Extrusion and rounding integrated machine for pharmacy

An all-in-one machine, one-piece technology, which is applied in the field of pharmaceutical extrusion and rounding all-in-one machines, which can solve the problems of non-meshing and crushing, and inability to easily replace the screen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

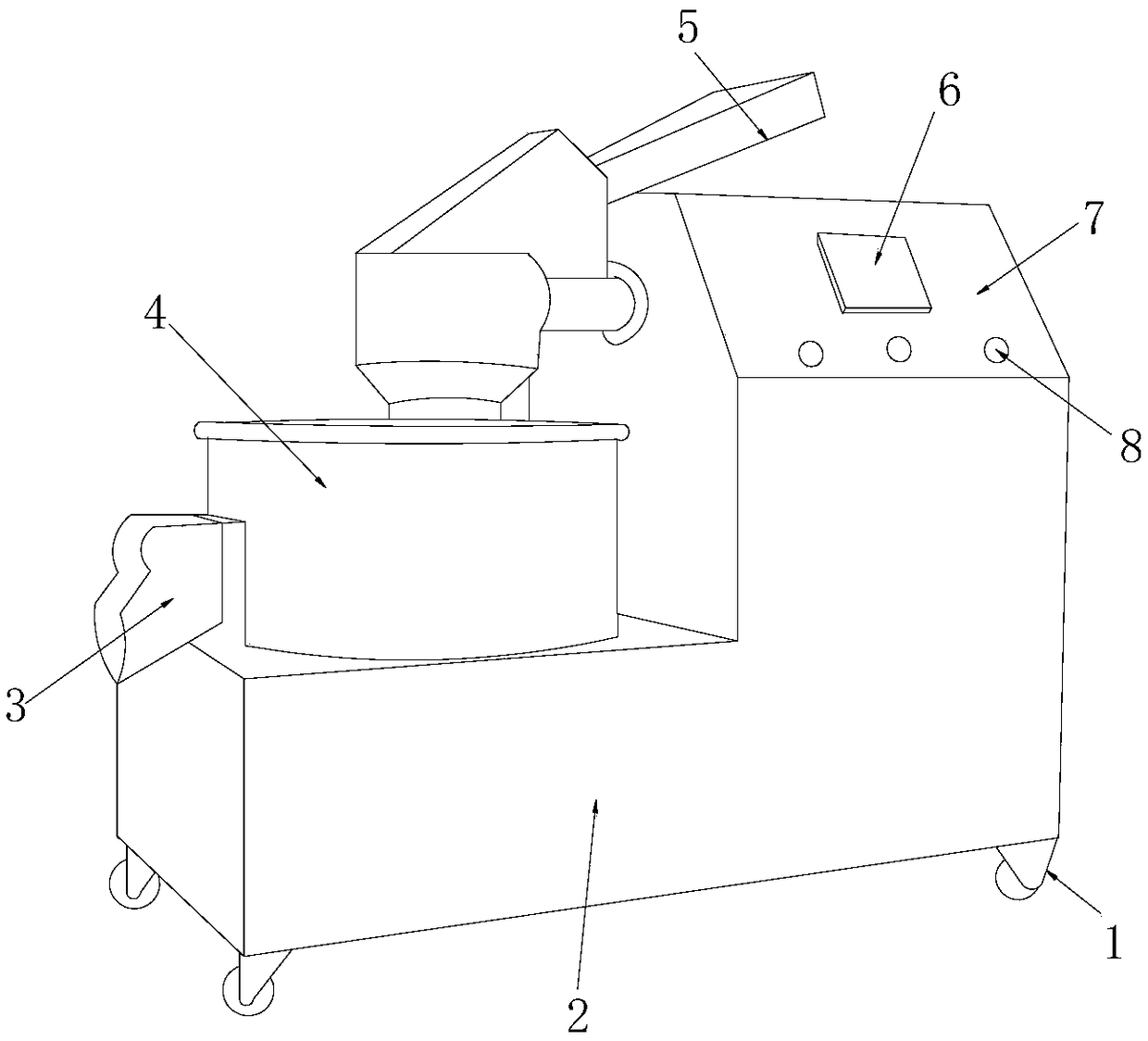

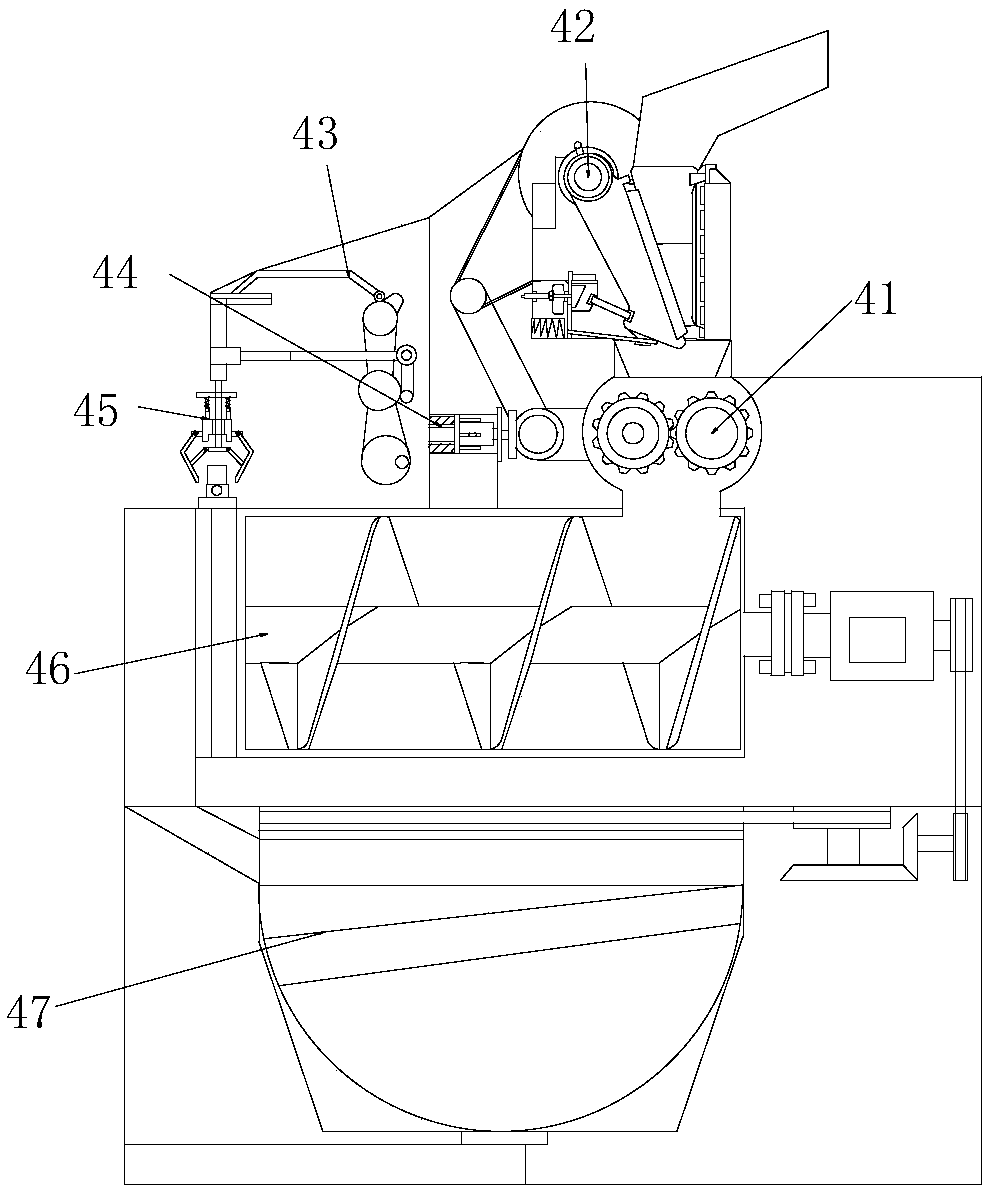

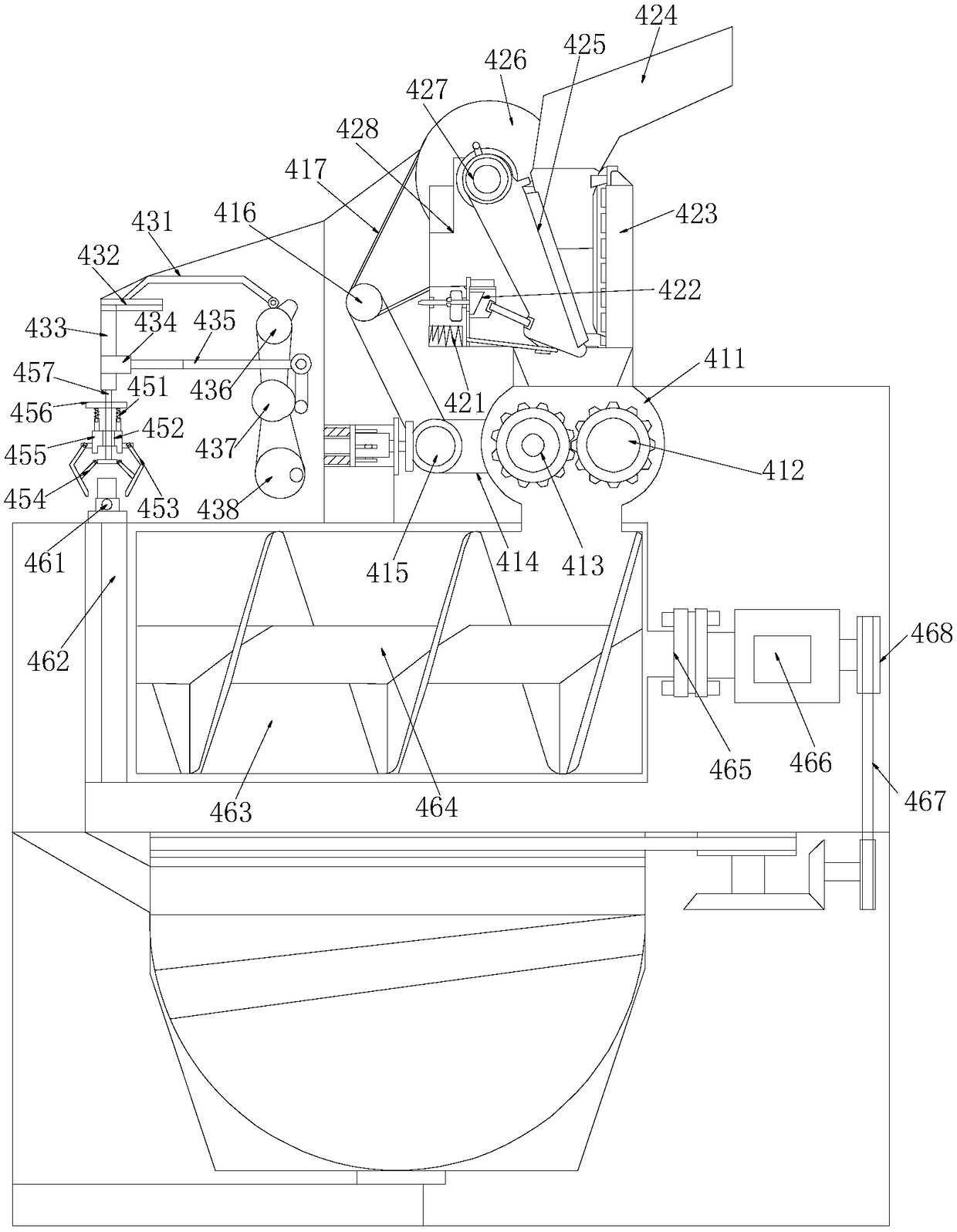

[0024] see Figure 1-Figure 5 , the present invention provides an integrated extrusion and throwing machine for pharmaceutical use, the structure of which includes: a moving wheel 1, a device housing 2, a discharge frame 3, an intelligent adjustment and production integrated device 4, a feed frame 5, a display screen 6, and a control panel 7 , the control key 8, the control panel 7 is located on the right side surface of the upper surface of the device housing 2 and is fitted with the device housing 2 to form an integrated structure, and the display screen 6 is located above the front surface of the control panel 7 and simultaneously The control panel 7 is fixedly connected, the control key 8 is embedded in the inner end surface of the control panel 7 and is movably connected with the control panel 7, and the intelligent adjustment and manufacturing integrated device 4 is perpendicular to the upper end surface of the device housing 2 to form an integration structure, the feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com