Magnetic separator and iron separation process applying same

A magnetic separator and magnetic separation technology, applied in cleaning methods using tools, cleaning methods using liquids, magnetic separation, etc., can solve the problems that the concentrate is not easy to be washed down, the effect of the concentrate is not good, etc., to reduce Pressure and water consumption, effect of improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

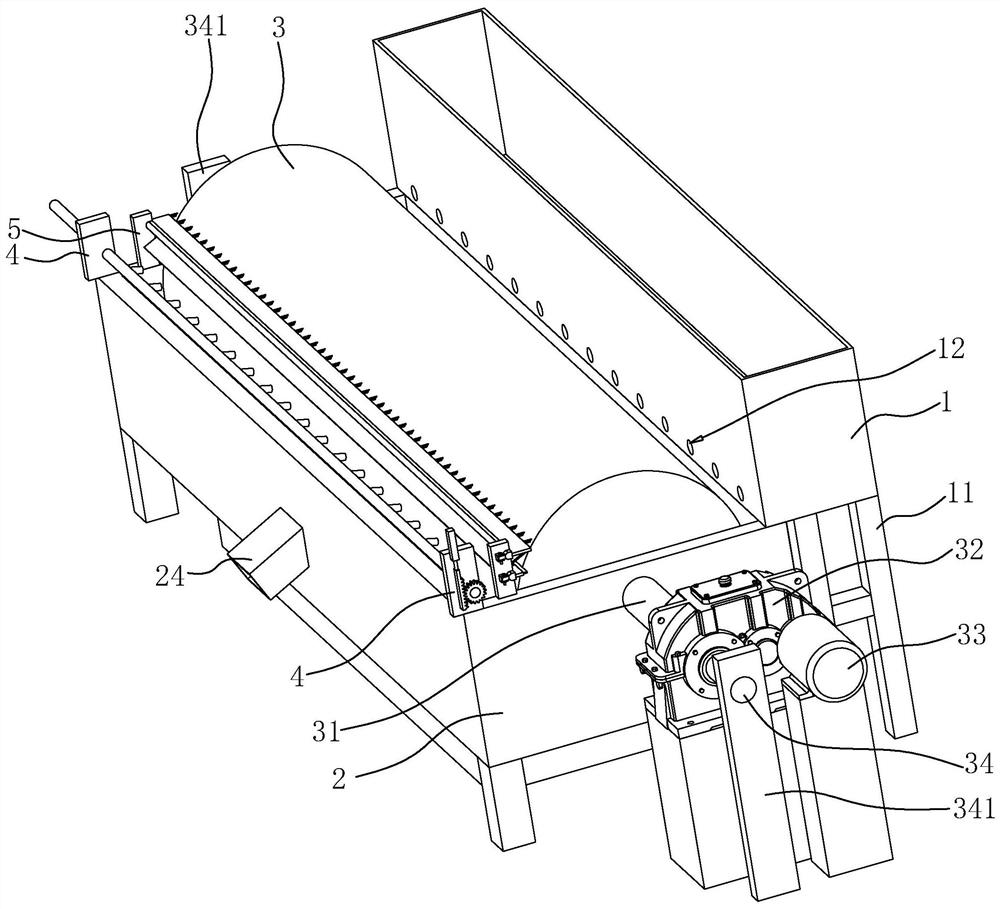

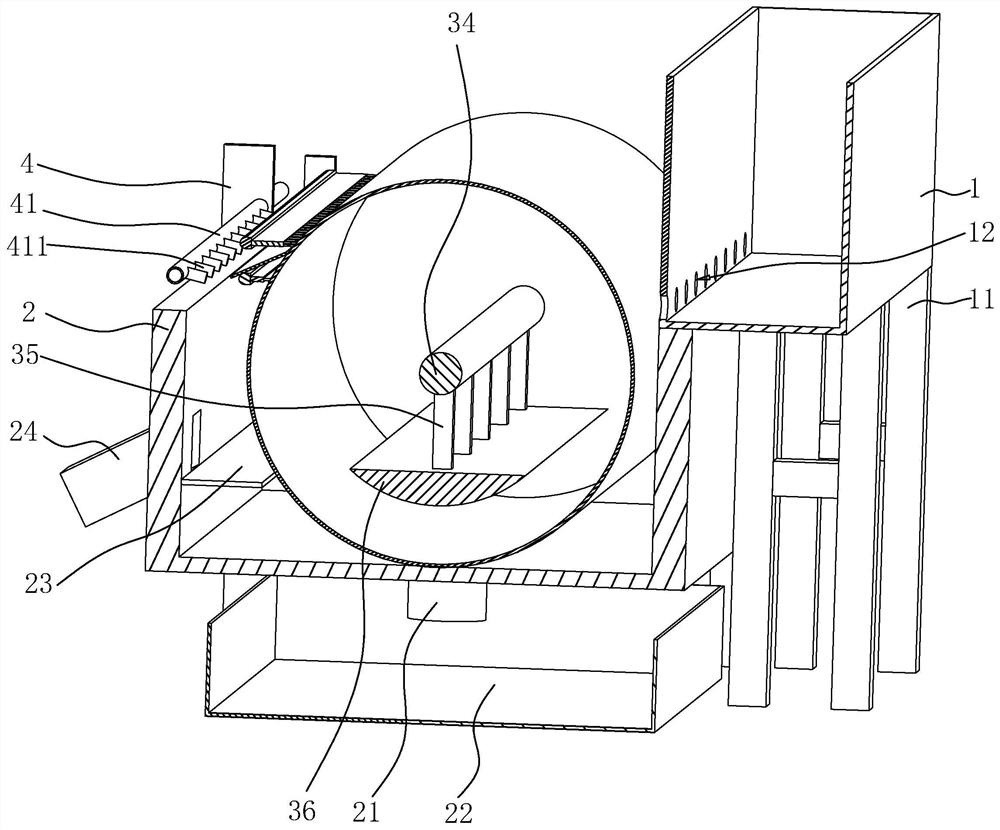

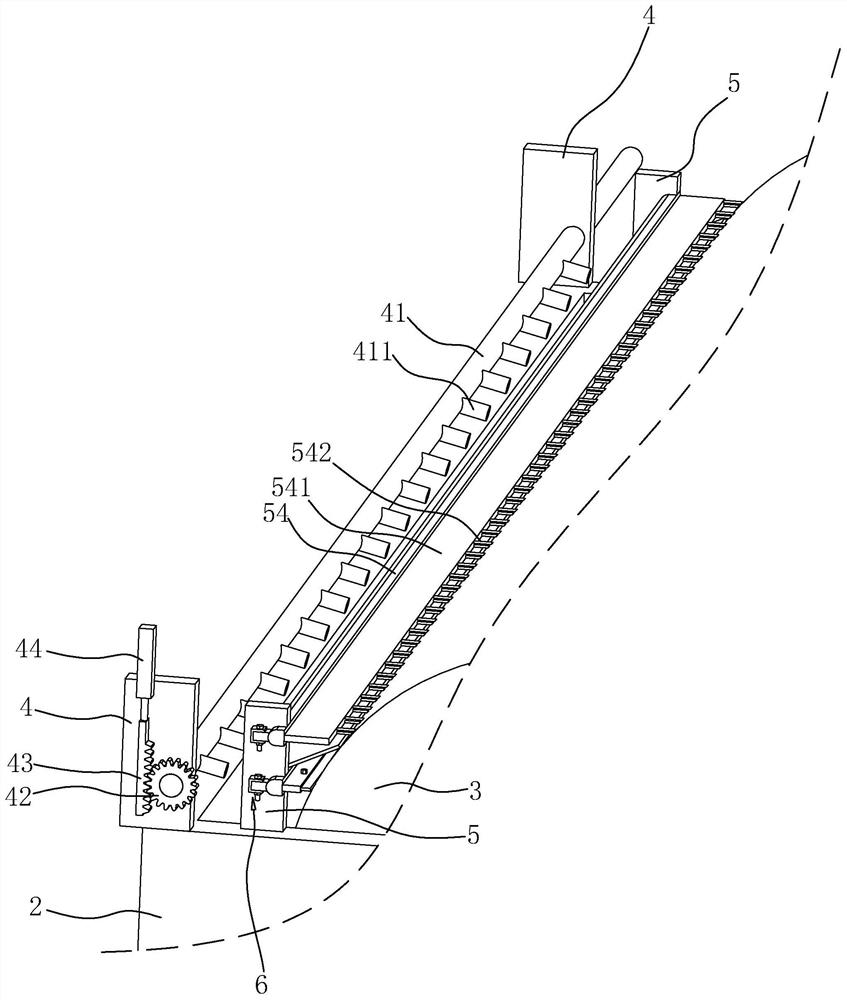

[0038] The following is attached Figure 1-4 The application is described in further detail.

[0039] The embodiment of the present application discloses a magnetic separator. refer to figure 1 , the magnetic separator includes a raw material box 1 and a magnetic separation box 2, the bottom of the raw material box 1 is fixedly connected with a support frame 11, the magnetic separation box 2 is arranged on one side of the raw material box 1, and the top of the magnetic separation box 2 is lower than the raw material box 1 bottom end. The side wall of the raw material box 1 is provided with an opening 12 near the bottom of the raw material box 1 , and the ore pulp flows out from the opening 12 of the raw material box 1 and flows into the magnetic separation box 2 .

[0040] The magnetic separation box 2 is provided with a cylinder 3, the two ends of the cylinder 3 are respectively fixed with connecting shafts 31, the connecting shafts 31 are connected with the inner wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com