Patents

Literature

51results about How to "Full scrape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

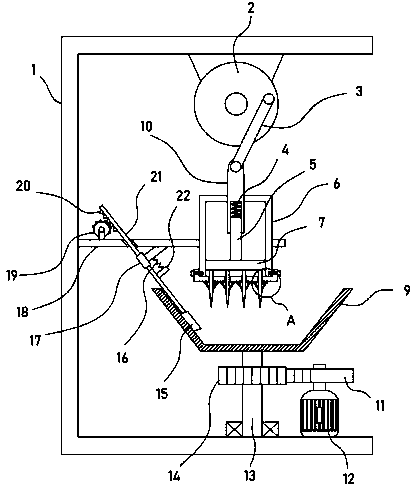

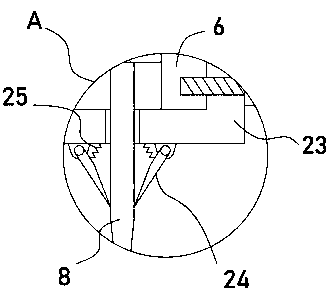

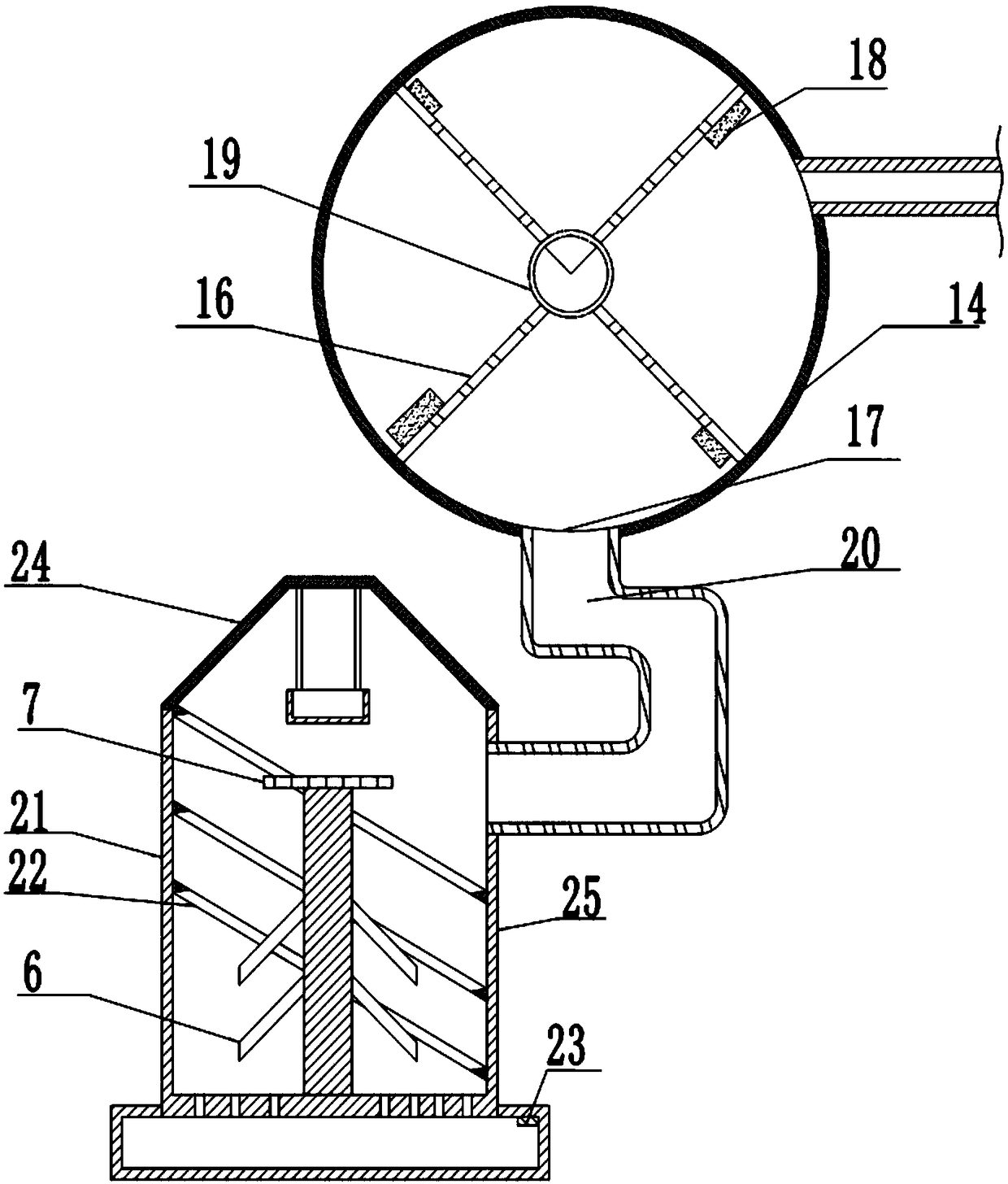

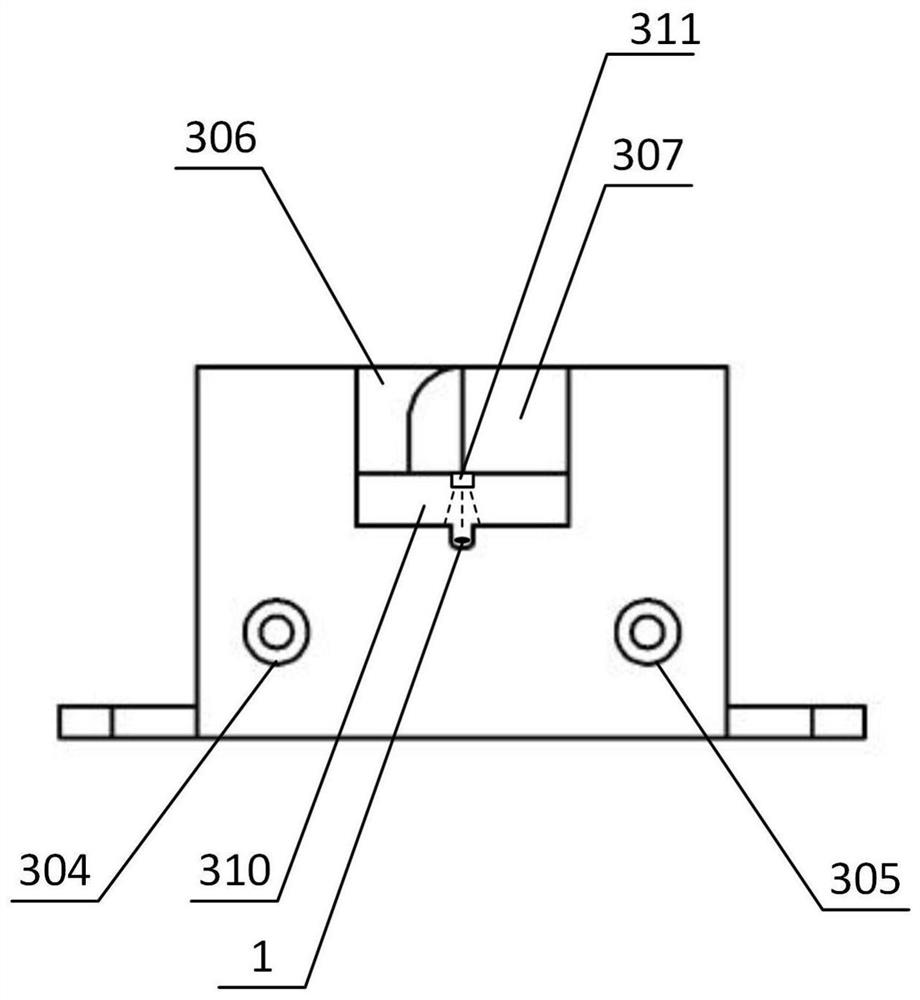

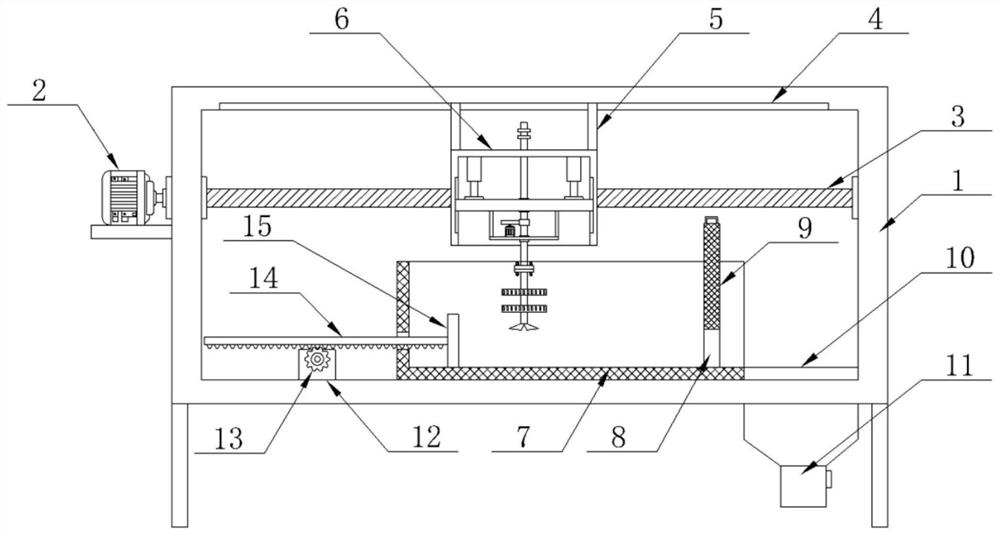

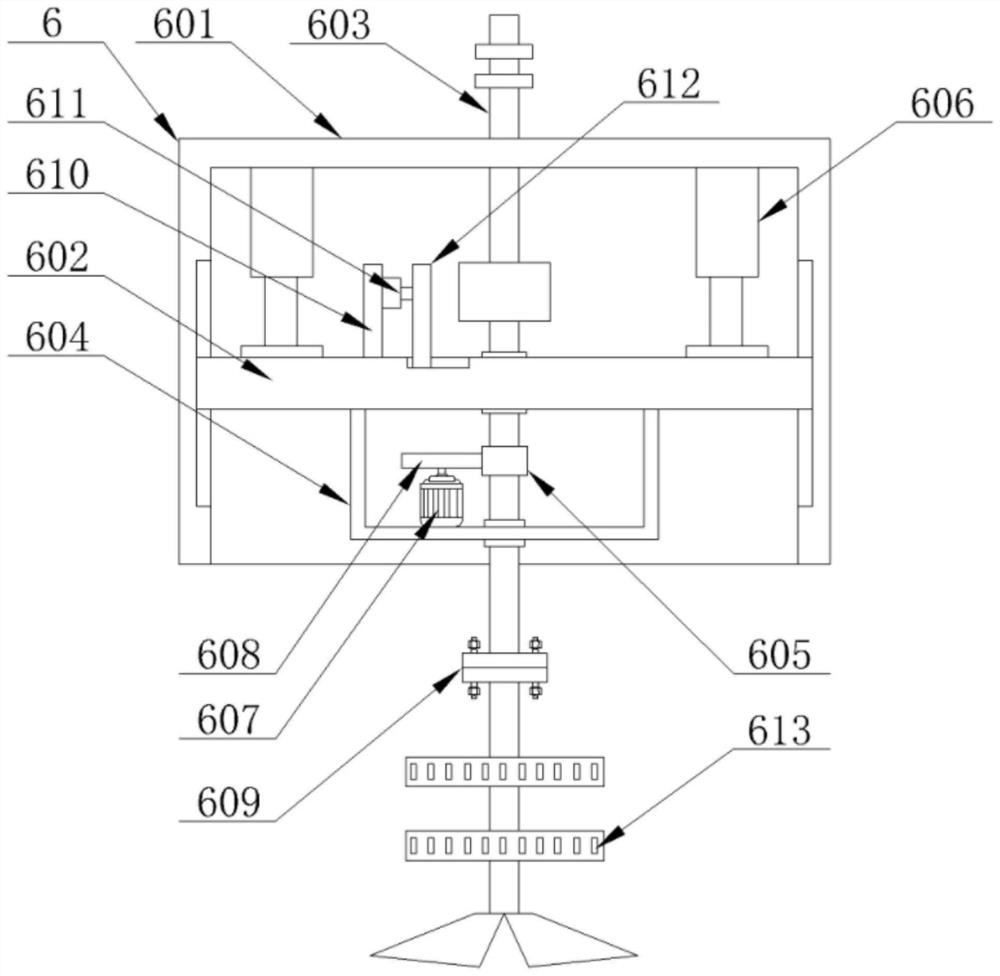

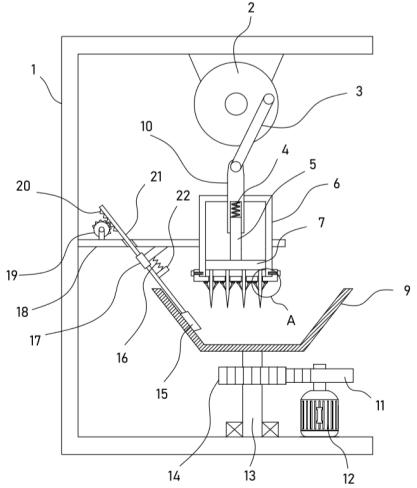

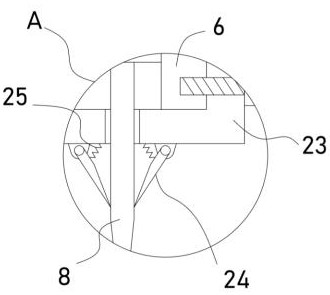

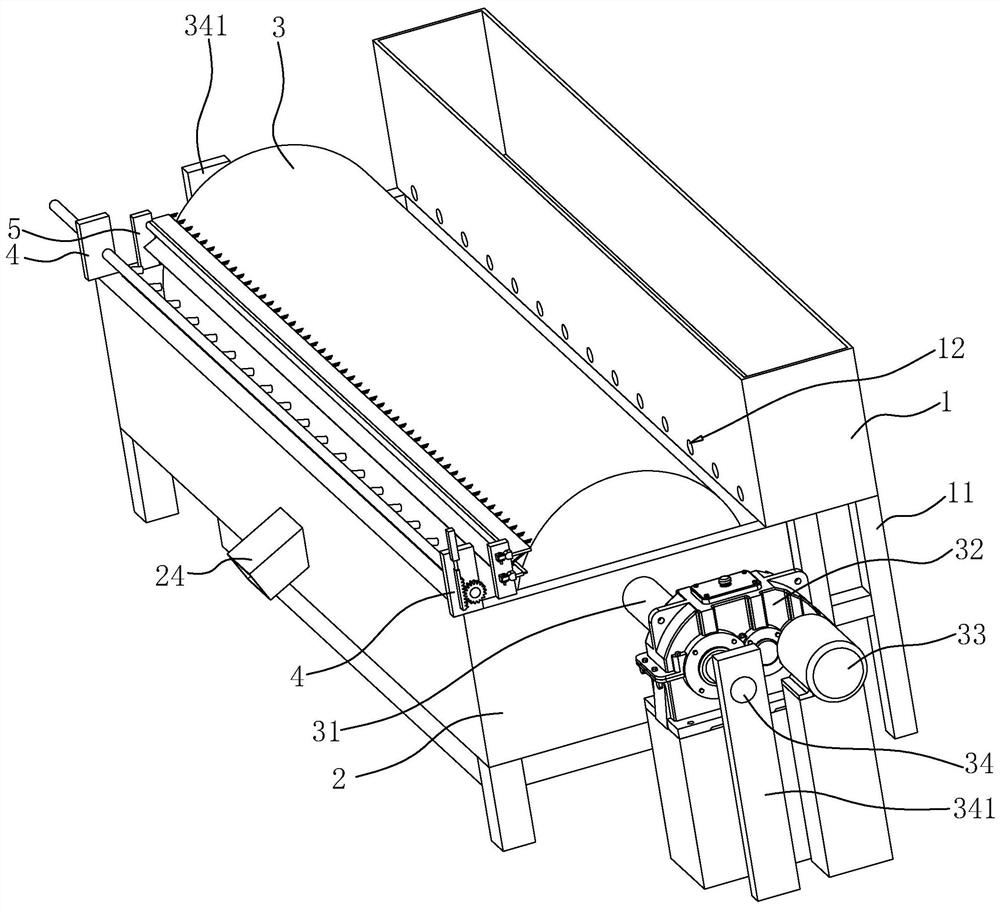

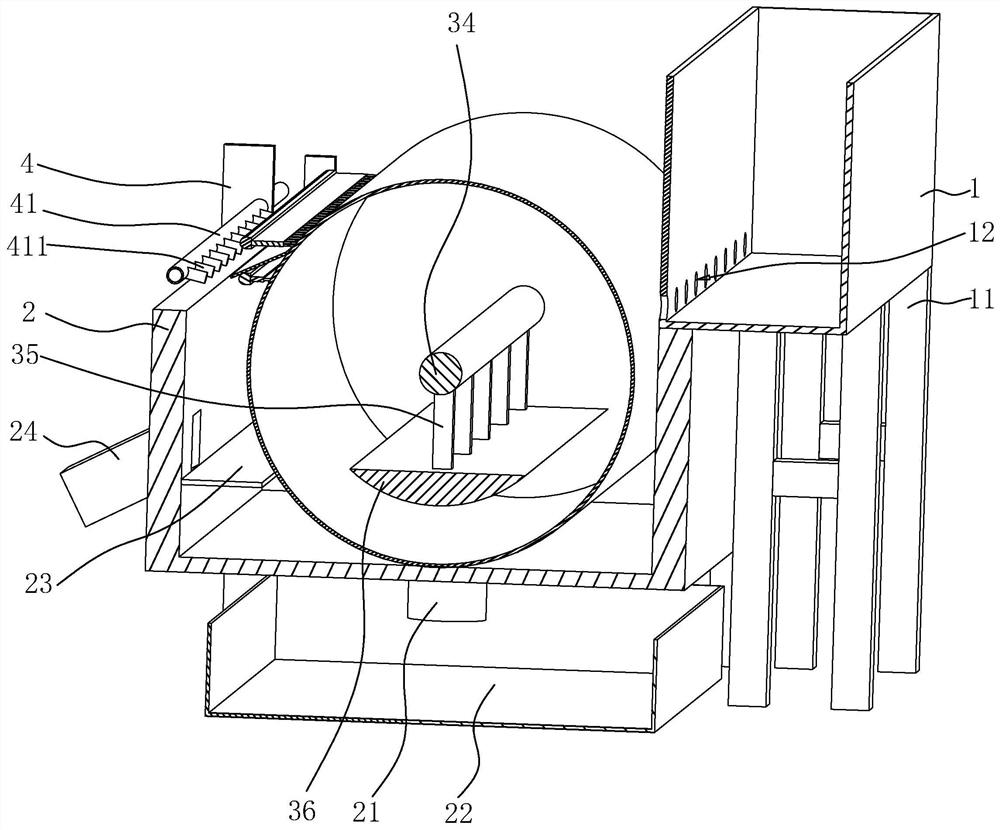

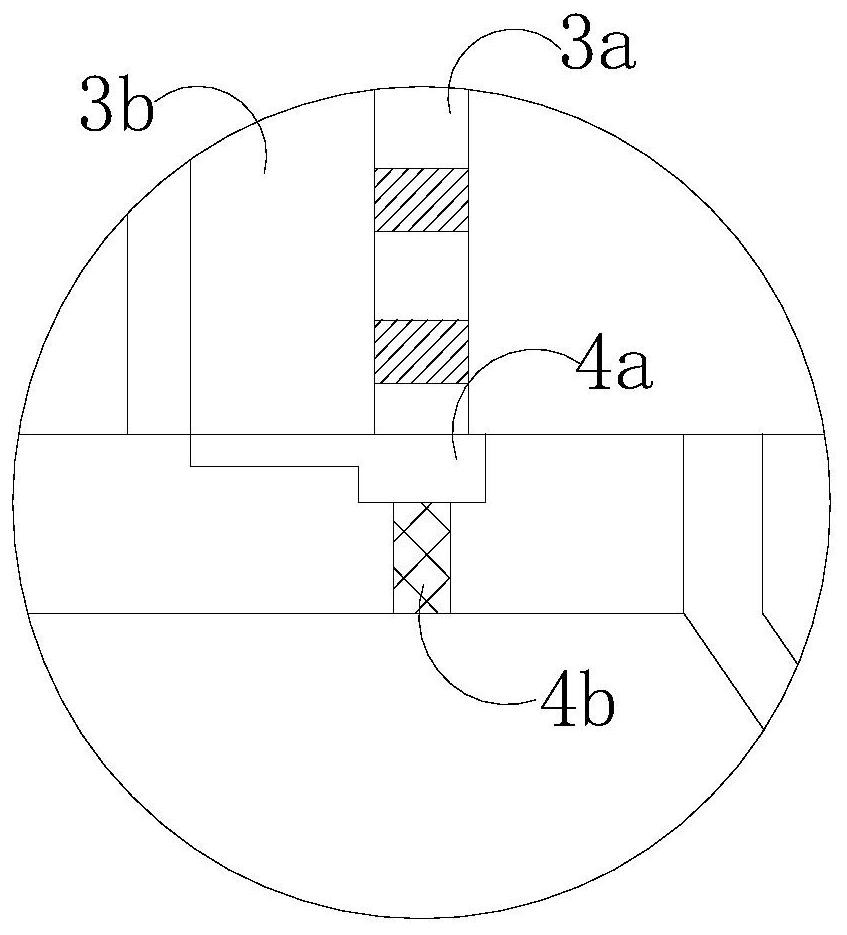

Meat stuffing chopping device for food processing

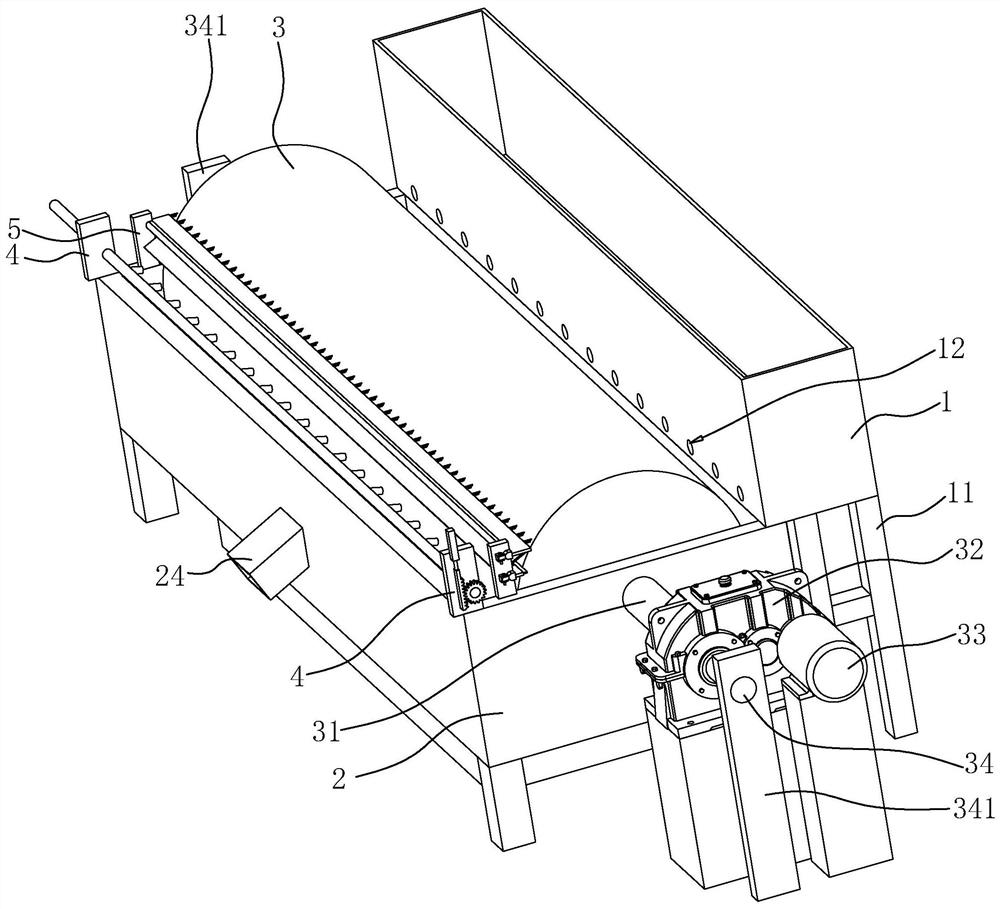

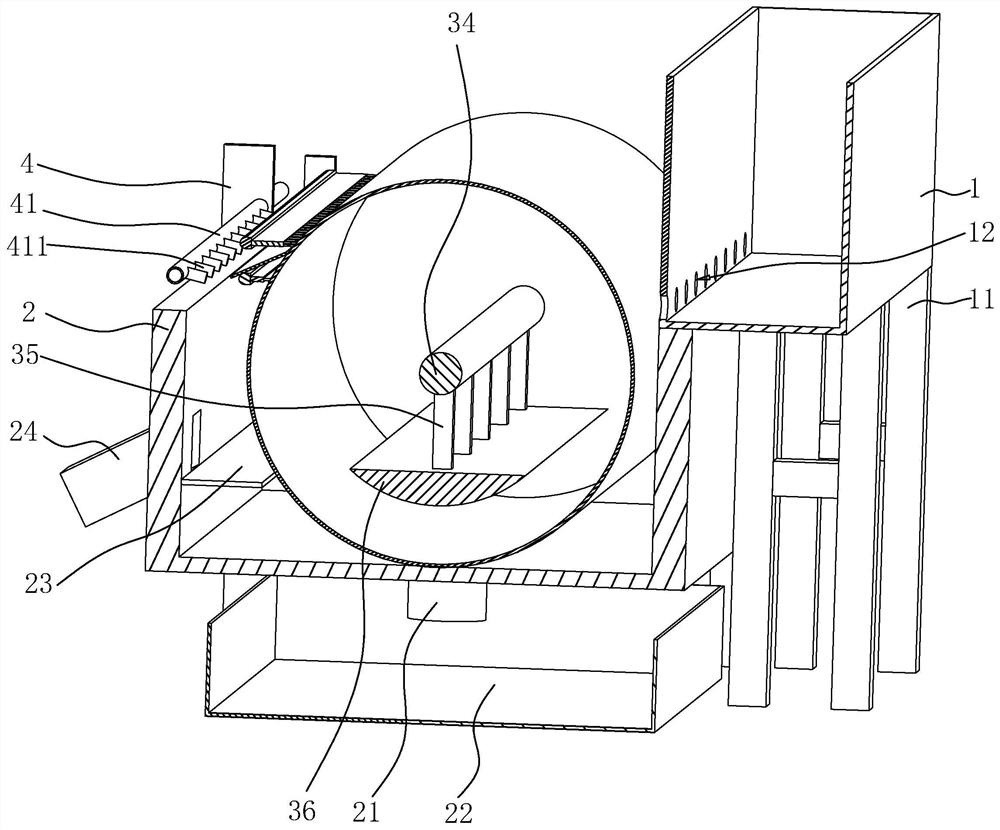

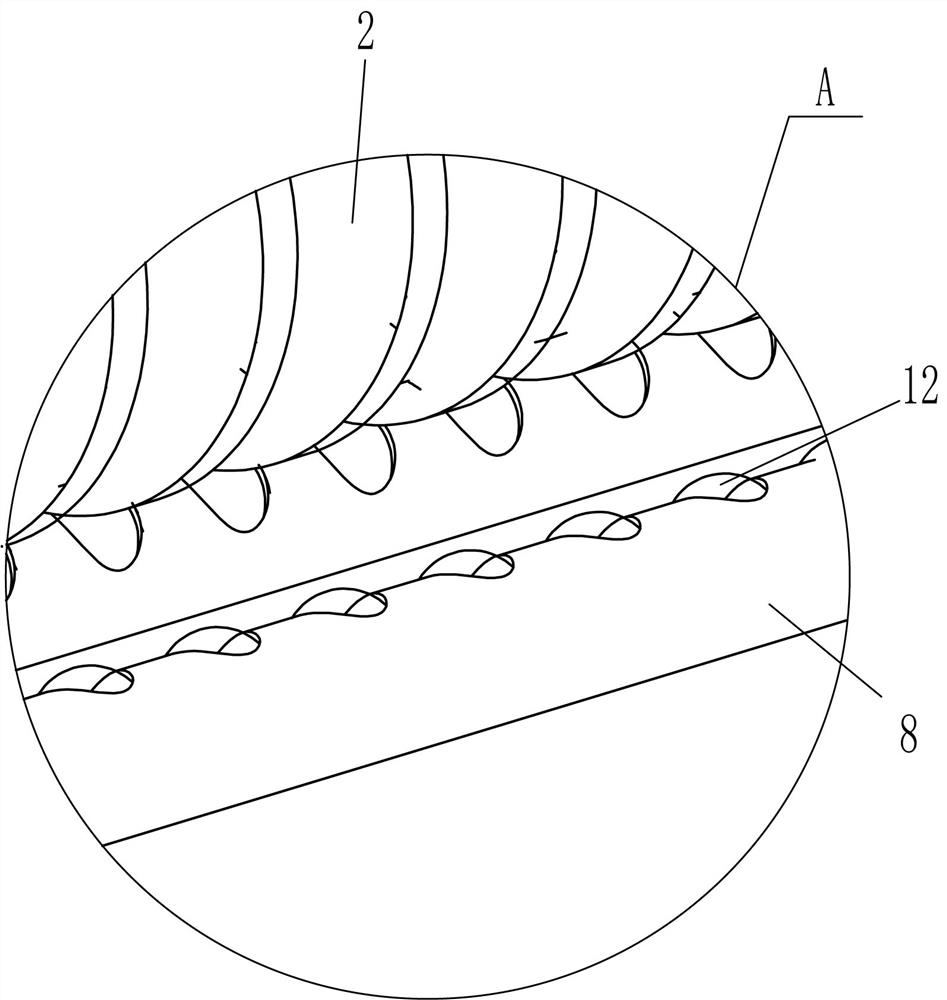

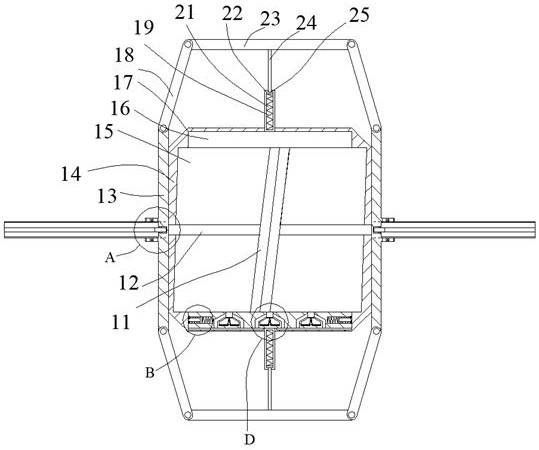

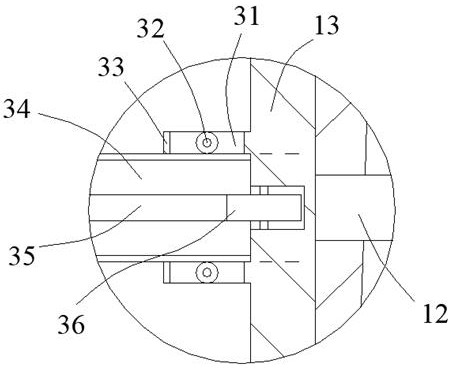

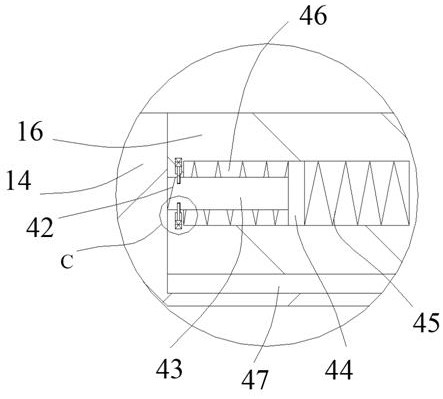

The invention discloses a meat stuffing chopping device for food processing, and relates to the technical field of food processing machinery. The device comprises an operation frame, and a meat mincing groove is rotationally formed in the operation frame; a chopping mechanism is arranged on the meat mincing groove and comprises a plurality of crushing knives uniformly fixed at the bottom of a knife holder; a bottom plate for allowing the crushing knives to slide through is arranged below the knife holder, a scraper which abuts against the crushing knives is hinged to the bottom of the bottom plate, and the crushing knives are eccentrically installed in the meat mincing groove. The crushing knives are driven by the knife holder to move up and down to conduct repeated cutting and crushing onmeat in the meat mincing groove, and the meat mincing groove can be intermittently rotated so that meat in the meat mincing groove can comprehensively and repeatedly chopped; the minced meat adheringto the side walls of the crushing knives can be fully scraped away by the scraper, so that the up-down movement of the crushing knives is smoother, and the meat chopping effect is improved. The arranged scraper can scrape away meat blocks adhering to the inner wall of the meat mincing groove, so that the meat is more thoroughly chopped.

Owner:JIANGSU FOOD & PHARMA SCI COLLEGE

Automatic potato peeling processing device

The invention relates to the technical field of automated machinery, in particular to an automatic potato peeling processing device. The automatic potato peeling processing device comprises an outer box body, a rotating rod and a blade holder, wherein a sliding groove is fixedly connected to the top of the right side wall of the outer box body; a first reciprocating motor is arranged on the sliding groove; a push rod is fixedly connected to the lower end of a second reciprocating motor; the rotating rod is inserted into a threaded cylinder; an arc-shaped fixing frame is fixedly connected to one surface of the inner side of an electric air cylinder; a first supporting spring and a second fixing rod are inserted into a first fixing rod; the four corners of an outward end face of the blade holder are fixedly connected with four second supporting springs, and a first movable baffle is hinged to the lower end of the arc-shaped fixing frame through a spring hinge. According to the automaticpotato peeling processing device, the structural design is reasonable; blades can be freely adjusted to tightly fit the surface of a potato under the action of the second supporting springs, so that the problem of small application range of existing potato peeling devices is solved. The thrust generated by the second reciprocating motor can ensure that the potato is fully scraped by the blade, sothat peeling of the potato is more thorough.

Owner:甄城

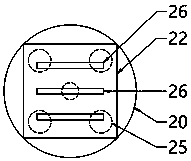

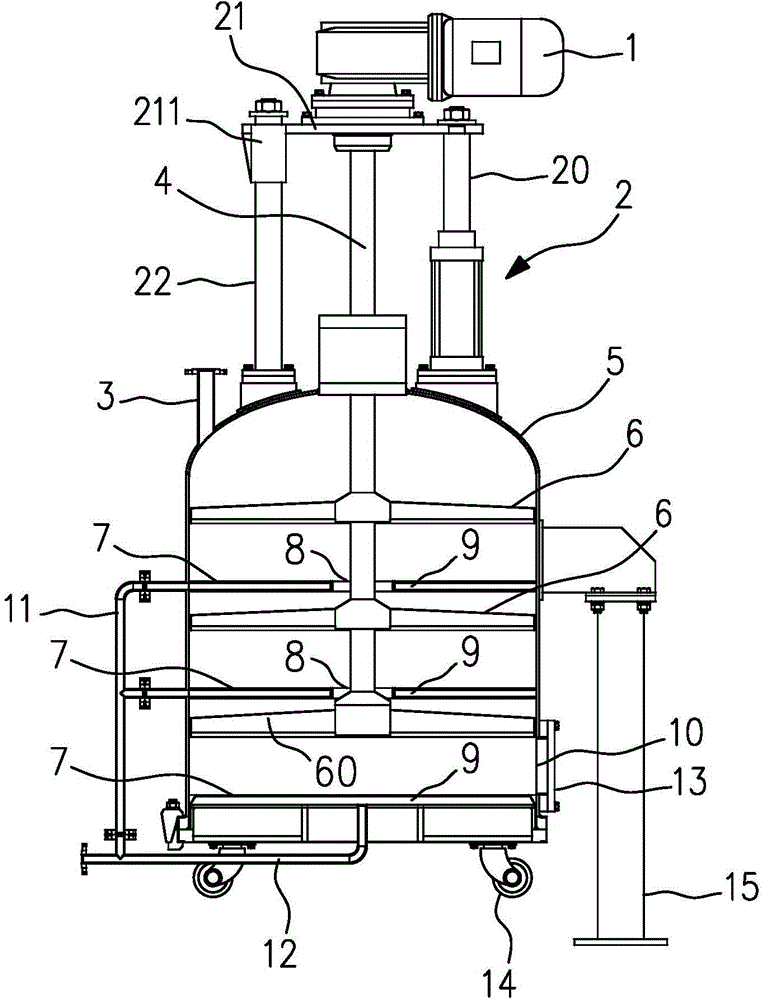

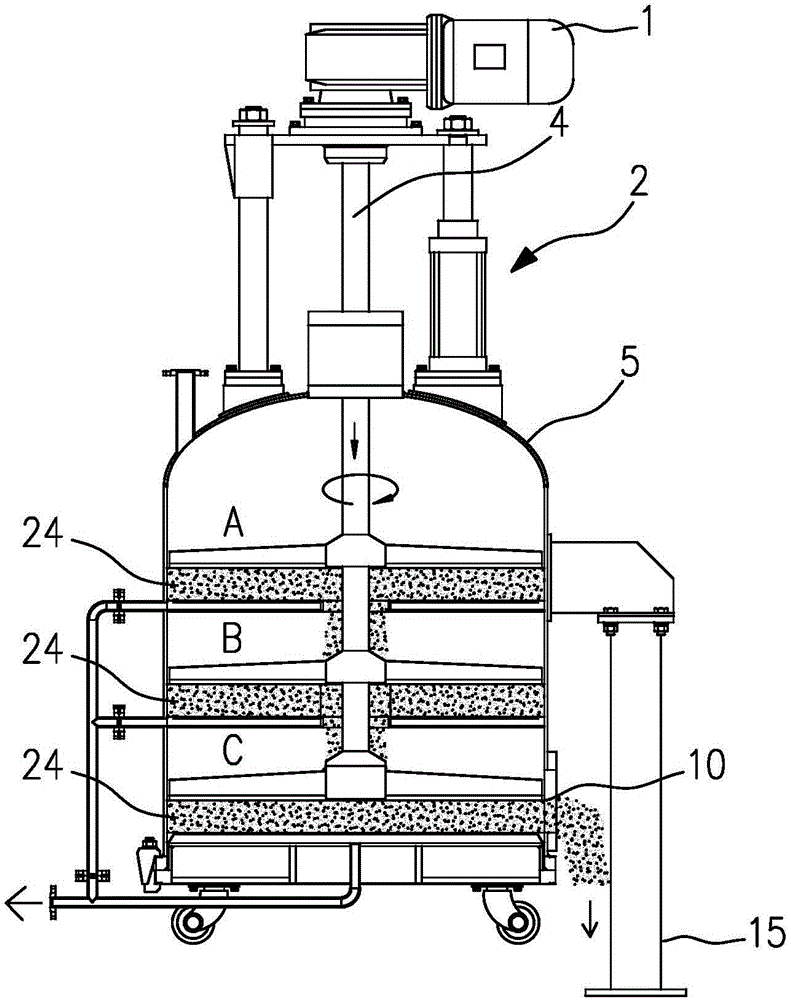

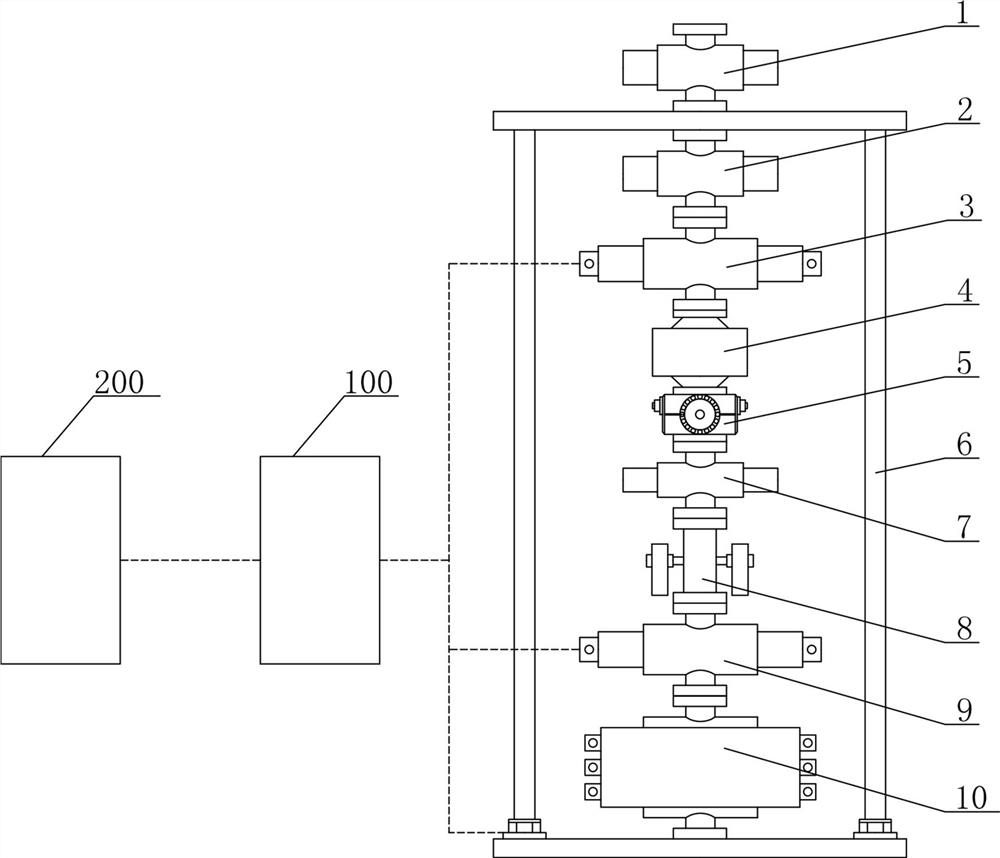

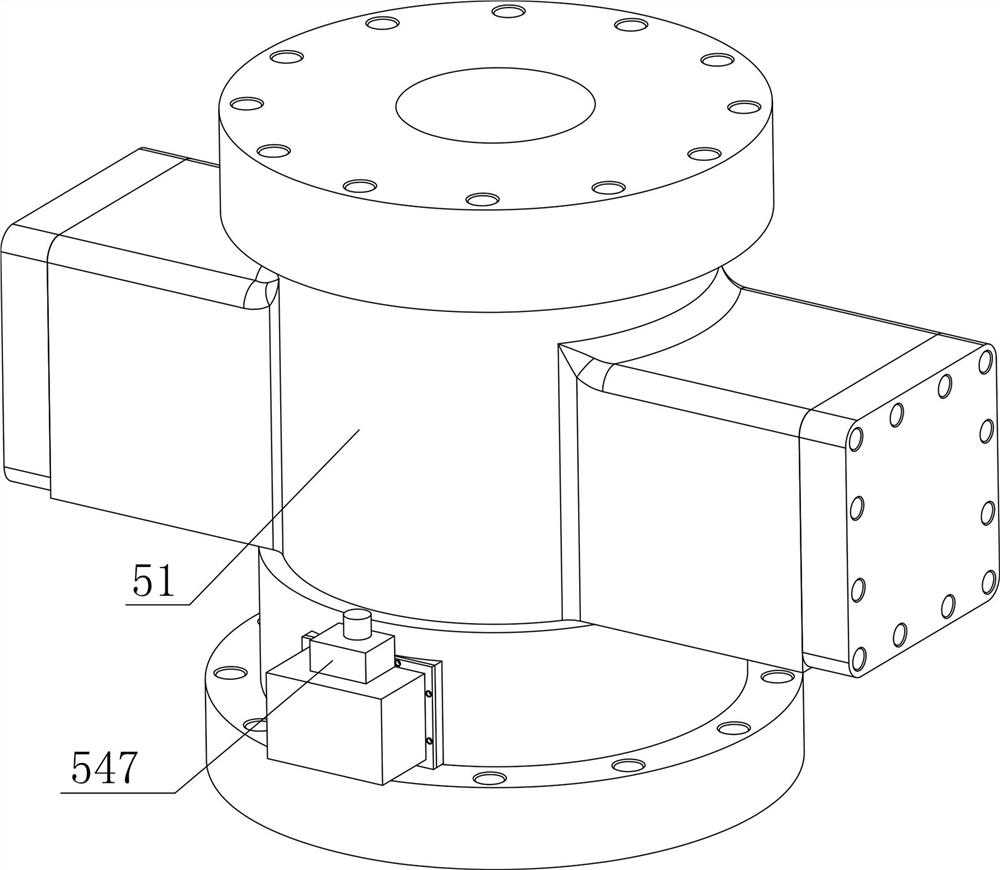

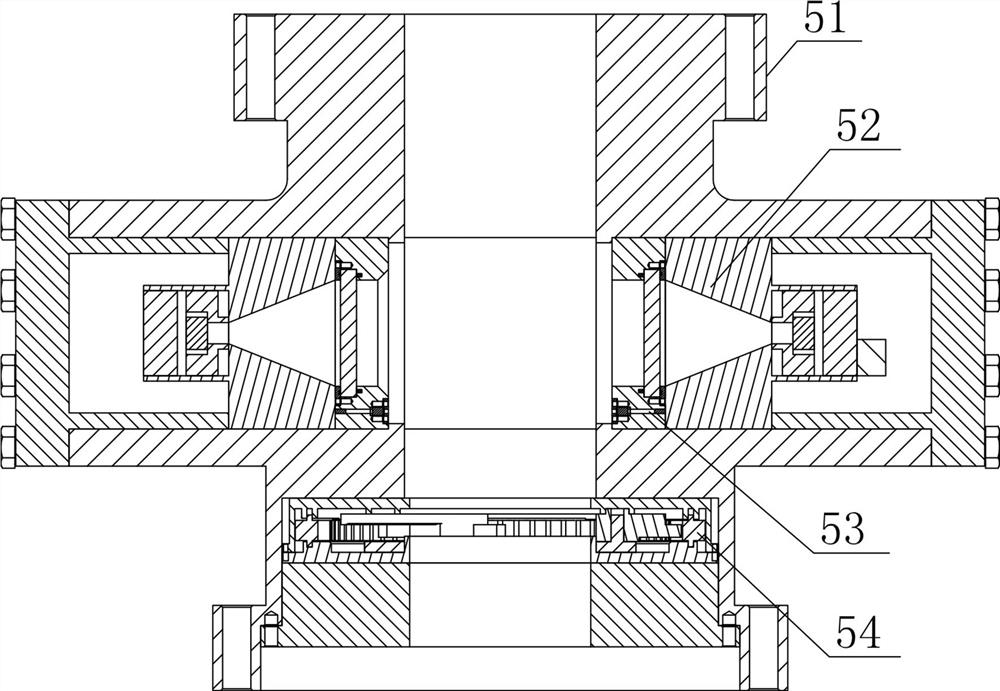

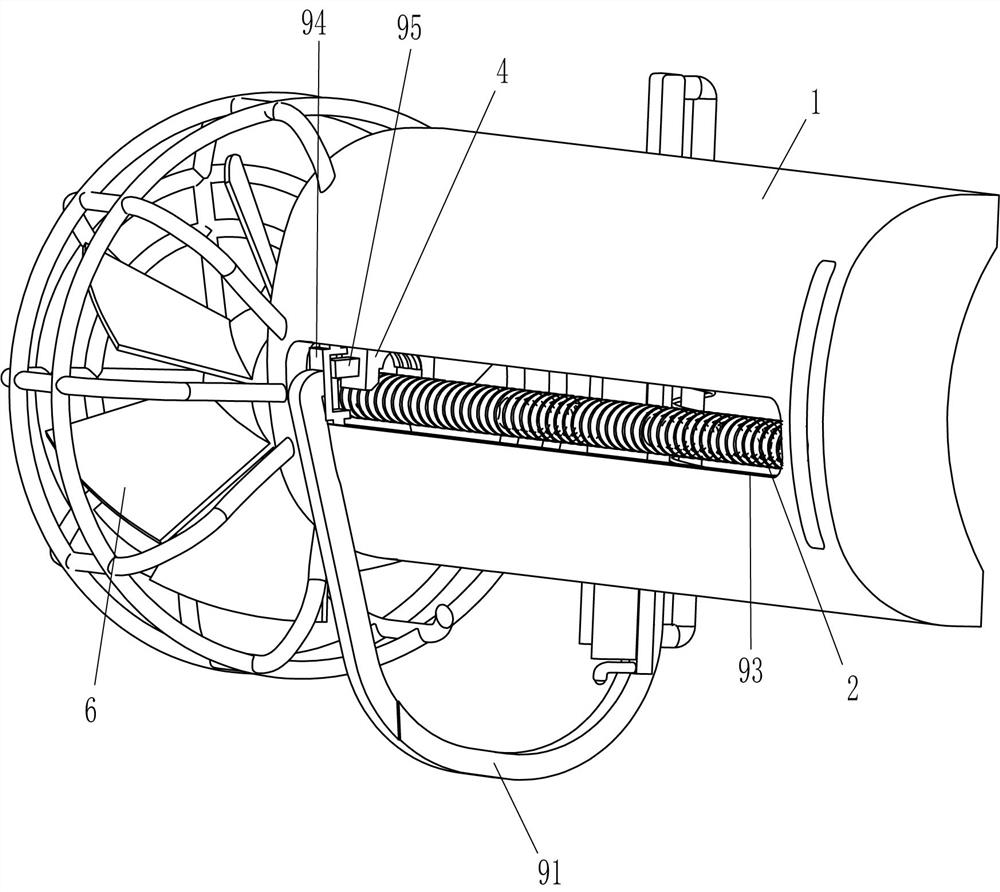

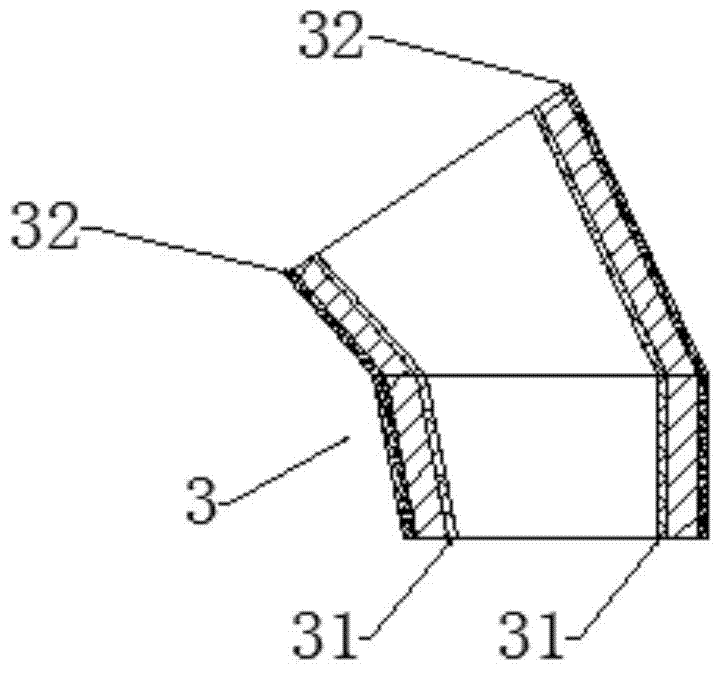

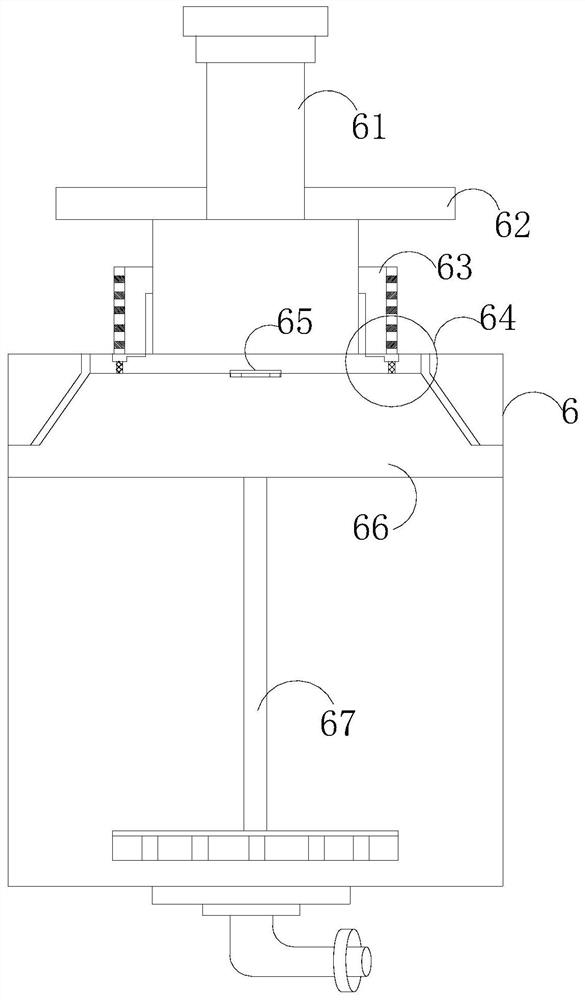

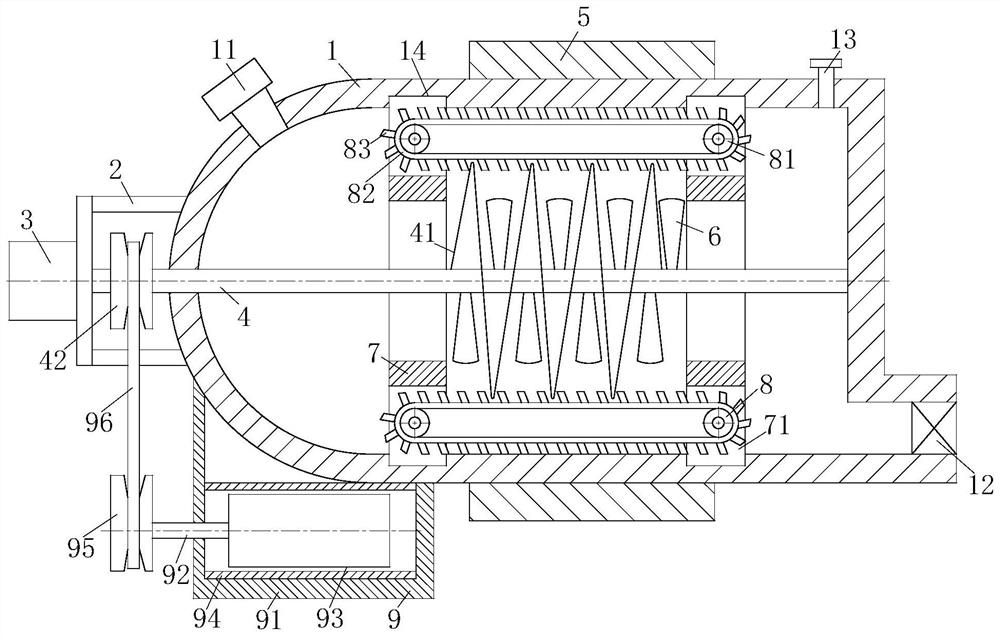

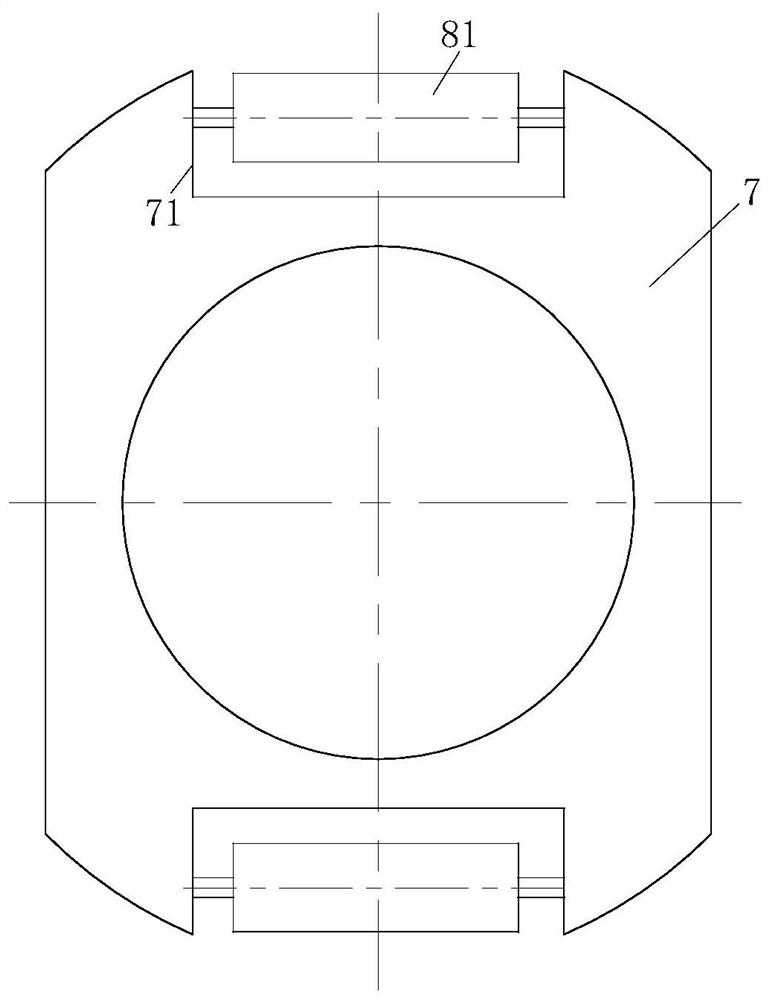

Layer-stepping type multi-filter disc filter machine

ActiveCN104645690ASimple structureLarge filter areaStationary filtering element filtersEngineeringFilter effect

The invention relates to a layer-stepping type multi-filter disc filter machine which comprises a cylindrical pressure container, wherein the container is provided with a feeding pipe, a rotating main shaft is arranged at the central axis of the container, and the rotating main shaft passes through the top of the container to be mutually connected with the output shaft of a gear motor; the top of the container is further fixedly provided with a displacement mechanism, and the displacement mechanism drives the rotating main shaft to move up and down in the container; at least two groups of filter devices are uniformly arranged along the vertical direction between the inner wall of the container and the rotating main shaft, any group of filter device comprises a filter disc and a scraper which are horizontally arranged, and the scraper of any group of filter device is arranged above the corresponding filter disc; a liquid discharge passage and a discharge passage which are used for communication and are communicated with the filter device are arranged in the container. The layer-stepping type multi-filter disc filter machine provided by the invention is compact in structure, the operation is reliable and stable, the filter effect is greatly improved, and the filtering effect is good.

Owner:HEFEI GENERAL MACHINERY RES INST

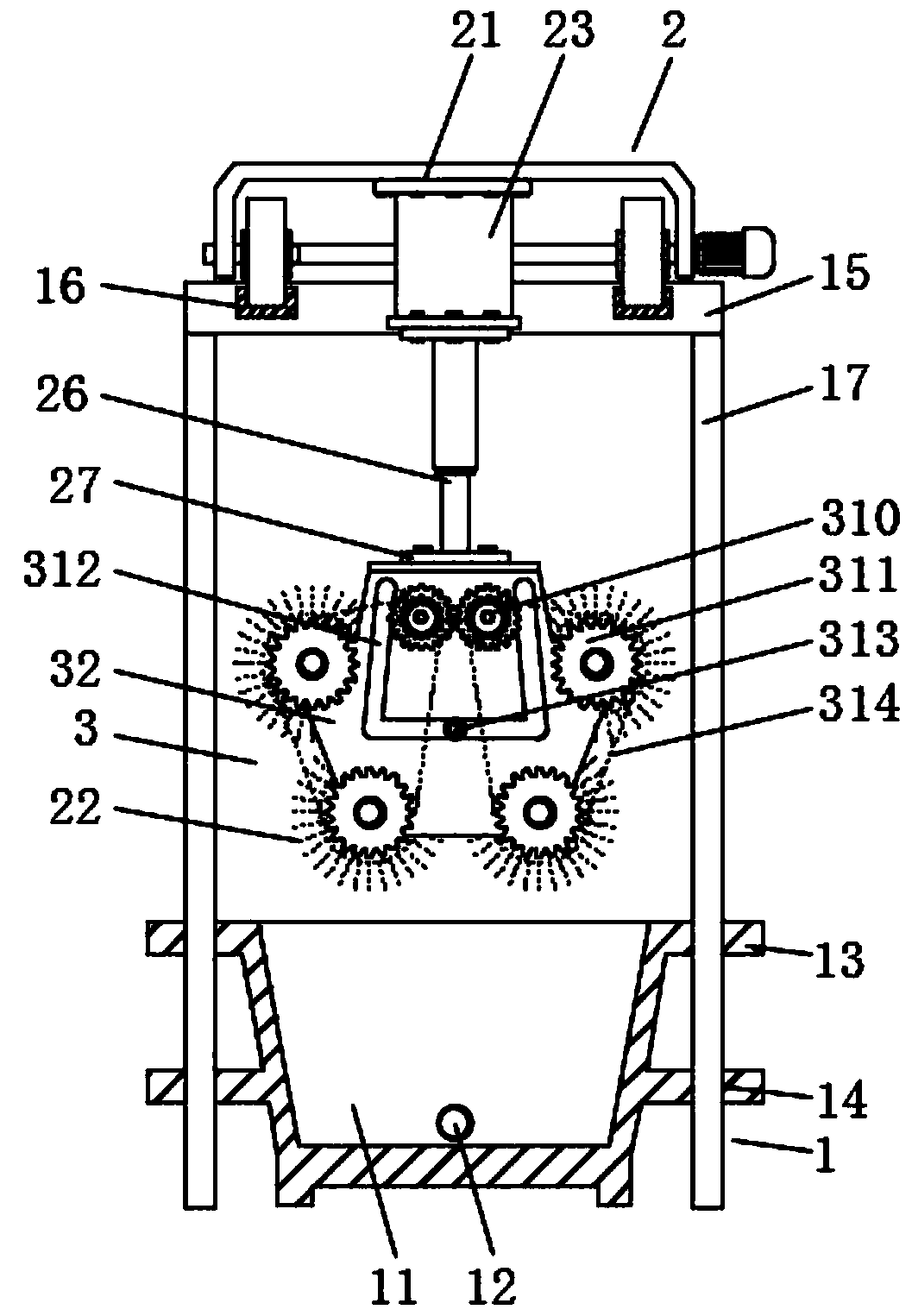

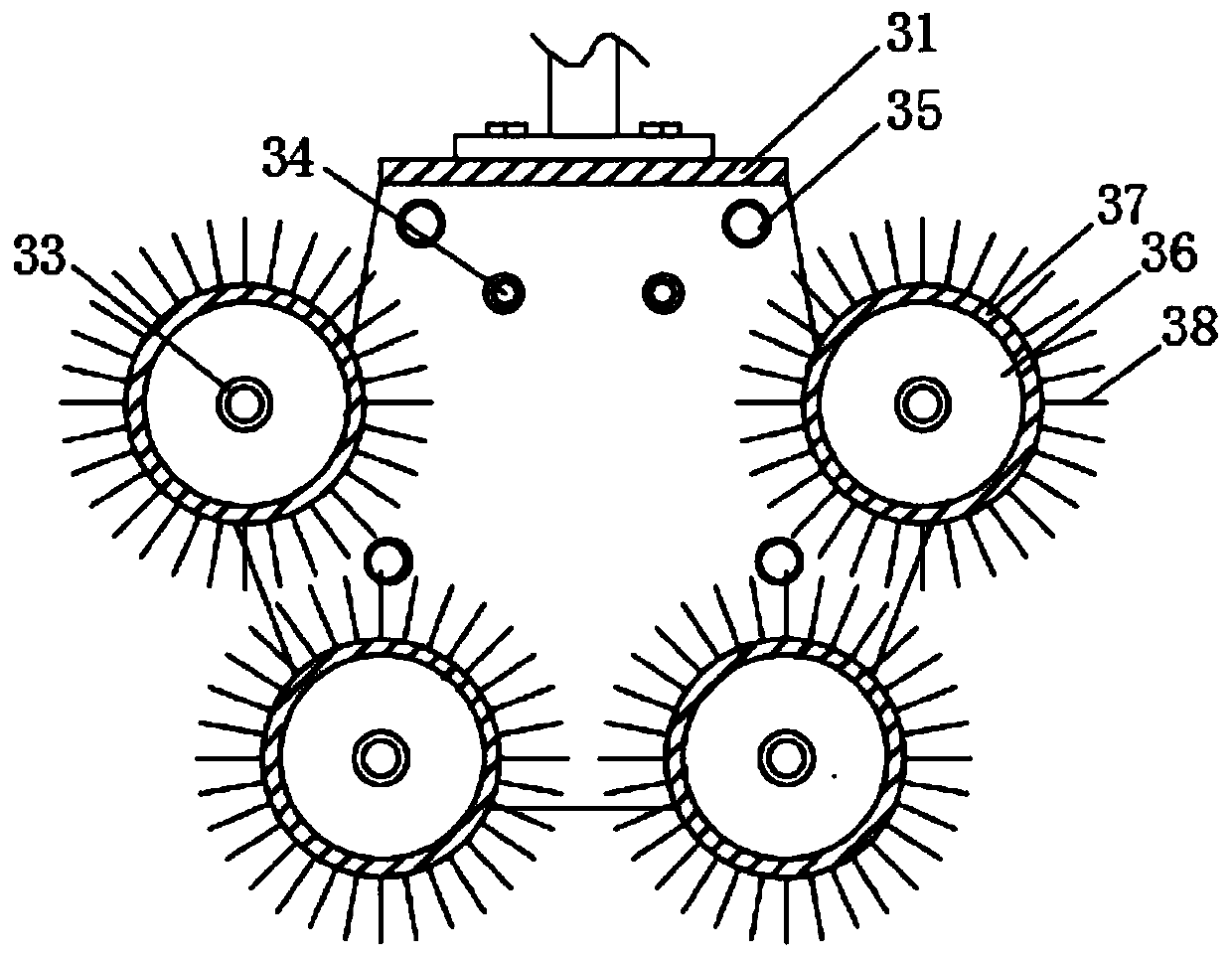

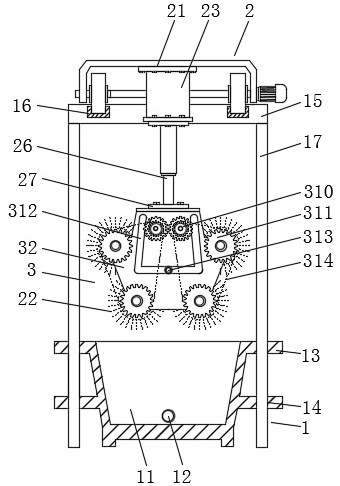

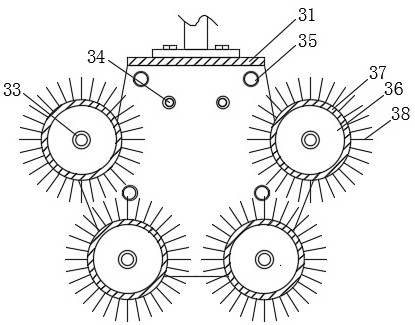

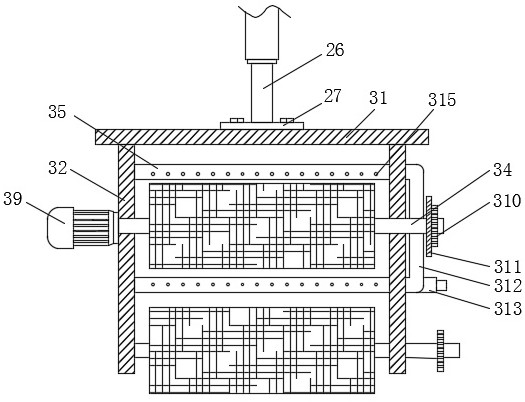

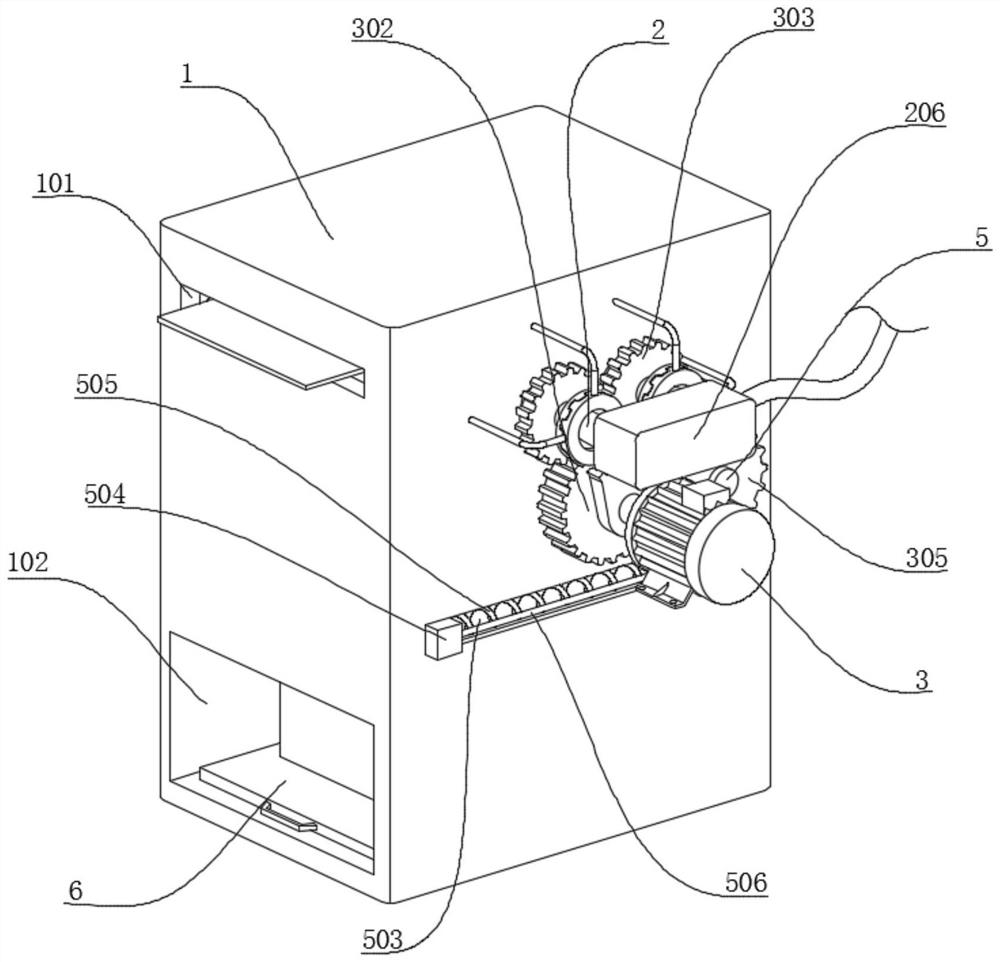

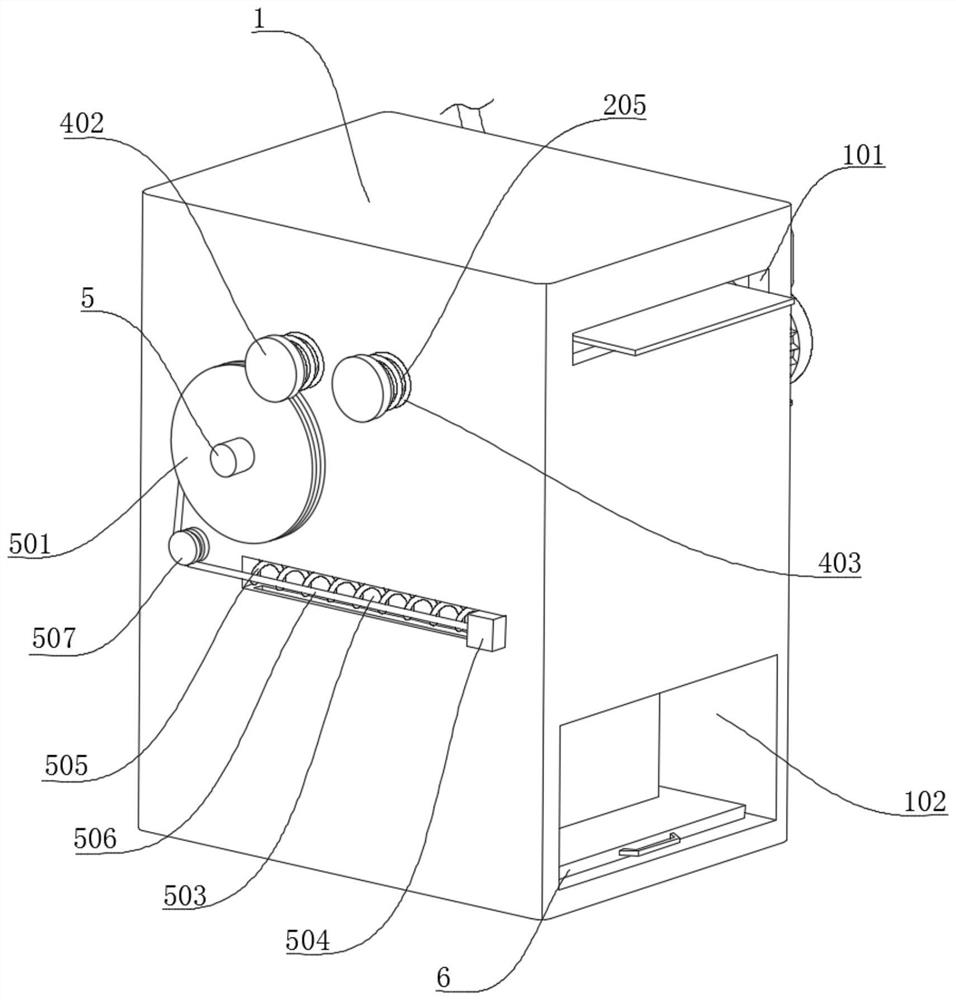

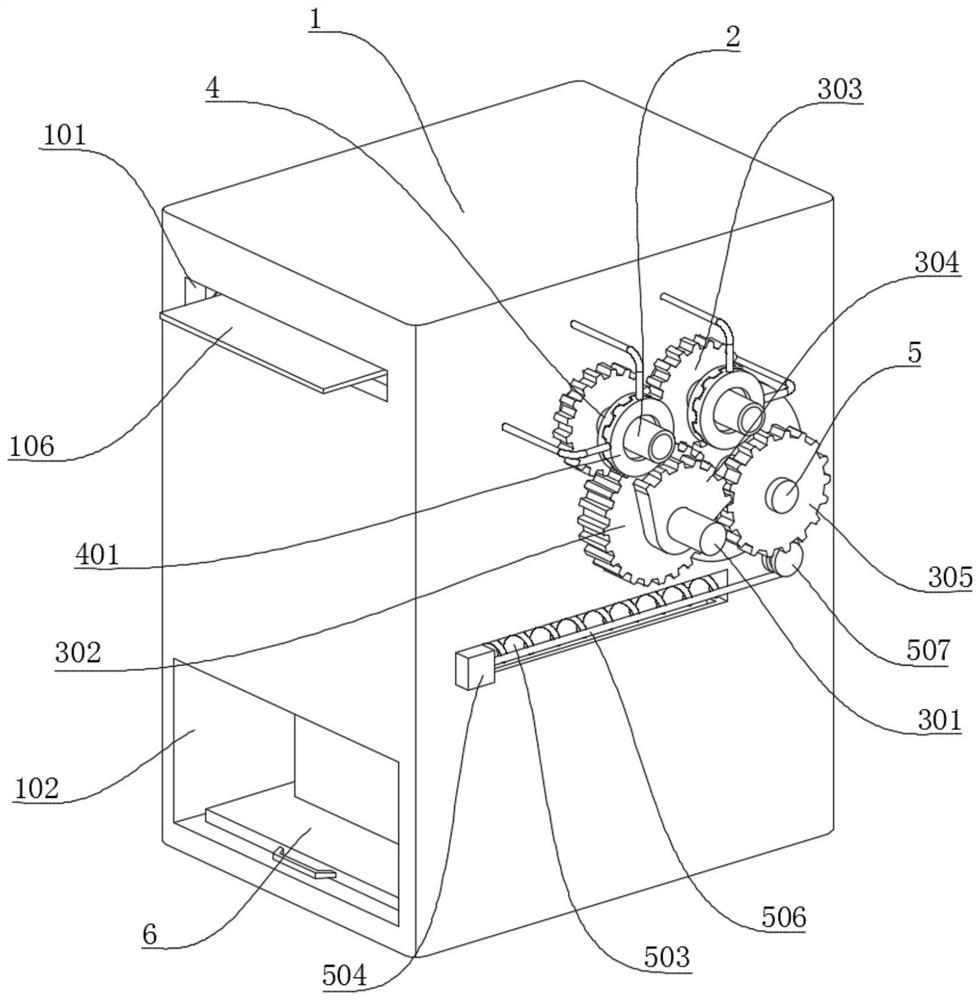

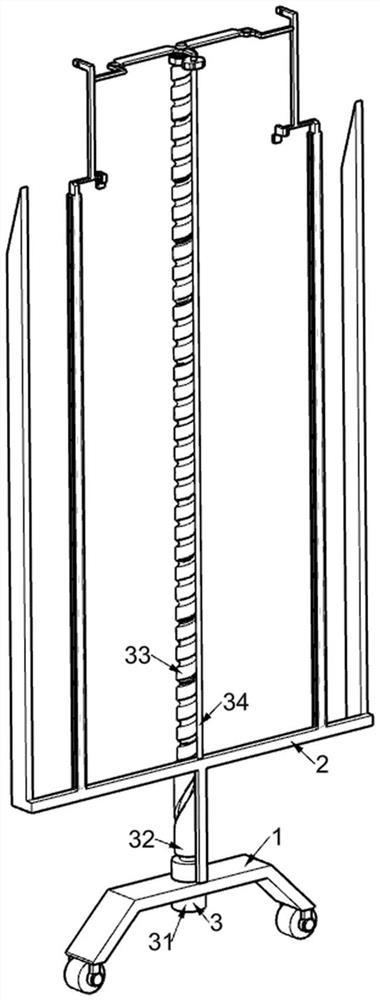

Manger cleaning equipment for livestock breeding

ActiveCN110576009AEasy to cleanAvoid frictionAnimal feeding devicesHollow article cleaningBristleMotor drive

The invention discloses manger cleaning equipment for livestock breeding. The equipment comprises a manger rack structure, a horizontal movement mechanism and a washing mechanism, the horizontal movement mechanism is installed at the upper side of the manger rack structure, and the washing mechanism is erected at the lower side of the horizontal movement mechanism; the manger rack structure comprises a feeding manger, a drainage port, external extension plates, insertion grooves, a connection plate, connection grooves and insertion rods. The drainage port is formed in one side of the feeding manger, the two external extension plates are fixedly connected to the outer side of the feeding manger, and the insertion grooves are formed in the four corners of each external extension plate; the insertion rods are embedded in all the insertion grooves. According to the manger cleaning equipment for livestock breeding, the distribution structure of washing cylinders of the washing mechanism ismatched with the groove wall structure so that bristles can sufficiently act on the inner wall of the feeding manger, the bristles are made from silicone rubber pieces, have high elasticity and can sufficiently scrape feed residues of the manger wall, so that the feed residues are gathered at the bottom of the feeding manger, the cleaning effect is good, a motor drives a mounting rack to move in the front-back direction, and the feeding manger is conveniently and comprehensively cleaned.

Owner:JIAXING DAMING INDAL

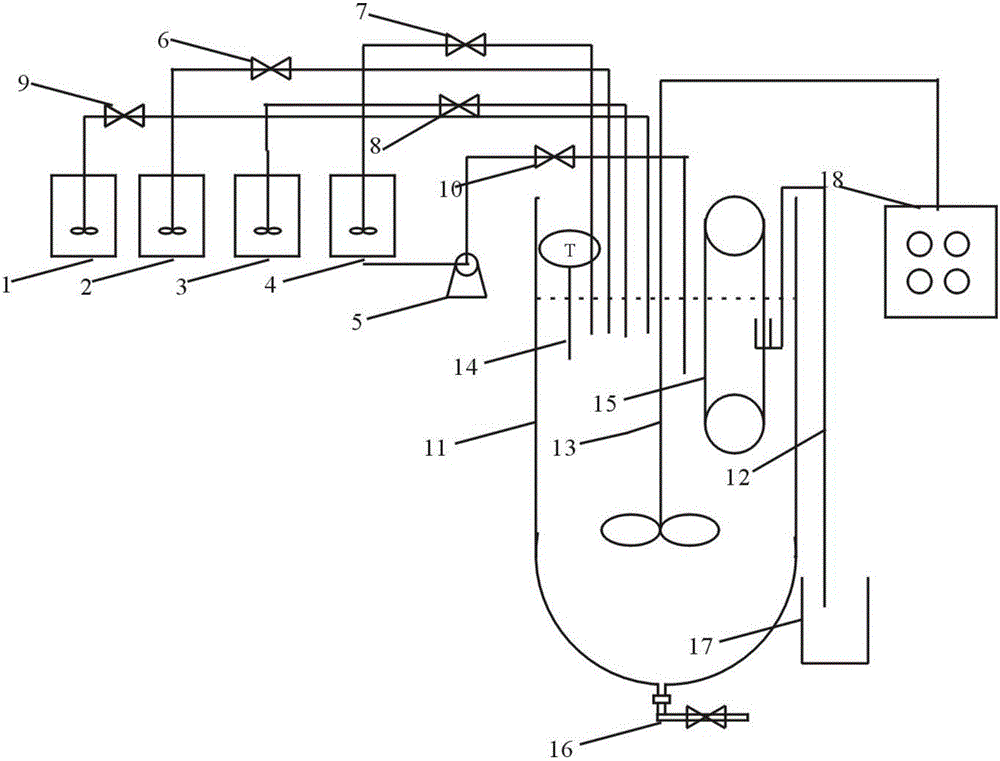

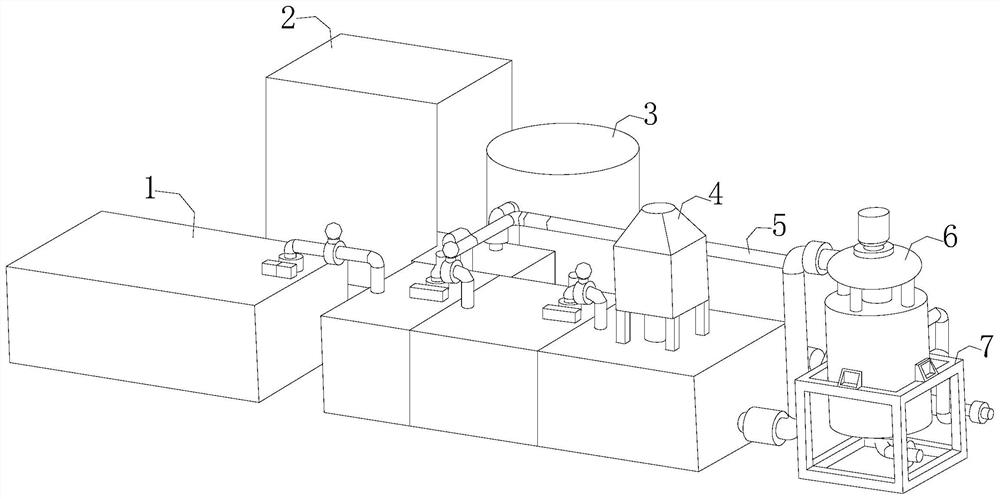

Waste emulsion quantitative reduction processing technology and apparatus

InactiveCN105000708AFlexible handlingGuaranteed liquidityMultistage water/sewage treatmentAutomatic controlEmulsion

The invention relates to a waste emulsion quantitative reduction processing technology and apparatus, and is suitable for processing waste emulsion produced in the fields of elevator industry, automobile manufacturing industry, high precision and high-end equipment manufacturing industry, etc. The processing technology comprises the following steps: adding the waste emulsion into a quantitative reduction apparatus, adding acids for demulsification, controlling the amount of the acids according to an abrupt change point of pH change values, skimming upper level floating oil by an oil skimmer, and discharging the lower waste liquid after neutralizing. After processing, the COD removal rate reaches to 85% or higher, and the oil substance removal rate reaches to 92%-98%, and the volume reduction amount of the waste emulsion is higher than 85%. The overall technology can be in automatic control conveniently, is used for realizing quantitative reduction processing, and thetechnology and apparatus have high processing efficiency andareeconomically feasible.

Owner:上海幽岫环保科技有限公司

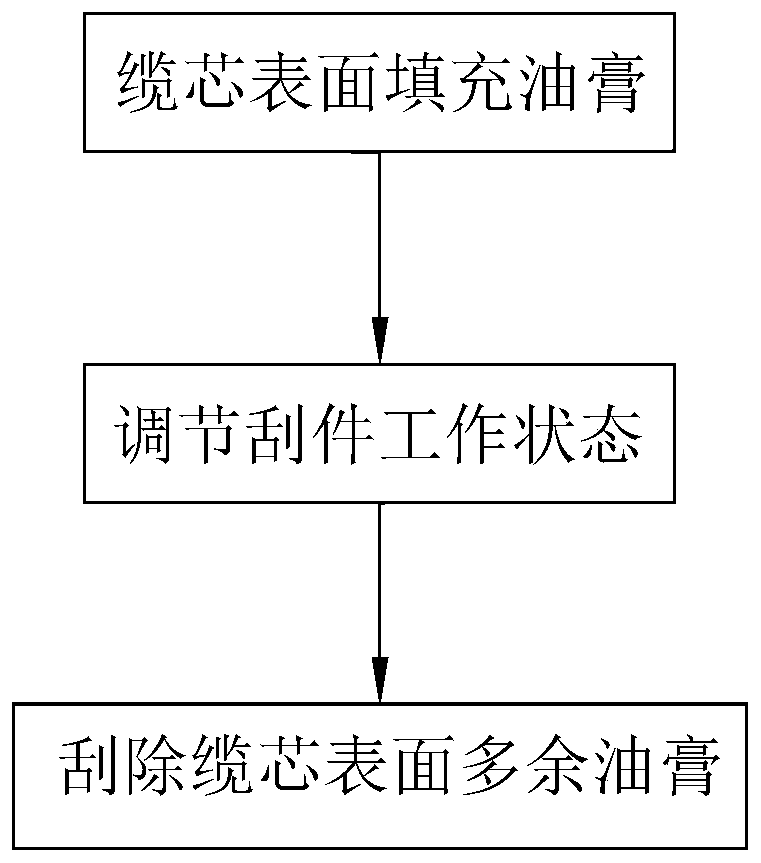

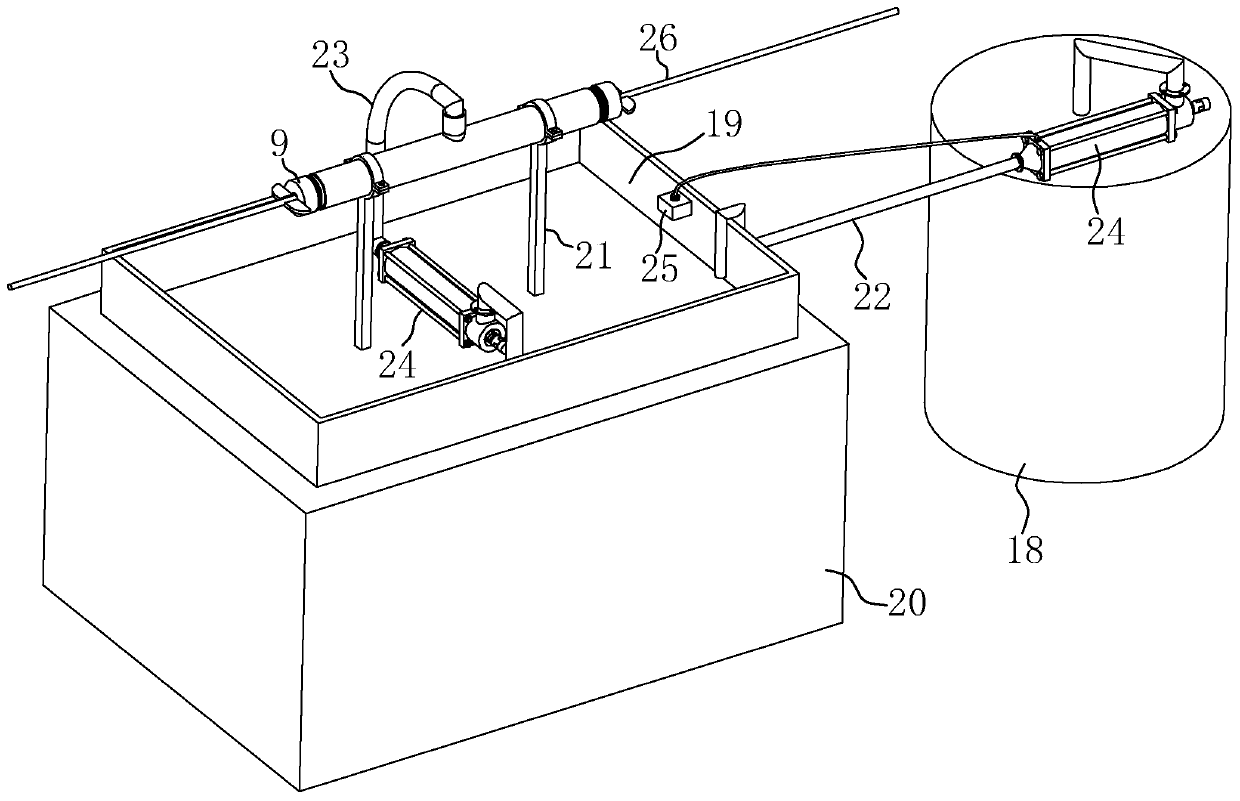

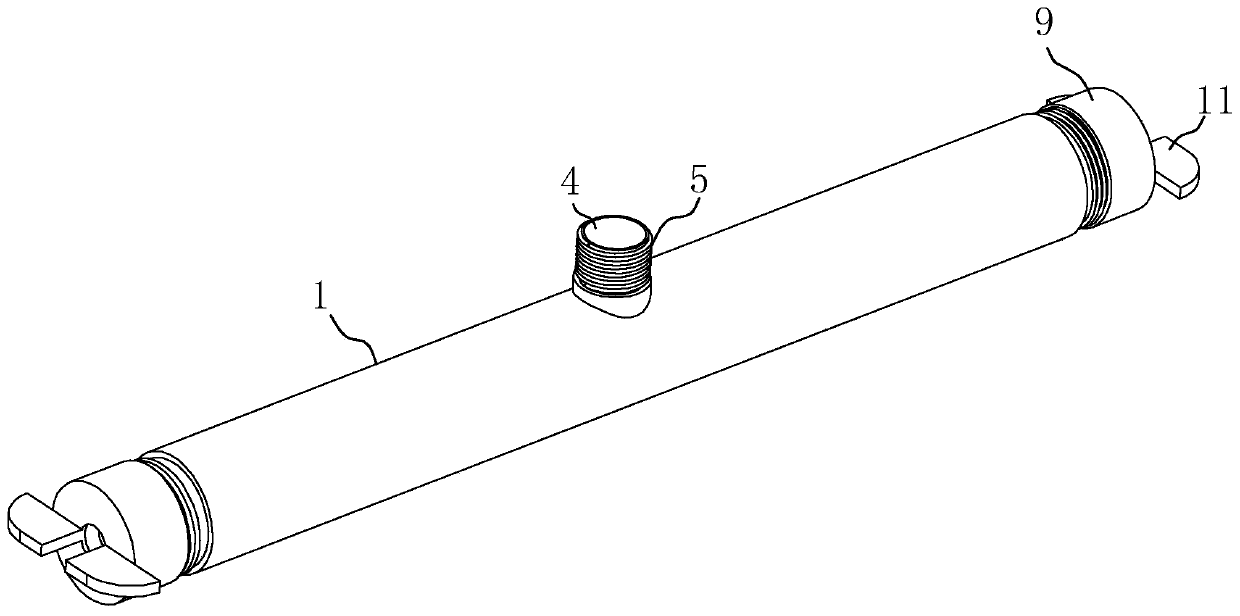

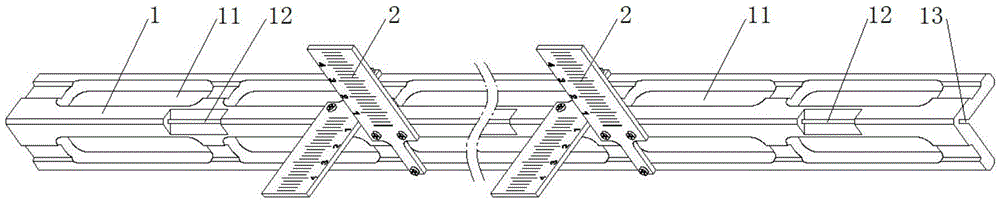

Jelly filling process

InactiveCN110673284ATake advantage ofReduce wasteFibre mechanical structuresProcess engineeringMechanical engineering

The invention discloses a jelly filling process. The jelly filling process comprises the following steps: firstly, forming a jelly layer on the surface of a cable core; then adjusting a scraping pieceto a working state of scraping the jelly; and finally making the scraping piece move relative to the cable core in order to scrape excess jelly on the surface of the cable core. After the surface ofthe cable core is filled with the jelly, a process of adjusting the scraping piece and scraping the jelly is added, so that the excess jelly can be scraped off in time after the surface of the cable core is fully filled with the jelly, thereby ensuring the normal proceeding of subsequent production and processing of the cable core, and effectively reducing the waste of the jelly at the same time.The scraped jelly can be reused in the step 1.

Owner:SHENZHEN XIN CHANG LONG NEW MATERIALS TECH CO LTD

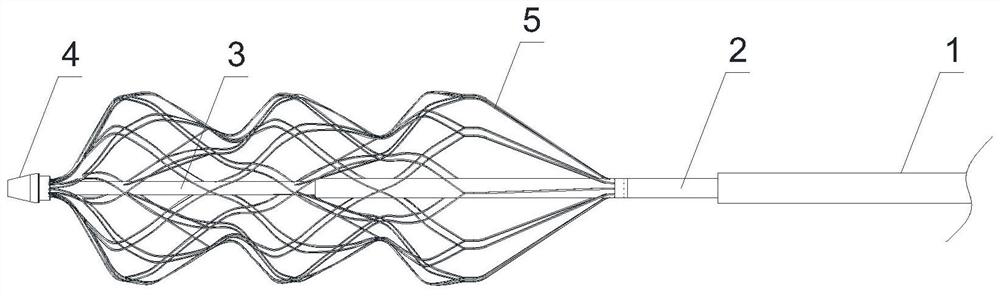

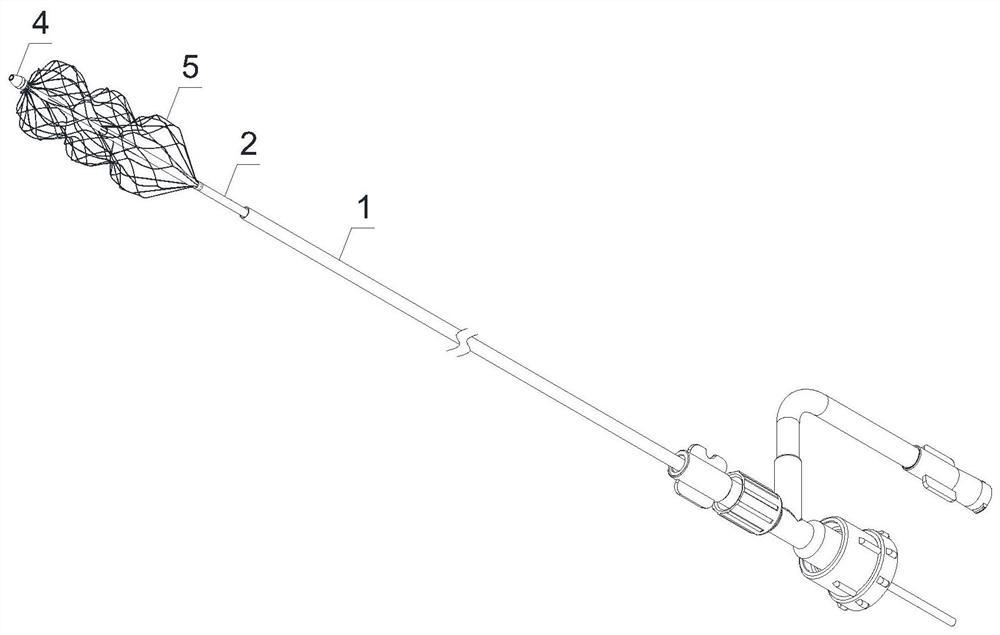

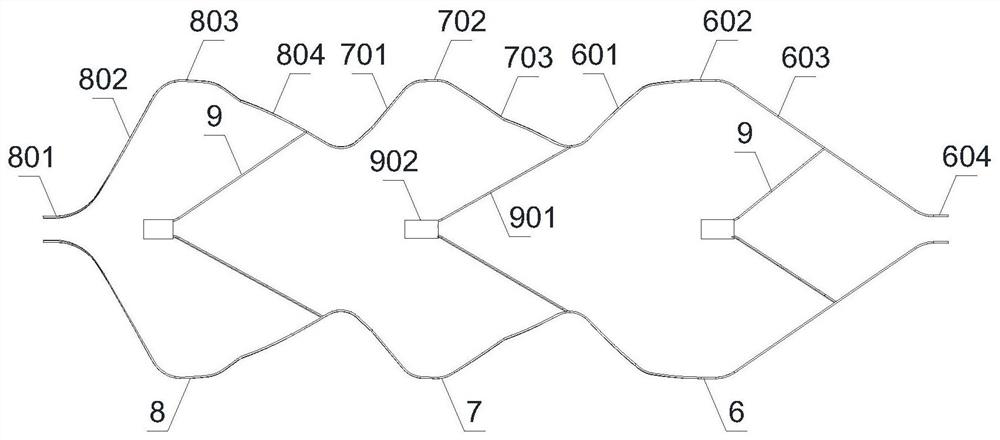

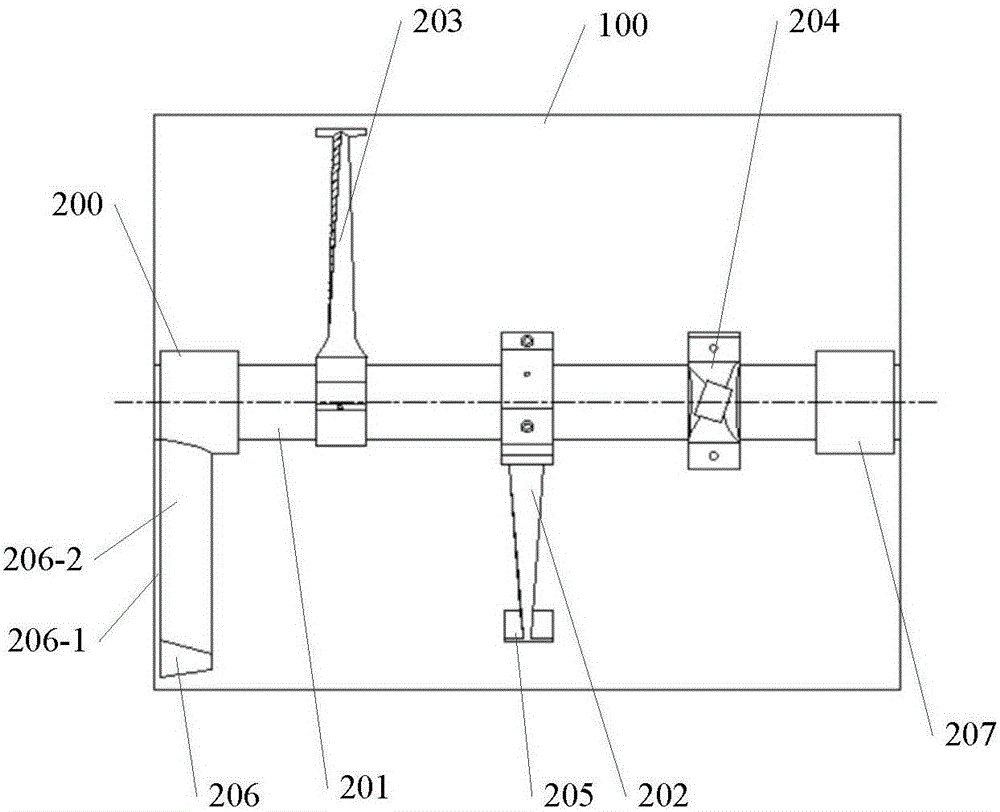

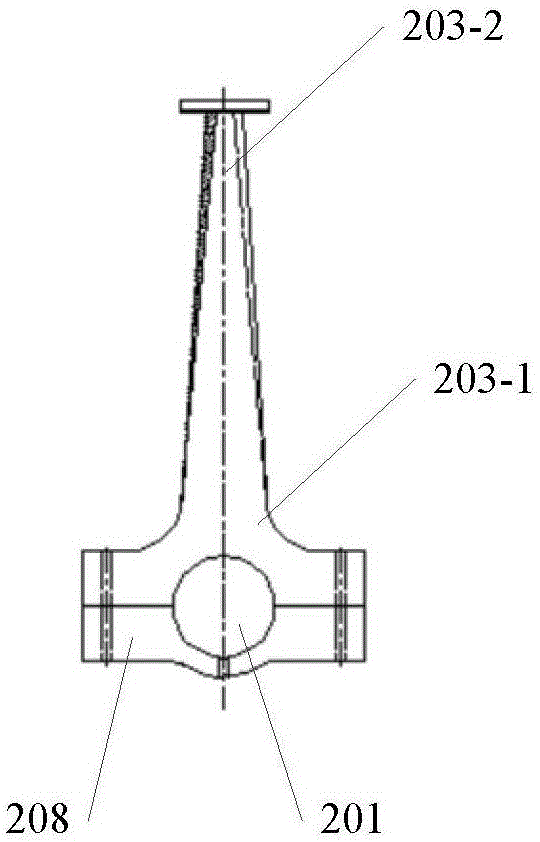

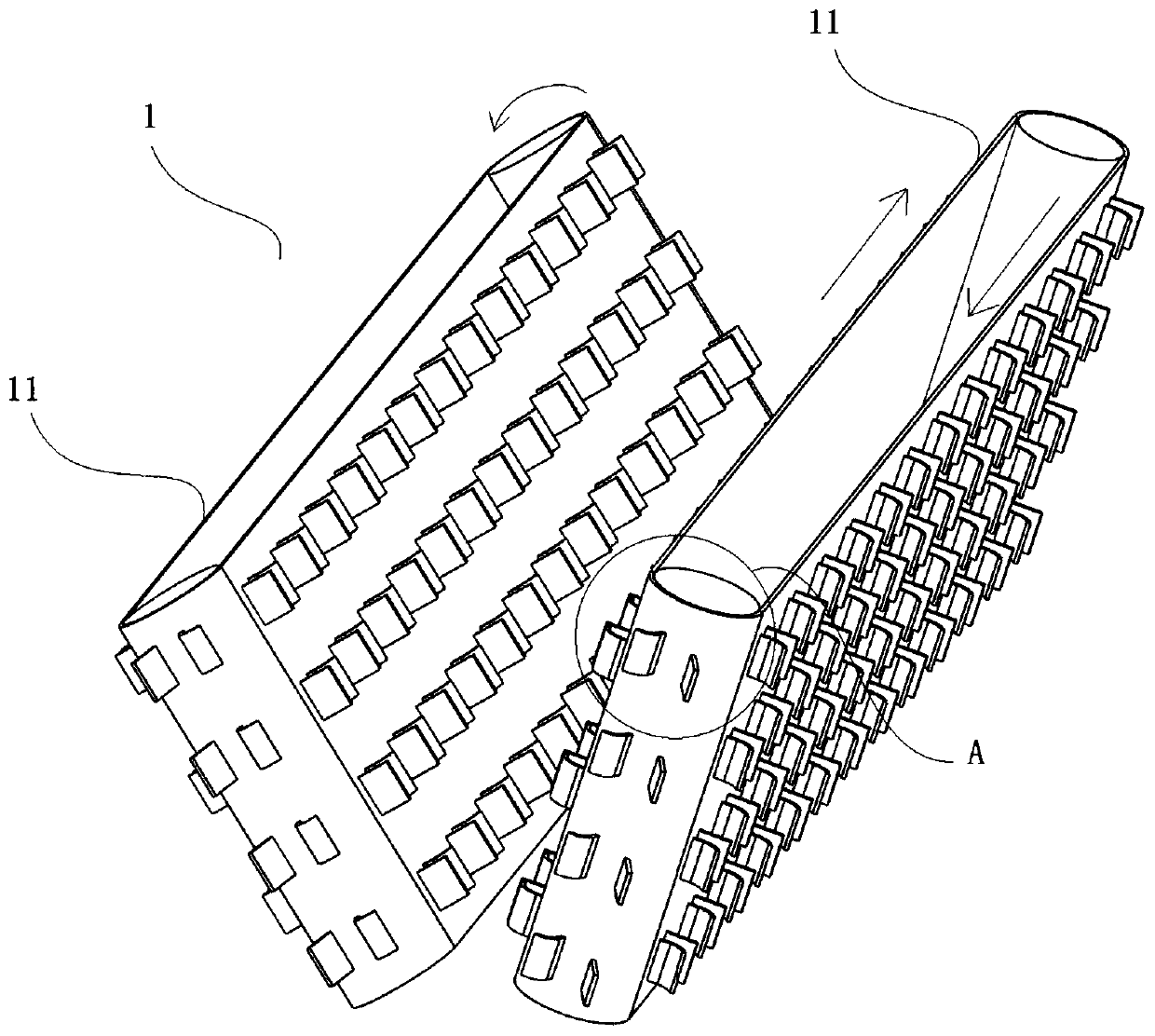

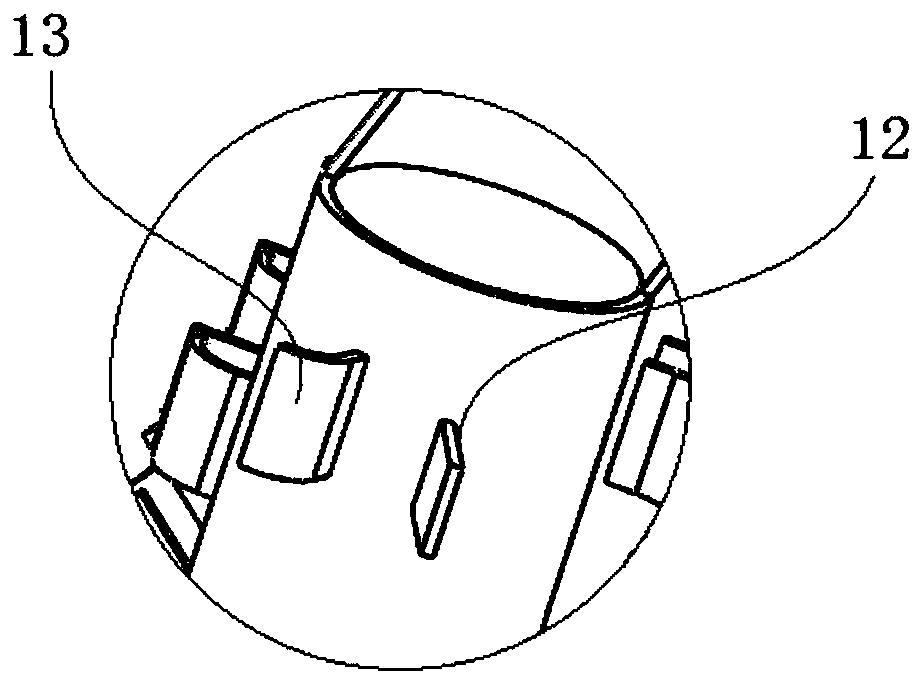

Double-layer mesh cage type thrombus extraction stent and assembly thereof

The invention discloses a double-layer mesh cage type thrombus extraction stent and an assembly thereof, and belongs to the technical field of vascular intervention medical treatment. The thrombectomydevice comprises an outer tube, a support fixing tube, a head end telescopic tube, a head end guide cap and a thrombectomy support. The support fixing pipe is sleeved with the outer pipe, the near end of the head end telescopic pipe is inserted into a far end pipe opening of the support fixing pipe, and a hollow head end guide cap is fixed to the far end of the head end telescopic pipe. The thrombectomy stent is formed by sequentially connecting an olive-shaped near-end mesh cage stent and an olive-shaped far-end mesh cage stent, and the near-end mesh cage stent and the far-end mesh cage stent are each internally provided with an internal conical mesh surface used for segmented blocking. By means of the internal conical mesh surface, the effect of sectionally intercepting thrombus in thenet cage can be achieved, and the thrombus is prevented from excessively extruding the third far-end conical net surface of the far-end net cage bracket when the thrombus is more; therefore, the problem that the thrombus escapes through the third far-end conical net surface after being crushed is avoided.

Owner:上海融脉医疗科技有限公司

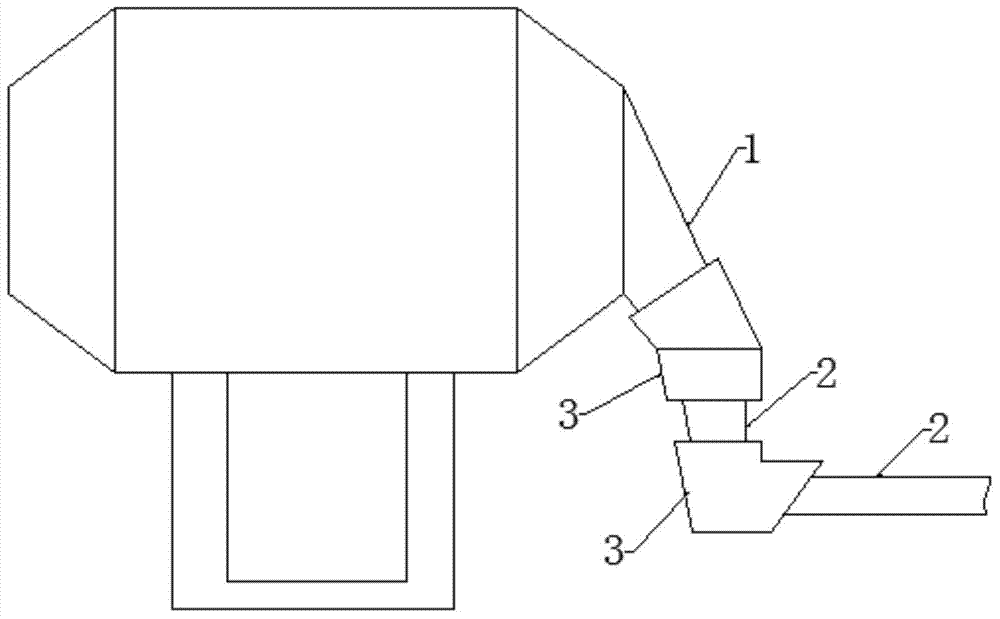

Dough kneading device

ActiveCN106689244ARotate well to mixFull scrapeMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsPulp and paper industryHardness

The invention discloses a dough kneading device which comprises a dough kneading cabin, a stirring device, at least three stirring blades and two wall scraping blades, wherein the stirring device comprises a stirring shaft which is arranged on the axis of the dough kneading cabin; two ends of the stirring shaft are shafted with side walls at two ends of the dough kneading cabin; one ends of the stirring blades are uniformly partitioned and are fixedly arranged on the stirring shaft; the other ends of the stirring blades extend towards the inner side wall of the dough kneading cabin; an end piece is arranged at the other end of any stirring blade; the area of the end piece is larger than that of the cross section of any stirring blade; one ends of the two wall scraping blades are respectively arranged at the shafted parts of two ends of the stirring shaft and the dough kneading cabin; the other ends of the two wall scraping blades extend towards the inner side wall of the dough kneading cabin. By adopting the dough kneading device, water and flour inside the dough kneading cabin can be sufficiently mixed within a short time, and kneaded flour flocculate blank granules can be relatively uniform in size and distribution; the hardness, the adhesiveness and the chewiness of a later product can be improved, the brightness of a later dough piece product can be also improved, and thus the dough can relatively well meet sensory quality requirements and taste requirements of Chinese customers on cooked wheaten food.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

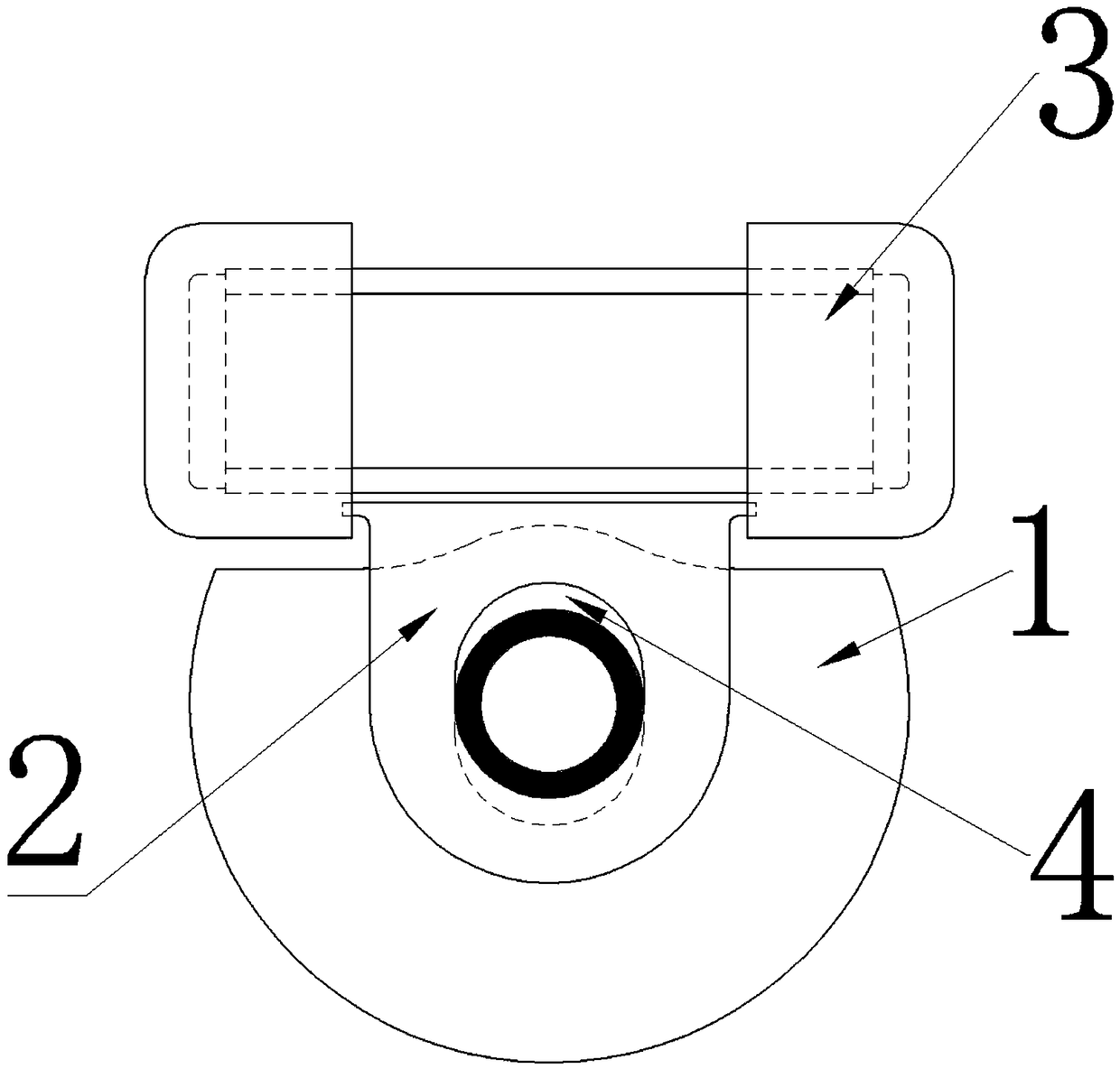

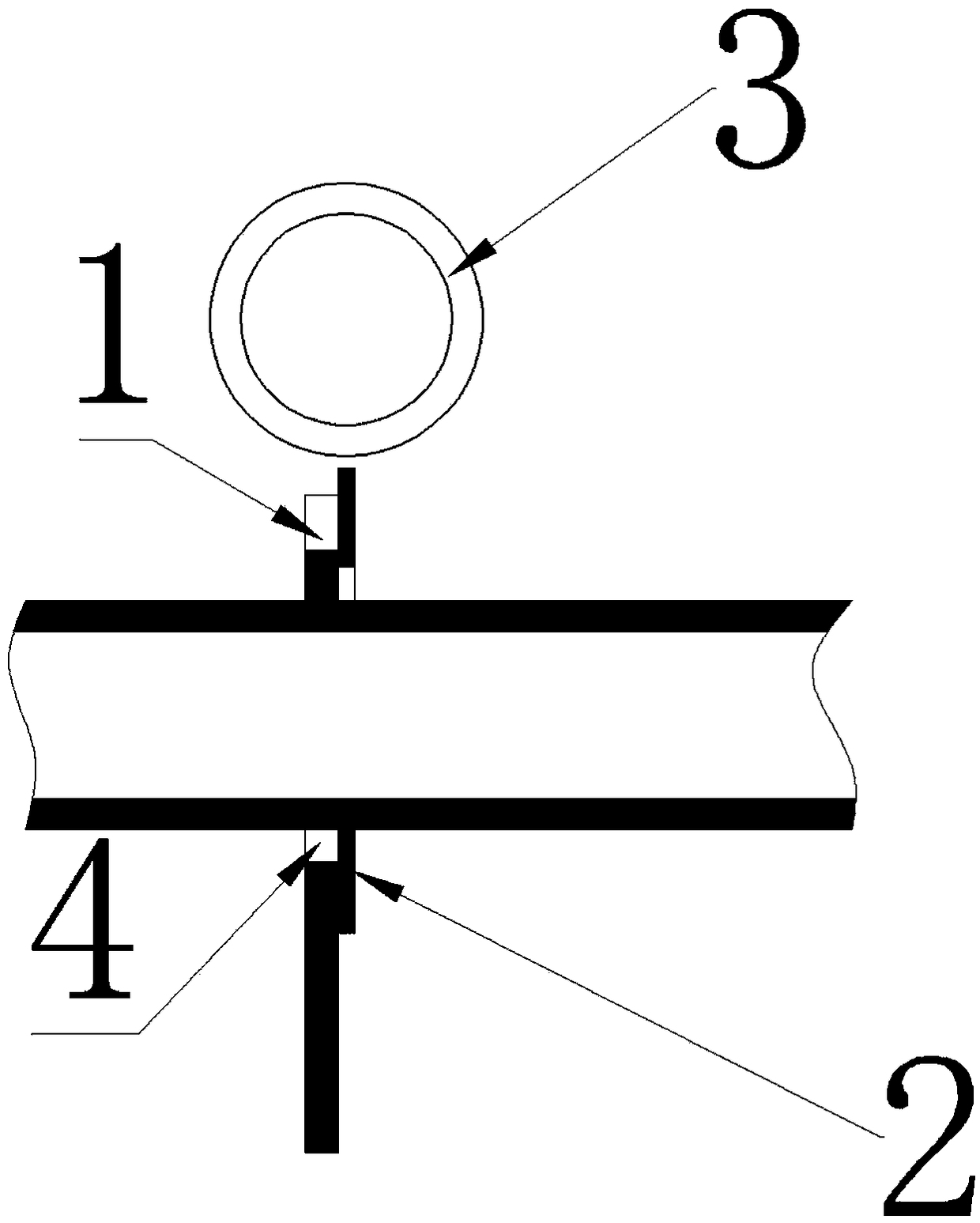

Pipe surface blowhole eliminating device and pipe surface blowhole eliminating method

The invention provides a pipe surface blowhole eliminating device and a pipe surface blowhole eliminating method. An upper pipe wall water scraping device conducts blowhole scraping work on the upperhalf surface of a pipe, and a lower pipe wall water scraping device conducts blowhole scraping work on the lower half surface of the pipe, that is, the blowhole scraping work is conducted on the uppersurface and the lower surface of the pipe respectively, so that the hole diameters of through holes are capable of being greater than the external diameter of the pipe; surface blowholes of the pipeare fully scraped, and the situation that impurities in circulating water scratch the surface of the pipe due to the fact that the sizes of the through holes are too small is avoided; and with the arrangement of a displacement adjustment device, the lower pipe wall water scraping device is adjusted, and relative positions of the through holes of the lower pipe wall water scraping device and the upper pipe wall water scraping device are adapted to the external diameter of the pipe, so that the effect of fully scraping the surface blowholes of the pipe is achieved.

Owner:SHANGHAI RIFENG IND

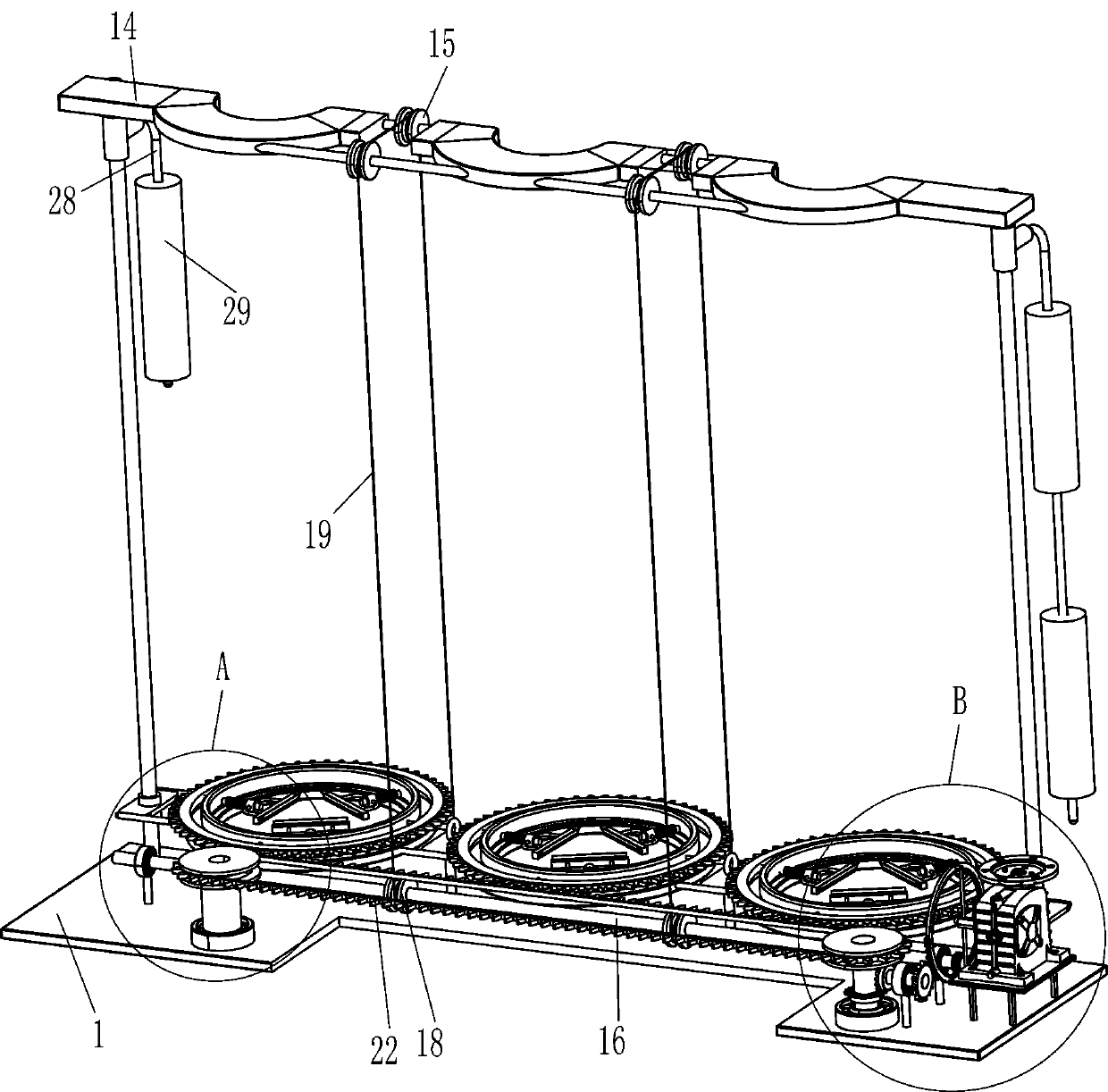

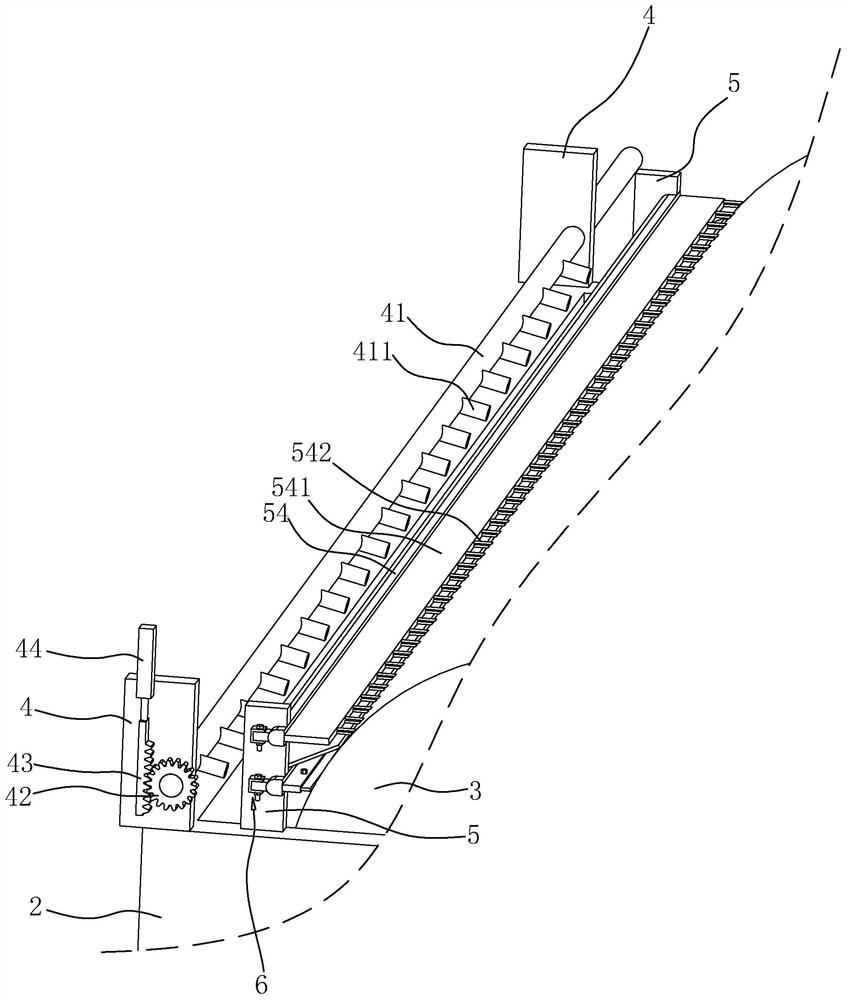

Peanut soil-removing and fruit-picking device

PendingCN110431981AGood removal effectEasy to collectDigger harvestersThreshersHookingMechanical engineering

The invention discloses a peanut soil-removing and fruit-picking device. The peanut soil-removing and fruit-picking device comprises a soil removing mechanism and a fruit picking mechanism sequentially arranged front and back, the soil removing mechanism includes two first conveying belts with a V-shaped setting, the first conveying belts are in codirectional differential motion, a plurality of scraping parts is arranged on the surface of the first conveying belt, and the scraping parts include vertical scraping parts and bent scraping parts; the fruit picking mechanism includes to second conveying belts with a V-shaped setting, the second conveying belts are in codirectional differential motion, a plurality of hooking parts is arranged on the surface of the second conveying belt, and thehooking parts include inverted U-shaped hooking parts; the first conveying belts and the second conveying belts are in codirectional motion. The peanut soil-removing and fruit-picking device has the advantages of compact structure, the working procedure that conveying is performed simultaneously with soil removing and fruit picking is especially suitable for removing soil with certain stickiness and can be integrated in a peanut harvester, the integration of digging, soil removing and fruit picking is realized, time is saved, and cost is saved.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

A cattle trough cleaning equipment for animal husbandry

ActiveCN110576009BEasy to cleanAvoid frictionAnimal feeding devicesHollow article cleaningAnimal scienceCrop livestock

The invention discloses manger cleaning equipment for livestock breeding. The equipment comprises a manger rack structure, a horizontal movement mechanism and a washing mechanism, the horizontal movement mechanism is installed at the upper side of the manger rack structure, and the washing mechanism is erected at the lower side of the horizontal movement mechanism; the manger rack structure comprises a feeding manger, a drainage port, external extension plates, insertion grooves, a connection plate, connection grooves and insertion rods. The drainage port is formed in one side of the feeding manger, the two external extension plates are fixedly connected to the outer side of the feeding manger, and the insertion grooves are formed in the four corners of each external extension plate; the insertion rods are embedded in all the insertion grooves. According to the manger cleaning equipment for livestock breeding, the distribution structure of washing cylinders of the washing mechanism ismatched with the groove wall structure so that bristles can sufficiently act on the inner wall of the feeding manger, the bristles are made from silicone rubber pieces, have high elasticity and can sufficiently scrape feed residues of the manger wall, so that the feed residues are gathered at the bottom of the feeding manger, the cleaning effect is good, a motor drives a mounting rack to move in the front-back direction, and the feeding manger is conveniently and comprehensively cleaned.

Owner:JIAXING DAMING INDAL

Hand wash table water purifying and recycling device

InactiveCN109113140AAvoid containingFull scrapeDomestic plumbingWater supply installationSewagePurified water

The invention relates to the technical field of hand wash tables, in particular to a hand wash table water purifying and recycling device. The device comprises a pool table and a rack, the rack is provided with a filter device, the lower side of the pool table is communicated with a drain pipe capable of stretching vertically, one end, which is far away from the pool table, of the drain pipe is communicated with a T-pipe, the T-pipe is arranged on the right side of the filter device, the right side of the T-pipe is provided with a sewage pipe, the filter device comprises a filter drum, a waterpipe is communicated between the filter drum and a branch pipe on the left side of the T-pipe, and a purified water collecting tank is arranged below the filter drum; a filter residue collecting pipeis arranged in the filter drum and provided with a through hole, a revolving shaft sleeves the outside of the filter residue collecting pipe, the revolving shaft is rotationally connected with the filter residue collecting pipe and provided with a residue discharge hole, and blades are welded with the revolving shaft. By adopting the scheme, the hand wash table water purifying and recycling device can be used for domestic water purifying and recycling, and the water purifying efficiency can be improved.

Owner:贵州省习水县人民医院

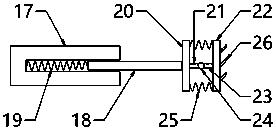

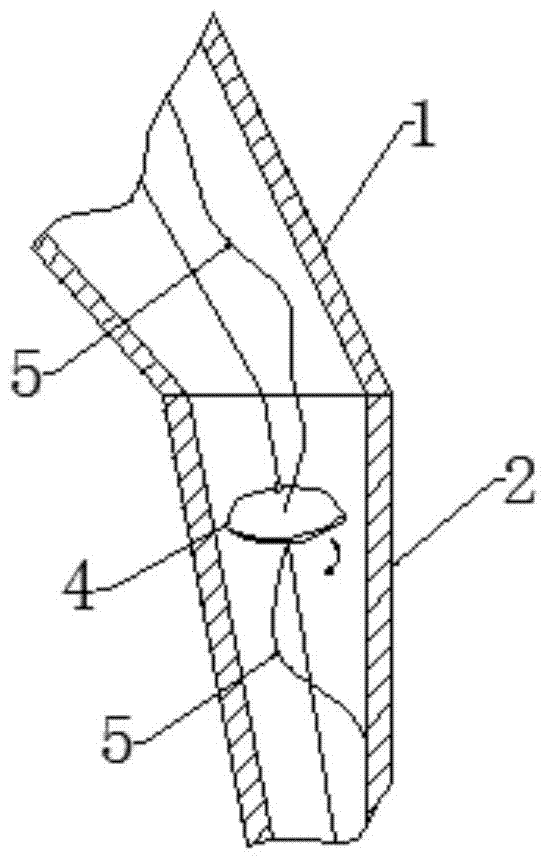

Jet oiling mechanism and double-sided para-aramid fiber oiling device

ActiveCN112626627AImprove sealingPrevent leakageFilament/thread formingTextile treatment machine arrangementsFiber bundleStructural engineering

The invention relates to the technical field of para-aramid fiber oiling devices, in particular to a jet oiling mechanism which comprises a wire feeding groove that comprises a first positioning groove and a second positioning groove, wherein a plurality of nozzles connected with an oil pump are arranged above the wire feeding groove, and the first positioning groove, the second positioning groove and the nozzles are located on a same straight line. The double-sided para-aramid fiber oiling device comprising the jet oiling mechanism comprises a first guide roller, a second guide roller and a third guide roller, wherein the two jet oiling mechanisms which are vertically arranged are arranged between the first guide roller and the second guide roller, and an oil filtering mechanism is arranged between the second guide roller and the third guide roller. According to the jet oiling mechanism, the oiling efficiency and the oiling agent infiltration effect can be improved, the double-sided para-aramid fiber oiling device comprising the jet oiling mechanism can efficiently conduct double-face oiling on a para-aramid fiber bundle, and finally the high-quality aramid fiber bundle is obtained.

Owner:山东精恒科技有限公司

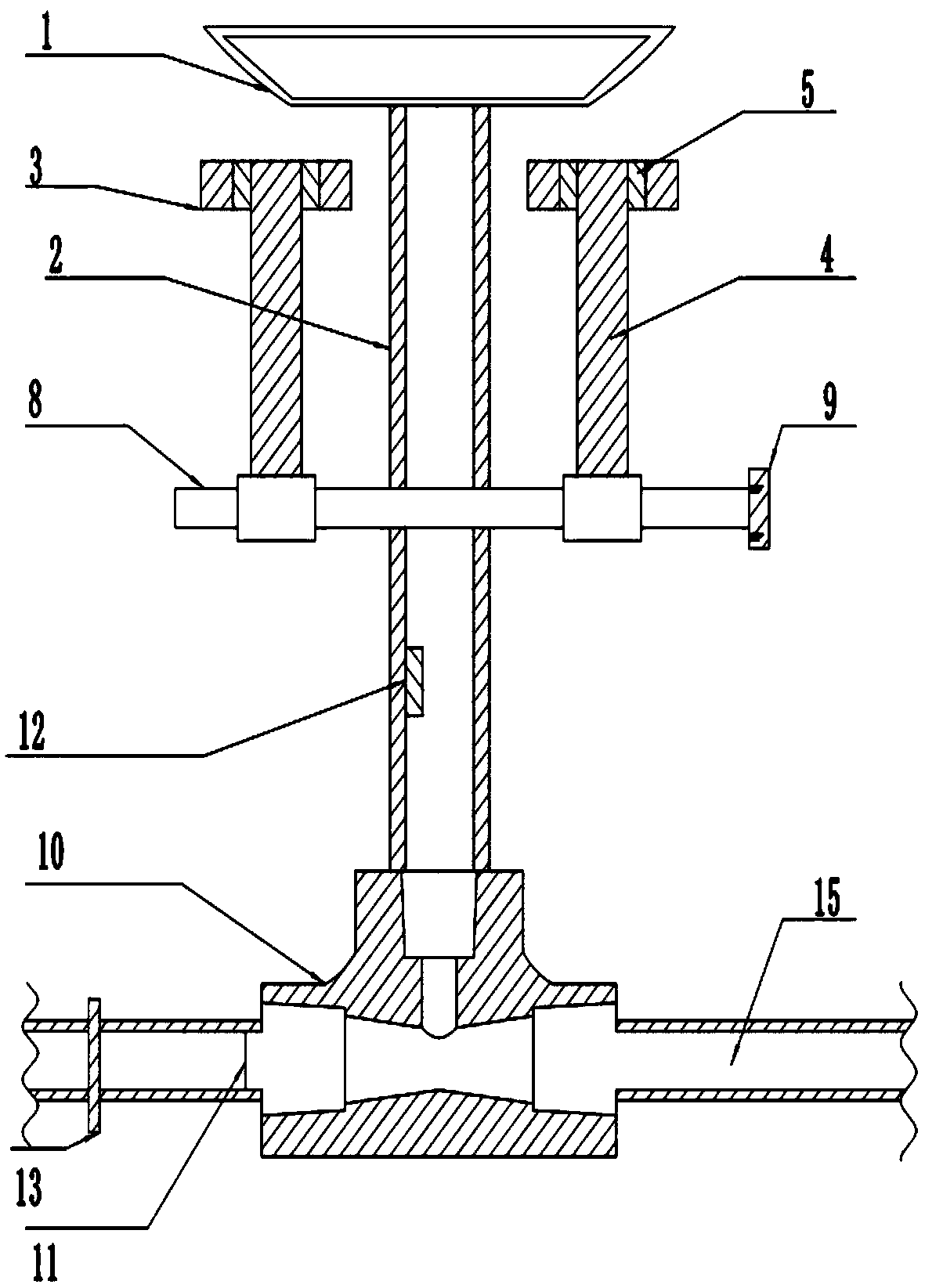

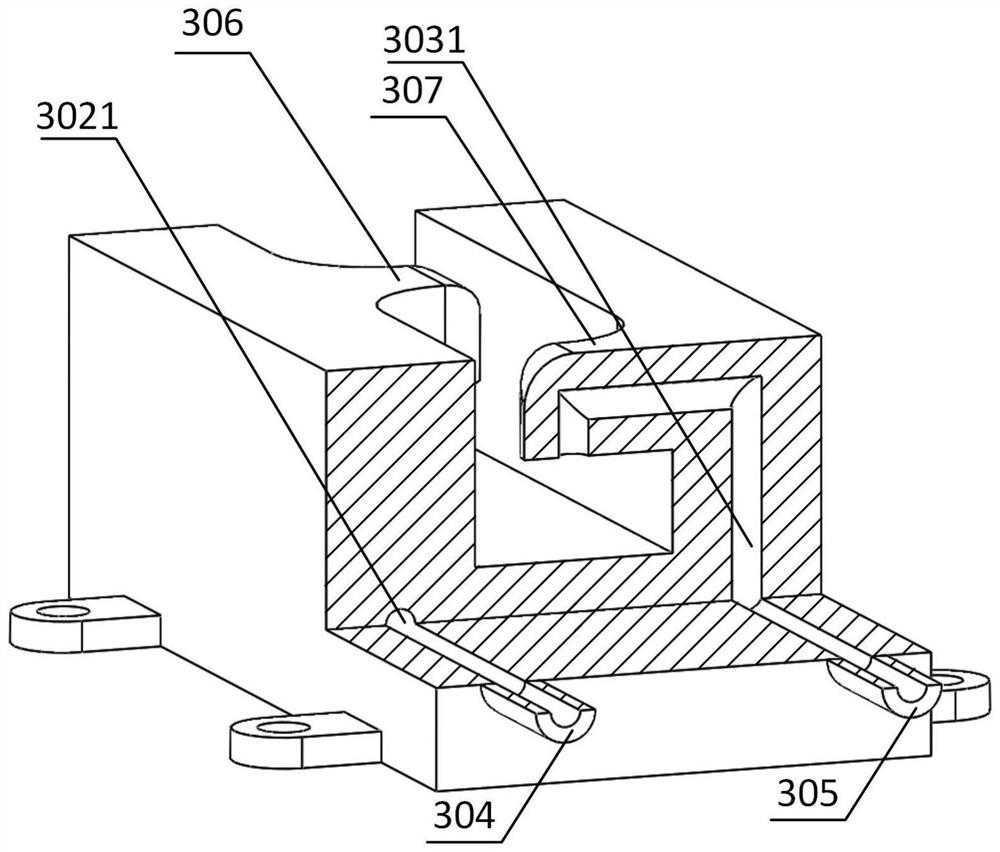

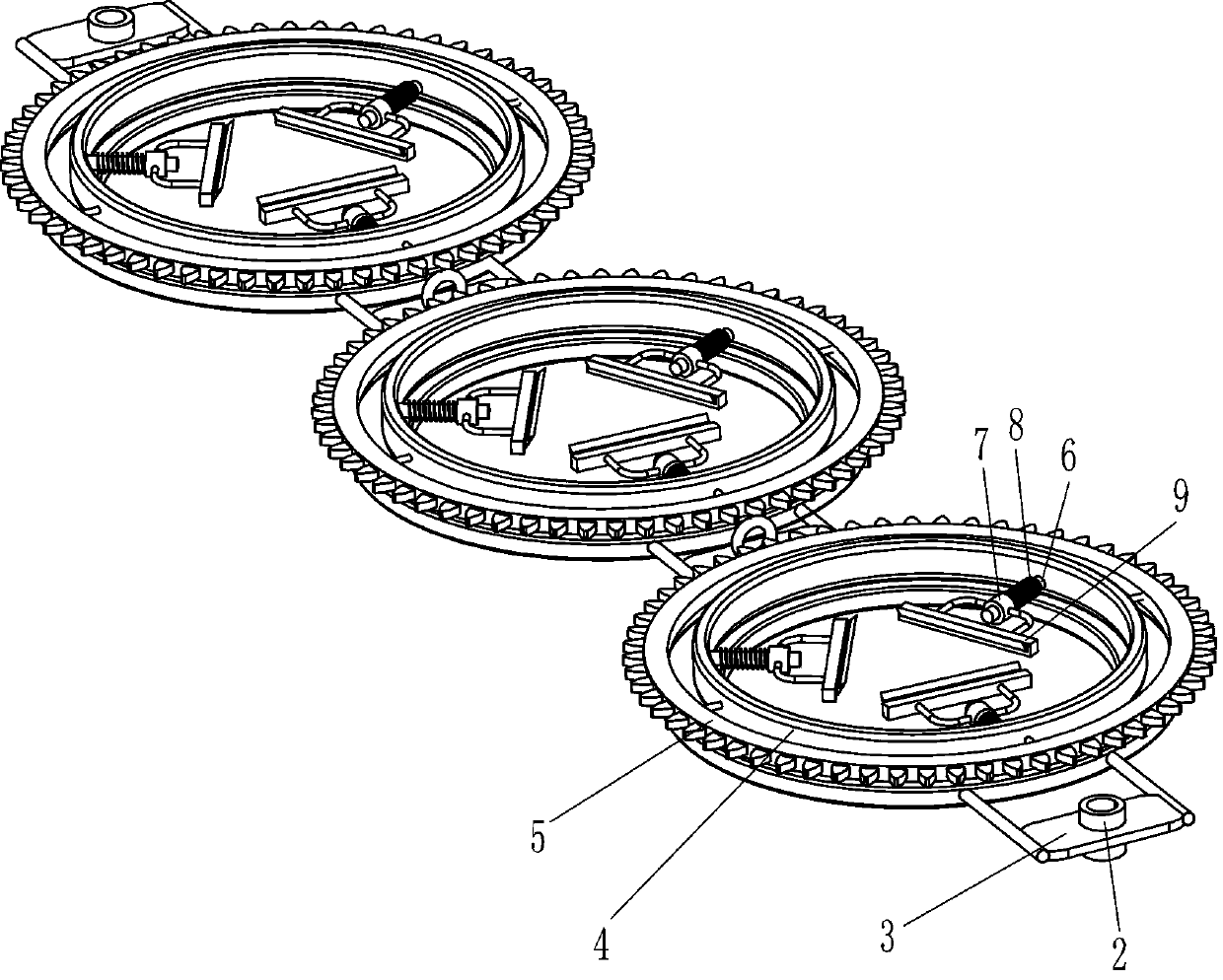

Automatic peeling device for lower part of mulberry fork

The invention relates to a peeling device, in particular to an automatic peeling device for the lower part of a mulberry fork. According to the automatic peeling device for the lower part of the mulberry fork, the mulberry fork can be automatically peeled, the working efficiency can be improved, and the safety risk can be reduced. The automatic peeling device for the lower part of the mulberry fork comprises a support, a peeling assembly, a power assembly, a top plate, a lifting assembly, a transmission assembly and the like; and the peeling assembly for peeling through blades is arranged on the support, the power assembly for providing power through a motor is arranged on the support, the top plate is arranged on the support, the lifting assembly for lifting in a pulling mode is arrangedon the top plate and the support assembly, and the transmission assembly for transmission in a rotating mode is arranged on the support. According to the automatic peeling device for the lower part ofthe mulberry fork, through cooperation of a gear motor and a circular ring, a scraper does not need to be manually used for peeling the mulberry fork, the working efficiency is improved, through cooperation of a volute spring and a reel, the mulberry forks can be rapidly peeled, and the safety risk is reduced.

Owner:陈乃香

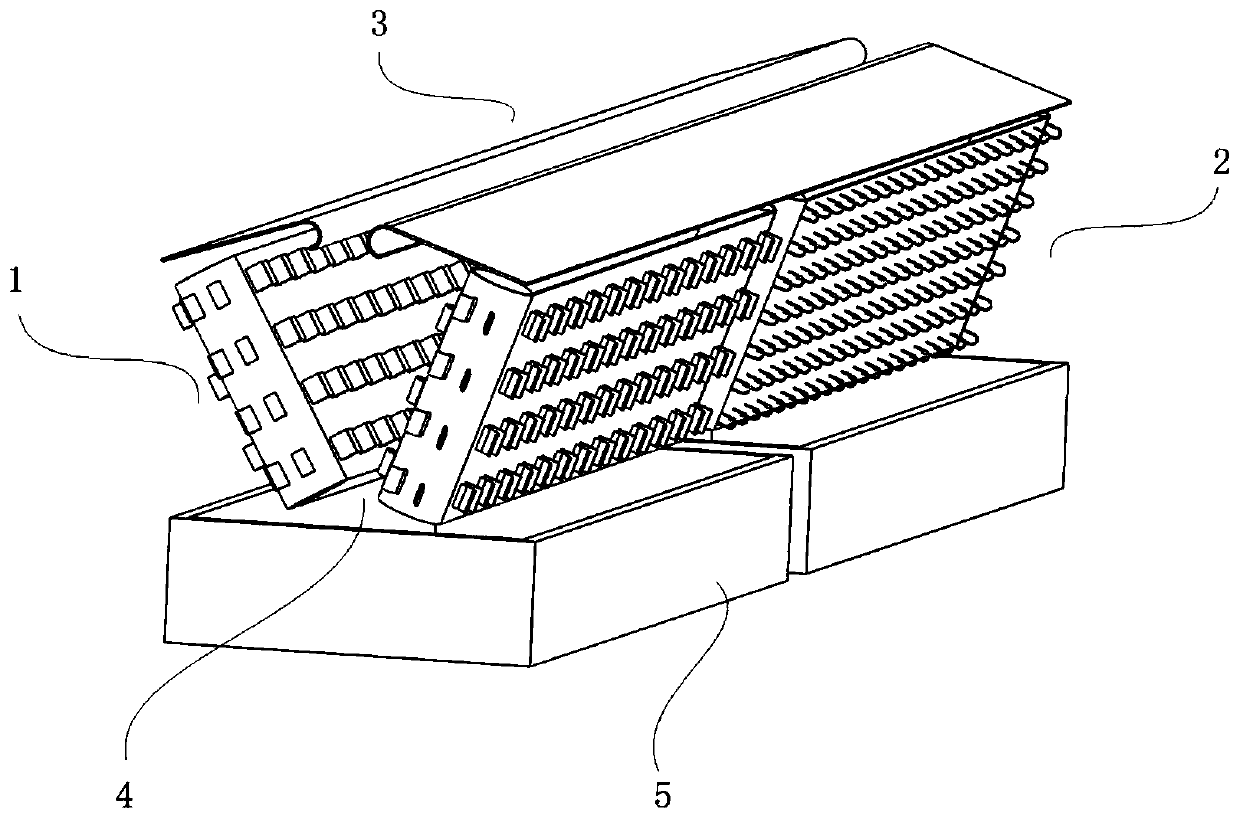

Carding machine for textile processing

InactiveCN114717784AGood removal effectEffective take outMechanical cleaningPressure cleaningEngineeringManual handling

The carding machine for textile processing comprises a hollow machine box, a cloth inlet and a cloth outlet are formed in the side wall of the machine box, the inner side wall of the machine box is rotationally connected with a guide roller, a steering roller and two cloth conveying rollers through bearings, and the side wall of the machine box is slidably connected with two air inlet pipes in a penetrating mode; the end, located in the machine box, of the air inlet pipe is fixedly connected with a rotating cylinder in a penetrating mode, a plurality of scraping blocks are fixedly connected to the outer side wall of the rotating cylinder, a plurality of air suction holes are formed in the side wall of the rotating cylinder, a plurality of absorption covers are fixedly connected to the outer side wall of the rotating cylinder, and the side wall of the side, away from the air inlet pipe, of the rotating cylinder is rotationally connected with a connecting rod through a bearing. The device has the advantages that lint is scraped and adsorbed twice, compared with the prior art, the device has better scraping and adsorbing effects, the situation that scraping is not thorough due to the fact that scraped thread ends and hair balls fall off is avoided, feeding and stacking are automatically conducted, manual operation is avoided, the labor intensity is greatly reduced, and the carding efficiency is improved.

Owner:张锐发

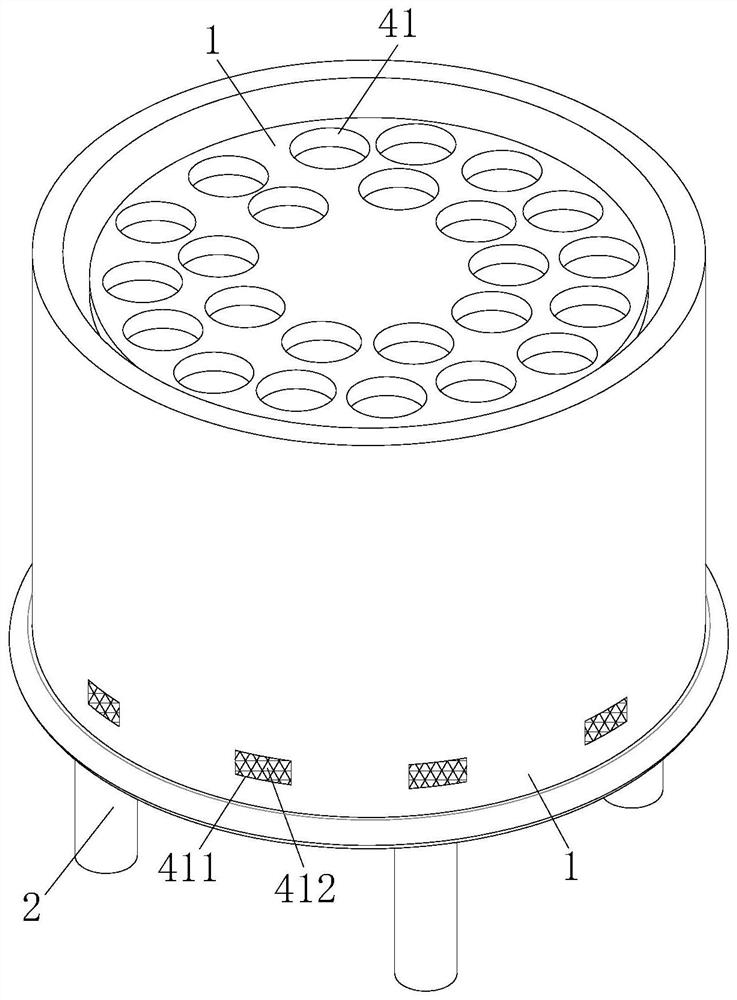

Cucumber thorn centralized cleaning device for cucumber product processing based on breakage prevention

ActiveCN111713715AAvoid breakageImprove surface qualityFood treatmentAgricultural scienceAgricultural engineering

The invention provides a cucumber thorn centralized cleaning device for cucumber product processing based on breakage prevention. The cucumber thorn removing device comprises a centralized thorn removing barrel used for removing thorns of cucumbers, supporting legs used for supporting the centralized thorn removing barrel, a thorn removing movement control mechanism used for generating thorn removing power and dynamically controlling the thorn removing process, and an anti-breakage thorn scraping mechanism used for preventing the cucumbers from being broken and scraping thorns on the surfacesof the cucumbers, and relates to the field of agricultural product processing. According to the cucumber thorn centralized cleaning device for cucumber product processing based on breakage prevention,a structure capable of comprehensively protecting cucumbers and comprehensively and efficiently removing thorns is designed according to the problem that centralized burr removal is difficult in theexisting cucumber processing process; and therefore, the problems that centralized thorn removal is difficult to carry out on cucumbers generally during cucumber processing, the cucumbers are prone tobreakage in the thorn removal process, certain losses are caused, the cucumbers are different in size, unified thorn removal is inconvenient, and the cucumber processing efficiency is low due to comprehensive reasons are effectively solved.

Owner:绍兴市达冷肯生物科技有限公司

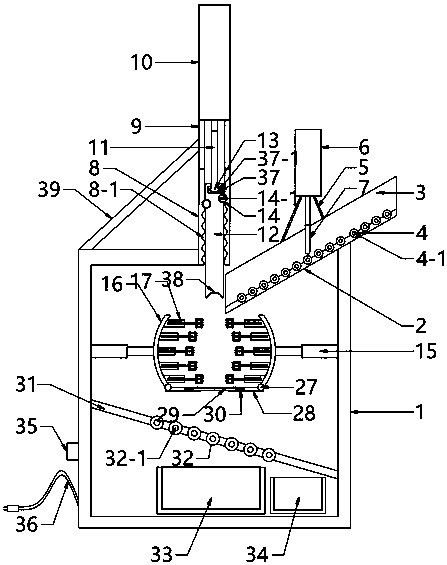

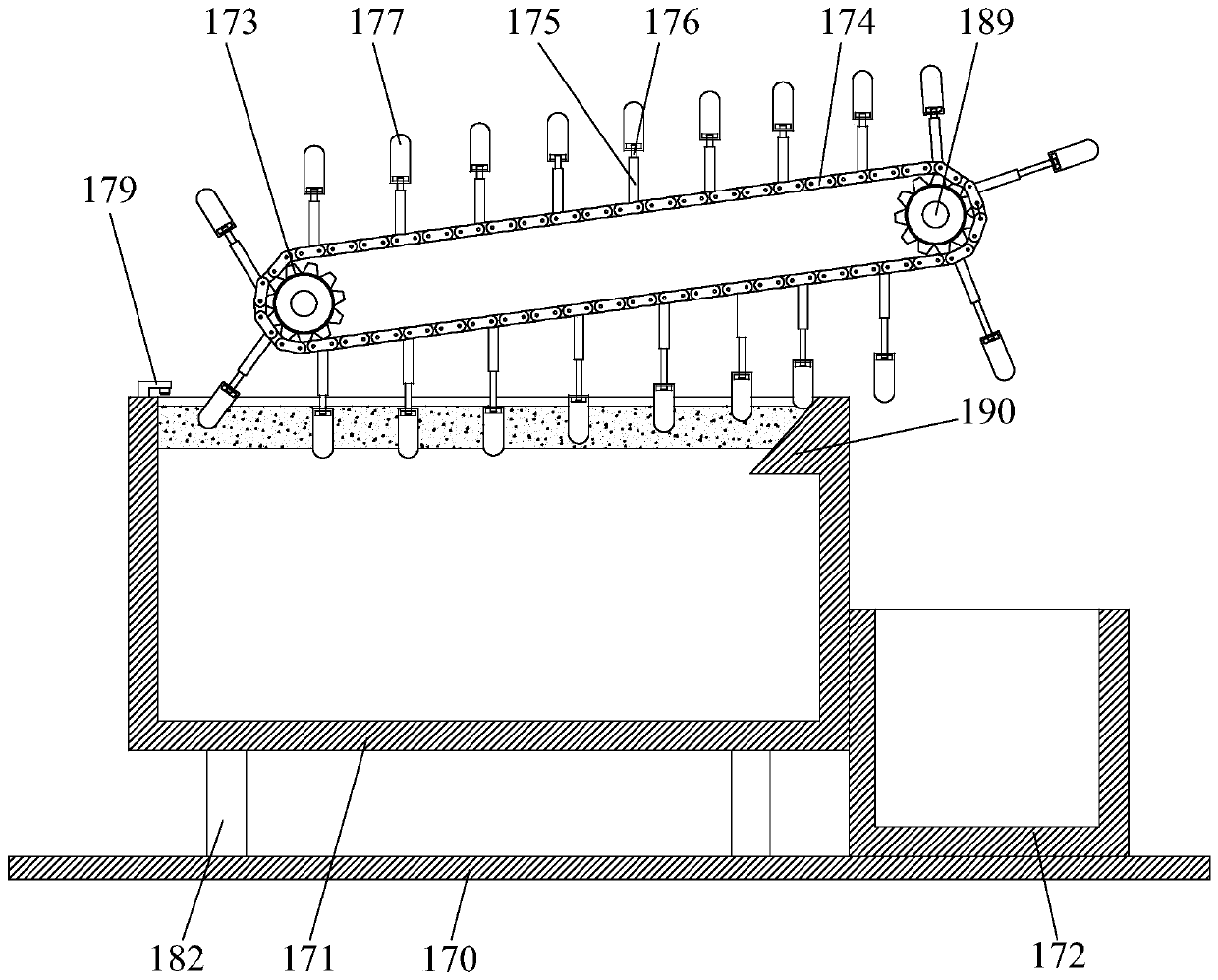

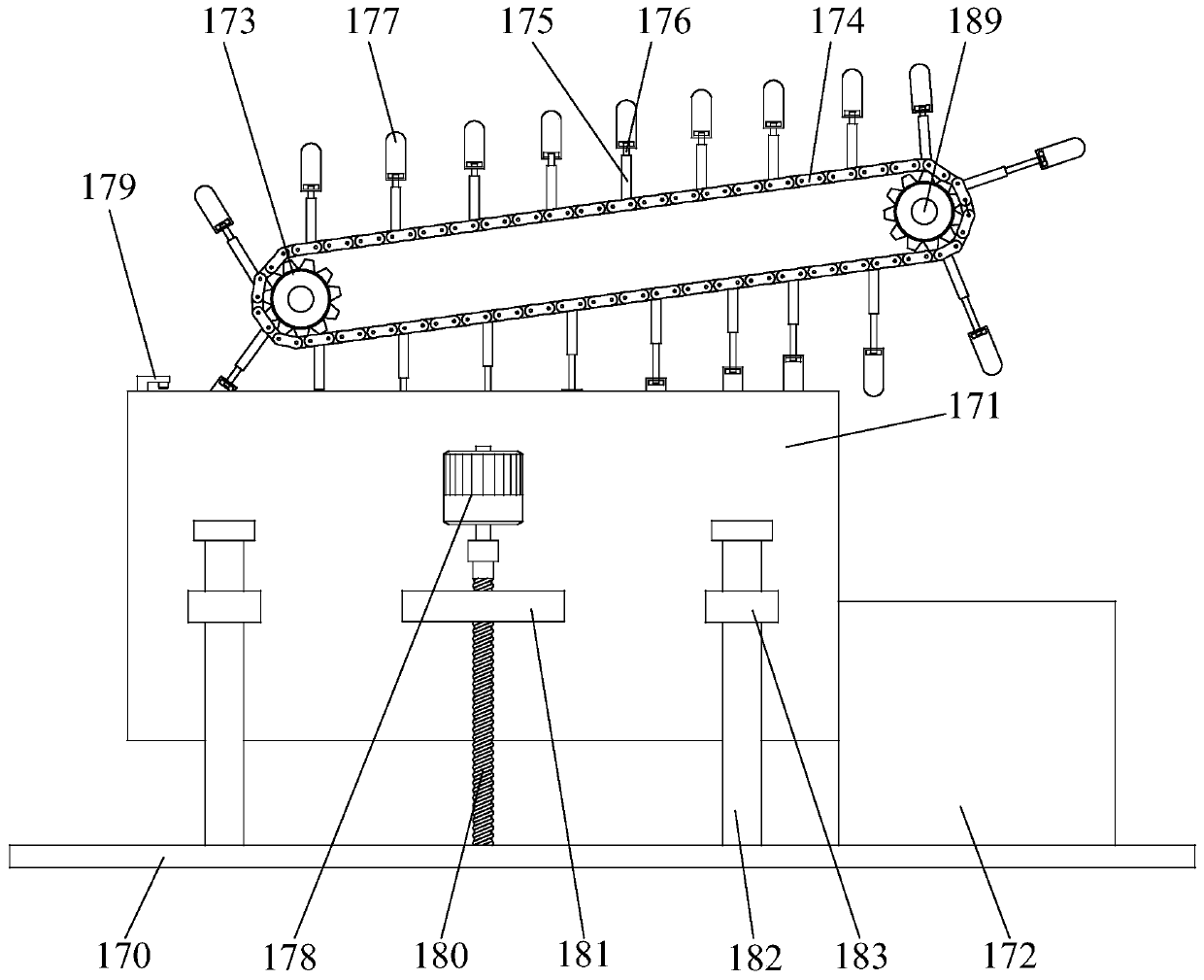

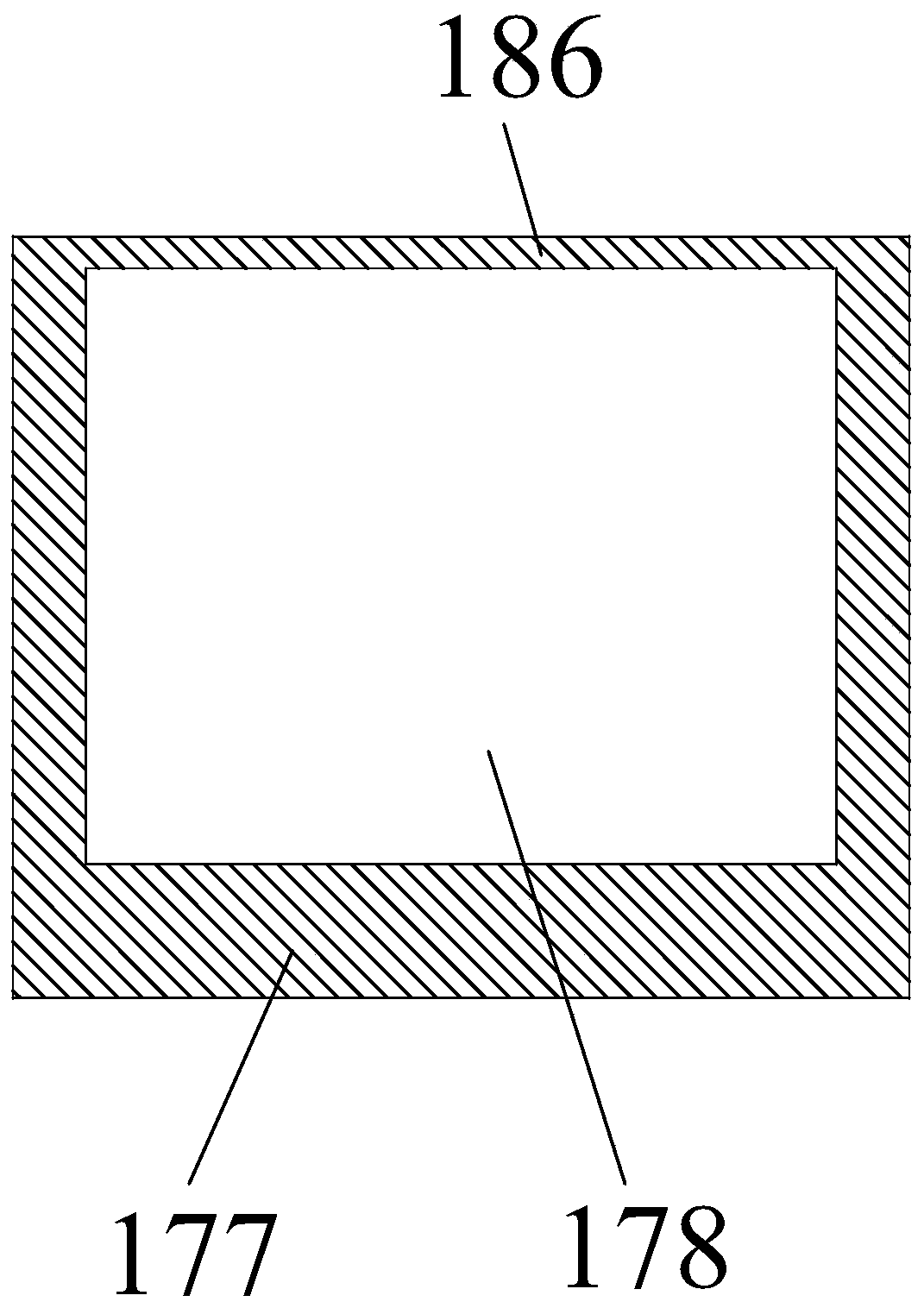

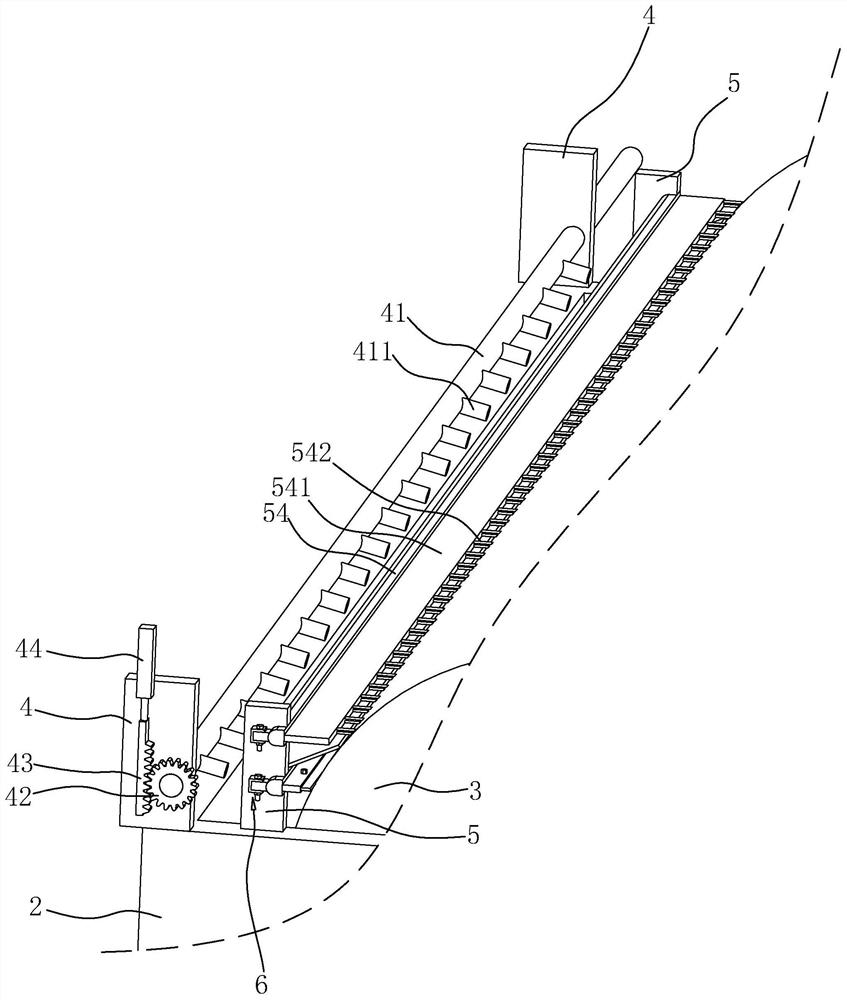

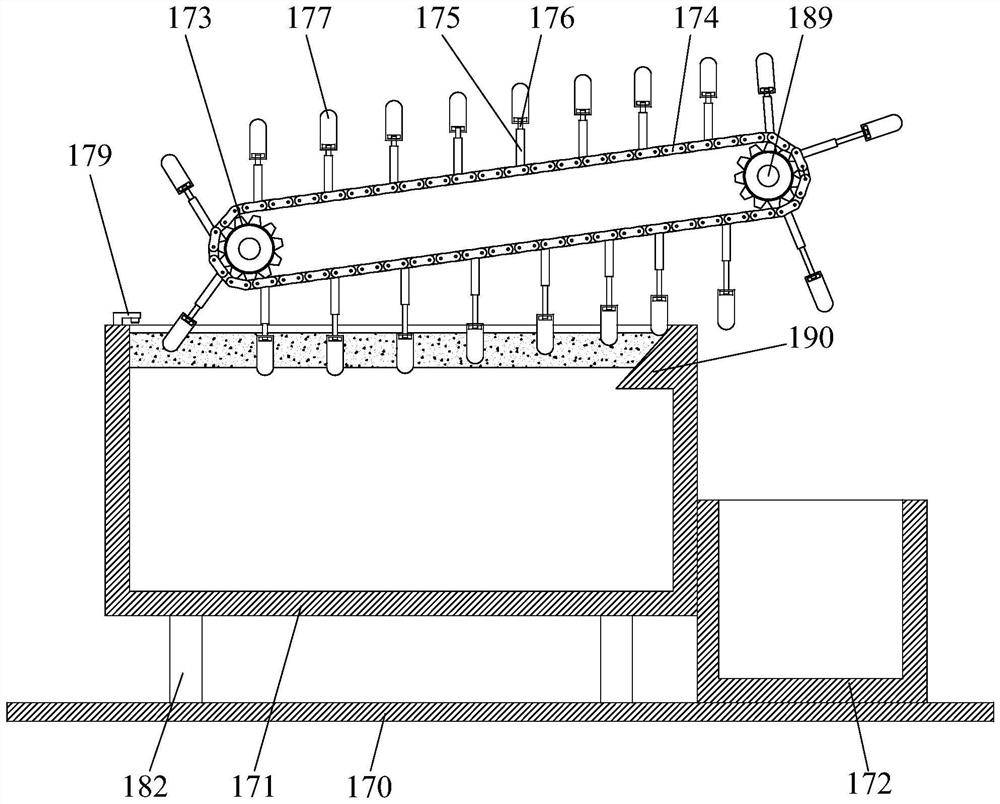

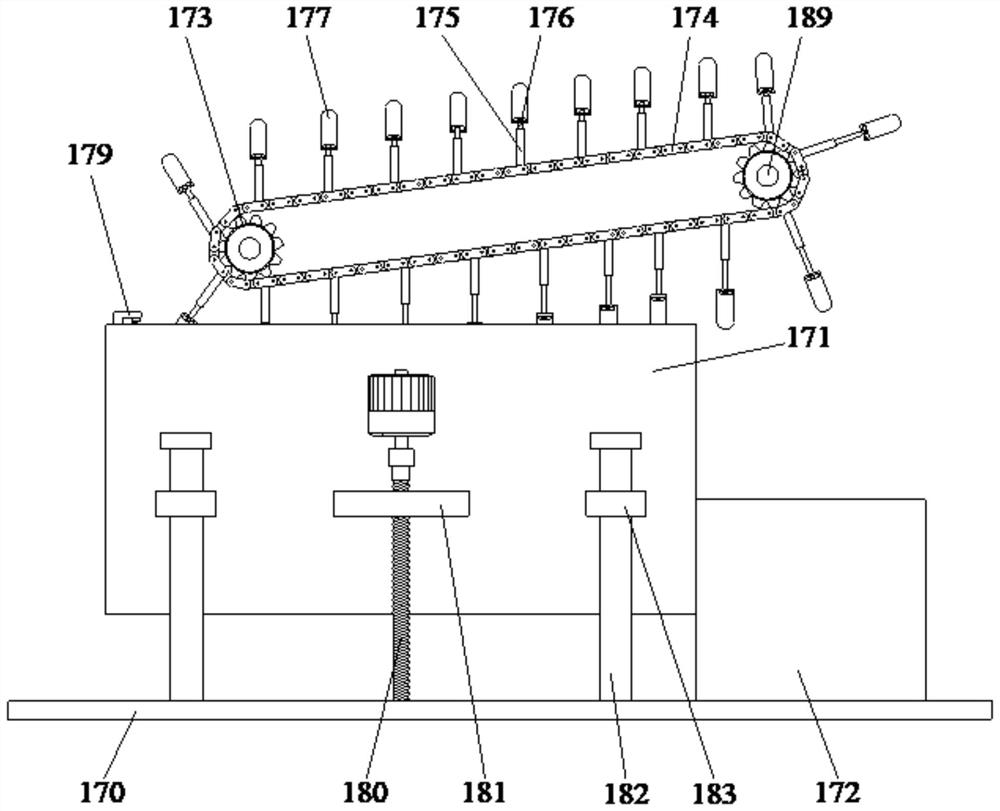

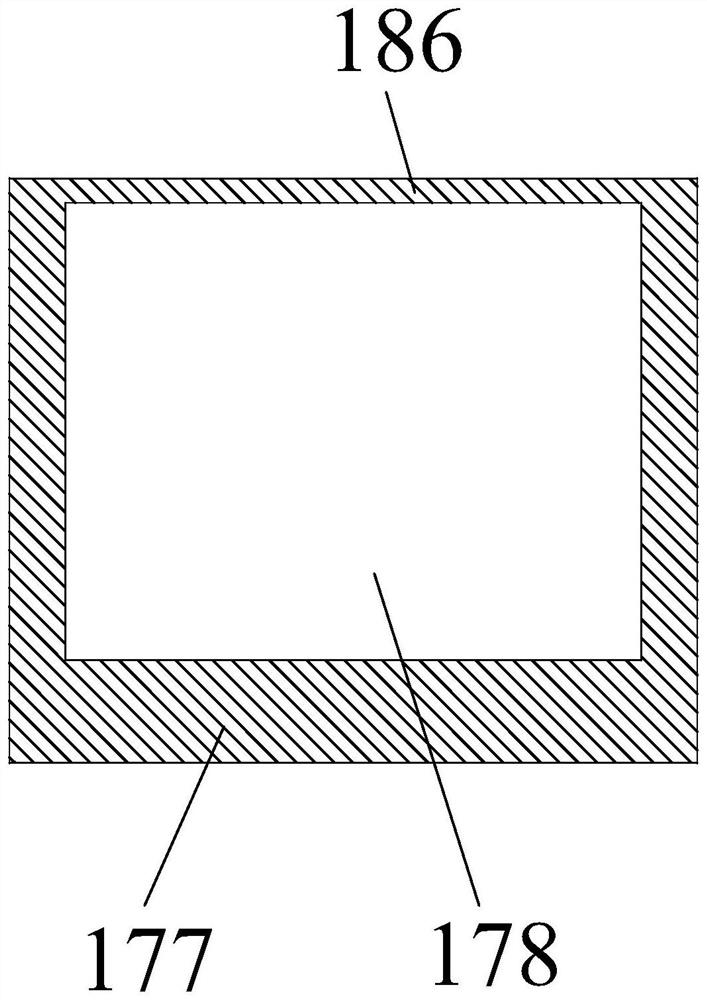

Automatic oil scraping system for swill separation and automatic oil scraping method thereof

ActiveCN110975337AImprove scraping efficiencyLarge amount of scraping oilLiquid separation auxillary apparatusFatty/oily/floating substances removal devicesElectric machineryBuoyant flow

The invention discloses an automatic oil scraping system for swill separation and an automatic oil scraping method thereof. The automatic oil scraping system comprises an oil scraping frame, a storagetank, an oil collecting tank, an automatic oil scraping mechanism, a lifting mechanism, a liquid level sensor and an oil scraping controller. The storage tank is used for separating an oil-water mixture into a water layer and an oil layer. The automatic oil scraping mechanism comprises an oil scraping motor, a chain wheel, a chain and an oil scraping assembly. The lifting mechanism comprises a driving assembly and a lifting assembly. The driving assembly is used for driving the storage tank to be close to the chain in the vertical direction, and the liquid level sensor is used for detecting the relative height between the oil level of the oil layer and the bottom wall of the storage tank. The oil scraping controller is used for judging whether the relative height is greater than a presetheight or not and driving the lifting mechanism to conduct related actions. The oil scraping amount and the oil scraping efficiency are improved, it is guaranteed that oil at different depths is scraped, oil scraping is realized through buoyancy, the oil scraping efficiency can be further improved and the purity of the scraped oil is guaranteed.

Owner:ANHUI TIANJIAN ENVIRONMENTAL PROTECTION

Waste paper treatment device convenient for internal cleaning for environment-friendly machinery

InactiveCN111764190AImprove efficiencyAvoid cloggingHollow article cleaningPaper recyclingElectric machinerySteel tube

The invention discloses a waste paper treatment device convenient for internal cleaning for environment-friendly machinery in the technical field of waste paper treatment. The device comprises a box body, a flange and a stirrer, wherein a mounting base is arranged at the top of the left outer wall of the box body; a driving motor is mounted at the top of the mounting base; two left groups of connecting plate and two right groups of right connecting plate are movably connected into the sliding groove; driving assemblies are fixedly mounted at the bottom of the four groups of connecting plates;an internal thread sleeve is mounted on the rear end surface of the driving assembly; the internal thread sleeve is arranged on the outer wall of the lead screw in a sleeving manner through a thread;a paper pulp stirring tank is arranged on the inner wall of the bottom of the box body; the paper pulp stirring tank is positioned at the front end of the lead screw; the stirrer at the bottom of thedriving assembly can be rapidly disassembled and replaced with a paper pulp stirring tank cleaning device; the driving assembly can horizontally move left and right while ascending and descending, sothat paper pulp attached to the inner wall of the paper pulp stirring tank can be fully scraped; and a high-pressure water source connected into the steel pipe can flush the inner wall of the paper pulp stirring tank, and the cleaning efficiency is improved.

Owner:卢松伟

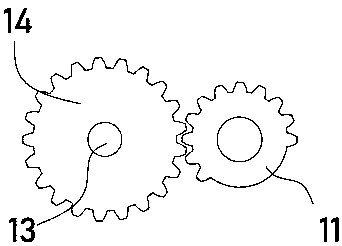

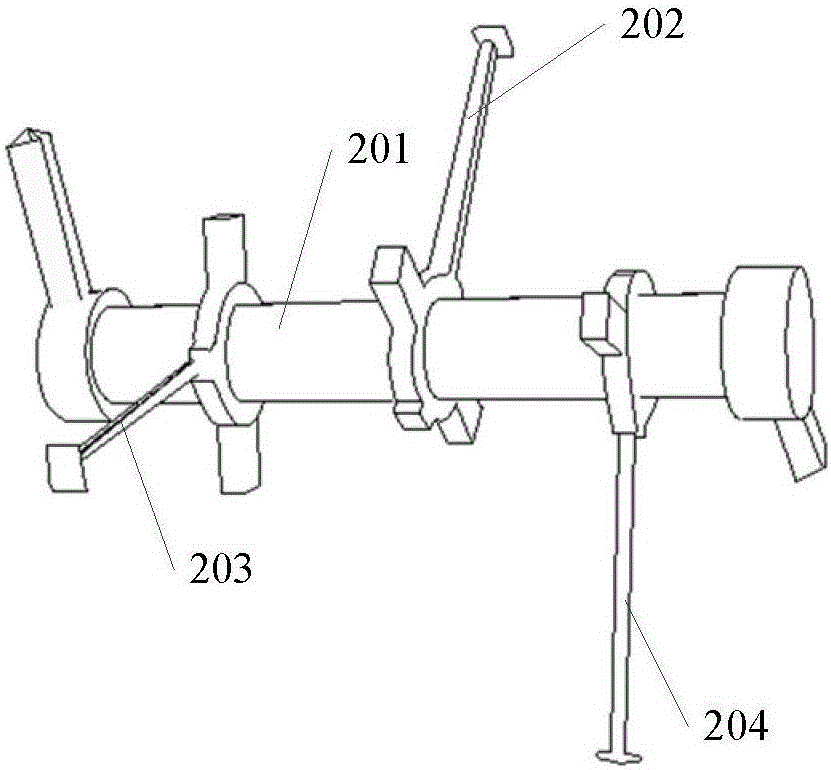

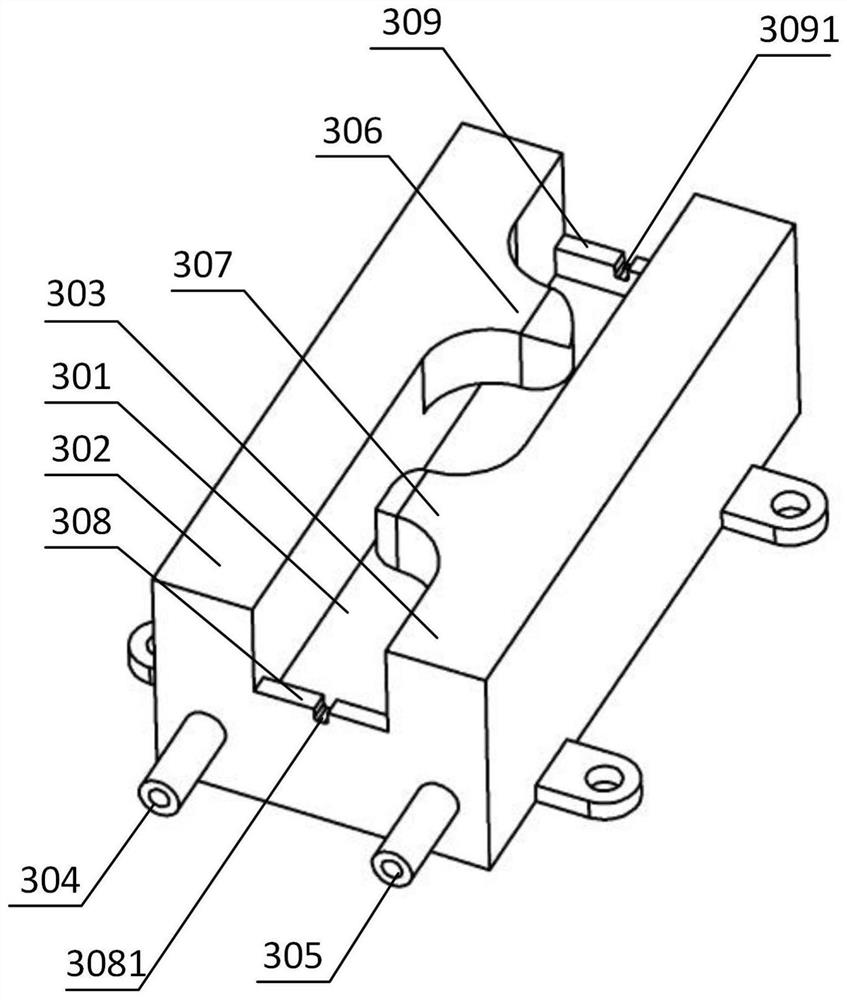

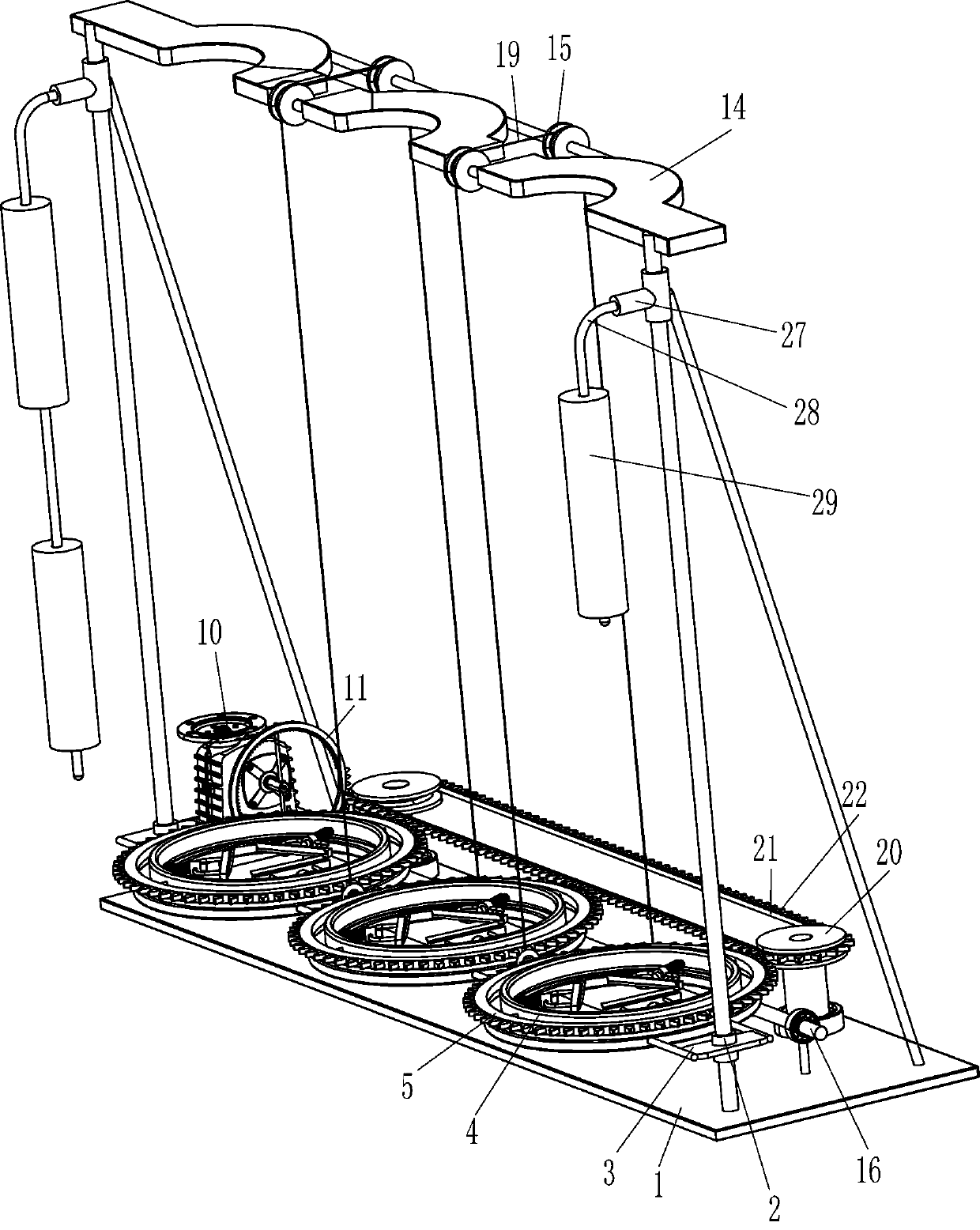

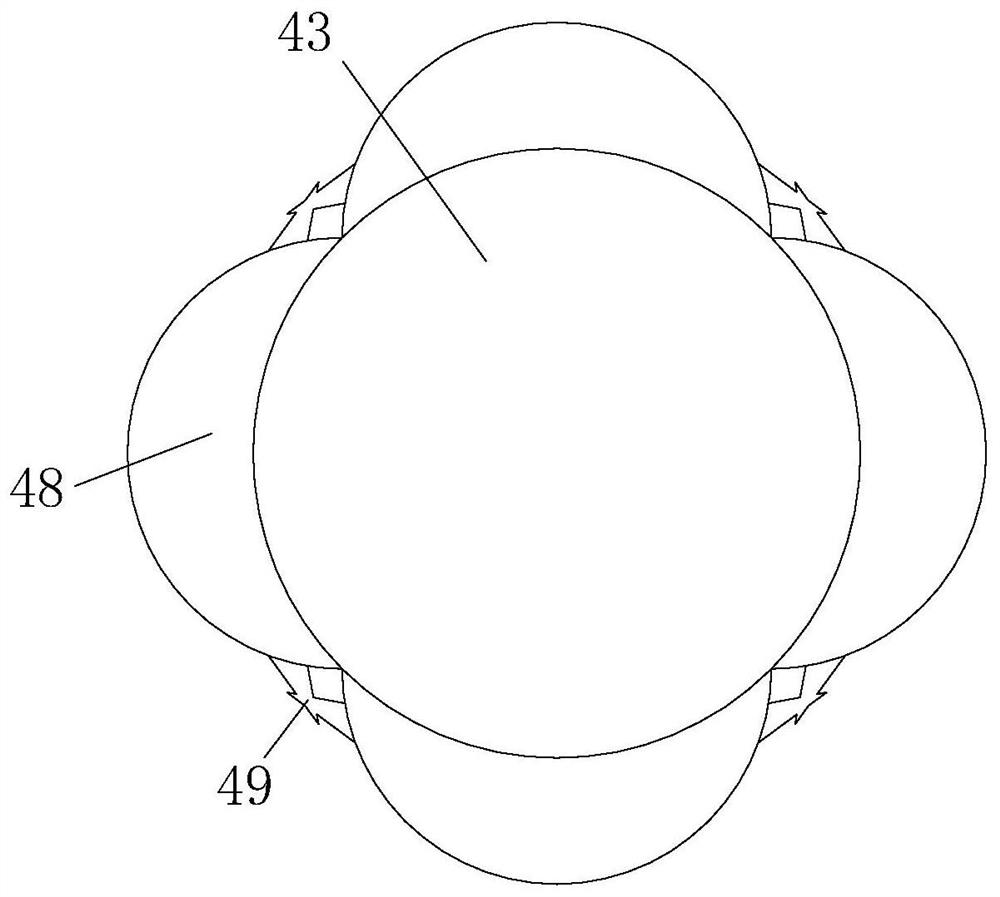

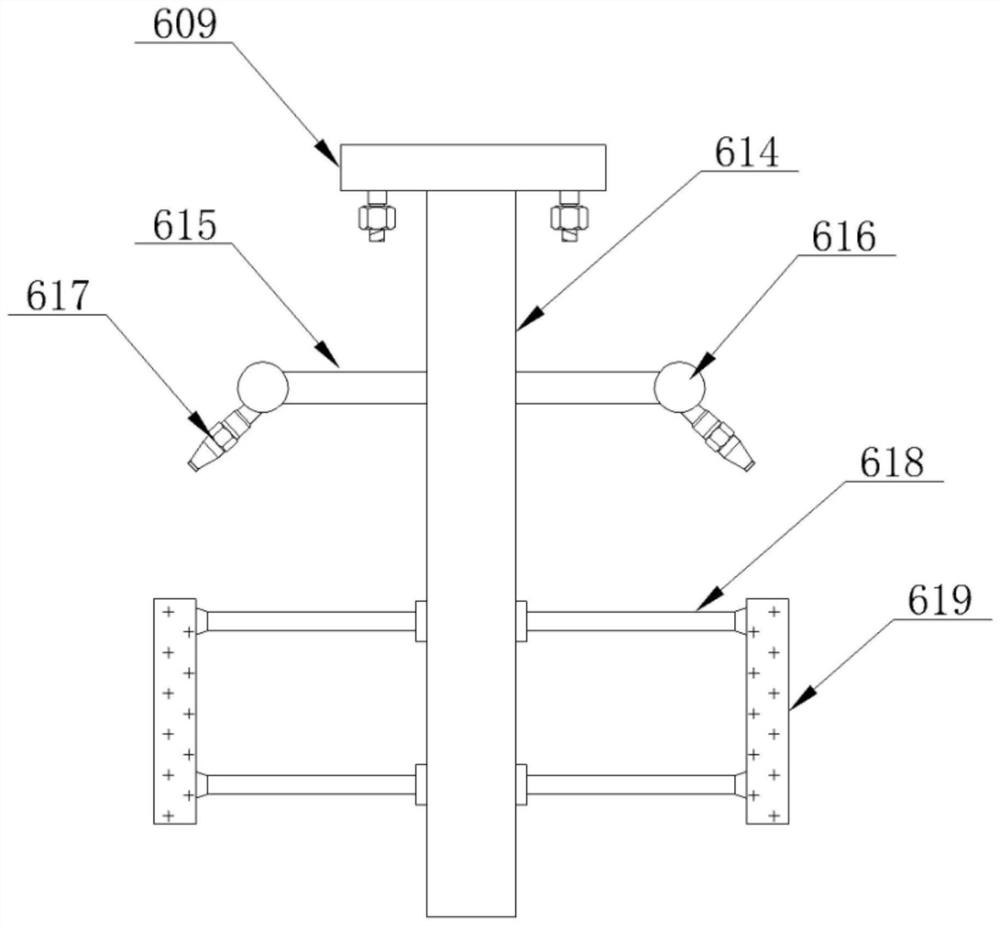

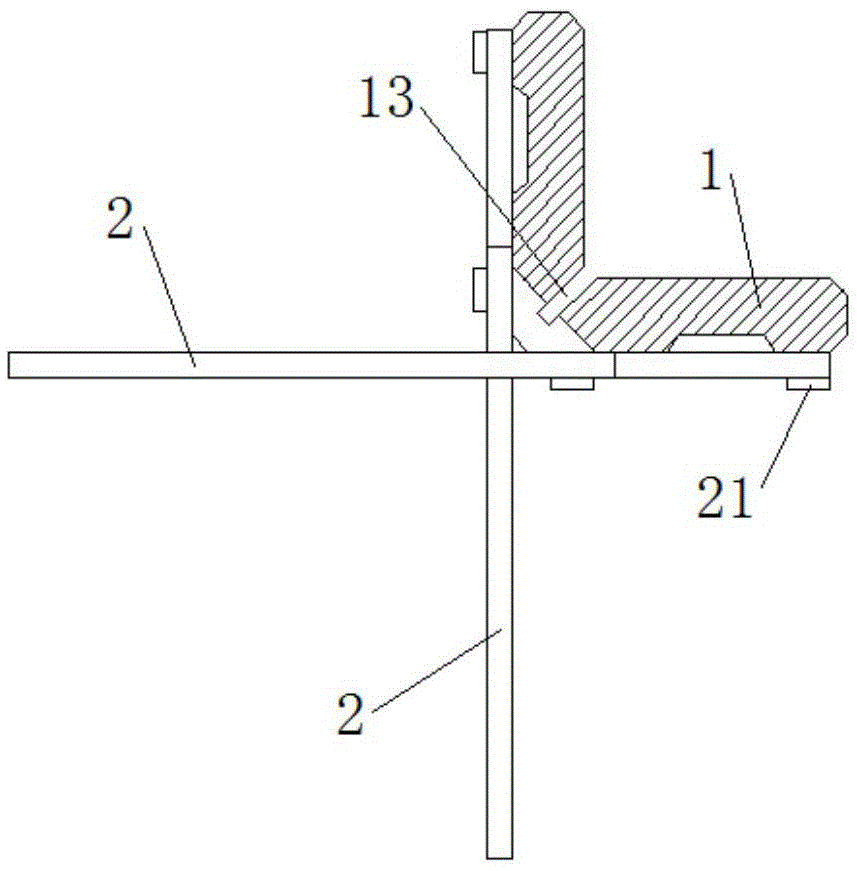

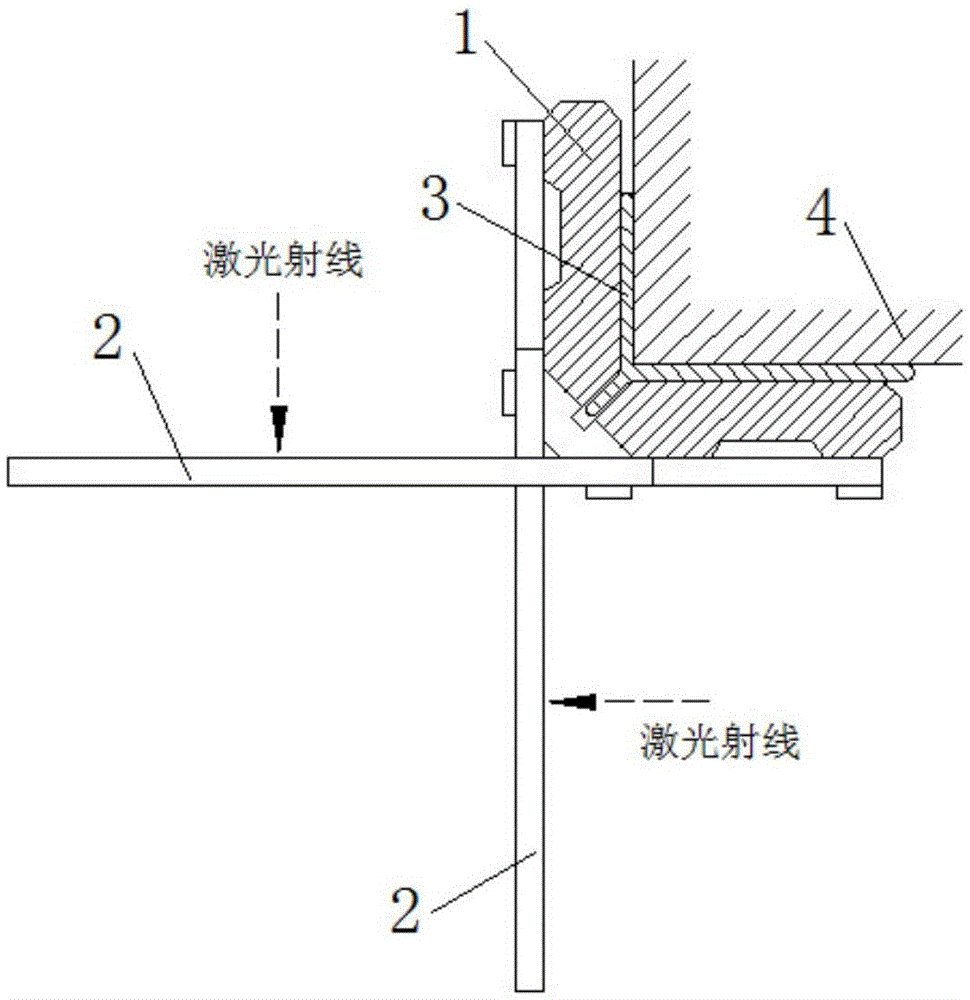

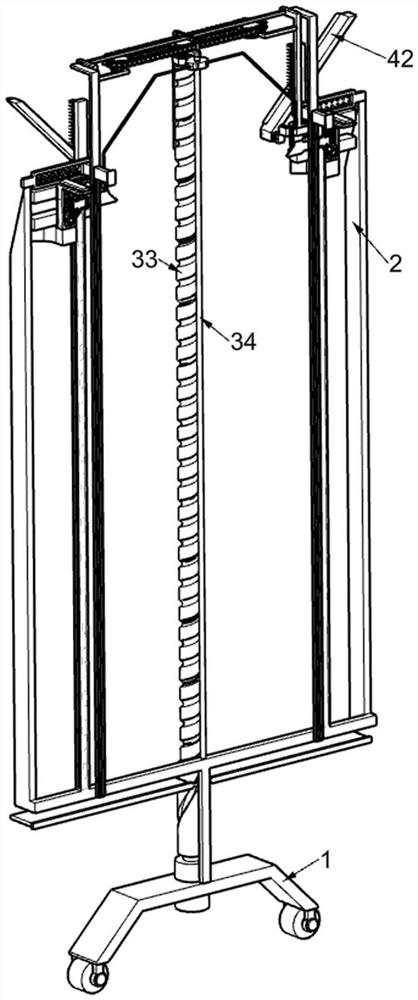

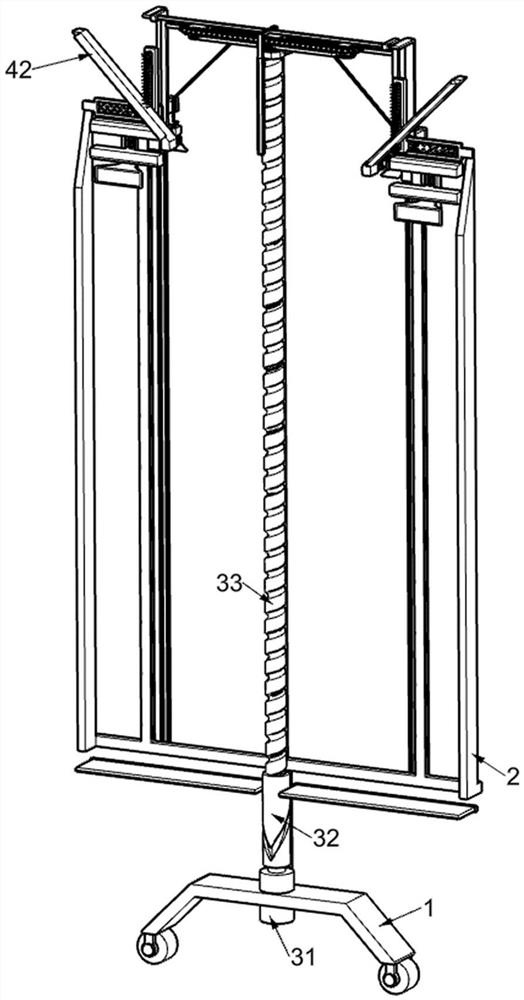

Coupling recognition system for snubbing oil tube tripping operation

ActiveCN114352270AAccurately determine the locationAccurately judge the statusSurveyConstructionsMarine engineeringCoupling

The invention belongs to the technical field of snubbing operation, and discloses a snubbing tubing tripping operation coupling recognition system which comprises a coupling recognition device, and the coupling recognition device comprises a cleaning module and a diameter measuring module; the cleaning module comprises a base, a planetary outer gear rotationally mounted on the base and an intermediate gear rotationally mounted on the base, a plurality of vertical shafts are arranged on the intermediate gear, planetary inner gears meshed with the planetary outer gear are rotationally mounted on the vertical shafts, and scraping plates are mounted on the planetary inner gears; the planetary outer gear is connected with the first driving unit, and the intermediate gear is connected with the second driving unit. According to the oil pipe coupling detection device, the cleaning module and the diameter measurement module are combined, the cleaning module scrapes impurities on the pipe wall, the precision of the diameter measurement module can be improved, accurate prediction of the position of an oil pipe coupling is achieved, and safety risks caused by measurement errors of a traditional coupling detection device are thoroughly eliminated.

Owner:SICHUAN SHENGNUO OIL & GAS ENG TECH SERVICE CO LTD +1

Magnetic separator and iron separation process applying same

ActiveCN112844826AReduce stress and water usageImprove cleaning efficiencyCleaning using toolsMagnetic separationMagnetic separatorStructural engineering

The invention relates to a magnetic separator which comprises a magnetic separation box and a roller, the roller is located in the magnetic separation box, the two ends of the roller are fixedly connected with connecting shafts correspondingly, the two connecting shafts are rotationally connected with the inner wall of the magnetic separation box correspondingly, and the upper surface of the magnetic separation box is fixedly connected with two first supporting plates; the two first supporting plates are arranged at the two ends of the magnetic separation box in the length direction correspondingly, and a water spraying pipe is connected between the two first supporting plates. Two second supporting plates are fixedly connected to the upper surface of the magnetic separation box, first mounting grooves are formed in the side walls, close to the roller, of the two second supporting plates, first mounting blocks are arranged at the sides, close to the roller, of the second supporting plates, and the two ends of each first mounting block are located in the corresponding first mounting grooves correspondingly; a first scraper is fixedly connected to the side, close to the roller, of the first mounting block, and a rubber plate is connected to the side, close to the roller, of the first scraper and makes contact with the outer wall of the roller. The magnetic separator has the effect of fully scraping iron fine powder on the roller of the magnetic separator.

Owner:迁安市中润工贸有限公司

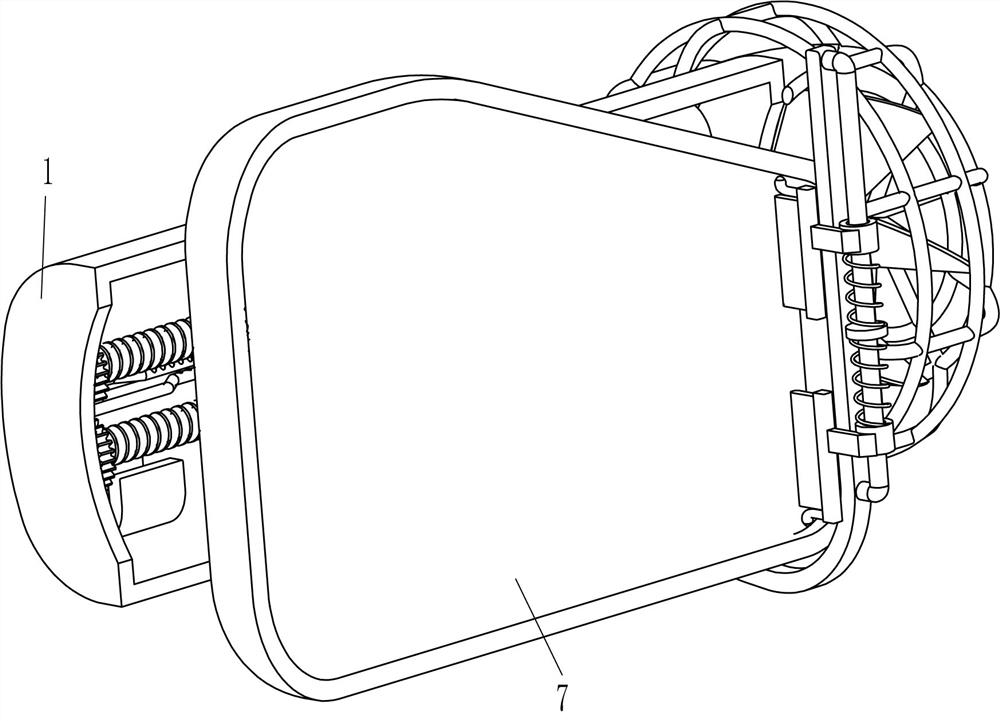

Wind-driven window wiper for automobile rearview mirror

PendingCN112265505AAvoid dangerous accidentsEasy to operateVehicle cleaningOptical viewingRear-view mirrorFan blade

Owner:姚庭乖

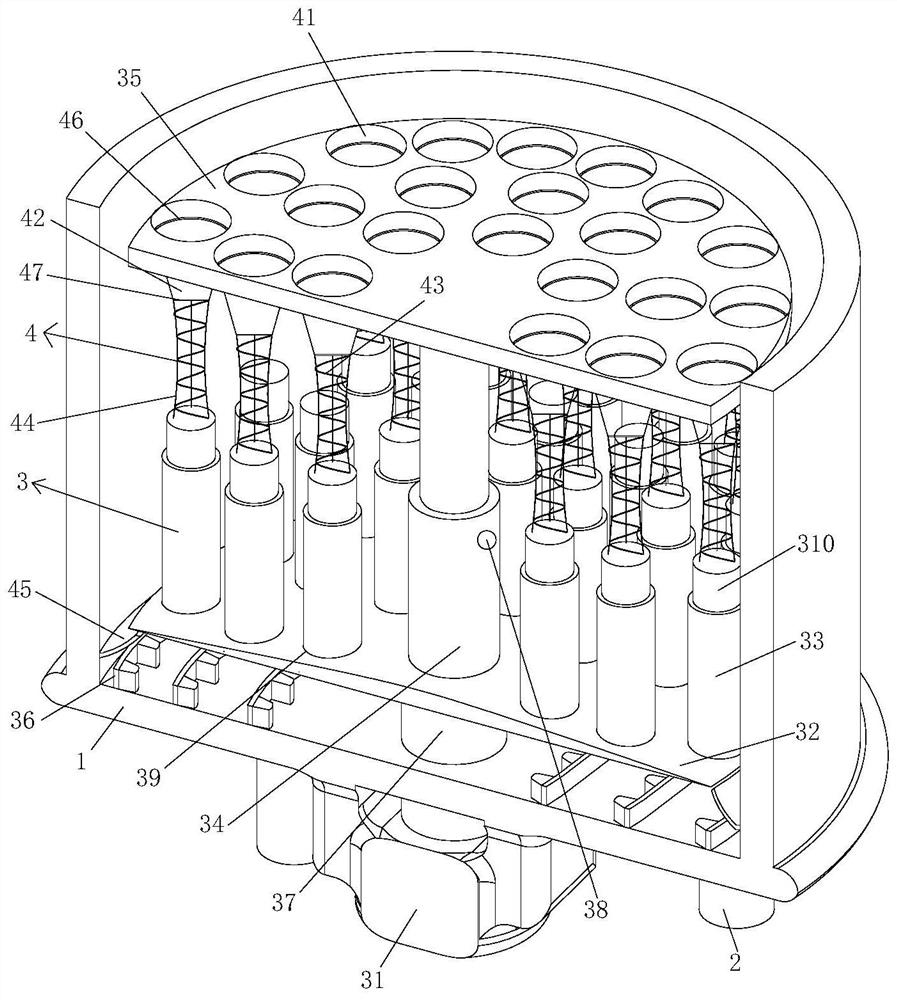

A food processing minced meat device

ActiveCN110100868BFull scrapeScrape off fullyMeat processing devicesEngineeringMechanical engineering

The invention discloses a mincing device for food processing meat stuffing, which relates to the technical field of food processing machinery, and comprises an operating frame, in which a minced meat tank is rotatably provided, and a minced meat tank is provided with a mincing mechanism, which includes A number of crushing knives are evenly fixed on the bottom of the knife seat. A bottom plate for the crushing knives to slide through is provided under the knife seat. A scraper abutting against the crushing knives is hinged at the bottom of the bottom plate. The crushing knives are installed eccentrically in the minced meat tank; The knife seat drives the crushing knife to reciprocate up and down to achieve repeated cutting and crushing of the minced meat tank. At the same time, the minced meat tank rotates intermittently, so that the meat in the minced meat tank can be comprehensively chopped repeatedly. The minced meat adhered to the side wall of the knife is fully scraped off, the up and down movement of the crushing knife is smoother, and the effect of chopping meat is improved, and the set spatula can scrape off the meat sticking to the inner wall of the minced meat tank, so that Meat is minced more fully and thoroughly.

Owner:JIANGSU FOOD & PHARMA SCI COLLEGE

An automatic oil scraping system and automatic oil scraping method for swill separation

ActiveCN110975337BScrape GuaranteeRealize the collectionLiquid separation auxillary apparatusFatty/oily/floating substances removal devicesElectric machinerySprocket

The invention discloses an automatic oil scraping system and an automatic oil scraping method for swill separation. The automatic oil scraping system includes an oil scraping frame, a storage tank, an oil collecting tank, an automatic oil scraping mechanism, a lifting mechanism, a liquid level sensor and an oil scraping controller. The storage tank is used to separate the oil-water mixture into a water layer and an oil layer. The automatic oil scraping mechanism includes an oil scraping motor, a sprocket, a chain and an oil scraping assembly. The lifting mechanism includes a driving assembly and a lifting assembly, the driving assembly is used to drive the storage tank and the chain close in the vertical direction, and the liquid level sensor is used to detect the relative height between the oil level of the oil layer and the bottom wall of the storage tank. The oil scraping controller is used to judge whether the relative height is greater than a preset height, and to drive the lifting mechanism to perform relevant actions. The invention improves the oil scraping volume and oil scraping efficiency, ensures oil scraping at different depths, and realizes oil scraping through buoyancy, can further improve oil scraping efficiency and ensure the purity of the scraped oil.

Owner:ANHUI TIANJIAN ENVIRONMENTAL PROTECTION

Reinforced concrete stirrer

InactiveCN104493979AReduce solidificationAvoid cloggingDischarging apparatusReinforced concreteThermal insulation

The invention relates to building machinery and in particular relates to a reinforced concrete stirrer. The concrete stirrer comprises a discharge opening and a conveying pipeline connected with the discharge opening, wherein reinforcing sleeves are respectively arranged outside the discharge opening and the conveying pipeline in a sleeving manner; each reinforcing sleeve is an annular sleeve; a buffer layer is attached to the inner peripheral surface of each reinforcing sleeve; a thermal insulation layer is attached to the peripheral surface; and a scraper which can move in the pipeline is arranged in the conveying pipeline. According to the stirrer disclosed by the invention, the problems that the discharging structure is fragile and easy to break and block and the like in the prior art are solved, and a concrete stirrer of a firm and smooth discharging structure is obtained.

Owner:重庆市荣昌区粤兴不锈钢有限公司

External angle punch rod for wall plastering and its application method

ActiveCN104018651BGuaranteed straightnessQuick installationBuilding constructionsArchitectural engineeringBuilding construction

The invention discloses an external corner punching bar for wall plastering and a method for using the same, belonging to the field of building construction equipment. A male corner punching bar for wall plastering according to the present invention includes a profile body and a scale plate. The shape of the profile body is an "L"-shaped right angle formed by two panels perpendicular to each other. The inner side of the right angle is provided with an installation notch, and the two panels of the profile main body are respectively provided with scraping grooves at intervals; the scale plates are respectively fixed on the two panels of the profile main body, and the scale plate There are two or more evenly distributed on each panel. The invention greatly improves the construction efficiency and can significantly improve the construction quality, and has the advantages of simple structure, convenient manufacture, reliability and durability, low cost and strong versatility, and is especially suitable for mortar mechanical spraying powder walls, and is easy to realize practicality and commercialization.

Owner:常州杰普森建材科技有限公司

Aluminum alloy door and window multi-face frame film tearing equipment for architectural decoration

ActiveCN113815979AEasy to stickFully shedPlastic recyclingBinding material removalEngineeringStructural engineering

The invention relates to the field of architectural decoration, in particular to aluminum alloy door and window multi-face frame film tearing equipment for architectural decoration, which comprises a roller frame, a special-shaped wedge-shaped slotted bracket, a driving mechanism, a film scraping mechanism and the like, wherein the special-shaped wedge-shaped slotted bracket is fixedly installed on the top face of the roller frame; the driving mechanism is arranged on the roller frame; and the film scraping mechanism is arranged on the special-shaped wedge-shaped slotted bracket. A protective film on an aluminum alloy door and window frame is scraped off by rotating a film scraping plate I by 45 degrees, then the protective film adheres to a clamping plate, the clamping plate moves downwards to pull the protective film to move downwards, and the protective film on the aluminum alloy door and window frame is torn off.

Owner:重庆沐卡建材有限公司

A magnetic separator and an iron selection process using the magnetic separator

ActiveCN112844826BImprove cleaning efficiencyFull scrapeCleaning using toolsMagnetic separationMagnetic separatorStructural engineering

The application relates to a magnetic separator, which includes a magnetic separation box and a drum. The drum is located inside the magnetic separation box. The two ends of the drum are respectively fixedly connected with connecting shafts. The two connecting shafts are respectively connected to the inner wall of the magnetic separation box in rotation. The upper surface of the box is fixedly connected with two first support plates, and the two first support plates are respectively arranged at the two ends of the length direction of the magnetic separation box, and a water spray pipe is connected between the two first support plates; The upper surface is fixedly connected with two second support plates, the side walls of the two second support plates close to the drum are provided with first installation grooves, the side of the second support plate close to the drum is provided with a first installation block, the first The two ends of the installation block are respectively located in the corresponding first installation grooves. The first installation block is fixedly connected with the first scraper on the side close to the roller. The first scraper is connected with the rubber plate on the side close to the roller. outer wall contact. The application has the effect of fully scraping the fine iron powder on the drum of the magnetic separator.

Owner:迁安市中润工贸有限公司

Camellia oil squeezing equipment

InactiveCN112457911ASqueeze fullyReduce outflowFatty-oils/fats productionAgricultural engineeringCamellia cuspidata

The invention discloses camellia oil squeezing equipment. The equipment comprises a box body; an internal containing cavity is formed in the box body; symmetrical containing cavities are formed in theupper side and the lower side of the internal containing cavity in a communicated mode; pushing blocks are arranged in the containing cavities in a sliding mode; symmetrical sliding frame bodies arearranged on the two sides of the box body; a matching rod is arranged on one side of each sliding frame body; a pushing plate is arranged on one side of each matching rod; the matching rods penetratethrough the box body in a sliding mode; the pushing plates abuts against the pushing blocks; a moving device for driving the sliding frame bodies to move is arranged on one side of each sliding framebody; and extrusion devices enabling the pushing blocks to extrude downwards in the sliding process of the sliding frame bodies are arranged between the sliding frame bodies and the pushing blocks. With the equipment adopted, camellia seeds can be fully extruded, and the situation that the camellia oil flows out slowly due to the fact that the camellia seeds block an extrusion area can be prevented.

Owner:杨桂英

A sewage processor for industrial wastewater treatment

ActiveCN110803791BPrevent proliferationAvoid false positivesFatty/oily/floating substances removal devicesSpecific water treatment objectivesIndustrial waste waterControl system

Owner:GEZHOUBA EXPLOSIVE HUNAN ERHUA CIVIL EXPLOSIVES

A kind of industrial rubber cracking device

ActiveCN109233891BEvenly heatedIncrease the speed of crackingLiquid hydrocarbon mixture productionElectric machineEngineering

The invention belongs to the technical field of rubber cracking equipment and specifically relates to an industrial rubber cracking device. The industrial rubber cracking device comprises a cracking furnace, a mounting frame, a motor, a rotating shaft, a heating block, a stirring rod, mounting blocks, cleaning modules and a controller; a feeding port, a discharge hole and an exhaust port are formed on the cracking furnace; the mounting frame is arranged on a left wall of the cracking furnace; the motor is arranged on the mounting frame; the rotating shaft is located in the cracking furnace; one end of the rotating shaft is connected with an output shaft of the motor; the other end of the rotating shaft is rotatably arranged on an inner wall on the right side of the cracking furnace; the heating block is arranged on an outer wall of the cracking furnace; the stirring rod is arranged on the rotating shaft; the stirring rod is used for stirring rubber; the quantity of mounting blocks is two; the mounting blocks are horizontally symmetric arranged in the cracking furnace; rectangular through slots are longitudinally symmetric formed on the mounting blocks; the quantity of cleaning modules is two; the cleaning modules pass through the rectangular through slots of the mounting blocks; the controller is located on the left side of the cracking furnace.

Owner:安徽省赛旺商贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com