Electromagnetic driver of sewing machine

An electromagnetic drive, sewing machine technology, applied in sewing machine components, sewing equipment, cloth pressing mechanisms, etc., can solve the problems of insufficient magnetic force, difficult and inconvenient pressing feet of sewing machines, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

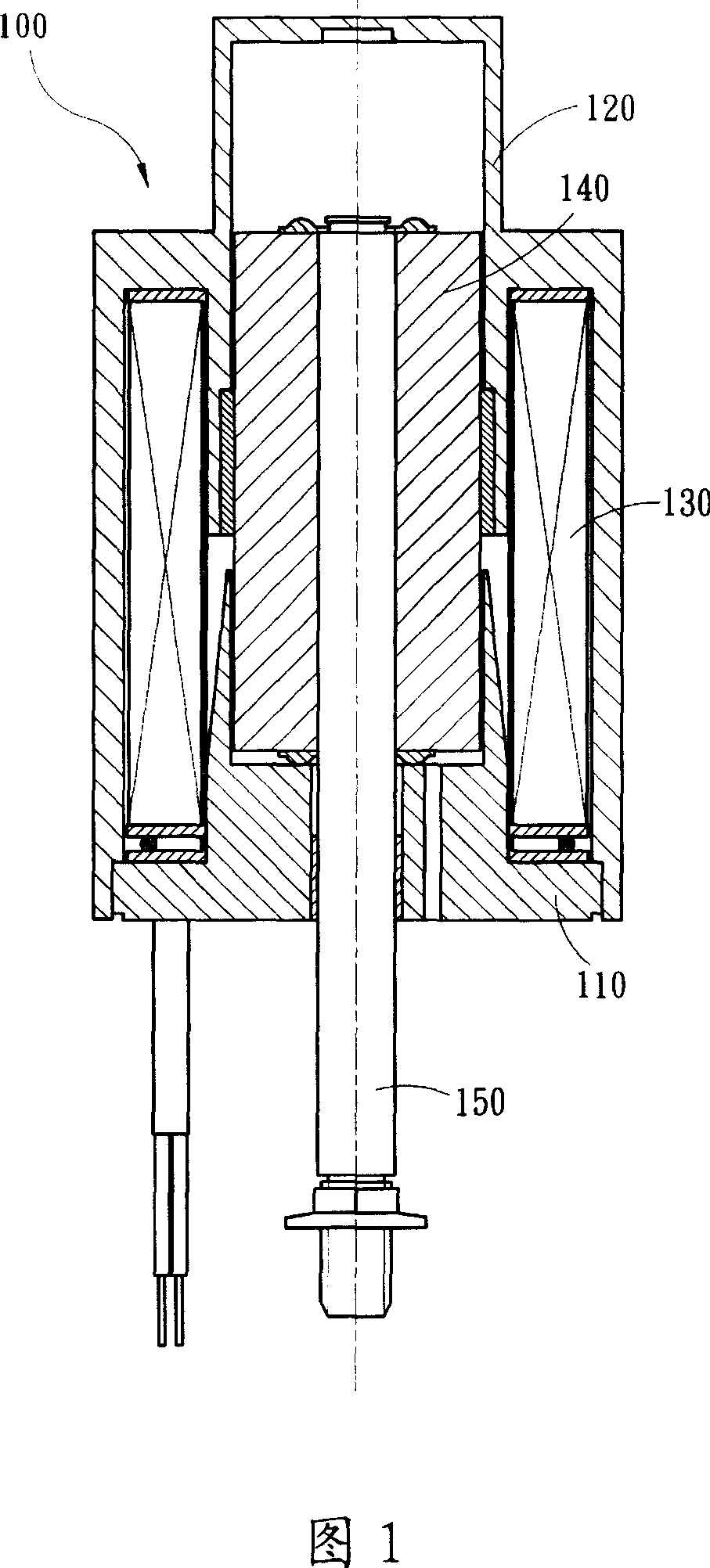

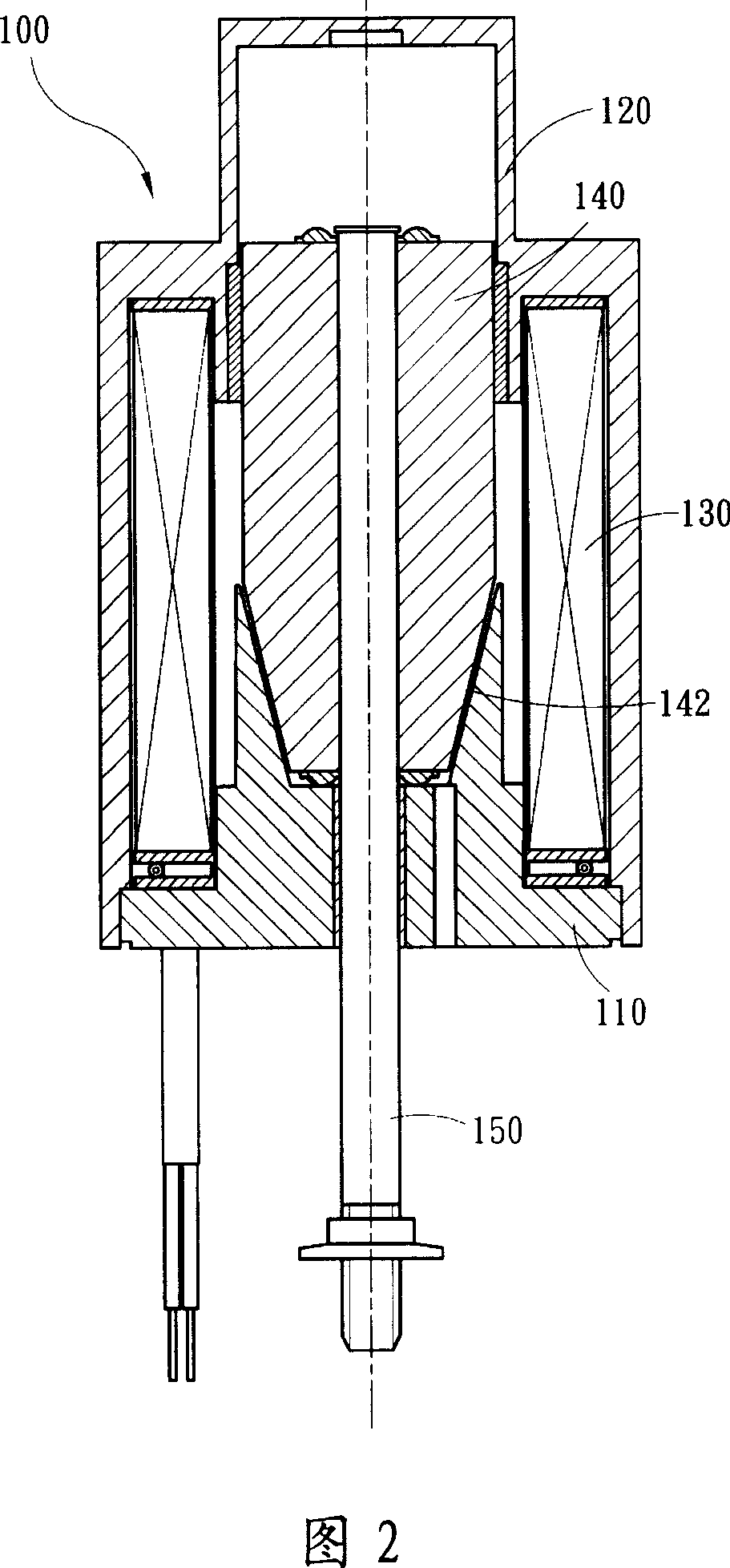

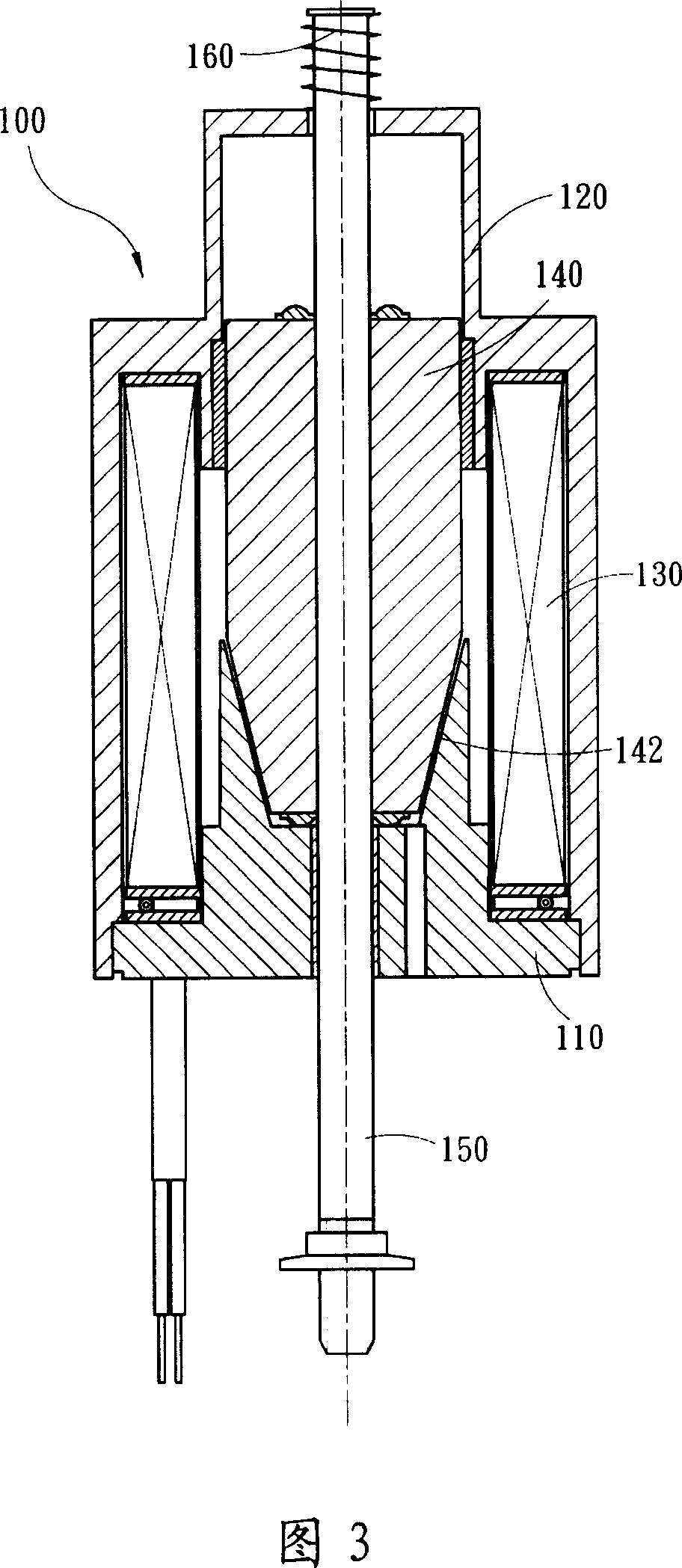

[0028] For further elaborating the technical means and effect that the present invention takes for reaching the intended invention purpose, below in conjunction with accompanying drawing and preferred embodiment, to the electromagnetic drive device of the sewing machine that proposes according to the present invention its specific implementation, structure, feature and effect Its effect is described in detail below.

[0029] First, please refer to the Pic 4-1 , Figure 4-2 , Figure 5-1 and Figure 5-2 Shown is the electromagnetic driving device 200 of the sewing machine of the present invention, which is used to drive the action of a presser foot 310 connected to the sewing machine 300. The presser foot 310 is connected by a linkage device 320 and the electromagnetic driving device. 200, and in the present embodiment, the electromagnetic driving device 200 is installed on the outside of the sewing machine 300 in an upright manner, which is mainly composed of a metal base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com