Plasma positioning cutting device based on X-Y-Z-axis system

A positioning cutting, plasma technology, applied in the direction of plasma welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of inability to guarantee cutting stability and cutting precision, parts cannot be directly transported away, and high equipment cost, so as to avoid Personal injury, fast cutting, and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order for those skilled in the art to better understand the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and the following embodiments.

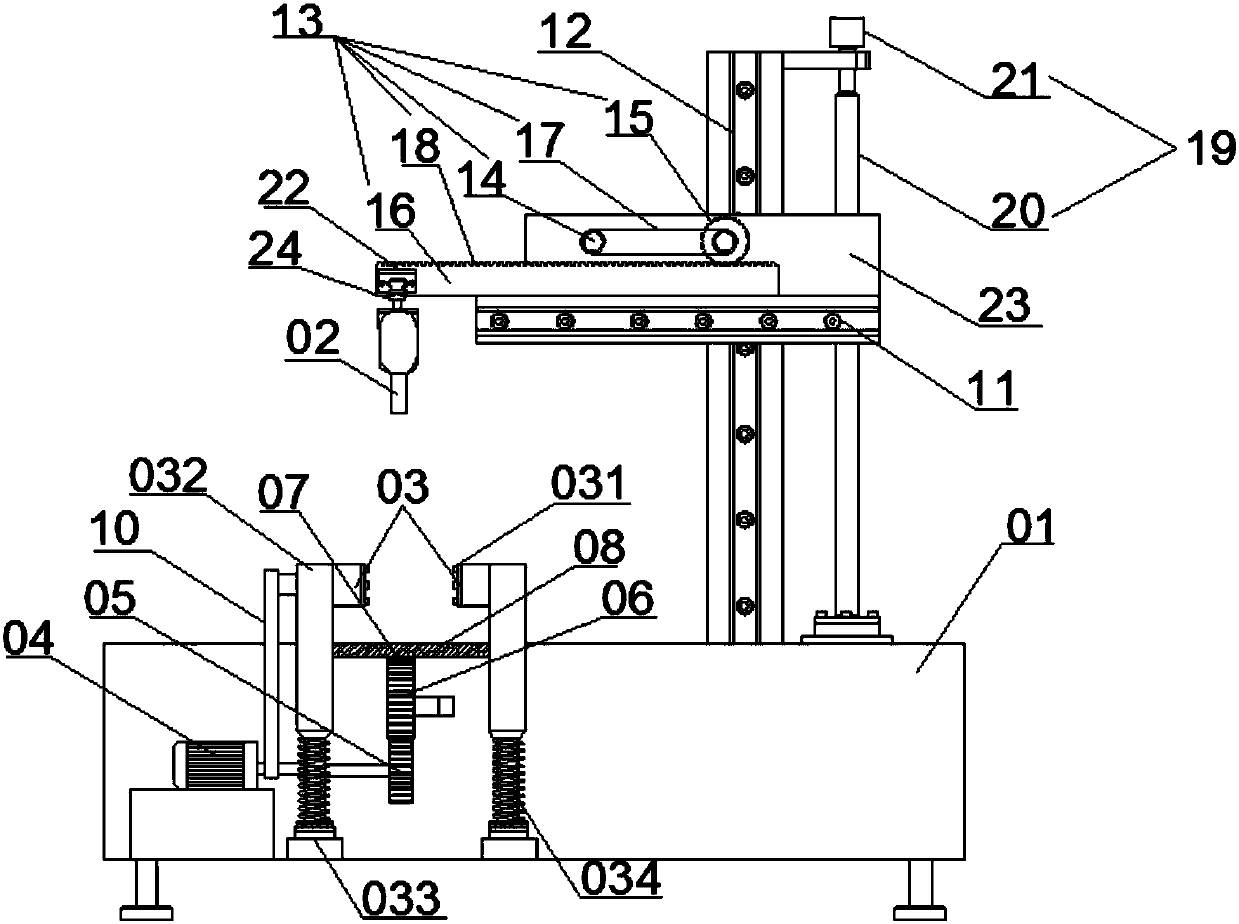

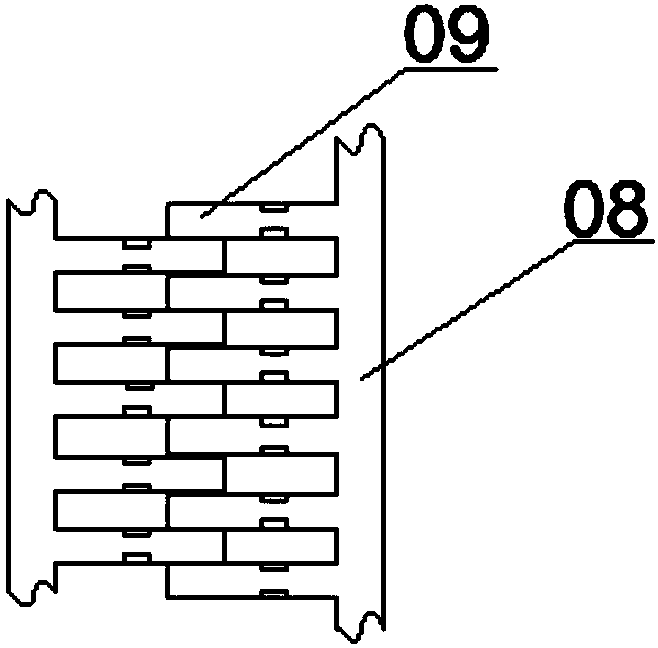

[0027] Please refer to figure 1 with figure 2 As shown, this embodiment provides a plasma positioning cutting device based on the XYZ three-axis system, including a processing table 01, a plasma spray gun 02, a clamping device 03 for clamping the plasma spray gun 02, and a driving plasma spray gun arranged on the processing table 01 02 An XYZ-axis motion assembly that moves freely along the X-axis, Y-axis, and Z-axis directions. Specifically, the clamping device 03 includes two oppositely arranged triangular chucks 031, a support column 032, and a threaded connection with the support column 032. The supporting seat 033 and the triangular chuck 031 are arranged on the supporting parts through bearings, and a damping spring 034 is arranged between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com