Radiator for high-voltage transformer oil tank and power module

A technology of high-voltage transformers and heat sinks, which is applied in the direction of transformer/inductor cooling, etc., can solve the problems of power supply short circuit, too many liquid circuit connections, and burnt out power supply, so as to prevent burnout, improve heat transfer efficiency, and prevent liquid circuit The effect of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

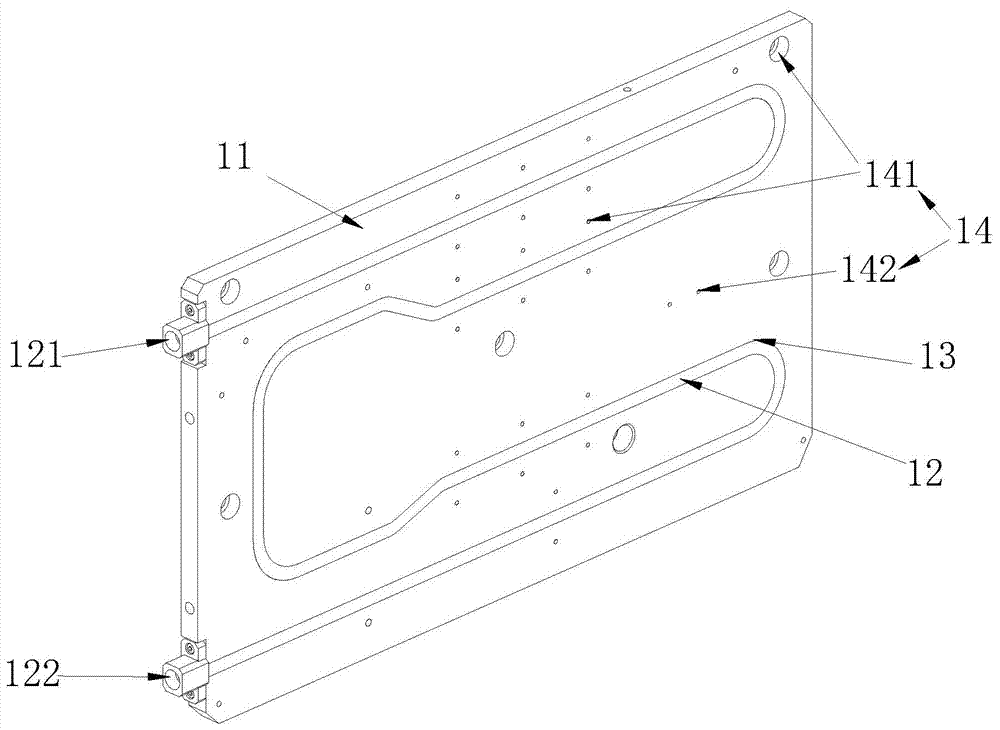

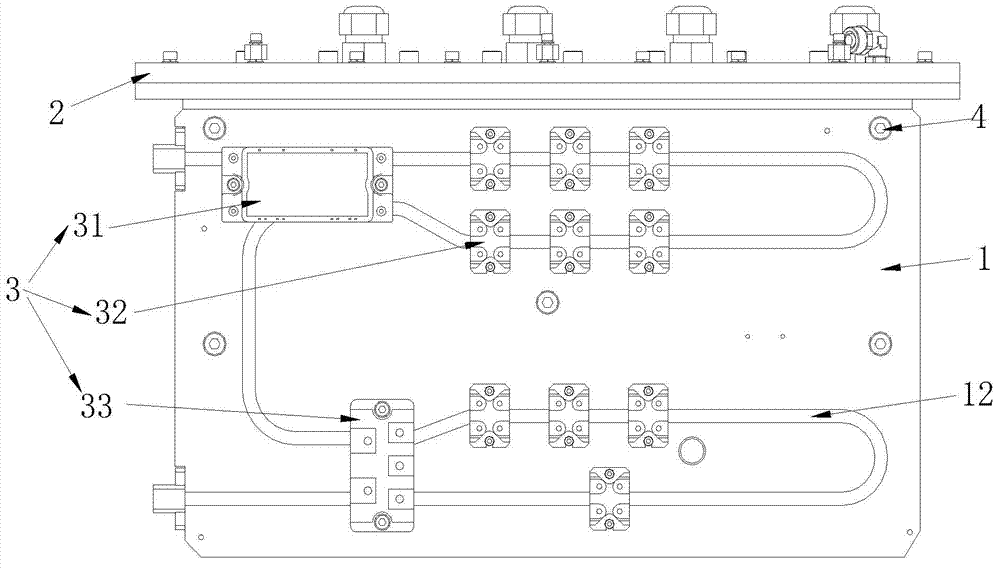

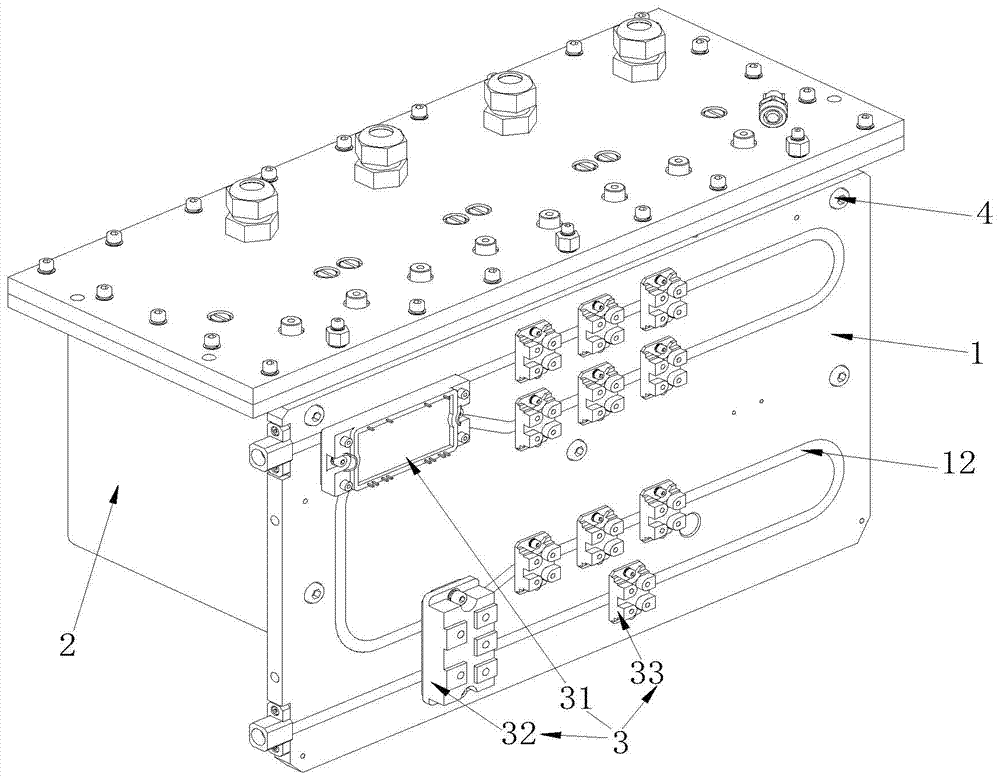

[0027] Such as figure 1 As shown, a heat dissipation device for a high-voltage transformer oil tank and a power module is provided, including a base plate 11 and a copper tube 12, a curved groove 13 is provided on the surface of the base plate 11, and the copper tube 12 is embedded in the groove 13 Inside, the gap between the groove 13 and the copper pipe 12 is filled with a high thermal conductivity material, and the high thermal conductivity material is preferably a high thermal conductivity epoxy resin glue. The copper tube 12 is an integral copper tube whose size and shape match the size and shape of the groove 13 to facilitate the installation of the copper tube 12 and ensure the heat dissipation effect. A portion of the copper pipe 12 exposed outside the substrate 11 is flush with the surface of the substrate 11 . The two ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com