Needle stem mechanism of double-needle sewing machine

A sewing machine and needle bar technology, which is applied in the field of needle bar mechanism, can solve problems such as fretting wear, achieve the effects of improving productivity, improving corrosion resistance, and realizing the simplification of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] (Overall configuration of the embodiment of the present invention)

[0059] Below, according to Figure 1 to Figure 11 , the embodiments of the present invention will be described in detail.

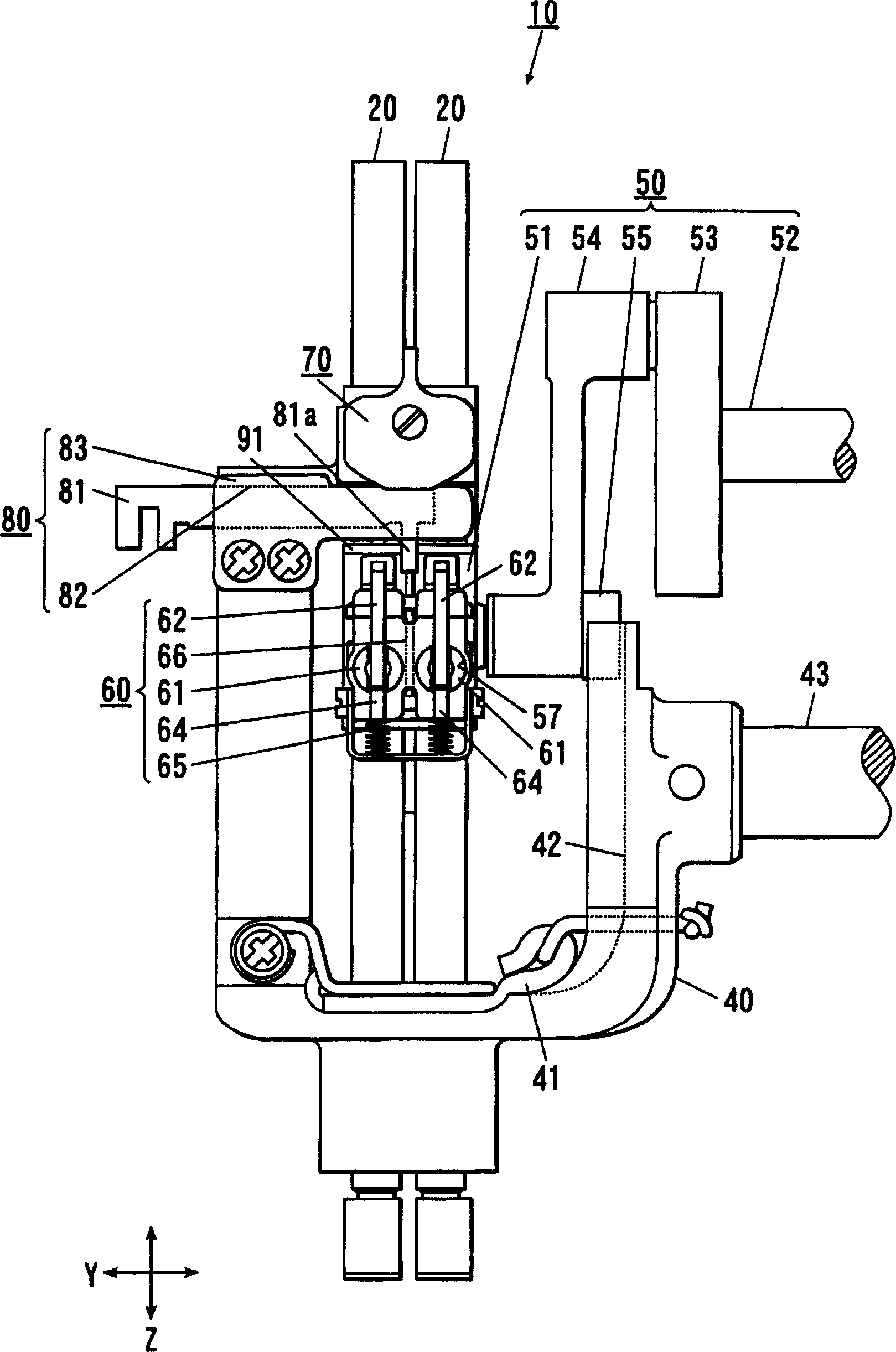

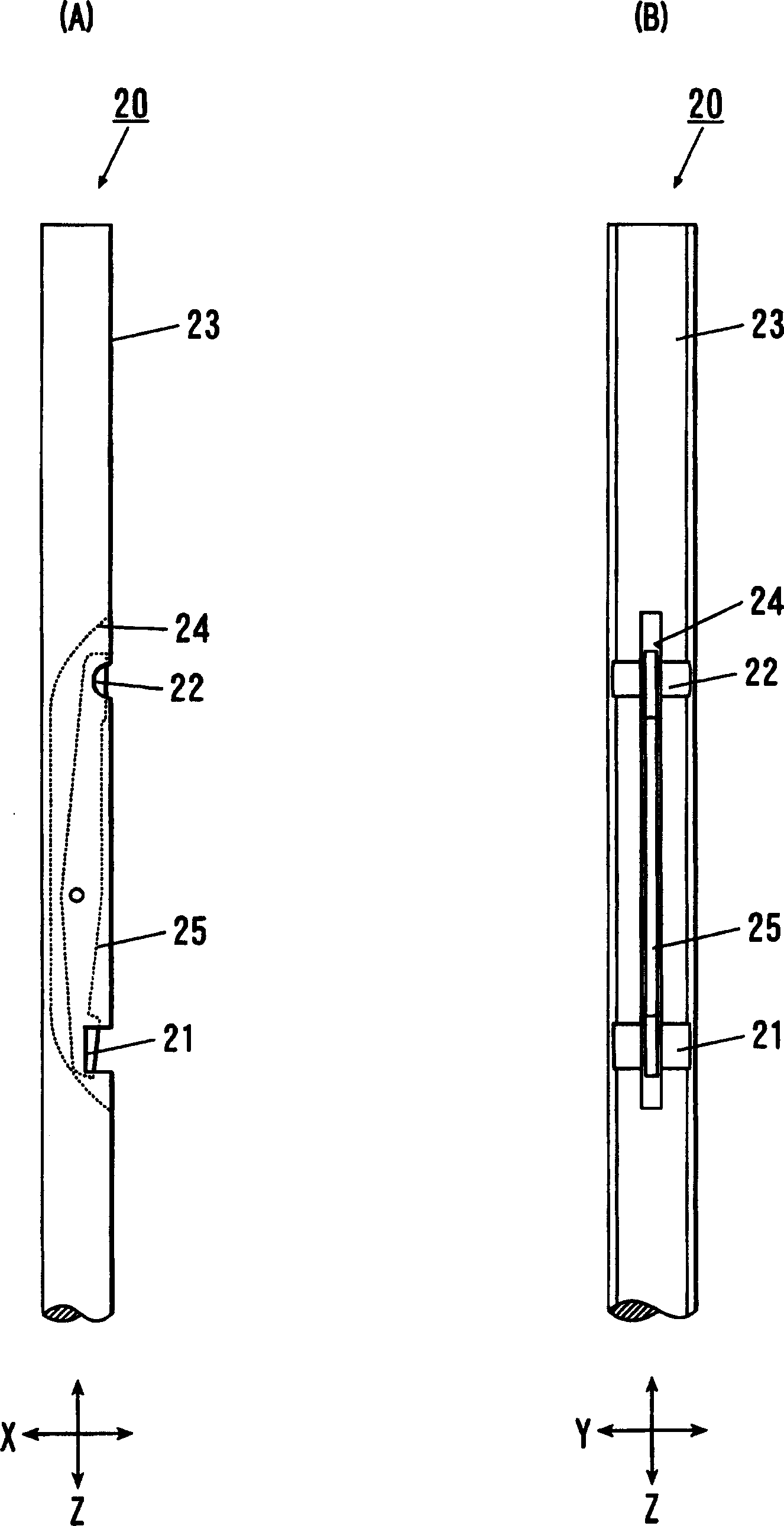

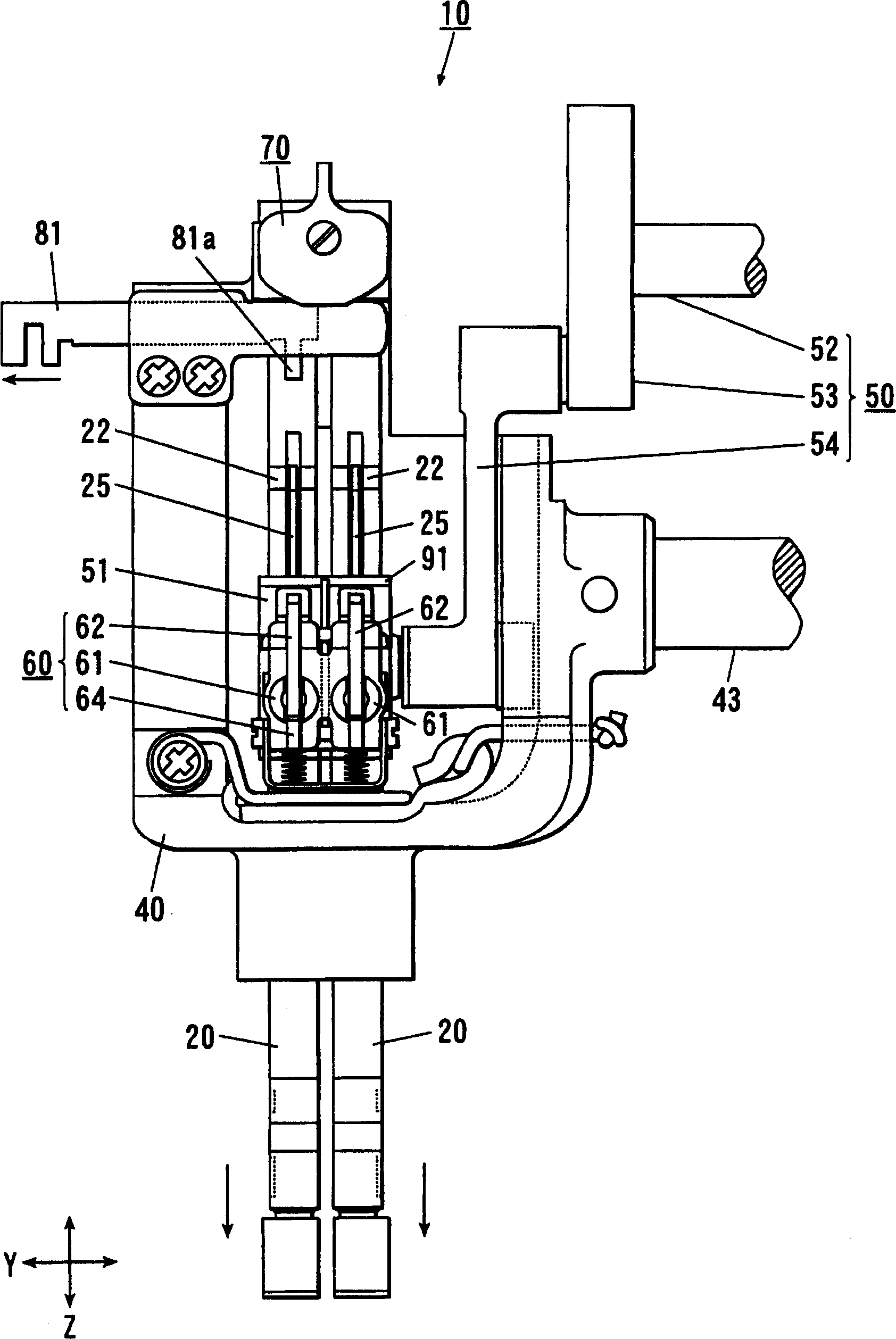

[0060] figure 1 It is a front view of the needle bar mechanism 10 of the double-needle sewing machine according to the embodiment of the present invention, figure 2 (A) is a side view in which a part of the needle bar 20 is omitted, figure 2 (B) is the front view, image 3 A front view of the needle bar mechanism 10 when the needle bar is lowered is shown.

[0061] The double-needle sewing machine has general various mechanisms required for sewing such as the following mechanisms, namely, a sewing machine frame that accommodates and maintains various components for sewing; as the needle bar mechanism 10 to be described below, The sewing machine motor that drives the power source of the two machine needles up and down; the rotary hook mechanism or the loop mechanism, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com