Special equipment for ceramic cutting

A special equipment, ceramic technology, applied in the field of special equipment for ceramic cutting, can solve the problems of saw blade jitter, accuracy impact, high labor cost, and achieve the effect of small jitter, good stability, and increased cutting freedom.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

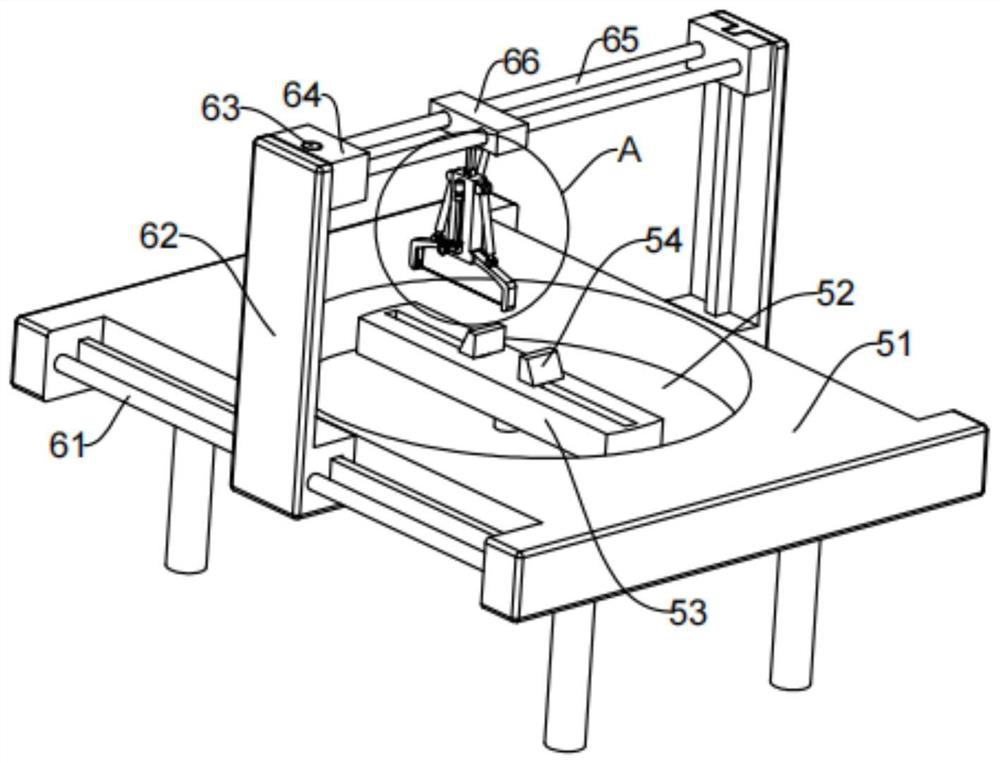

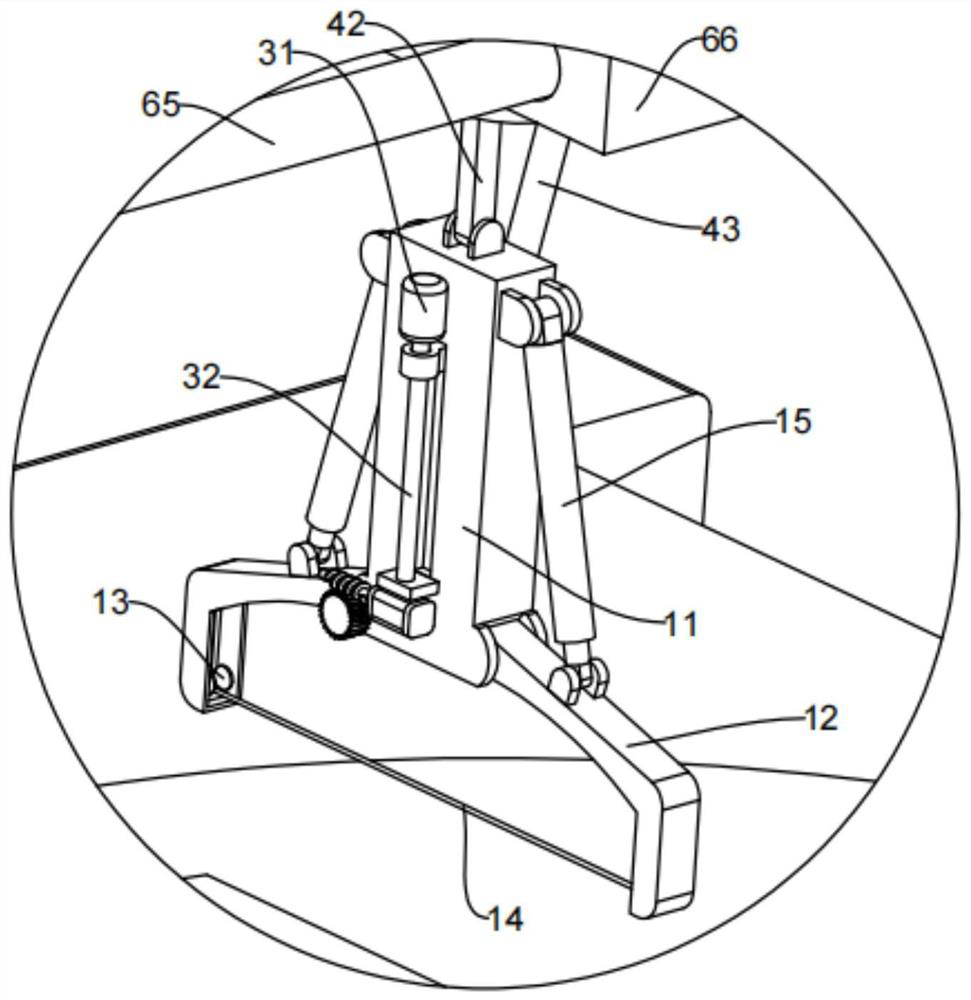

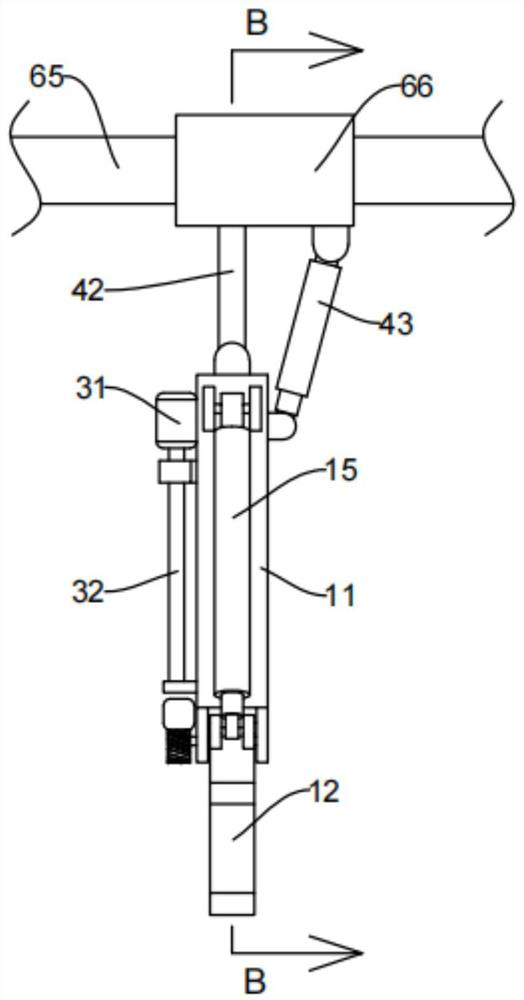

[0025] refer to Figure 1 to Figure 5 As shown, this embodiment provides a special equipment for ceramic cutting, which is mainly used for multi-angle and multi-shape stable cutting of ceramic materials.

[0026] This embodiment includes a bed 51, and the bed 51 is provided with a drive mechanism for driving the base 11 to move in three directions. The drive mechanism includes a vertical arm 62 slidingly arranged on the side of the bed 51, The side rotation of the bed 51 is provided with a first screw 61 driven by a power source, the first screw 61 is screwed to the vertical arm 62, and the vertical arm 62 slides up and down with a vertical movement block 64 , the vertical arm 62 is rotated with a vertical second screw rod 63 driven by the power source, the second screw rod 63 is threaded with the vertical movement block 64, and the vertical movement block is rotated with a horizontal The third screw rod 65 driven by the power source to rotate is provided with a translation b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com