Model suitable for triangular profiled bar manufacturing

A profile and model technology, which is applied in the field of making models from triangular profiles, can solve problems that affect processing efficiency, product smoothness, and appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

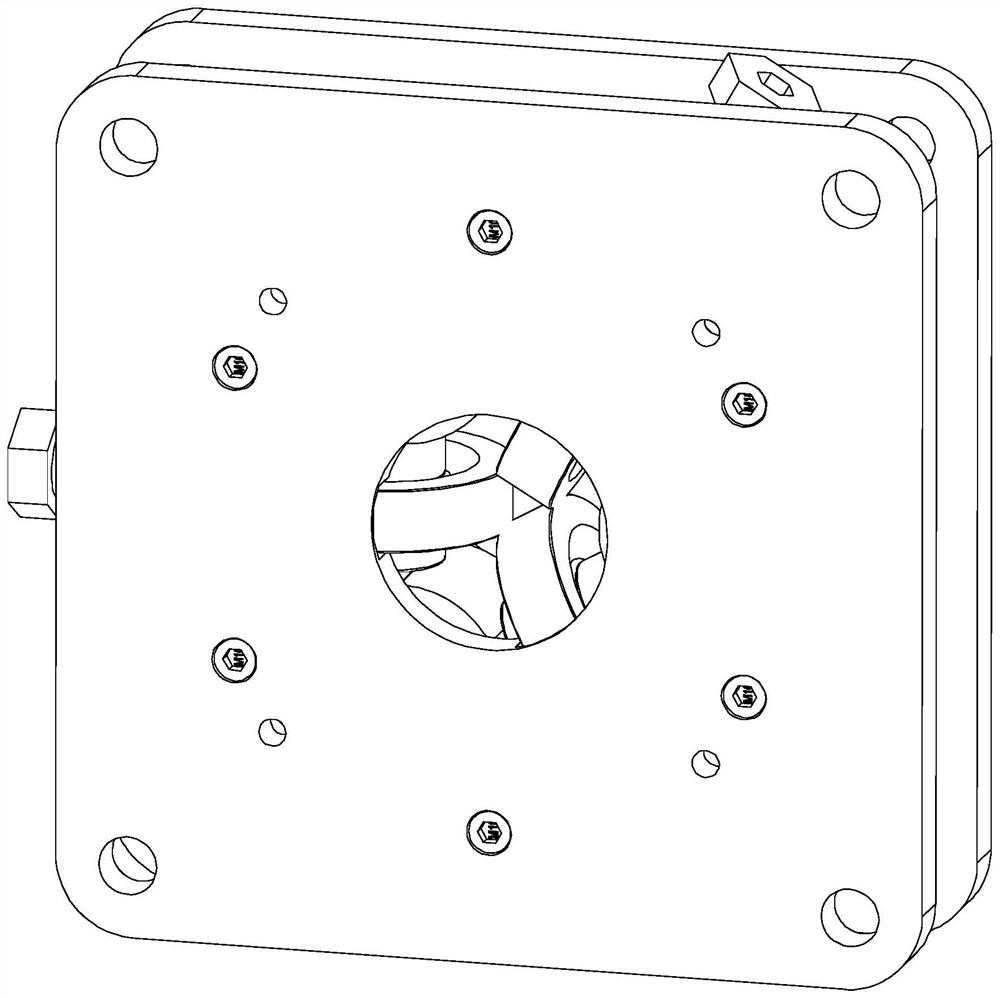

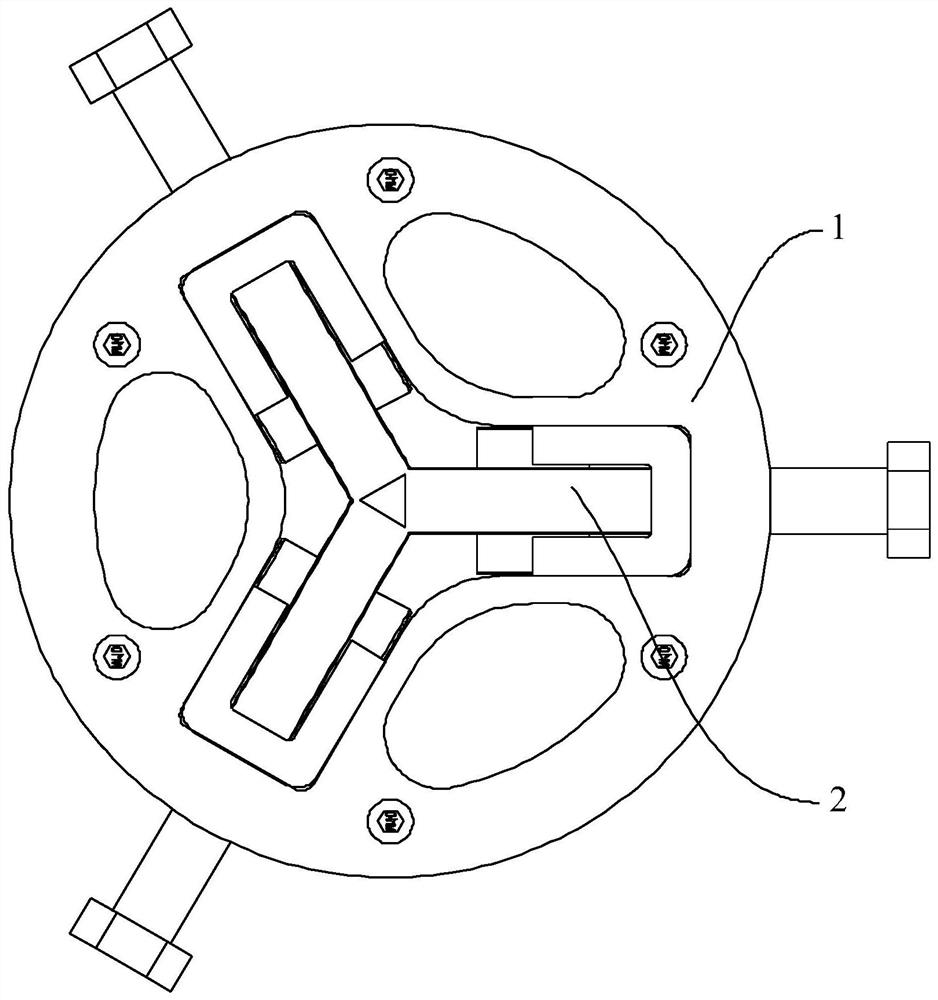

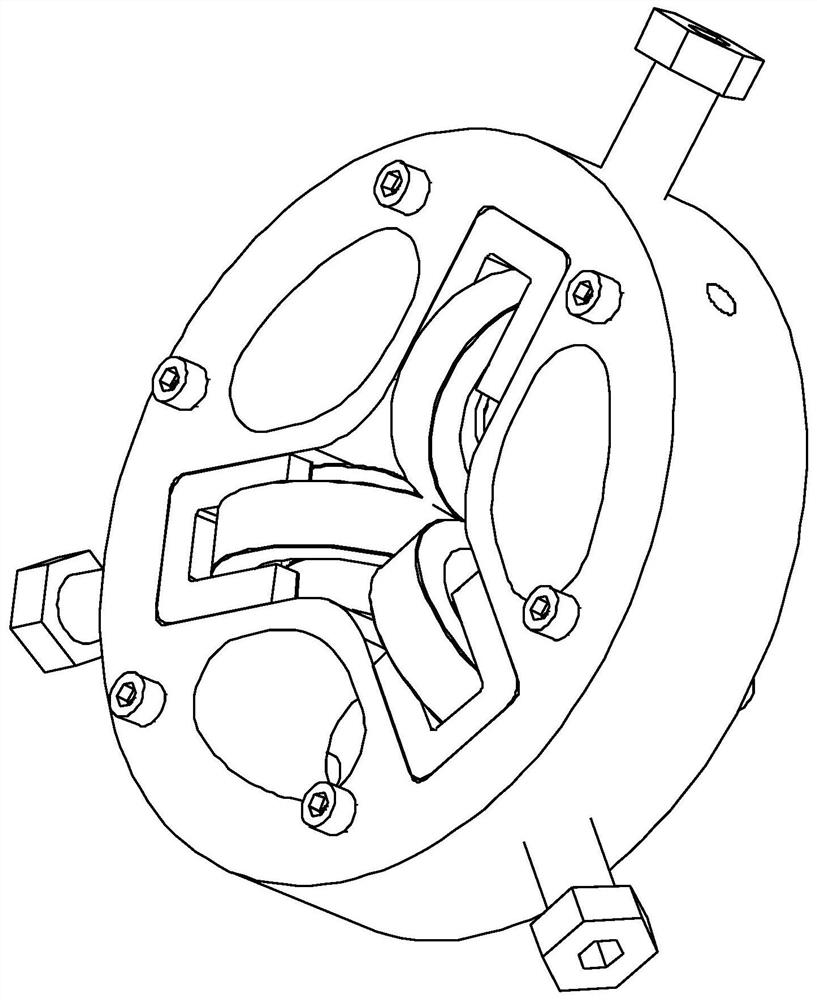

[0023] The present invention is suitable for making models of triangular profiled materials such as Figure 1-Figure 6 As shown, it includes the installation formwork 1, three roller forming structures 2 nested and installed in the installation formwork 1, and two cover plates 3 fixed on both sides of the installation formwork 1. The installation formwork 1 has a Y-shaped The through hole 11 and the three roller forming structures 2 are respectively installed in the channel of the Y-shaped through hole 11. The roller forming structure 2 includes a U-shaped seat 21, a bearing 22 installed and fixed on the U-shaped seat 21, and a rotatable The roller 23...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com