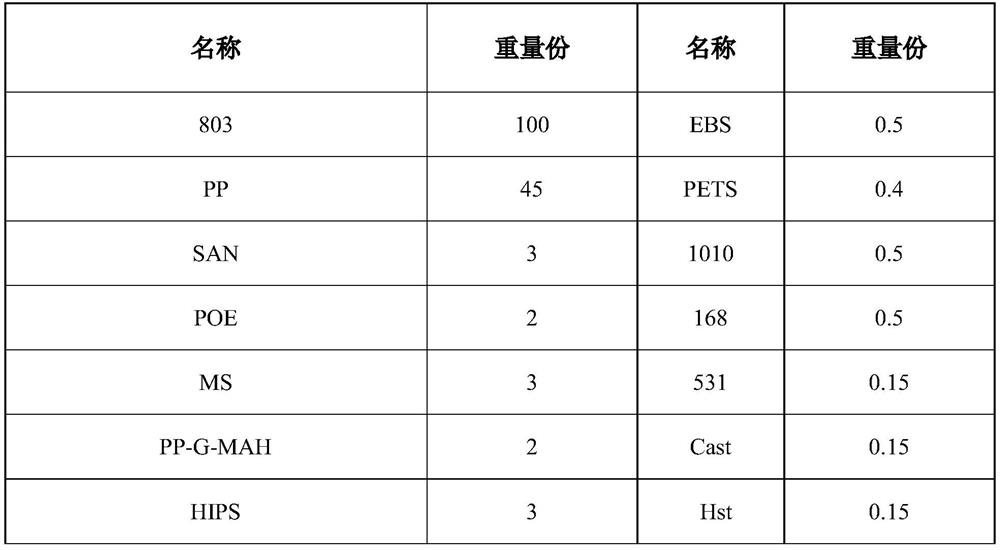

Environment-friendly composite plastic with pearlescent effect and multicolor pattern effect and preparation method of environment-friendly composite plastic

The invention belongs to the technical field of plastic preparation, and relates to an environment-friendly composite plastic with a pearlescent effect and a multicolor pattern effect and a preparation method of the environment-friendly composite plastic. The plastic is composed of the following components in parts by weight: 70-200 parts of styrene thermoplastic resin, 40-100 parts of auxiliary materials, 1-20 parts of a macromolecular compatilizer, 0.1-10 part of an auxiliary agent, 0.1-5 part of a lubricating agent and 0.1-4 part of a color master batch, wherein the auxiliary materials areMS, HIPS and PP; and the auxiliary agent is composed of an anti-aging agent, an anti-ultraviolet agent and an inorganic or organic filler. According to the invention, the appearance of the plastic canbe improved without adding pearl powder, pearl color masterbatch or special color masterbatch, and the plastic has the pearl effect and the multicolor pattern effect; the preparation method is simple, safe and environmentally friendly, and avoids high cost and pollution caused by secondary processing of plastic products; and meanwhile, the mechanical and physical properties and processability ofthe plastic can be adjusted to meet requirements of various actual application scenes, the defects of existing plastic products are overcome, and the method is high in yield, low in cost and suitablefor large-scale production.

Owner:南京元初科技有限公司

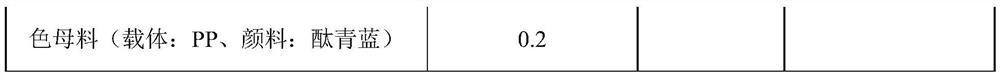

Gear machining process

The invention discloses a gear machining process. The gear machining process comprises the following steps that raw materials for making a gear are prepared and comprise, by weight, 9-12 parts of C, 4-6 parts of Cr, 900-1000 parts of Fe, 20-25 parts of Mo, 5-7 parts of Ni, 25-30 parts of Ti, 12-16 parts of Nb, 3-6 parts of Be, 3-6 parts of Ta, 3-6 parts of Zr, 3-6 parts of V, 3-6 parts of W, 3-6 parts of aluminium nitride, 4-7 parts of rare earth element, 4-7 parts of nanometer zirconium dioxide, 15-20 parts of surface treating agent and 50-80 parts of nitrogen, and mixed powder raw materialsA are put into a gear mold to be pressed and formed under pressure of 600-620 Mpa. The powder is made into the gear, the efficiency is high, a finished product is good, and the gear machining processis suitable for being popularized.

Owner:洪新阳

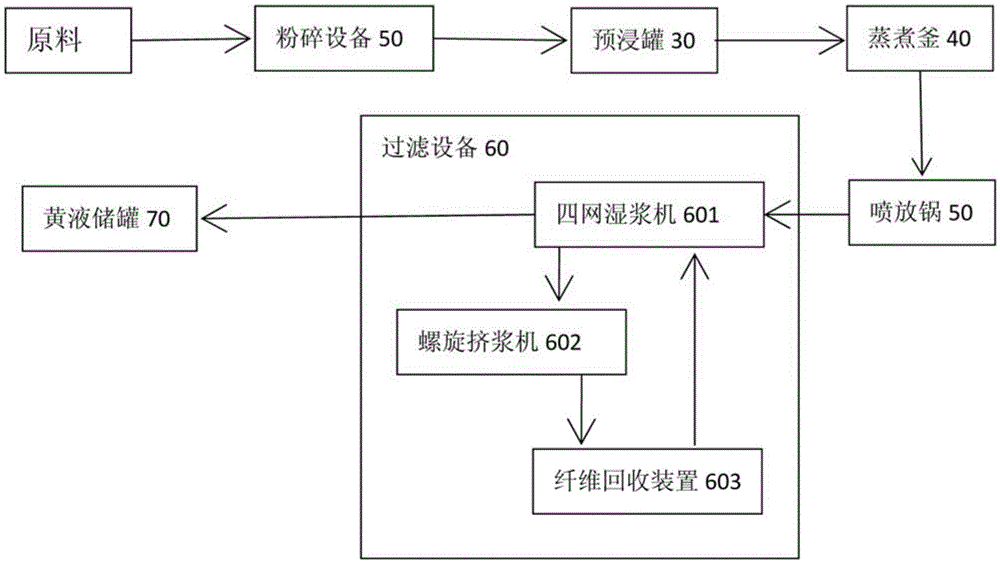

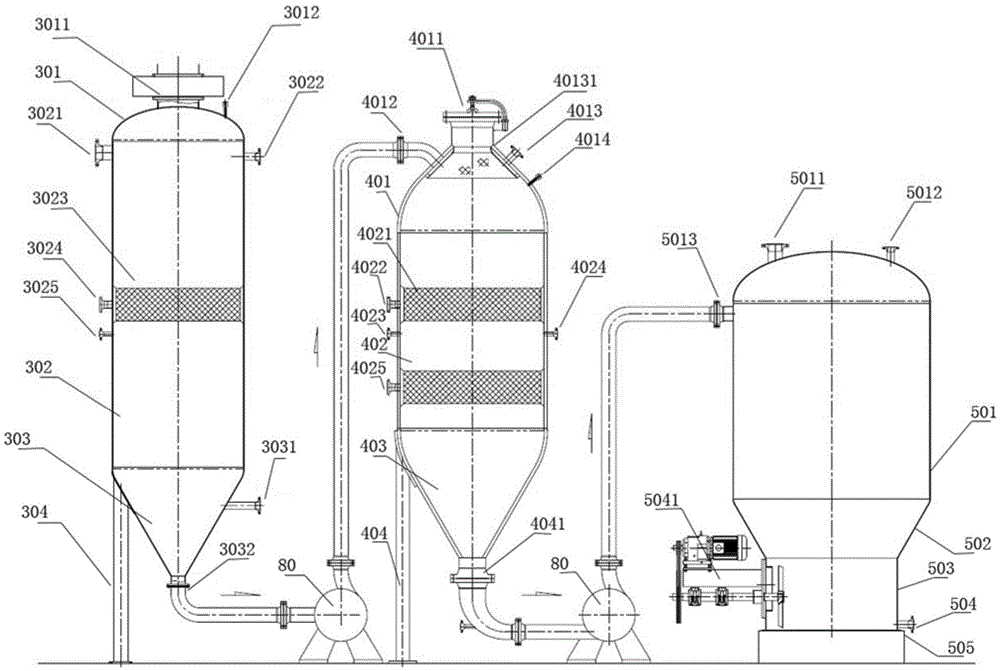

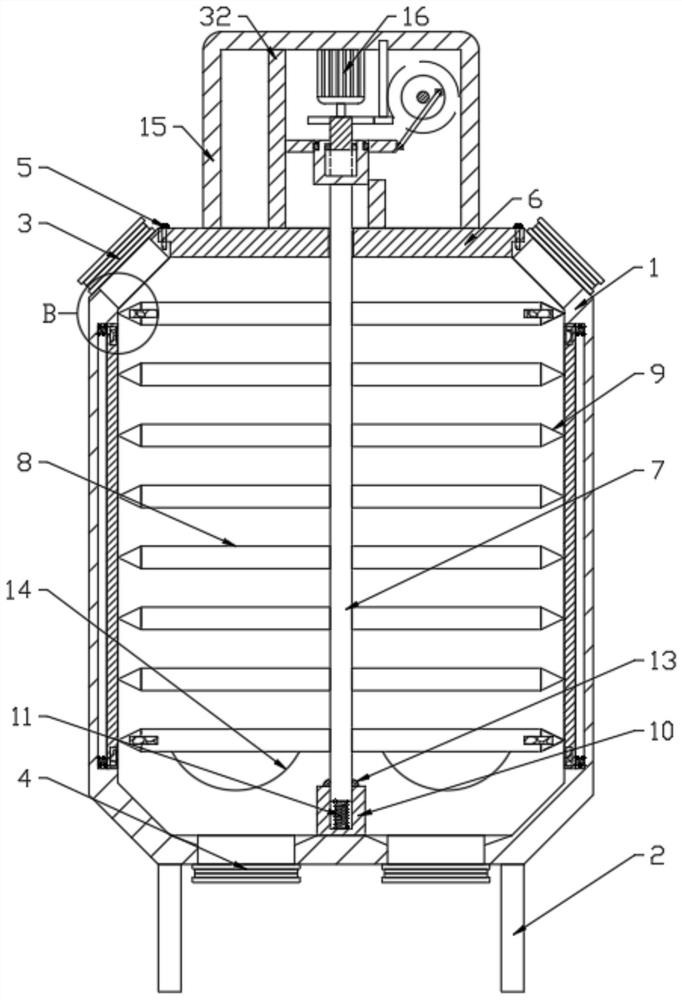

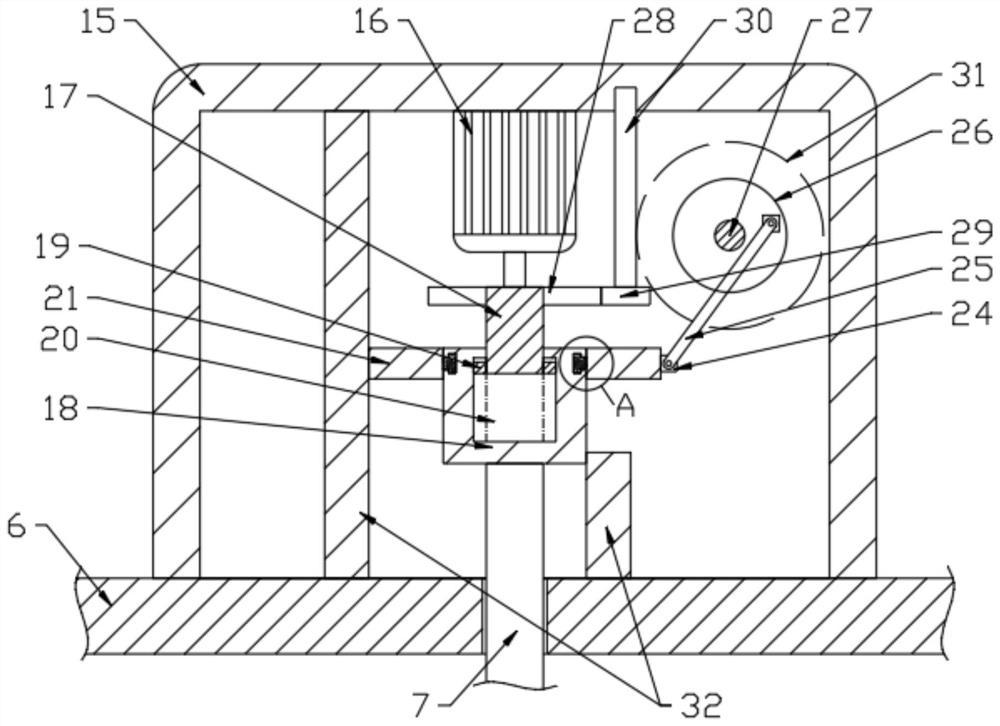

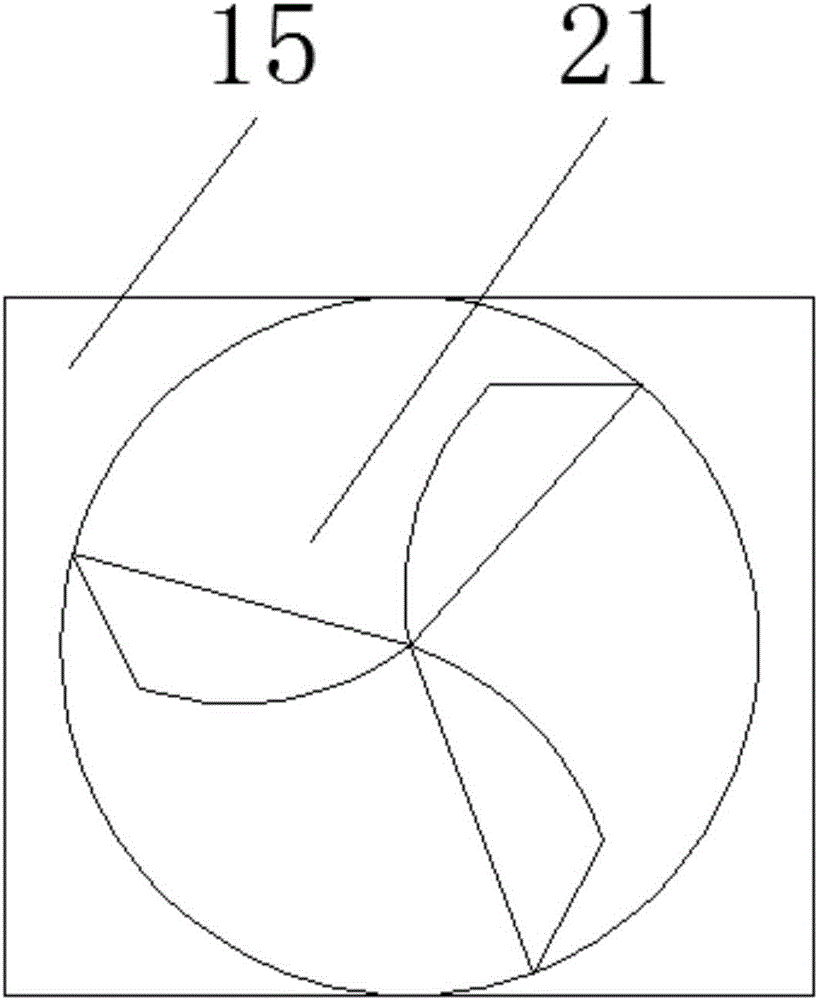

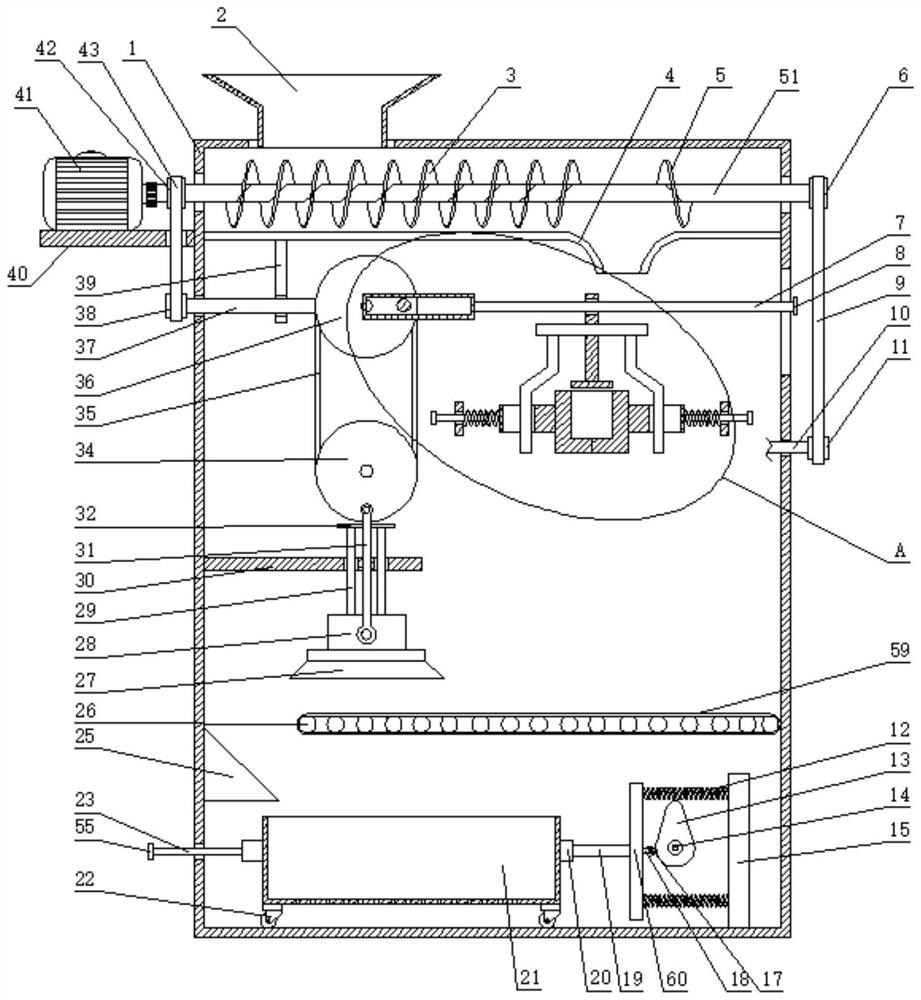

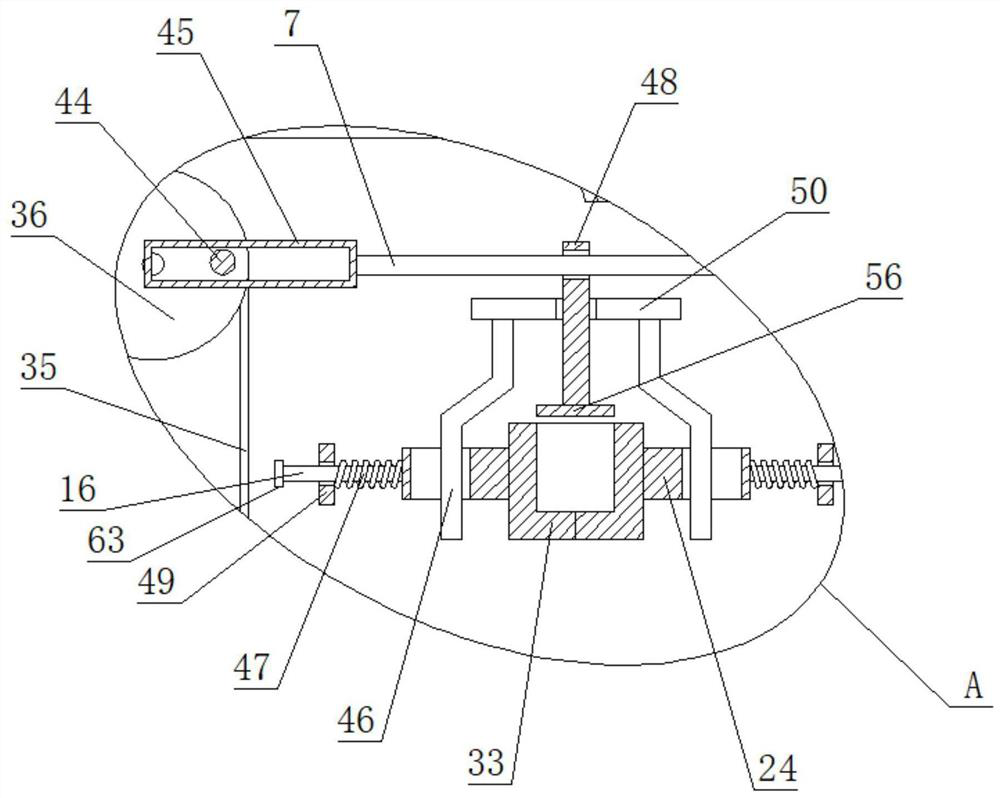

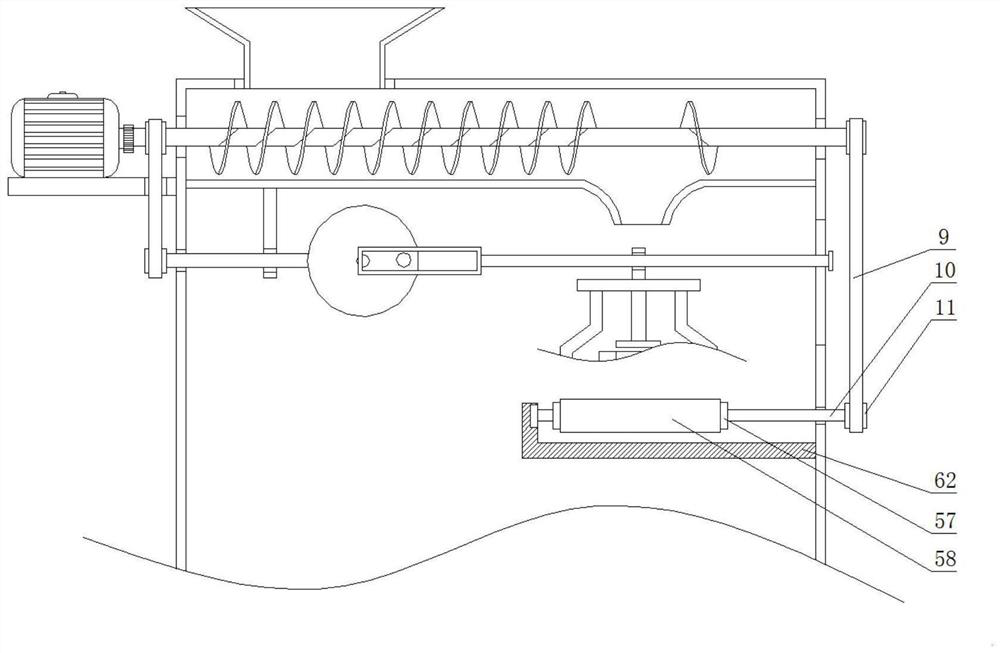

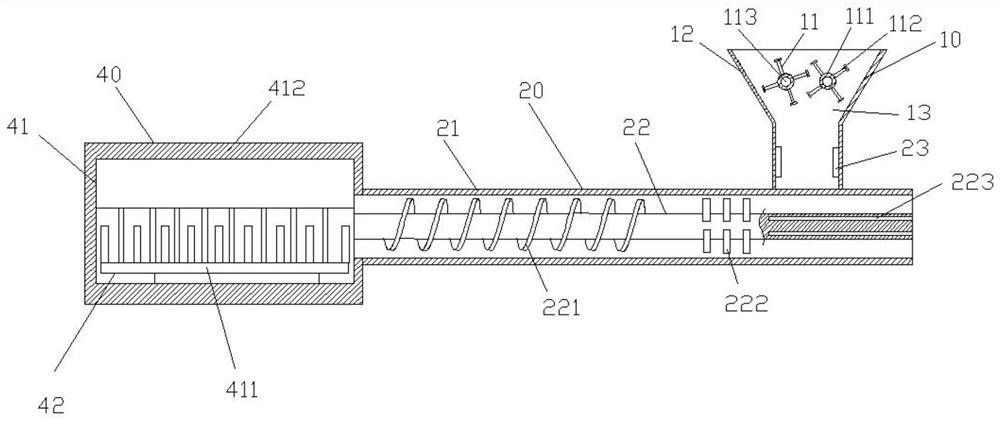

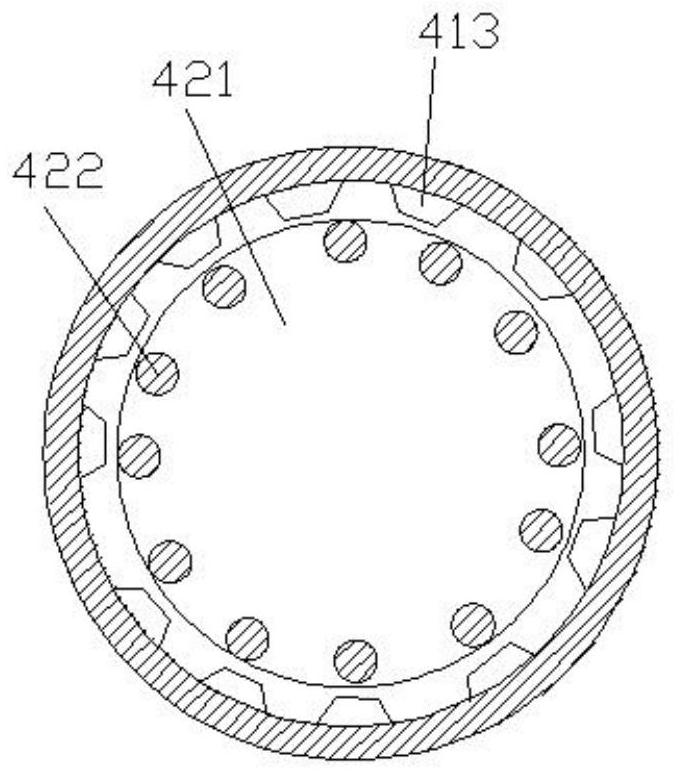

Equipment for preparing bamboo pulp

InactiveCN105484086AGood finished productPretreatment with water/steamDigestersWater immersionLiquid storage tank

The invention discloses equipment for preparing bamboo pulp. The equipment comprises pulverization equipment, a preimpregnation tank, a steaming and boiling kettle, a blow tank, filtering equipment and a yellow liquid storage tank; the pulverization equipment is used for pulverizing bamboo raw materials; the preimpregnation tank is used for conducting hot water immersion on the pulverized bamboo raw materials and generating initial bamboo pulp; the steaming and boiling kettle is used for mixing the initial bamboo pulp with a catalyst, conducting high temperature and high pressure steaming and boiling to obtain reaction bamboo pulp and blowing the reaction bamboo pulp into the blow tank; the blow tank is used for stirring the reaction bamboo pulp, then solid-liquid separation is conducted on the reaction bamboo pulp through the filtering equipment, yellow liquid and solid residues are obtained, and the yellow liquid is stored in the yellow liquid storage tank. By means of the equipment for preparing the bamboo pulp, through circulatory pulping conducted through the filtering equipment, the purer bamboo pulp can be obtained.

Owner:FUJIAN HONG YU AN BIOTECH

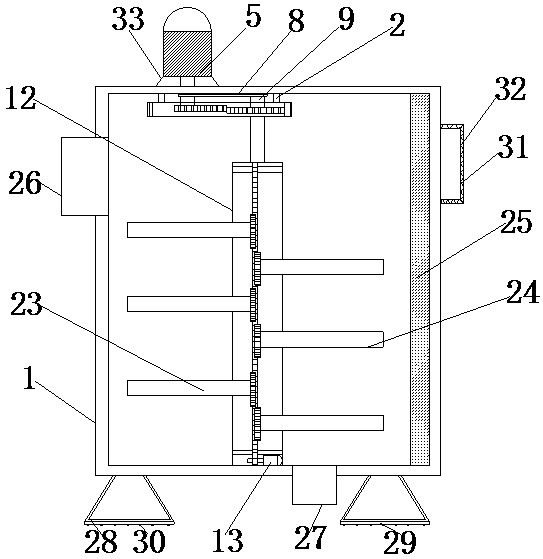

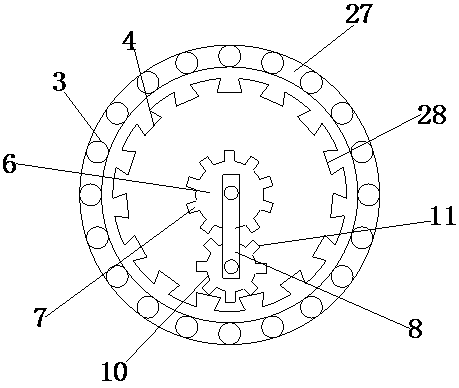

Concrete stirring device for constructional engineering

PendingCN112873547AEffective stirringAvoid shakingHollow article cleaningCement mixing apparatusGear wheelClassical mechanics

The invention discloses a concrete stirring device for constructional engineering. The concrete stirring device comprises box body feeding interfaces, a plurality of discharging interfaces and supporting columns arranged at the lower end of the box body, and a box cover is connected with the upper end of the box body through connecting bolts. A rotating rod, stirring columns and scraping blocks are arranged on the box body, a case arranged at the upper end of the box body, and a rotating assembly, a displacement assembly and a connecting assembly are arranged in the case. A moving cylinder is arranged on the side wall of the box body, and a vibration assembly is arranged in the box body. A motor drives a connecting column to rotate, so that a connecting cylinder rotates under the action of a clamping block and a sliding groove, then the rotating rod rotates, and the rotating rod rotates to stir concrete in the box body. A connecting column rotates to enable a driving gear to rotate, then the connecting cylinder and the rotating rod move up and down while rotating through a driven gear, a worm gear, a worm, a rotating disc, a long rod, a connecting block and other components, then the stirring columns move up and down while stirring is conducted, and concrete in the box body is effectively stirred.

Owner:龙凤

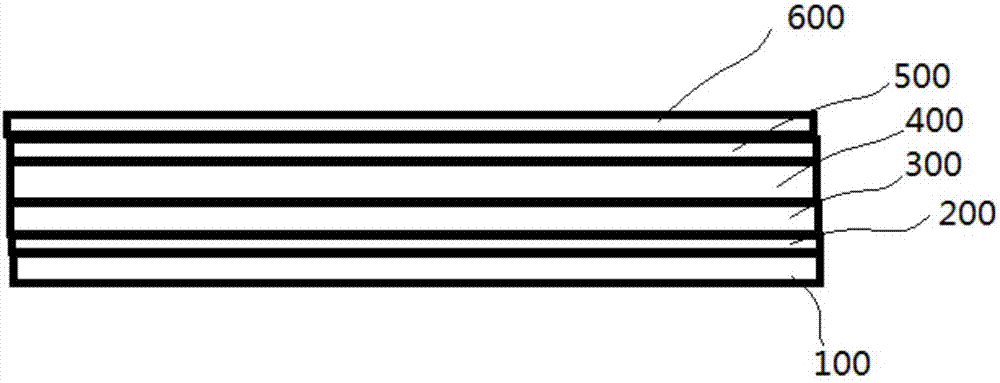

Thin type rammed earth wall and manufacturing method thereof

ActiveCN107366403AGood finished productMeet the requirements of antique decorationCovering/liningsClimate change adaptationRammed earthMechanical engineering

The invention discloses a thin type rammed earth wall which is attached to a base plane. The thin type rammed earth wall is characterized by consisting of a leveling putty layer adhered on the base plane, an alkali-resistant primer layer adhered on the leveling putty layer, a rammed earth layer adhered on the alkali-resistant primer layer, a sand-containing surface layer adhered on the rammed earth layer and a top facing layer adhered on the sand-containing surface layer. The thin type rammed earth wall has the beneficial effects that: the effect of a finished product is beautiful, the texture of the finished product is close to that of old rammed earth wall, and requirements, on antique decoration, of people are met. The invention further discloses a manufacturing method for the thin type rammed earth wall.

Owner:斓图涂装工程(上海)有限公司

Preparation method for Actinidia chinensis Planch wine

InactiveCN109306306AEasy to operateGood finished productAlcoholic beverage preparationPEARFruit wine

The invention discloses a preparation method for Actinidia chinensis Planch wine. The method comprises the steps that 500-600 g of Actinidia chinensis Planch, 200-300 g of autumn pears, 200-300 g of kumquats and 200-300 g of oranges are taken and are sequentially washed with dilute brine, clear water, clear water and warm water at the temperature of 40 DEG C; the fruits are pulped and are put intoa wine jar, and 150-200 g of baijiu is injected into the cleaned wine jar; 20-60 g of red yeast rice is added into the wine jar, and uniform stirring is carried out; sealed fermenting is carried outin the wine jar, the fermentation time is 30-90 d, and the fermentation temperature is 15-20 DEG C; the fermented fruit wine is bottled and sealed so as to obtain the Actinidia chinensis Planch wine.According to the method, the Actinidia chinensis Planch serves as the main raw material, the autumn pears, the kumquats and the oranges are added, the Actinidia chinensis Planch wine is prepared according to a special preparation process, and the method has the characteristics of being easy to operate and excellent in finished product.

Owner:顾俊

Dehydrating method of fresh sweet-scented osmanthus

The invention provides a dehydrating method of fresh sweet-scented osmanthus. The dehydrating method comprises the following steps of firstly harvesting fresh sweet-scented osmanthus, then performing spreading for cooling, spreading the harvested fresh sweet-scented osmanthus in a resurgence machine, keeping the fresh sweet-scented osmanthus in the resurgence machine for 5-6h, after the fresh sweet-scented osmanthus is cooled through spreading, placing the cooled sweet-scented osmanthus in a drying machine, performing drying under the condition of the temperature being 60-90 DEG C and the thickness of the spread sweet-scented osmanthus being 1-1.5cm for 20-25min until the weight loss of the dried sweet-scented osmanthus is 40-45%, and then performing blending on tea and the sweet-scented osmanthus. The problems that the dehydrating production of the fresh sweet-scented osmanthus by a conventional sweet-scented osmanthus tea producing and processing method is limited to be in a laboratory, the spreading time is not easy to master, the fresh sweet-scented osmanthus is easy to deteriorate after being placed at room temperature for 6h, the finished products of the sweet-scented osmanthus tea for scenting often have aqueous stuffy gas and wet odor, great losses are caused for enterprises, and industrial production is difficult to realize. The invention belongs to the field of processing of sweet-scented osmanthus black tea.

Owner:GUIZHOU TEA RES INST +1

Chocolate coating machine with wind direction adjustable

InactiveCN106561763AIncrease the speed of solidificationImprove efficiencyBaked articles handlingDrive wheelDrive shaft

The invention discloses a chocolate coating machine with the wind direction adjustable. The chocolate coating machine comprises a workshop, a partition plate and a storeroom. The storeroom, the partition plate and the workshop constitute an outer shell of the chocolate coating machine. A motor and a fixed fan are mounted inside the storeroom. A transmission shaft of the motor is connected with a driving wheel of an upper supporting plate and a lower supporting plate through a linkage shaft. A cross beam and an adjustable fan protection hood are mounted inside the workshop. The cross beam is mounted at the top of the workshop, and the adjustable fan protection hood is mounted in the middle of the cross beam. The cross beam is fixedly connected with the upper supporting plate and the lower supporting plate through a connecting plate. The bottom of the outer shell of the chocolate coating machine is provided with fixed plates through a support. According to the chocolate coating machine, the wind direction of an adjustable fan can be changed by adjusting the direction of an adjustable threaded rod through a linkage device; and it can be effectively guaranteed that under the condition of chocolate liquid coating, through rotation of the adjustable fan, the wind direction is adjusted, and thus it is guaranteed that a coating is applied uniformly and curing of chocolate liquid is accelerated.

Owner:中农众创众投电子科技有限公司

PET (Polyethylene Terephthalate) sheet production method and production equipment thereof

InactiveCN113021727AImprove efficiencyGood finished productSievingScreeningPolyethylene terephthalatePolyethylene terephthalate glycol

The invention discloses a PET (Polyethylene Terephthalate) sheet production method and production equipment thereof. The PET sheet production equipment comprises an equipment shell, wherein a feeding hopper is inserted in the position, close to the left side, of the top of the equipment shell; two first bearings are fixedly connected to the position, close to the top, of the left side of the equipment shell; the two first bearings are arranged up and down; and a third rotating rod penetrates through an inner cavity of the first bearing located on the top. According to the PET sheet production method and the production equipment thereof provided by the invention, through mutual cooperation of all the components, the equipment can stir materials while conveying the materials, the efficiency is high, the finished product effect is good, the speed is high while a model is pressed, an automatic demolding function is achieved, materials can be trimmed and cut after demolding, cut chippings and materials can be separated through the equipment, and the rapid discharging effect is achieved, so that the labor amount and the labor cost of workers are greatly saved, and the yield and the product quality are improved.

Owner:泉州亦辉塑胶有限公司

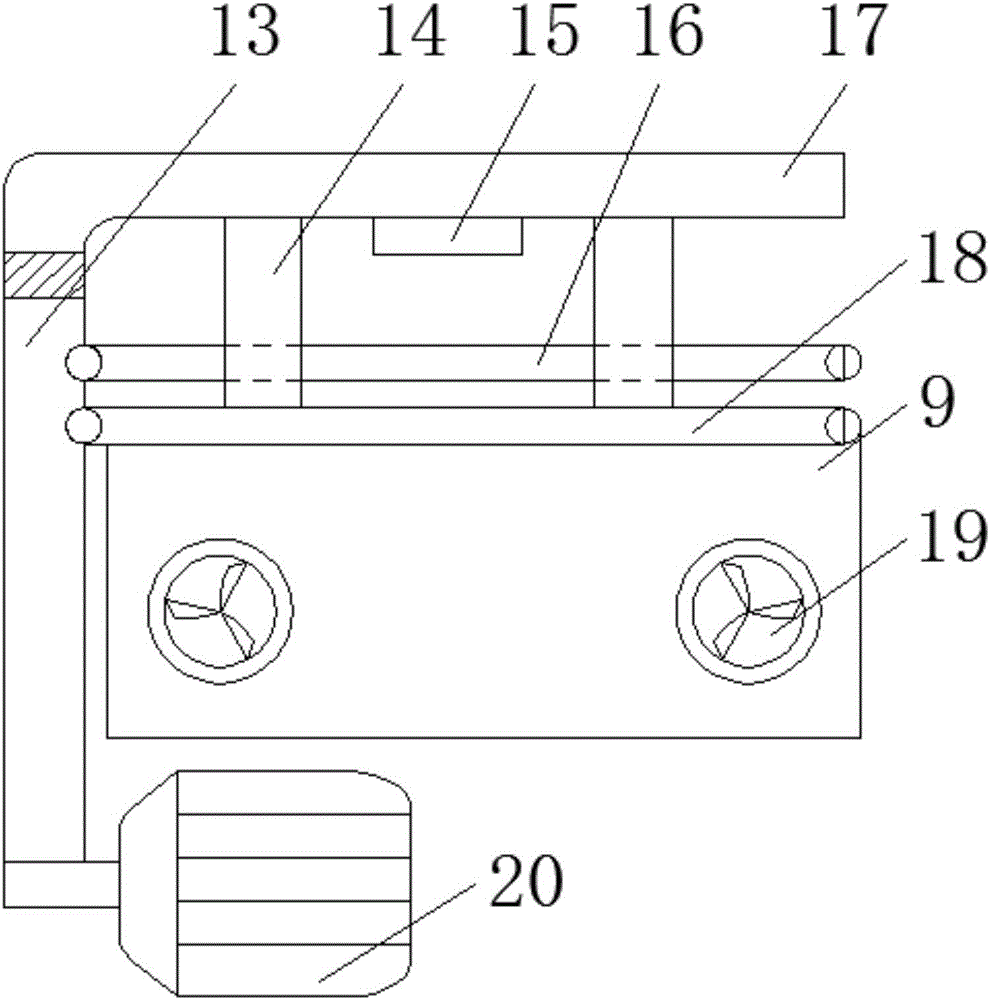

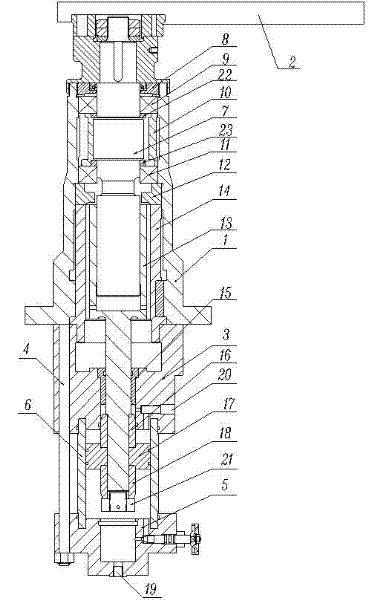

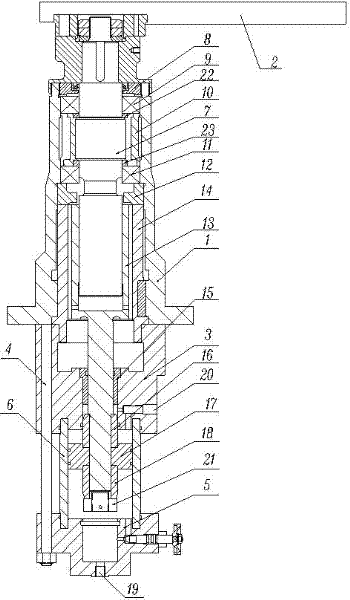

Suction head rotating device

The invention discloses a suction head rotating device, which is characterized by that an armset for sucking materials is connected with one end of a housing, an upper cylinder cover is connected with the other end of the housing, the upper cylinder cover is connected with a lower cylinder cover through a fixed screw, a cylinder liner is arranged between the upper cylinder cover and the lower cylinder cover; a spiral splined shaft is arranged in the housing, one end of the spiral splined shaft is positioned in the armset for sucking materials, a gland nut, a first bearing, a lining, a second bearing, a spacer bush and a spiral splined cylinder shaft are sleeved sequentially from top to bottom on the part of the spiral splined shaft out of the housing, the sidewall of the end of the spiral splined shaft in the cylinder liner is provided with a splice cap; a guide sleeve, a piston and a cushion collar are sleeved sequentially from top to bottom on the part of the spiral splined shaft in the cylinder liner, the cushion collar is connected with the slice cap, the sidewall of the lower cylinder cover is provided with a first air inlet, and the upper cylinder cover is provided with a second air inlet. The invention had the advantages of improving working efficiency, low cost and simple structure.

Owner:NANTONG WEIMING FINISHING MACHINERY

Oil well cement slurry convenient to use

InactiveCN109399971AImprove performanceEasy to useCement productionDrilling compositionFiberSodium Bentonite

The invention discloses oil well cement slurry convenient to use. The oil well cement slurry comprises, by weight, 35-48 parts of limestone, 24-31 parts of sandstone, 17-26 parts of converter slag, 13-23 parts of nodularized silicon powder, 8-17 parts of ordinary silicon powder, 39-48 parts of water, 23-36 parts of polyurethane elastomers, 19-26 parts of polyisocyanate, 13-24 parts of bentonite, 11-23 parts of biopolymers, 9-17 parts of fiber derivatives with high molecular weights, 11-25 parts of organic phosphate and 34-47 parts of gypsum. The oil well cement slurry has the advantages of good performance and applicability to high-temperature and high-pressure severe environments.

Owner:泸州高智知识产权运营有限公司

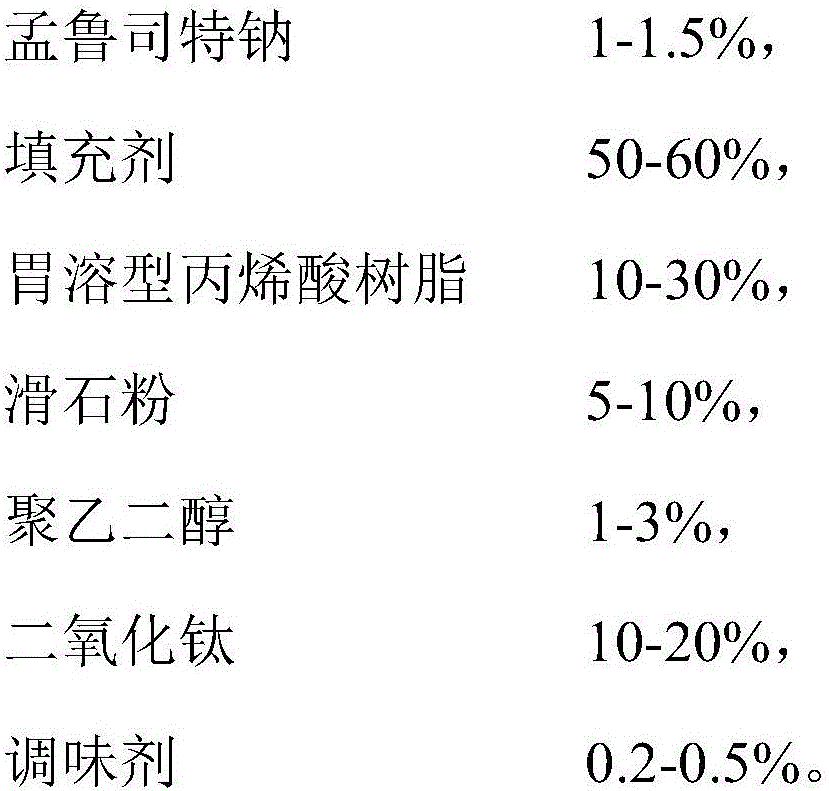

A kind of montelukast sodium granule and preparation method thereof

InactiveCN103860480BSafe to takeEasy to takeInorganic non-active ingredientsGranular deliveryPolyethylene glycolPolymer chemistry

Owner:珠海天翼医药技术开发有限公司

Preparation method of oil well cement for petroleum extraction

InactiveCN109516699AImprove performanceGood finished productCement productionDrilling compositionFiberSodium Bentonite

The invention discloses a preparation method of oil well cement for petroleum extraction. The oil well cement comprises the following components in parts by weight: 35-48 parts of limestone, 24-31 parts of sandstone, 17-26 parts of converter slag, 13-23 parts of spheroidized silicon powder, 8-17 parts of ordinary silicon powder, 39-48 parts of water, 23-36 parts of polyurethane elastomer, 19-26 parts of polyisocyanate, 13-24 parts of bentonite, 11-23 parts of biopolymer, 9-17 parts of high-molecular-weight fiber derivatives, 11-25 parts of organic phosphate and 34-47 parts of gypsum. The cement slurry obtained by using the preparation method is better in performance and more suitable for a high-temperature and high-pressure rugged environment.

Owner:泸州高智知识产权运营有限公司

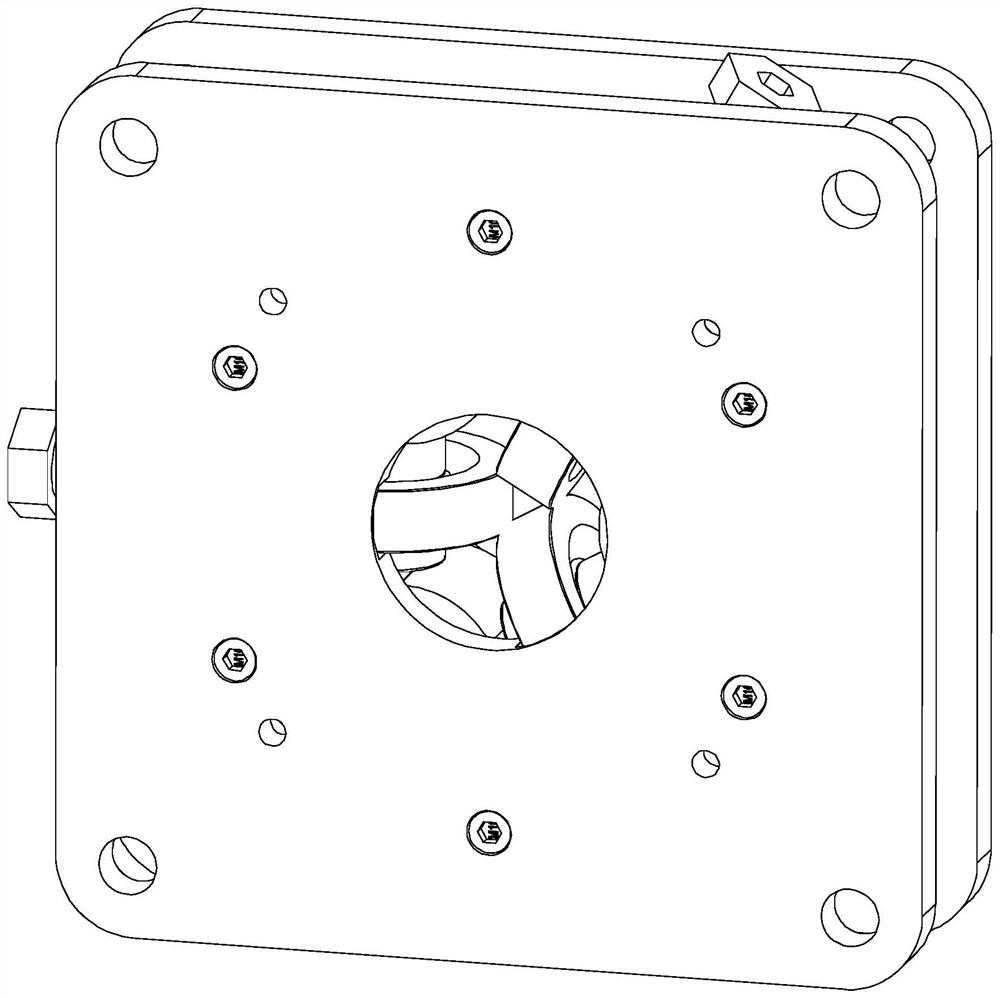

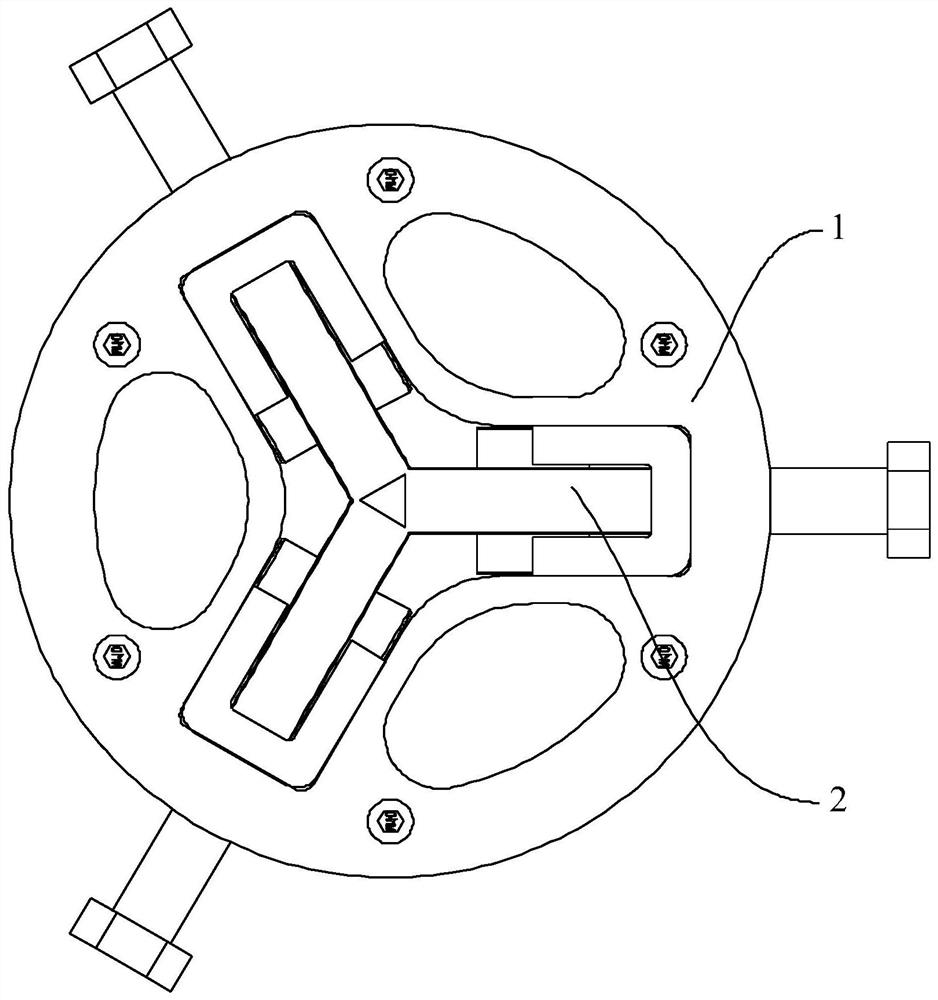

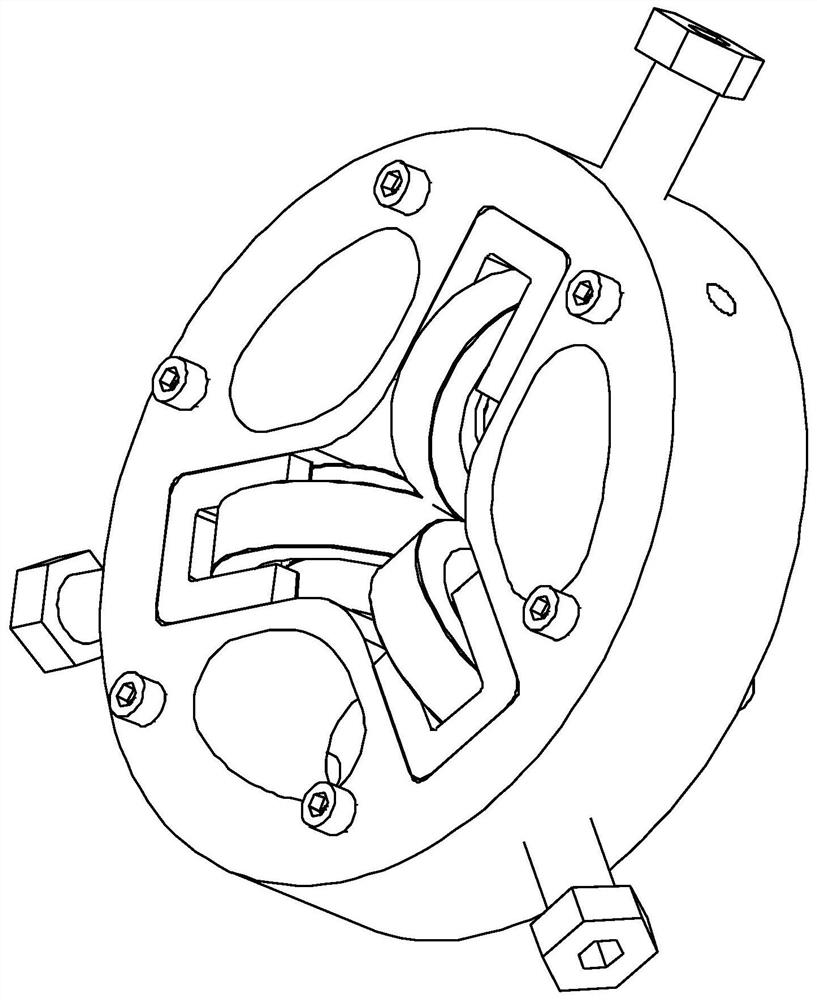

Model suitable for triangular profiled bar manufacturing

The invention relates to a model suitable for triangular profiled bar manufacturing. The model suitable for triangular profiled bar manufacturing comprises a mounting mold frame, three roller formingstructures and two cover plates, wherein a Y-shaped through hole is formed in the mounting mold frame, the three roller forming structures are correspondingly mounted in channels of the Y-shaped through hole correspondingly, each roller forming structure comprises a U-shaped base, a bearing fixedly installed on the U-shaped base and a roller rotationally arranged on the bearing, screw holes are formed in the positions, corresponding to all the channels of the Y-shaped through hole, of the side wall of the mounting mold frame, screw rods penetrate through the screw holes and abut against the backs of the U-shaped bases, the rollers of the three roller forming structures are in contact with one another and form a triangular gap in the middle, circular through holes are formed in the positions, corresponding to the triangular gap, of the two cover plates, and strip-shaped grooves are formed in the two cover plates corresponding to the rollers. Based on the scheme, by means of the arrangement, metal passing through the model can be machined into a product with the triangular section, meanwhile, the friction between a mold and a machined material can be reduced, the drawing force is small, the machining work efficiency is improved, meanwhile, the overall structure is stabler, and the finished product effect is better.

Owner:广州众山精密科技有限公司

Waist-strengthening kidney-tonifying wine and preparation method thereof

InactiveCN108066492AShorten the soaking timeHigh content of active ingredientsUrinary disorderPlant ingredientsMedicineKidney

The invention provides waist-strengthening kidney-tonifying wine and a preparation method thereof. The preparation method includes: treating several medicinal materials having wiast-strengthening andkidney-tonifying functions according to a weight ratio to obtain compound extract; using Baijiu as base wine, and mixing the compound extract with the Baijiu according a certain weight ratio to obtainthe waist-strengthening kidney-tonifying wine. The kidney-tonifying wine prepared by the method can effectively relieve symptoms like waist and knee pain, frequent micturition and kidney deficiency of patients.

Owner:GUANGXI BOTANICAL GARDEN OF MEDICINAL PLANTS

High-performance coating preparation device and method

PendingCN112755875AGood finished productWell mixedTransportation and packagingMixersProcess engineeringManufacturing engineering

The invention discloses a high-performance coating preparation device, which comprises a pre-crushing structure, a conveying structure, a feeding structure and a final crushing structure, the pre-crushing structure communicates with one end of the conveying structure, the feeding structure communicates with the pre-crushing structure, the pre-crushing structure comprises two crushing rotors, a feeding funnel and a crushing cavity, the crushing cavity communicates with the conveying structure, and the two crushing rotors are both rotationally connected with the crushing cavity. The invention further provides a high-performance coating preparation method which comprises the high-performance coating preparation device and further comprises the following steps of subjecting resin to pre-smashing; feeding the materials; preparing a molten mixture; and cooling the molten mixture, and conducting crushing and final crushing to prepare the high-performance coating. According to the present invention, the structure of the preparation device is improved on the basis of the prior art, such that the raw materials can be completely mixed during the coating preparation so as to completely disperse an auxiliary agent and a pigment in the resin, such that the final powder coating product finished product is good.

Owner:江苏海丰新材料有限公司

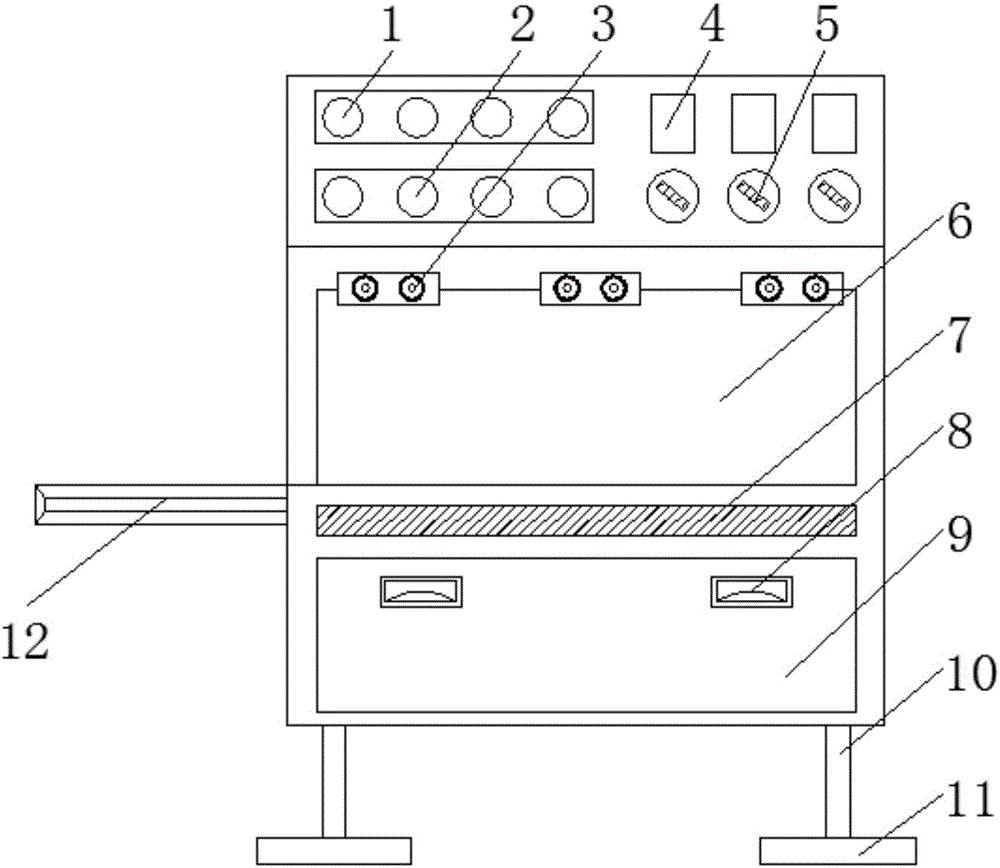

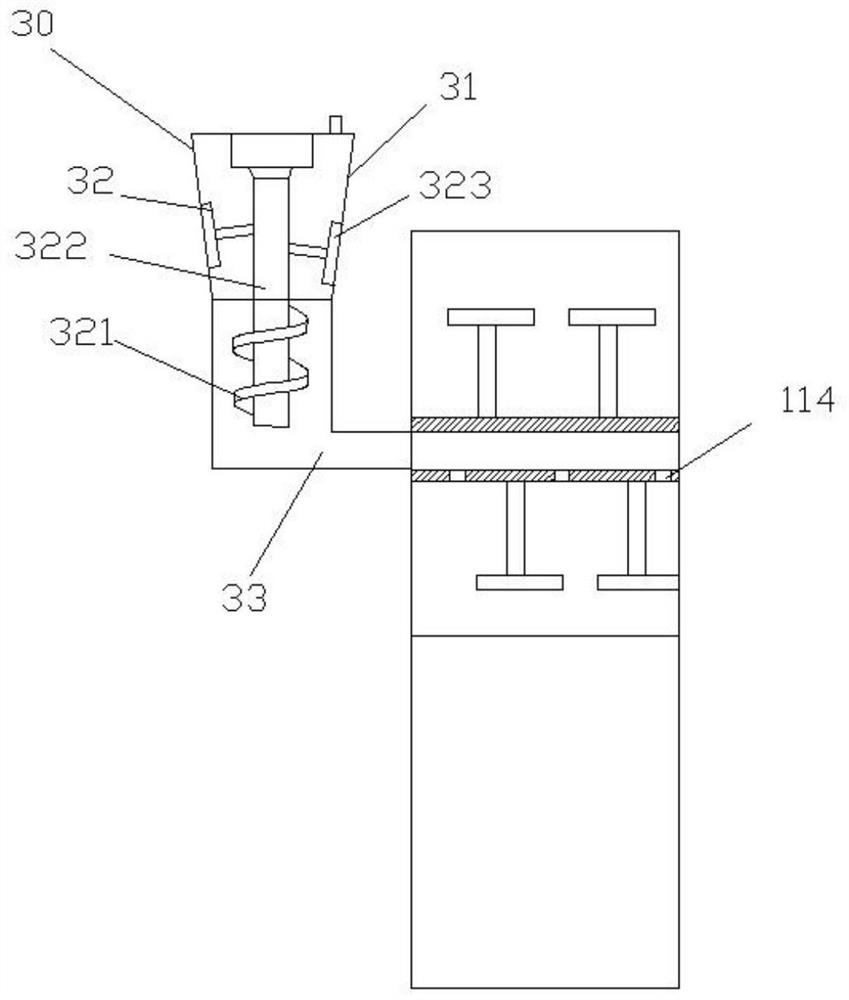

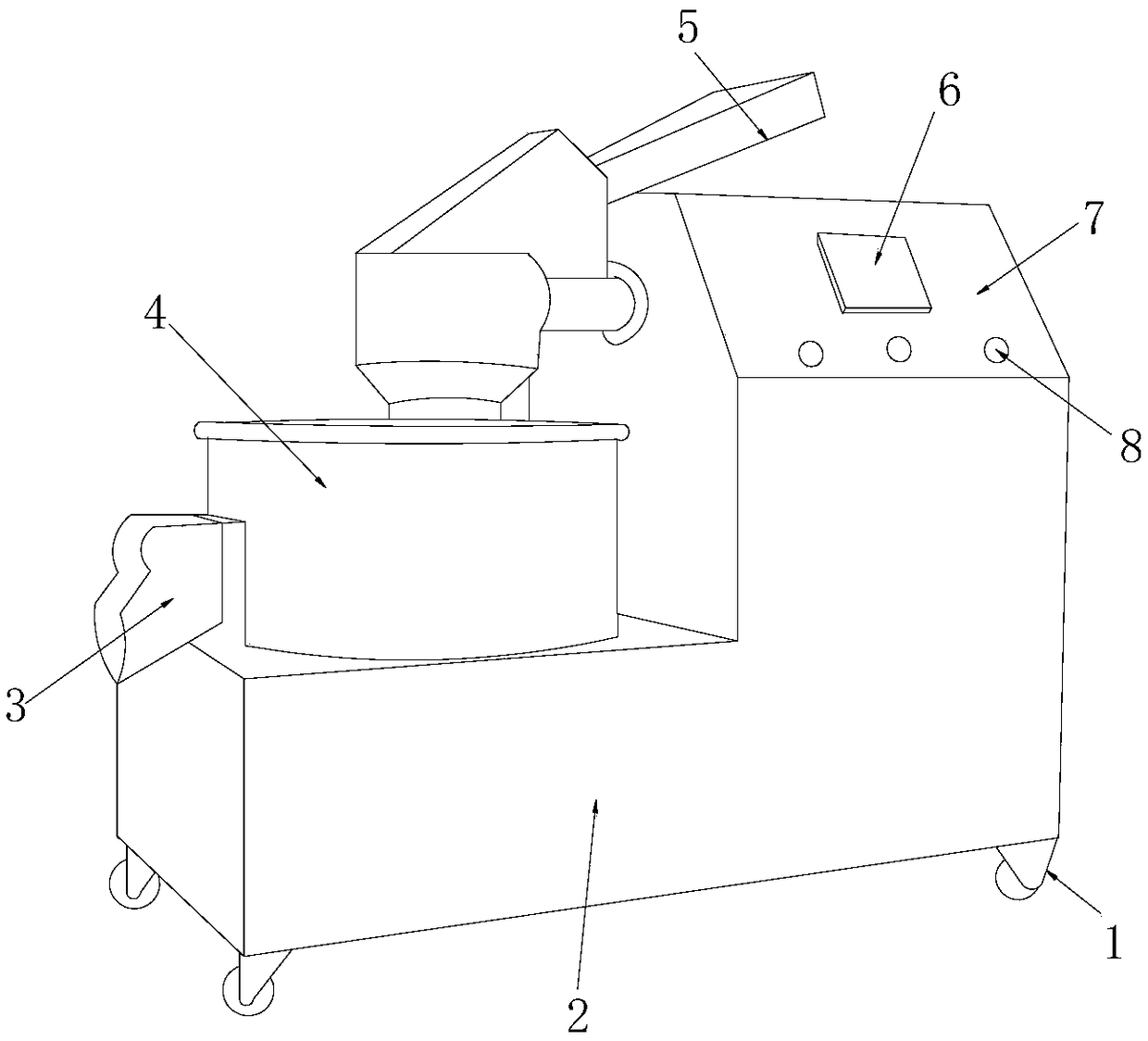

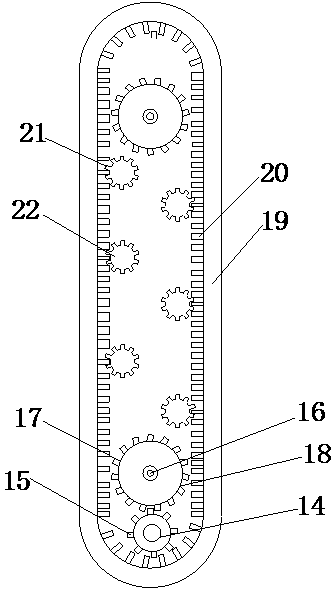

Extrusion and rounding integrated machine for pharmacy

InactiveCN108771625AStable outputEasy to replacePharmaceutical product form changeGrain treatmentsEngineeringIntegrated devices

The invention discloses an extrusion and rounding integrated machine for pharmacy. The machine structurally comprises moving wheels, a device casing, a discharging frame, an intelligent adjustment andproduction integrated device, a feeding frame, a display screen, a control panel and control keys, wherein the control panel is located on the right surface of the upper surface of the device casingand fit with the device casing to be mounted into an integrated structure, the display screen is arranged above the front end surface of the control panel and fixedly connected with the control panel,the control keys are embedded in the inner side end surface of the control panel and connected with the control panel in a running fit manner, the intelligent adjustment and production integrated device is perpendicular to the upper side end surface of the device casing and forms an integrated structure with the device casing, and the feeding frame is mounted on the back side surface of the intelligent adjustment and production integrated device through welding. The device can first extrude and crush overlarge raw materials and then perform meshing smashing, and besides, a screen in the device can be replaced more conveniently, so that the equipment can work more stably and produce excellent finished products.

Owner:湖州御筵科技有限公司

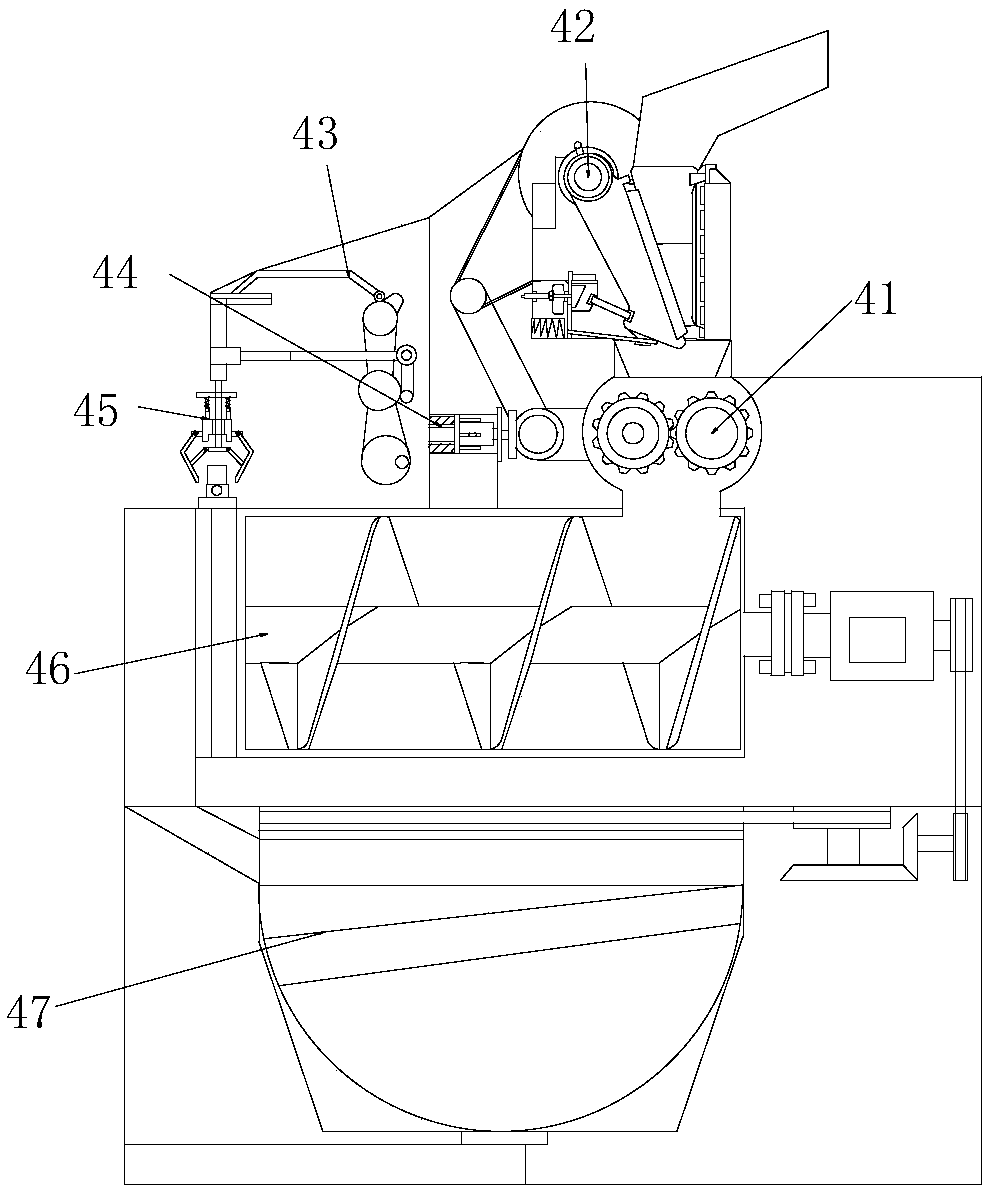

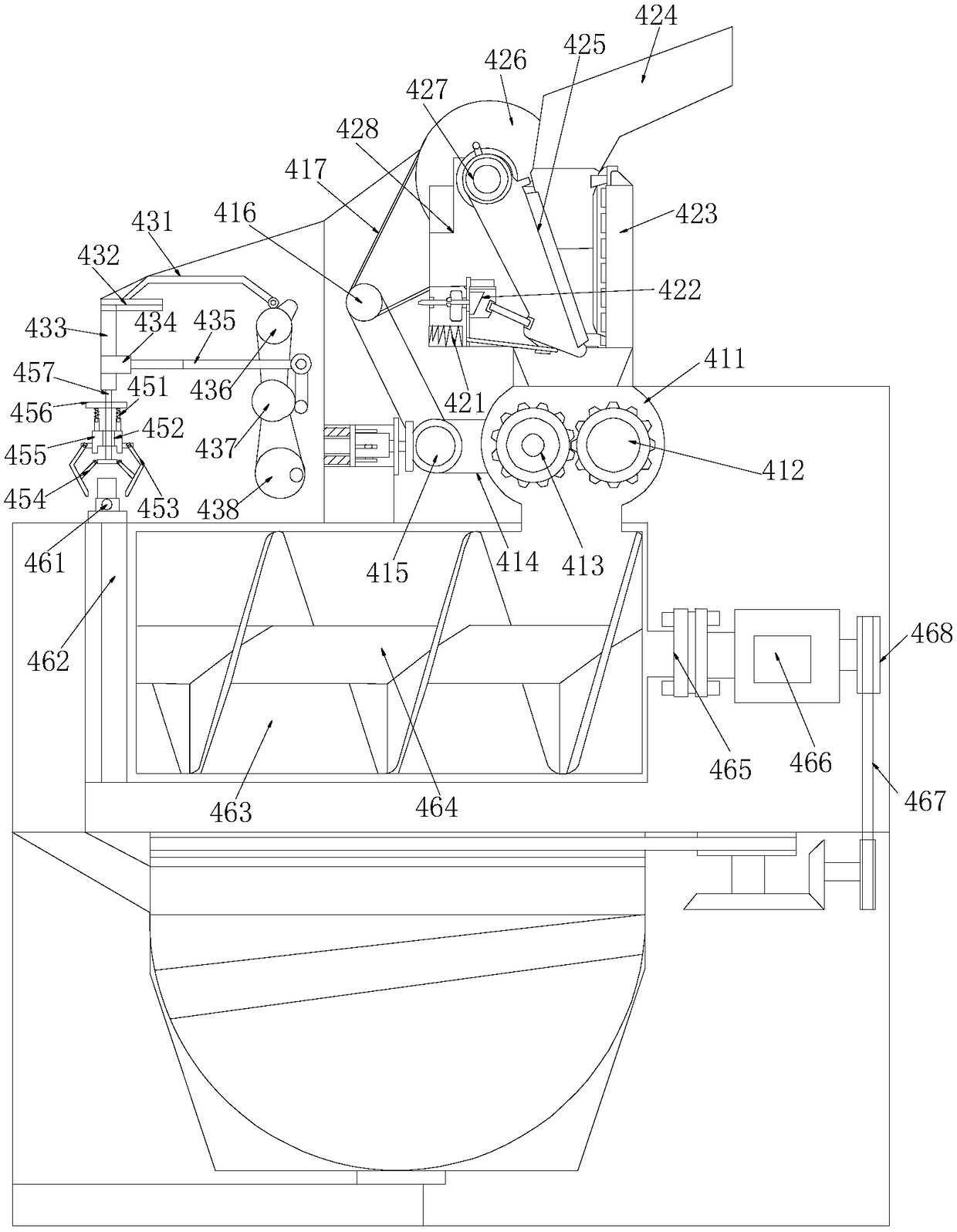

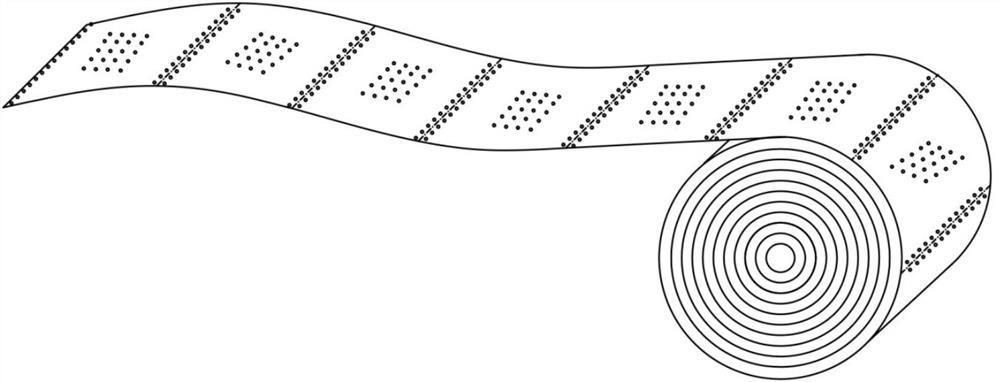

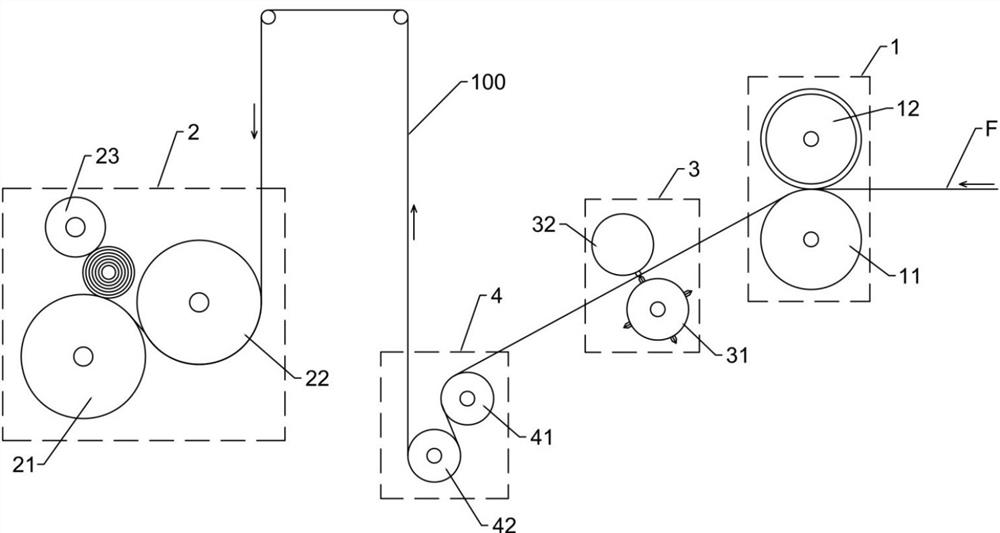

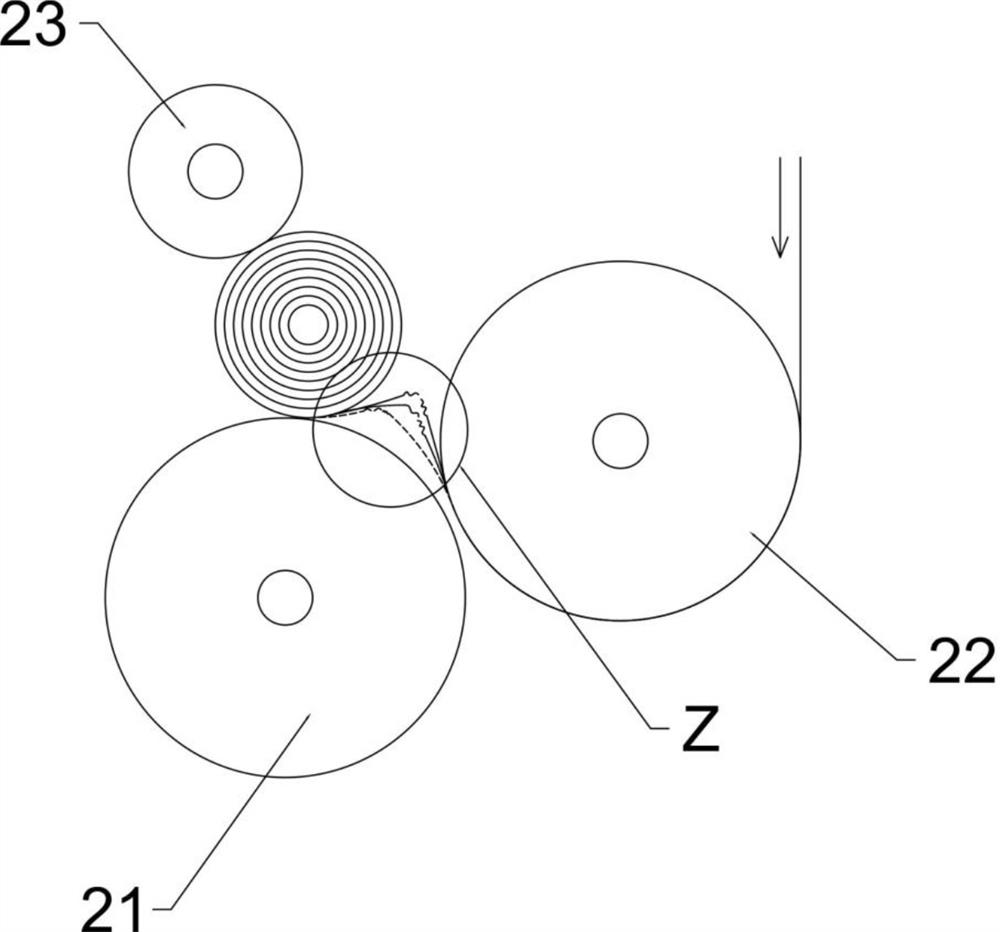

Self-adaptive dynamic adjustment paper embossing and winding mechanism

PendingCN113264402AImprove positionEasy embossingMechanical working/deformationArticle deliveryPunchingEngineering

The invention discloses a self-adaptive dynamic adjustment paper embossing and winding mechanism which comprises an embossing roller set and a rewinding roller set, paper is embossed by the embossing roller set and then conveyed to the winding roller set through a preset long conveying path to be rewound, and a punching device and a self-adaptive fine adjustment device are sequentially arranged on the long conveying path. The punching device is used for punching the embossed paper, and the self-adaptive fine adjustment device is used for pulling the punched paper to be conveyed to the rewinding roller set along the long conveying path. The self-adaptive fine adjustment device correspondingly changes the traction rate based on the paper breaking position of the paper on the rewinding roller set, and the embossing rate of the embossing roller set, the traction rate of the self-adaptive fine adjustment device and the punching rate of the punching device are in dynamic linkage.

Owner:佛山达健实验设备有限公司

A plastic granule mixer with two-way mixing function

Owner:滨州市科创孵化器有限公司

A kind of vat dye suspension wet short steam pad dyeing process

ActiveCN106012587BImprove dye uptakeImprove stabilityDyeing processLiquid/gas/vapor textile treatmentAccelerantPhotochemistry

The invention discloses a vat dye suspension wet shortened steaming pad dyeing technology. The technology includes the following steps of 1, dye liquor padding, wherein fabric to be dyed is padded in vat dye suspension dye liquor, dipping and padding are carried out twice respectively, and the vat dye suspension dye liquor is prepared from 0.1-5% of superfine powder vat dye (oxf), 1-20 g / L of a reductant, 1-3 g / L of a penetrant, 1-3 g / L of a dispersant and 5-30 g / L of an accelerant; 2, alkali liquor padding, wherein the fabric to be dyed is directly padded in alkali liquor, dipping and padding are carried out once respectively, and the alkali liquor is prepared from 5-30 g / L of caustic soda and 0-10 g / L of sodium hydrosulfite; 3, steam reduction, wherein saturated steam is adopted for rapid steaming; 4, oxidation, wherein hydrogen peroxide is adopted for oxidation. According to the vat dye suspension wet shortened steaming pad dyeing technology, the level dyeing property and color fastness of the dyeing technology are significantly improved; besides, the technology is simple and saves energy.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

A bedside table surface grinding equipment

ActiveCN110576370BIncrease linkageImprove grinding efficiencyGrinding drivesGrinding machinesSanderElectric machinery

The invention discloses a bedside table surface grinding device, which comprises a grinder shell, a working cavity is arranged inside the grinder shell, a driving mechanism is arranged in the working cavity, the driving mechanism is used for the operation of the driving device, and the driving The right side of the mechanism is provided with a square grinding mechanism. The square grinding mechanism includes a top plate fixedly connected to the rear end wall of the working chamber. There is a speed change gear and a first push rod, and the first push rod is located on the lower side of the speed change gear. This device is aimed at the required process when polishing the surface of the bedside table, and can use the form of a large grinding disc to rotate at a high speed to achieve a wide range of grinding , to speed up the grinding efficiency, and the square repeated grinding method can be used to grind the corners of the surface of the bedside table. The grinding is finer and the finished product is better. The device only uses one motor as the power source, and the overall linkage is high.

Owner:诸暨市合纵科技有限公司

Rock color coating and preparation method thereof

The invention discloses a rock color coating. The coating is a composition of an agent A and an agent B, wherein the weight ratio of the agent A to the agent B is 1:1. A preparation method of the coating comprises the following steps: preparing the agent A and the agent B respectively and then uniformly mixing the agent A and the agent B according to the weight ratio of 1:1 to obtain the rock color coating. The rock color coating has the characteristics of energy conversation, environment-friendliness, ultra acid / alkali resistance, durability, water resistance, attractive appearance, safety, and reliability.

Owner:杭州潮头建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com