A kind of vat dye suspension wet short steam pad dyeing process

A technology of wet short pad dyeing and suspension, which is applied in the field of vat dye suspension wet short pad dyeing process, and can solve the problems of dip dyeing process, such as poor level dyeing and color fastness, application restrictions, and high requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

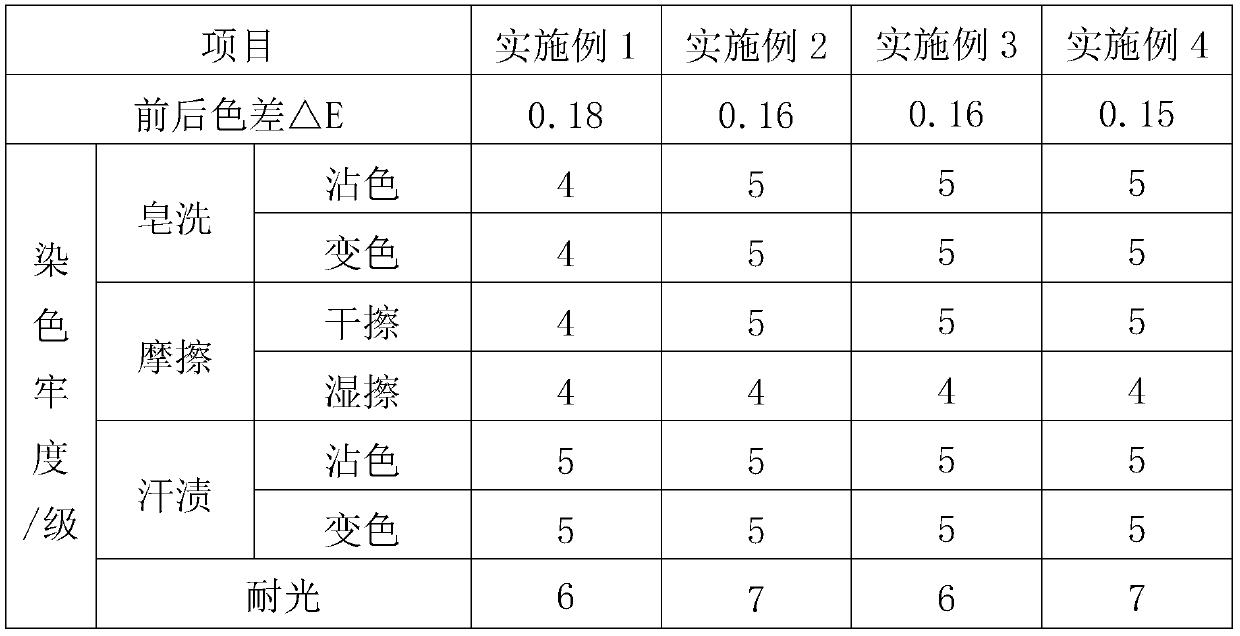

Examples

Embodiment 1

[0021] In this embodiment, a vat dye suspension wet short steam pad dyeing process includes the following processes:

[0022] S1, padding dyeing solution, according to the bath ratio of 1:5, the fabric to be dyed is padded in the vat dye suspension dyeing solution, two dipping and two padding, the temperature of the padding tank is 55 ° C, and the excess rate is 60%. Said vat dye suspension dye liquor comprises: superfine powdered vat dye 5% (oxf), reducing agent 1g / L, penetrating agent 3g / L, diffusing agent 1g / L, accelerator 30g / L;

[0023] S2, padding lye, directly padding the fabric to be dyed obtained through S1 treatment in lye, one dipping and one rolling, the temperature of the padding tank is 45 ℃, and the excess rate is 70%, and the lye includes : caustic soda 5g / L, hydrosulfite 10g / L;

[0024] S3. Reduction steaming, using saturated steam for rapid steaming, the temperature of reduction steaming is 100°C, and the steaming time is 2 minutes;

[0025] S4. Oxidation, ...

Embodiment 2

[0027] In this embodiment, a vat dye suspension wet short steam pad dyeing process includes the following processes:

[0028] S1, padding dyeing solution, according to the bath ratio 1:40, the fabric to be dyed is padded in the vat dye suspension dyeing solution, two dipping and two rolling, the temperature of the padding tank is 35 ° C, and the excess rate is 100%. Said vat dye suspension dye liquor comprises: superfine powdered vat dye 0.1% (oxf), reducing agent 20g / L, penetrating agent 1g / L, diffusion agent 3g / L, accelerator 5g / L; The preparation method of the vat dye comprises: mixing the vat dye and modified sodium lignosulfonate with water, then rotary cutting at high speed to obtain a slurry suspension with a fineness of 10-30um; Pulverize and grind to obtain a primary dye with a fineness of 5-10um; filter the primary dye through a filter element of 0.1-0.5um, and then spray dry to obtain the ultrafine powdered vat dye, the vat dye, modified The weight ratio of the mod...

Embodiment 3

[0035] In this embodiment, a vat dye suspension wet short steam pad dyeing process includes the following processes:

[0036]S1, padding dyeing solution, according to the bath ratio of 1:10, the fabric to be dyed is padded in the vat dye suspension dyeing solution, two dipping and two rolling, the temperature of the padding tank is 50 ° C, and the excess rate is 70%. Said vat dye suspension dye liquor comprises: superfine powdered vat dye 2% (oxf), reducing agent 10g / L, penetrating agent 2g / L, diffusion agent 2g / L, accelerator 15g / L; The preparation method of the vat dye comprises: mixing the vat dye and modified sodium lignosulfonate with water, then rotary cutting at high speed to obtain a slurry suspension with a fineness of 10-20um; Pulverize and grind to obtain a primary dye with a fineness of 5-10um; filter the primary dye through a filter element of 0.1-0.5um, and then spray dry to obtain the ultrafine powdered vat dye, the vat dye, modified The weight ratio of the per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com