Rock color coating and preparation method thereof

A paint and color stone technology, applied in the field of rock color stone paint and its preparation, can solve the problems of peeling, chalking, large color difference of stones, easy to fall and hurt people, etc., to reduce self-weight, reduce construction costs, and save colored sand Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below: a kind of rock color stone coating, this coating is the composition of A agent and B agent, and the weight ratio of both is 1:1, wherein,

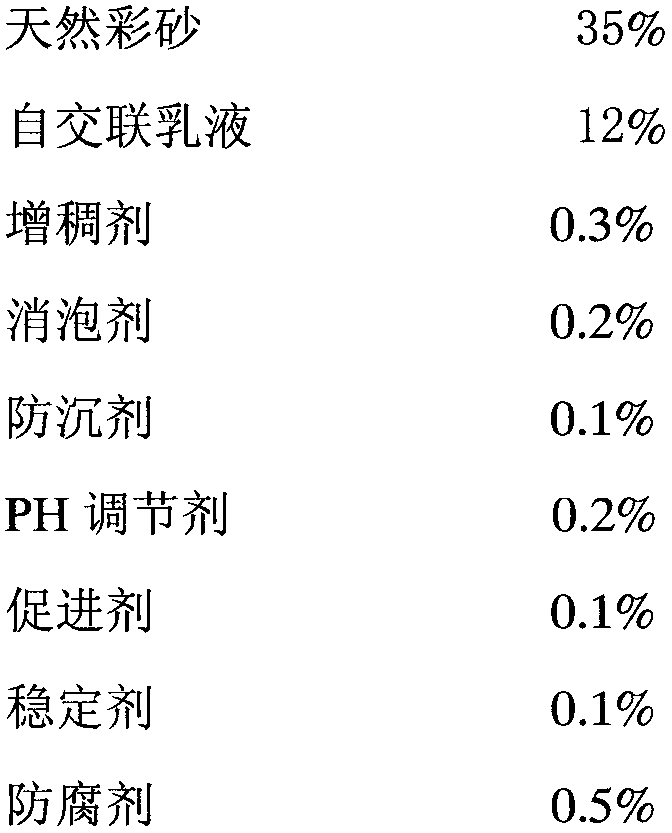

[0021] A agent is made up of the raw material of following percentage by weight:

[0022]

[0023]

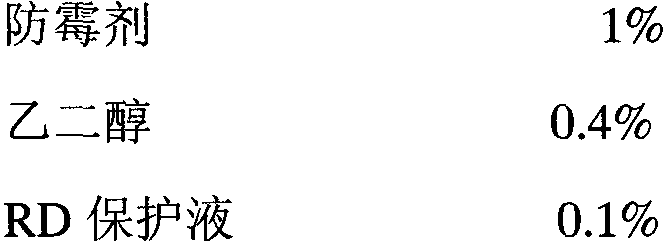

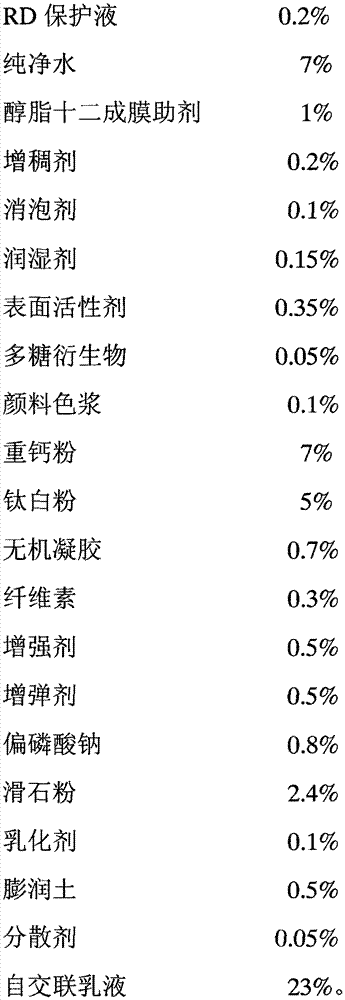

[0024] B agent is made up of the raw material of following weight percentage:

[0025]

[0026] Described self-crosslinking emulsion is self-crosslinking acrylic acid emulsion; Described thickener is polyethylene glycol distearate; Described defoamer is polydimethylsiloxane emulsion; Described anti-settling agent is Polyamide wax; The accelerator is epoxy silane; The preservative is the composition of benzoic acid, sodium benzoate and sorbic acid; The wetting agent is sodium dioctyl sulfosuccinate; The surface active The agent is alkylbenzenesulfonic acid compound; the heavy calcium powder is heavy calcium carbonate; the emulsifier is sorbitan fatty acid ester; the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com