Engineering sewage disposal device

A sewage treatment device and engineering technology, applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve uneven stirring, poor sewage flocculation effect, and small impurities in sewage Particles cannot be effectively removed and other problems, to achieve the best effect of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

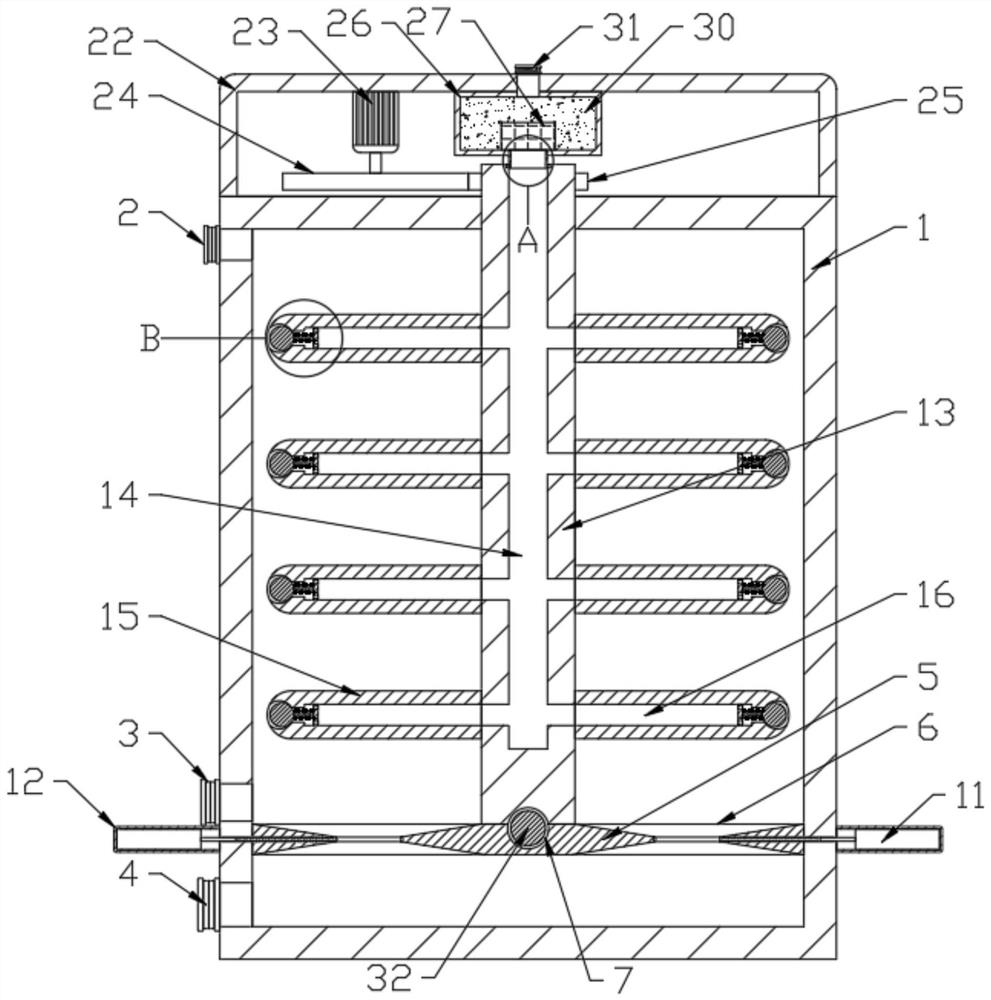

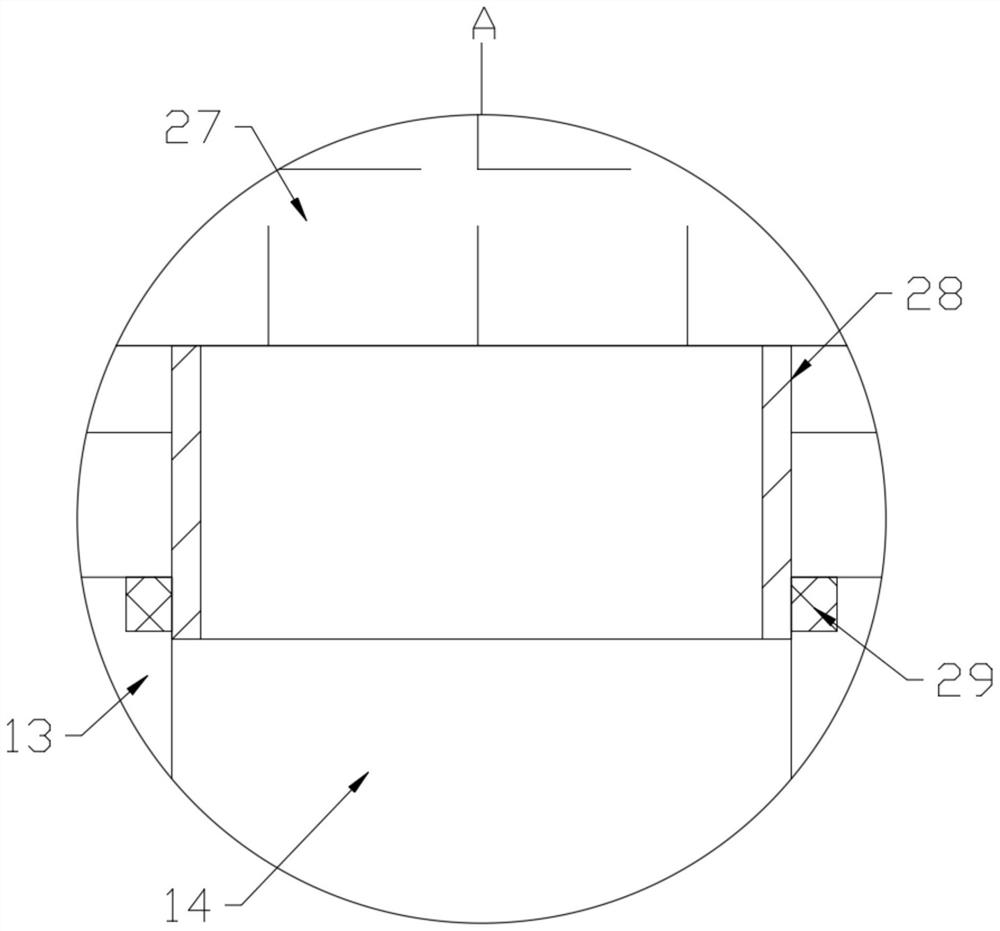

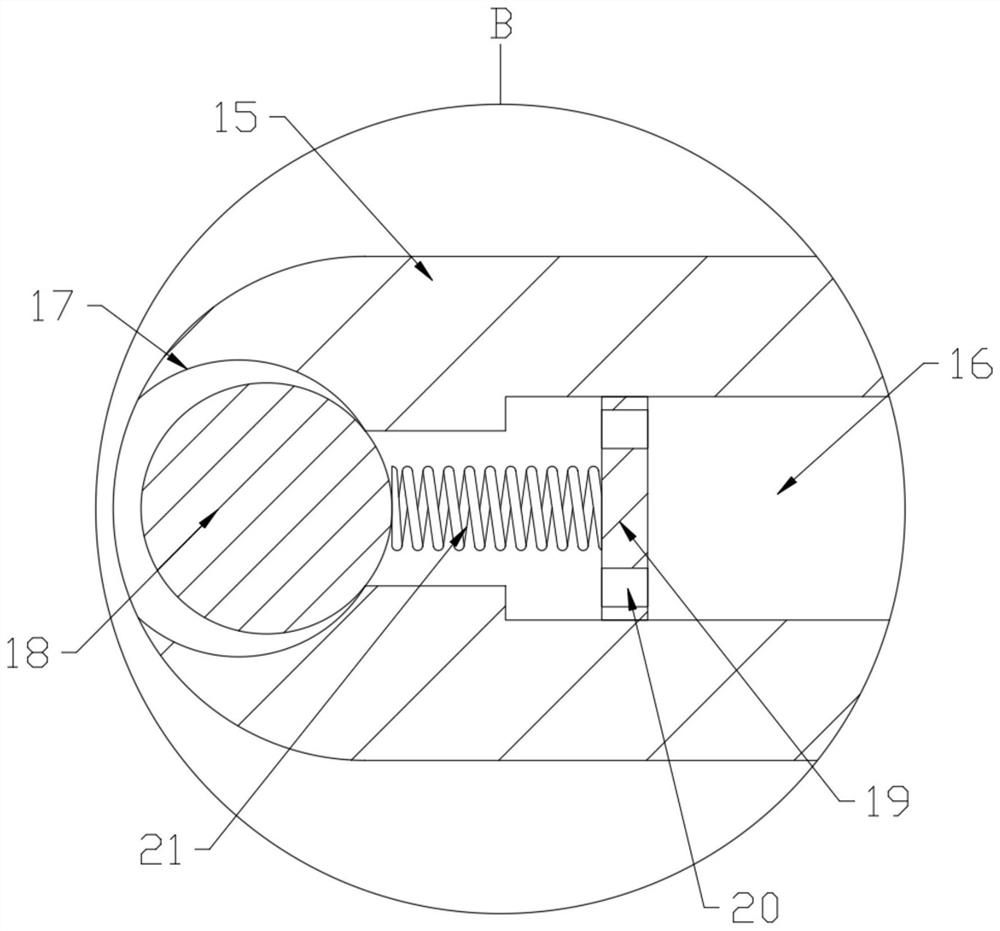

[0024] see Figure 1~5 , in the embodiment of the present invention, an engineering sewage treatment device includes a box body 1 and a water inlet 2, a water outlet 3 and a sewage outlet 4 arranged on the side of the box body 1, and the sewage to be treated passes through the inlet on the box body 1. The nozzle 2 enters the box body 1, and the box body 1 is fixedly connected with a fixed plate 5. The fixed plate 5 is provided with two drop grooves 6, and the side of the box body 1 is provided with a sealing assembly for closing the drop groove 6. The sealing assembly can work to The drop tank 6 is closed, so that the treated sewage and impurities are separately discharged from the box body 1. A rotating drum 13 is connected to the box body 1. A cavity 14 is provided in the rotating drum 13. Several stirring rods 15 are arranged on the rotating drum 13. The stirring rod 15 is provided with a transverse chamber 16 communicating with the cavity 14, and the stirring rod 15 is pro...

Embodiment 2

[0037] On the basis of Embodiment 1, further improvements are made, and the improvements are as follows: balls 32 are arranged between the rotating cylinder 13 and the fixed plate 5, the rotating cylinder 13 and the fixed plate 5 are in rolling connection with the balls 32, and the rotating cylinder 13 and the fixed plate 5 are provided with hemispherical grooves 7 for the balls 32 to roll. When the drum 13 rotates in the box body 1, the balls 32 roll in the hemispherical grooves 7 of the drum 13 and the fixed plate 5, so that the drum 13 rotates more smoothly. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com