High-temperature-resisting anticorrosion coating for inner wall of steel thermal pipeline and construction technology

A technology for anti-corrosion coatings and thermal pipelines, applied in anti-corrosion coatings, coatings, fire-resistant coatings, etc., can solve problems such as uneven coatings on pipelines, complex construction techniques, and easy to fall off, and achieve smooth and defect-free surfaces. Smooth and uniform, stable construction parameters control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

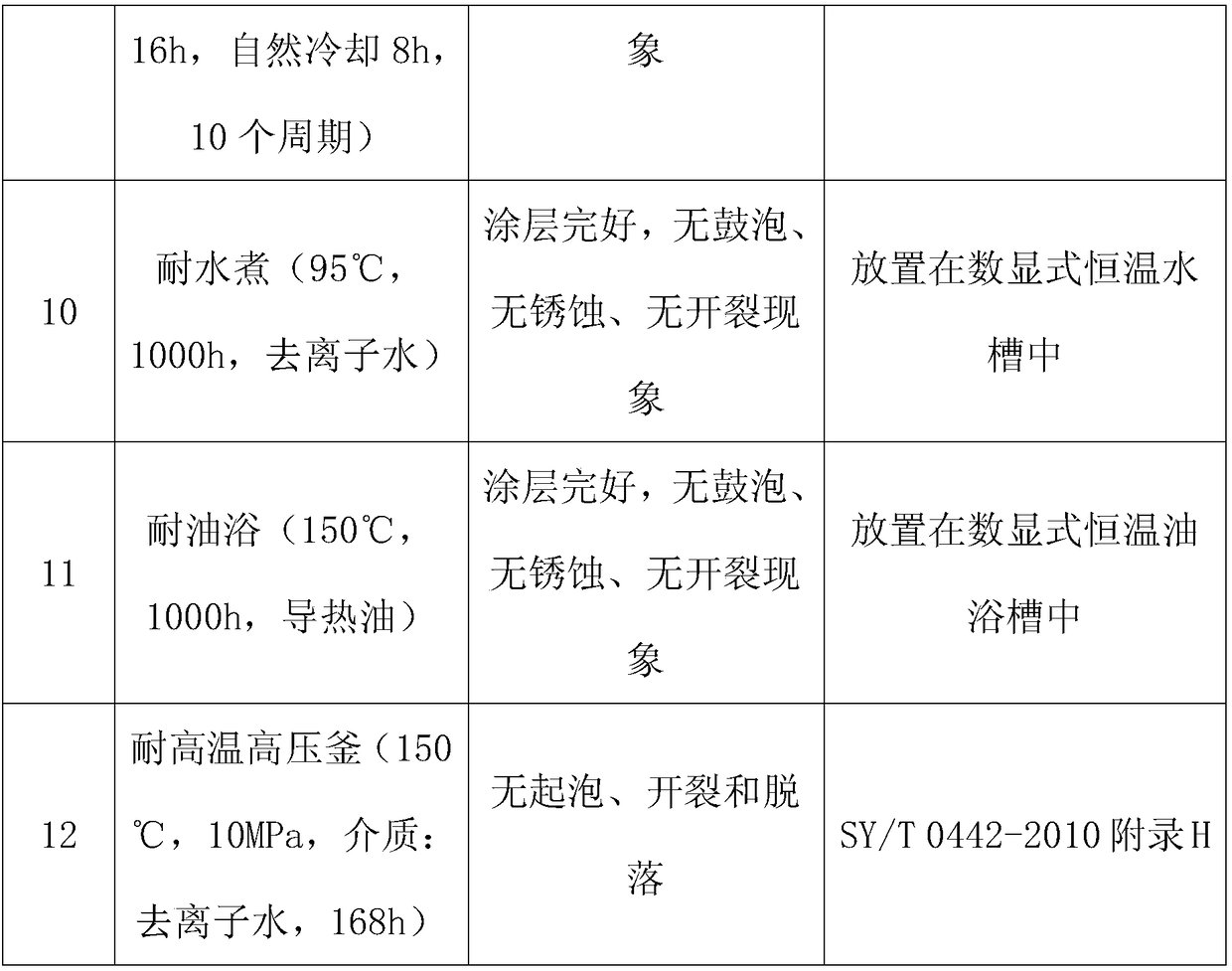

Examples

Embodiment 1

[0068] Step 1. Preparation of high temperature resistant anti-corrosion coating; put the base material and curing agent into a heating furnace or water bath device for preheating according to the mass ratio of 13:7, wherein the preheating temperature of the base material is 55°C, and the curing agent is preheated The heating temperature is 40°C. Stir evenly after preheating, add to the supply tank equipped with a heating and heat preservation device, continue to stir and keep warm, and wait for use; step 2, pretreatment of the inner surface of the steel pipe; after pretreatment, the inner surface of the steel pipe and the pipe Check the visible defects at the end; then sandblast or blast the inner surface of the steel pipe to remove rust; finally use a vacuum cleaner to remove all dust, debris and sand on the inner surface of the steel pipe; step 3, spray the inner surface of the steel pipe; put the pretreated steel pipe Transport to the spraying production line in the steel pi...

Embodiment 2

[0070] Step 1. Preparation of high-temperature resistant anti-corrosion coating; put the base material and curing agent into a heating furnace or water bath device for preheating according to the mass ratio of 7:3, the preheating temperature of the base material is 65°C, and the curing agent The temperature is 30°C, stir evenly after preheating, add to the supply tank equipped with heating and heat preservation devices, continue to stir and keep warm, and wait for use; step 2, pretreatment of the inner surface of the steel pipe; after pretreatment, the inner surface of the steel pipe and the end of the pipe Inspection of visible defects; then sandblasting or projectile rust removal on the inner surface of the steel pipe; finally, use a vacuum cleaner to remove all dust, debris and sand on the inner surface of the steel pipe; Step 3, spraying the inner surface of the steel pipe; transport the pretreated steel pipe Go to the spraying production line in the steel pipe and make it ...

Embodiment 3

[0072] Step 1. Preparation of high-temperature resistant anti-corrosion coating; put the base material and curing agent into a heating furnace or water bath device for preheating according to the mass ratio of 11:9, the preheating temperature of the base material is 70°C, and the curing agent The temperature is 25°C, stir evenly after preheating, add to the supply tank equipped with heating and heat preservation devices, continue to stir and keep warm, and wait for use; step 2, pretreatment of the inner surface of the steel pipe; after pretreatment, the inner surface of the steel pipe and the end of the pipe Inspection of visible defects; then sandblasting or projectile rust removal on the inner surface of the steel pipe; finally, use a vacuum cleaner to remove all dust, debris and sand on the inner surface of the steel pipe; Step 3, spraying the inner surface of the steel pipe; transport the pretreated steel pipe Go to the spraying production line in the steel pipe and make it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com