Robot posture controlled electric arc deposition laser forging additive manufacturing method and equipment

A technology of attitude control and additive manufacturing, which is applied in the field of additive manufacturing to achieve high efficiency, improved mechanical properties, and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

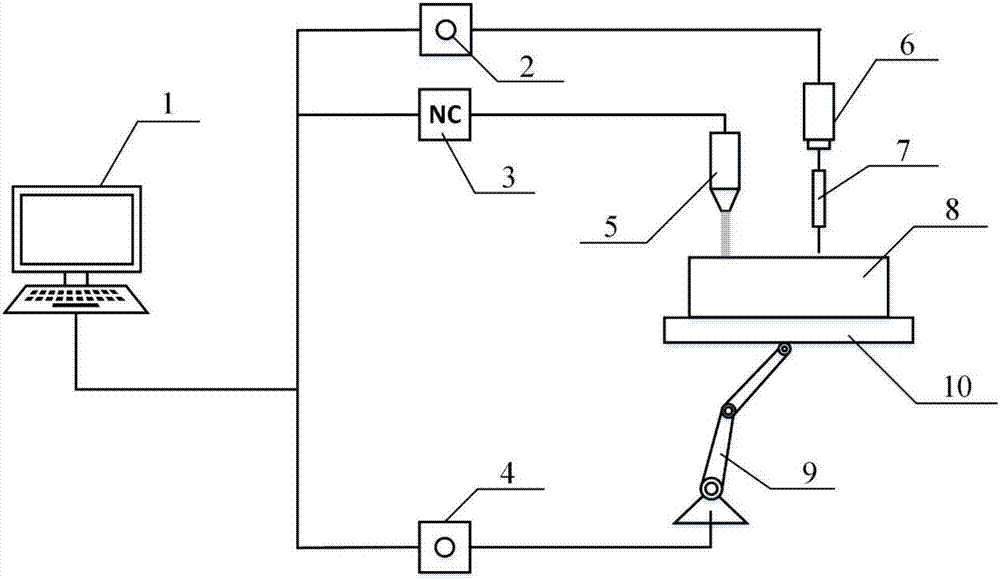

[0029] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

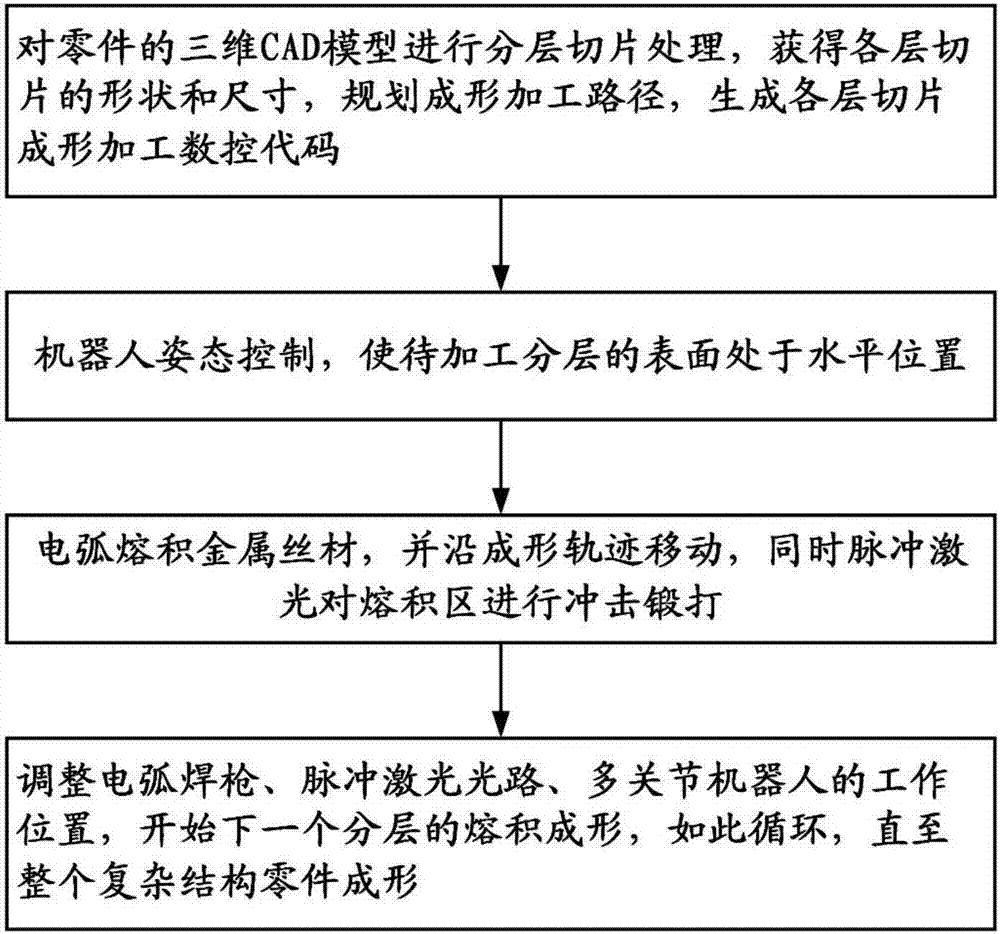

[0030] Please refer to figure 1 , figure 1 It is a flowchart of a specific implementation manner provided by the present invention, including:

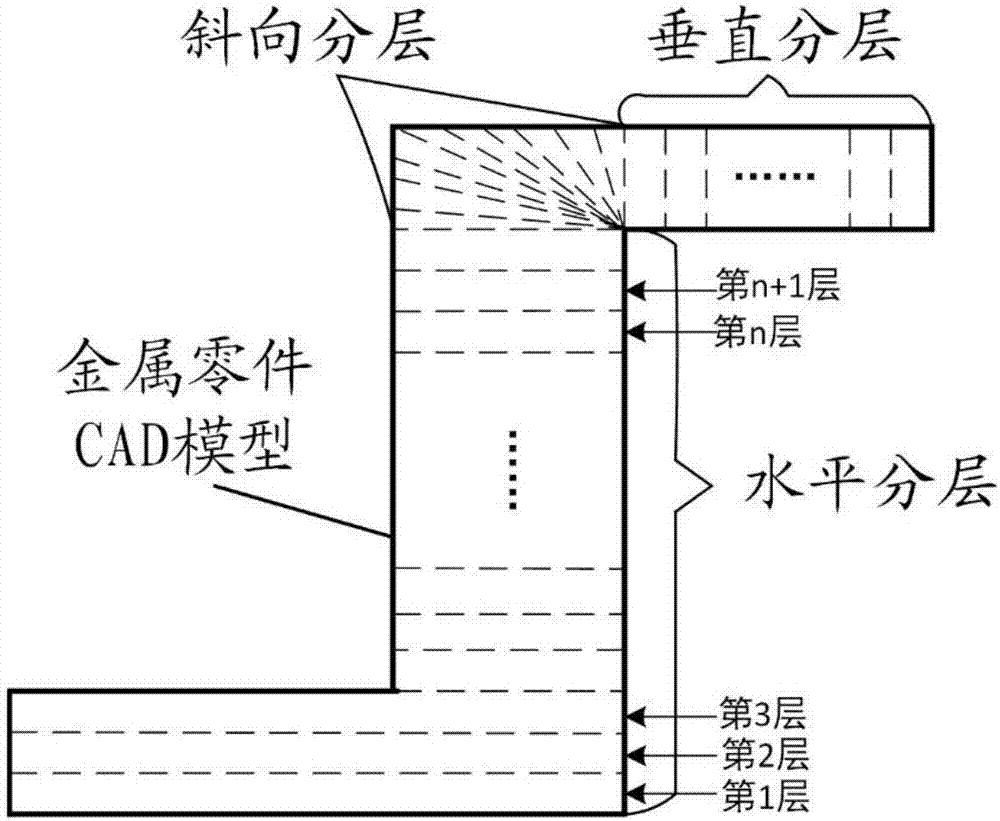

[0031] (1) Use computer software to perform layered slice processing on the three-dimensional CAD model of the part, obtain the shape and size of each layer of slice, plan the forming processing path, and generate the numerical control code for each layer of slice forming;

[0032] (2) The articulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse energy | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com